Hoffman 709xVmA - Data Sheet

Diunggah oleh

a2birdcageDeskripsi Asli:

Judul Asli

Hak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

Hoffman 709xVmA - Data Sheet

Diunggah oleh

a2birdcageHak Cipta:

Format Tersedia

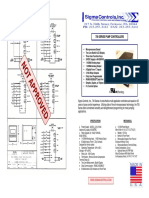

Hoffman |Controls 709D-VmA and 709E-VmA Series

Product Data Electronic Fan Speed Controllers

speed adjustment (RPM) over the input signal's span. An additional

independent cut off adjustment to maintain Minimum Speed, at or

above set point, or remove power from the motor at a pre-selected

value, is available.

Proportional Control

When controlling temperature, the variable flow of cold air (DA

mode) or warm air (RA mode), provides a proportional flow of condi-

tioned air over a 2°F span from the 906-VmA thermostat’s selected

set point. Mode change may be manual or automatic from a NO or

NC switch or aquastat. Closure provides a Reverse Acting function,

“open” provides a Direct Acting Function. When a constant flow or

pressure is required, a DA or RA mode may also be applicable.

Proportional and Integral Control - PI

In addition to the basic proportional function of the Variable Speed

709-VmA Series

Electronic Fan Speed Controller Drive controller, some application may require that the controller

control at set point, without any signal error (span). This application

therefore requires that the proportional signal be “integrated” so that

Description any demand (requirement) will be met at set point with no span or

signal error. The PI function is accomplished by adding, "plugging

Variable Speed Drive of Blower or Propeller fans can provide the

in", a 265-PI card to the main controller. When this optional acces-

optimum temperature, volume, or pressure as may be required by

sory is used, the input signal is connected directly to the PI terminal

an application. The application may be controlled as a Direct Acting

block rather than the 709 terminals. Set point and time constant

(DA) and/or Reverse Acting (RA) function. The Direct Acting (DA)

adjustments are made from the PI board. The time constant is

application provides a proportional increase in the signal input above

adjustable for minimizing or eliminating "hunting" of the control

a set point as the demand increases. Conversely, the Reverse Acting

signal. The 709 controller and 265-PI Interface Integrator may be

(RA) application provides a proportional increase in the signal input

used to control temperature, flow (fpm), or static pressure (WG).

below a set point as the demand increases.

The controller is available with or without a 24VAC power supply.

The D suffix after the 709 indicates that no 24VAC transformer is Application

provided. The E suffix indicates that the 24VAC transformer is PCB

1) Controlling conditioned air flow by varying the volume of air to

mounted and wired. D suffix models can function as 120V, 208-240V,

a space for maintaining a constant temperature in a zone or area,

277V, or 480V. E suffix models are available for use in 120V and 208-

or constant temperature of supply air.

240V applications.

2) Maintaining a constant flow rate (fpm) or volume (cfm) as the

The 709E controller has sufficient VA (power) to drive the

pressure of a system increases or decreases.

optional Proportional Integration (PI) Interface plug in card and

one of the the following signal sources; a Hoffman Controls 203- 3) Maintaining a constant negative or positive pressure within an air

5(24)V Flow Transducer, a 203-6(24)P Pressure Transducer, or a distribution system or space.

906VmA Thermostat. IMPORTANT: When using 709D series 4) Maintaining a constant pressure differential between two spaces

controllers, select a transformer to meet the requirements of all the or areas.

components being used.

Thermostat and Transducer Inputs

Variable Speed Drives can control the flow of conditioned air or

Thermostats are available for control of temperature in two ranges;

fluids to maintain temperature, maintain a constant flow as pressure

50°-90°F for environmental applications and 30°-180°F for commercial

changes, or maintain a constant pressure as a result of varying flow

or industrial applications with both 2-10V DC and 4-20mA outputs.

rates. These conditions can be controlled by providing a propor-

906-VmA Series thermostats utilize a linear millivolt sensor output that

tional output signal from a thermostat, flow, or pressure transducer.

directly converts mV to °F. (773mV=77.3°F) The 906 thermostat is

The 709-VmA Series controller accepts a 2-10V DC or 4-20mA

available with an optional "on" - "off" - "offset" three position switch.

input providing the set point and span for the application. A 906

Offset is adjustable from 0° to 20°F above or below setpoint. See 906

Series thermostat or 203 Series transducer provides the output that

Series thermostat Product Data for wall or remote type thermostats,

matches the 709-VmA Series Variable Speed Drive input require-

sensors, and available ranges.

ments. Averaging Air Flow or Static Pressure duct mounted "pick up"

assemblies up to 4000fpm or 4.0” WG are available for the 203 series Transducers are available to provide flow in fpm or pressure in

transducers. The controller provides a Minimum and Maximum inches water gauge (WG). Transducers are temperature compensated

and factory calibrated for various flow ranges up to 4000fpm and up

to 4.0" WG pressure. See 203-5(24)V Series for flow applications and

203-6(24)P Series for pressure applications. A 2-10V DC output signal

Specifications

only is standard for both flow or pressure transducers.

Signal Averaging Voltage, Input (nominal) 24V AC

Transformer Power 3.4VA

A 206-10-1 Series multiple input signal control, with averaging signal 709E Power, 24V AC 1.0 VA

output, is available for determining the collective average of the total Accessory Power Available 2.4VA

number of individual inputs when required. This interface can provide Frequency 60 Hz

a common output signal that represents the average of all inputs for

Voltage, Line (nominal)

setting a demand for the system. These inputs can be a DA and/or RA 709D-xVmA 120, 208-240,277, 480 VAC

function, and typically is the average of the multiple thermostat signals. 709E-xVmA 120, 208-240 VAC

This averaged output signal is represented by a 2-10V DC signal. Two

volts DC would represent zero demand, ten volts would represent

Current (maximum)

709x- VmA 5 Amps

100% demand. This multi-signal input, with average output signal 709x-BVma 10 Amps

represents the proportional percent value of the demand required of 709x-CVmA 18 Amps

the system. This average output signal can provide the percent demand

for multiple compressors, heating stages, etc. for setting the required Input Signals

DC Volts 2–10V DC

capacity for meeting the load.

Load Impedance 10,000 Ohms Min.

Flexibility DC milliAmps 4–20 m A D C

Load 500 Ohms

When the 709 controller is utilized with the optional PI Interface,

Thermostat, Flow or Pressure Transducer, all of the peripheral controls Operating Ambient 32°F to 120°F

provide a "closed loop" "single source" manufacturer of compo-

nents. Therefore, all of the controls are designed, manufactured, and

Humidity 95%, Non-condensing

calibrated to function together as a complete system. Dimensions (L x W x H) 5.0” x 5.5” x 3.15”

Features and Benefits 709D-VmA and 709E-VmA Series Product Illustration

���������������������������������������������������������������

Applicable for controlling shaded pole or permanent split �����������

capacitor motors. ��������� �����

• Multi-voltage applications.

• Minimum/Maximum speed adjustments. �� �� ��� ��� ���

��������

• Motor cut-out adjustment. ��� ���������

������

�������

�����

����

����

���

���

���

���������������

• Optional 265-PI Interface (Proportional Integration). ��� ���

���

• Optional 906 Series LM34 1°F/10mV Thermostat ���

���

���

���

��

• Optional 206-10-1 Signal Averaging Interface ��� ���

���

• Optional 203-5(24)V Flow, or 203-6(24)P Pressure

��� ���

���

Transducers.

2ºF, 4000 FPM, 4" H2O SPAN PERCENT

SPAN VS VDC OUTPUT

100

90 �� ��

80

70 709E-VmA Series

60 ���� ���� ��� �������

50

40 ����������

30 �������������

�������������

20 ���� ����������

10 �������������

���� ��������������

0 �����

0 2 4 6 8 10 ��

DC VOLTS OUT

* NOTE: If 709D Series controller is used, connect external

NOTE: Consult the 203-5 & 203-6 Series Transducer literature for transformer as shown in dotted lines.

complete details of applicable flow and pressure operating ranges. CAUTION: Ground only GND terminal on controller.

Hoffman|Controls

2463 Merrell Road, Dallas, Texas 75229 • Phone: (972) 243-7425 • Fax: (972) 247-8674 • Toll Free: 1-888-HCC-1190

www.hoffmancontrols.com Form:-172-0236-000 Rev. A

Anda mungkin juga menyukai

- Reference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 2Dari EverandReference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 2Belum ada peringkat

- Samson 3730 DatasheetDokumen12 halamanSamson 3730 DatasheetGabriel DpdBelum ada peringkat

- Reference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 1Dari EverandReference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 1Penilaian: 2.5 dari 5 bintang2.5/5 (3)

- T83843en 3730-3Dokumen12 halamanT83843en 3730-3aespinosa_rBelum ada peringkat

- Data Sheet T 8384-3 EN: Type 3730-3 Electropneumatic Positioner With HART CommunicationDokumen12 halamanData Sheet T 8384-3 EN: Type 3730-3 Electropneumatic Positioner With HART CommunicationThiago Rodrigo Oliveira SantosBelum ada peringkat

- P-Series VFD: New Firmware Makes Setup A SnapDokumen5 halamanP-Series VFD: New Firmware Makes Setup A SnapConde Garcia CalderonBelum ada peringkat

- VASCO 5 1 EngDokumen8 halamanVASCO 5 1 EngMuhammad ImranBelum ada peringkat

- Digest: Process ControlDokumen1 halamanDigest: Process ControlRaul tejadaBelum ada peringkat

- Controling AHU Duct PressureDokumen2 halamanControling AHU Duct PressureKumudu PereraBelum ada peringkat

- NRB 0282-0754 HDokumen8 halamanNRB 0282-0754 HZvonimir PerasovićBelum ada peringkat

- DS8792 Standard EU enDokumen17 halamanDS8792 Standard EU enItss Mee HadiBelum ada peringkat

- PID - Scanner 2000Dokumen12 halamanPID - Scanner 2000hectorivantovarjaimesBelum ada peringkat

- Relay For Voltage Control: Technical DataDokumen28 halamanRelay For Voltage Control: Technical DatasayedBelum ada peringkat

- Peak 150Dokumen4 halamanPeak 150scarface666Belum ada peringkat

- Automatic Voltage Regulator Reg D E.eberleDokumen28 halamanAutomatic Voltage Regulator Reg D E.eberleAnkur_soniBelum ada peringkat

- AV9900 01029 en NaDokumen181 halamanAV9900 01029 en NaAdiel CeballosBelum ada peringkat

- ARCA Fly ReglerInstr GBDokumen6 halamanARCA Fly ReglerInstr GBChanBelum ada peringkat

- ws8 Product Data Ge51r0419Dokumen4 halamanws8 Product Data Ge51r0419FareethAbdullahBelum ada peringkat

- SKU 99 FCU 4 Fan Coil ControllerDokumen10 halamanSKU 99 FCU 4 Fan Coil ControllerAiman AliBelum ada peringkat

- Peak® 150: Digital Control For Steam TurbinesDokumen4 halamanPeak® 150: Digital Control For Steam TurbinesgerardoBelum ada peringkat

- Key MFS 268Dokumen18 halamanKey MFS 268PabloBelum ada peringkat

- PB3308Dokumen2 halamanPB3308parrastevens930Belum ada peringkat

- OundationDokumen16 halamanOundationBernie EscobarBelum ada peringkat

- FAS-115DG Data Sheet 4921240116 UKDokumen7 halamanFAS-115DG Data Sheet 4921240116 UKWaseem AhmadBelum ada peringkat

- Newage Stamford Avr mx450 ManualDokumen4 halamanNewage Stamford Avr mx450 Manualfrancisco valladaresBelum ada peringkat

- Pressure Dependent and Pressure Independent ControlsDokumen4 halamanPressure Dependent and Pressure Independent ControlsrahulBelum ada peringkat

- Feedback 37 100Dokumen2 halamanFeedback 37 100Ashik AhmedBelum ada peringkat

- Variable Speed Benefits BROVFD-R1Dokumen4 halamanVariable Speed Benefits BROVFD-R1momin momaniBelum ada peringkat

- AM24 SR US 18Nm 19626Dokumen2 halamanAM24 SR US 18Nm 19626Multiservici Campo EliasBelum ada peringkat

- VS1MD BrochureDokumen8 halamanVS1MD Brochureskeyser34Belum ada peringkat

- Relay For OLTC Control & Transformer Monitoring: Technical DataDokumen32 halamanRelay For OLTC Control & Transformer Monitoring: Technical DataDang Hoai PhongBelum ada peringkat

- Brochure Keystone Epi 2 Quarter Turn Electric Actuators en 7736668Dokumen8 halamanBrochure Keystone Epi 2 Quarter Turn Electric Actuators en 7736668Abhijeet RedekarBelum ada peringkat

- 700 PC DS Pump ControllerDokumen2 halaman700 PC DS Pump ControllerOel NaubBelum ada peringkat

- Aire Acondicionado PrecisiónDokumen75 halamanAire Acondicionado PrecisiónEmanuel OsorioBelum ada peringkat

- Regulator PID KS 40 - KS 40-1 DatasheetDokumen8 halamanRegulator PID KS 40 - KS 40-1 DatasheetAco mijoskiBelum ada peringkat

- Reg DA RelayDokumen16 halamanReg DA Relayprabhakaran_hdecBelum ada peringkat

- ListBox User ManualDokumen4 halamanListBox User Manualsungjoo75Belum ada peringkat

- 2301A Speed Control: ApplicationsDokumen4 halaman2301A Speed Control: ApplicationsFabio Andres Plata TorresBelum ada peringkat

- 4 6 01-GBDokumen2 halaman4 6 01-GBMuhd Khir RazaniBelum ada peringkat

- D I G I T A L T H y R Istor Power Controllers (SCR)Dokumen4 halamanD I G I T A L T H y R Istor Power Controllers (SCR)mubs73Belum ada peringkat

- Proact™ P-Series Position Controller: ApplicationsDokumen5 halamanProact™ P-Series Position Controller: Applicationschao wangBelum ada peringkat

- Altronics AGV5 BLLTN 08-2003 PDFDokumen2 halamanAltronics AGV5 BLLTN 08-2003 PDFSMcBelum ada peringkat

- Specification Bulletin 695 33Dokumen28 halamanSpecification Bulletin 695 33mojsic6313Belum ada peringkat

- Agv5 Smart Gas Control Valve: "A-Series" Control ElectronicsDokumen2 halamanAgv5 Smart Gas Control Valve: "A-Series" Control ElectronicsJohn MontoyaBelum ada peringkat

- X55-600 BrochureDokumen9 halamanX55-600 BrochureEnrique MurgiaBelum ada peringkat

- SPM-D11 Series: Load Share SynchronizerDokumen4 halamanSPM-D11 Series: Load Share Synchronizersivana rodiahBelum ada peringkat

- Product Information: Reference OnlyDokumen5 halamanProduct Information: Reference OnlyCpe_CarloBelum ada peringkat

- Aermec PXA E INSTALLATION MANUAL EngDokumen8 halamanAermec PXA E INSTALLATION MANUAL EngMauricio Andres Vidal ColomaBelum ada peringkat

- ARCA Fly ARCAPRO GBDokumen6 halamanARCA Fly ARCAPRO GBcvfBelum ada peringkat

- MAGNAVALVE Mod ACDokumen25 halamanMAGNAVALVE Mod ACdahora13Belum ada peringkat

- DM110Dokumen2 halamanDM1103efooBelum ada peringkat

- 111-300 Trans Temp MonDokumen4 halaman111-300 Trans Temp MonLucian2001Belum ada peringkat

- Series 3730 Electropneumatic Positioner Type 3730-2 and Type 3730-3 With HART CommunicationDokumen8 halamanSeries 3730 Electropneumatic Positioner Type 3730-2 and Type 3730-3 With HART Communicationtree_99Belum ada peringkat

- ARCA Fly ReglerInstr GBDokumen6 halamanARCA Fly ReglerInstr GBavikbhaiBelum ada peringkat

- Catalog SB200Dokumen19 halamanCatalog SB200Song NguyễnBelum ada peringkat

- CH 8Dokumen81 halamanCH 8kfaliBelum ada peringkat

- HP & LP Bypass System - Steam Turbine Power PlantDokumen4 halamanHP & LP Bypass System - Steam Turbine Power Plantamer_arauf100% (13)

- Siemens TEC Heat Pump Controllers: Features ApplicationsDokumen4 halamanSiemens TEC Heat Pump Controllers: Features Applicationsvvukmirovic_2Belum ada peringkat

- Features and Benefits: Temperature ControllerDokumen2 halamanFeatures and Benefits: Temperature ControllerRICHARDBelum ada peringkat

- Variable Speed ControllerDokumen2 halamanVariable Speed ControllerHadi HussainBelum ada peringkat

- B.S.A.C.E.T., Mathura Machine Design/MD-II (KME602/RME603) B.Tech., 6 SEMESTER, CT-2, 2021-22Dokumen1 halamanB.S.A.C.E.T., Mathura Machine Design/MD-II (KME602/RME603) B.Tech., 6 SEMESTER, CT-2, 2021-22ROHIT SRIVASTAVBelum ada peringkat

- Power System Protection & Recent Trends by JDM - LatestDokumen152 halamanPower System Protection & Recent Trends by JDM - Latestraajesh692% (12)

- Comprehensive Fluid Mechanics ComprehensiveDokumen336 halamanComprehensive Fluid Mechanics ComprehensiveOsmr Ramos100% (1)

- Modicon X80 Modules - BMXDRA1605Dokumen5 halamanModicon X80 Modules - BMXDRA1605Vipper80Belum ada peringkat

- 12 Volts Elv Fan RangeDokumen2 halaman12 Volts Elv Fan Rangemahri725Belum ada peringkat

- Mechanical Properties of Fluids: Chapter TenDokumen20 halamanMechanical Properties of Fluids: Chapter TenjjBelum ada peringkat

- Pressure MeasurementDokumen19 halamanPressure Measurementdevarshikumar vaidya100% (1)

- MATH 3rd Grading Summative Test 3Dokumen3 halamanMATH 3rd Grading Summative Test 3Aubrey Gay Sarabosquez100% (2)

- 74LS123Dokumen10 halaman74LS123jonat09Belum ada peringkat

- University Physics: Waves and Electricity: Dr.-Ing. Erwin SitompulDokumen37 halamanUniversity Physics: Waves and Electricity: Dr.-Ing. Erwin SitompulAliBelum ada peringkat

- Units ConversionDokumen9 halamanUnits ConversionNoor M KhanBelum ada peringkat

- Cambridge Primary Checkpoint - Science (0846) April 2020 Paper 1 Mark SchemeDokumen12 halamanCambridge Primary Checkpoint - Science (0846) April 2020 Paper 1 Mark SchemeJivanna88% (8)

- Dynamics of Rigid BodiesDokumen9 halamanDynamics of Rigid BodiesJifford Rois HernanBelum ada peringkat

- Liberty Port-ZTE-ZXDU58-B121 Product Description PDFDokumen29 halamanLiberty Port-ZTE-ZXDU58-B121 Product Description PDFJCARLOS COLQUEBelum ada peringkat

- CE-EMC Test ReportDokumen97 halamanCE-EMC Test ReportDuy ChuBelum ada peringkat

- Zener Diode Problem Solving TechniquesDokumen6 halamanZener Diode Problem Solving TechniquesRaghul R100% (1)

- Janitza Manual Prophi 7 GBDokumen35 halamanJanitza Manual Prophi 7 GBJose TroscaBelum ada peringkat

- Stoichiometry Calculations With Chemical FormulasDokumen55 halamanStoichiometry Calculations With Chemical FormulassaneleBelum ada peringkat

- Trigonometry All Formulas by Aditya Sir WinnersDokumen5 halamanTrigonometry All Formulas by Aditya Sir Winnershkjhkjhk2Belum ada peringkat

- Sick - Ue 43mfDokumen4 halamanSick - Ue 43mfchnanduBelum ada peringkat

- DatasheetDokumen12 halamanDatasheetDjalma MoreiraBelum ada peringkat

- Consider A Two-Stage Cascade Refrigeration System .Dokumen5 halamanConsider A Two-Stage Cascade Refrigeration System .NaufalBelum ada peringkat

- ENGINEERING MECHANICS REFRESHER SET Preboard 2022Dokumen2 halamanENGINEERING MECHANICS REFRESHER SET Preboard 2022Marion Reinz MalubagBelum ada peringkat

- DS Flow IndicatorDokumen4 halamanDS Flow IndicatornathaBelum ada peringkat

- Heatmasters: Mobile Heat Treatment EquipmentDokumen2 halamanHeatmasters: Mobile Heat Treatment EquipmentAnand SankarBelum ada peringkat

- A Numerical Model For Thermal-Hydraulic Design of A Shell and Single Pass Low Finned Tube Bundle Heat ExchangerDokumen27 halamanA Numerical Model For Thermal-Hydraulic Design of A Shell and Single Pass Low Finned Tube Bundle Heat ExchangerSilvio PeluffoBelum ada peringkat

- General Layout of Modern Steam Power PlantDokumen15 halamanGeneral Layout of Modern Steam Power PlanttabishkhanaligBelum ada peringkat

- Forces and Fluids ProjectDokumen7 halamanForces and Fluids ProjectJose MederoBelum ada peringkat

- Hacking With Linux 2020:A Complete Beginners Guide to the World of Hacking Using Linux - Explore the Methods and Tools of Ethical Hacking with LinuxDari EverandHacking With Linux 2020:A Complete Beginners Guide to the World of Hacking Using Linux - Explore the Methods and Tools of Ethical Hacking with LinuxBelum ada peringkat

- Chip War: The Quest to Dominate the World's Most Critical TechnologyDari EverandChip War: The Quest to Dominate the World's Most Critical TechnologyPenilaian: 4.5 dari 5 bintang4.5/5 (227)

- Computer Science: A Concise IntroductionDari EverandComputer Science: A Concise IntroductionPenilaian: 4.5 dari 5 bintang4.5/5 (14)

- CompTIA Security+ All-in-One Exam Guide, Sixth Edition (Exam SY0-601)Dari EverandCompTIA Security+ All-in-One Exam Guide, Sixth Edition (Exam SY0-601)Penilaian: 5 dari 5 bintang5/5 (1)

- iPhone X Hacks, Tips and Tricks: Discover 101 Awesome Tips and Tricks for iPhone XS, XS Max and iPhone XDari EverandiPhone X Hacks, Tips and Tricks: Discover 101 Awesome Tips and Tricks for iPhone XS, XS Max and iPhone XPenilaian: 3 dari 5 bintang3/5 (2)

- Chip War: The Fight for the World's Most Critical TechnologyDari EverandChip War: The Fight for the World's Most Critical TechnologyPenilaian: 4.5 dari 5 bintang4.5/5 (82)

- CompTIA A+ Certification All-in-One Exam Guide, Eleventh Edition (Exams 220-1101 & 220-1102)Dari EverandCompTIA A+ Certification All-in-One Exam Guide, Eleventh Edition (Exams 220-1101 & 220-1102)Penilaian: 5 dari 5 bintang5/5 (2)

- Amazon Web Services (AWS) Interview Questions and AnswersDari EverandAmazon Web Services (AWS) Interview Questions and AnswersPenilaian: 4.5 dari 5 bintang4.5/5 (3)

- CompTIA A+ Complete Review Guide: Core 1 Exam 220-1101 and Core 2 Exam 220-1102Dari EverandCompTIA A+ Complete Review Guide: Core 1 Exam 220-1101 and Core 2 Exam 220-1102Penilaian: 5 dari 5 bintang5/5 (2)

- iPhone Unlocked for the Non-Tech Savvy: Color Images & Illustrated Instructions to Simplify the Smartphone Use for Beginners & Seniors [COLOR EDITION]Dari EverandiPhone Unlocked for the Non-Tech Savvy: Color Images & Illustrated Instructions to Simplify the Smartphone Use for Beginners & Seniors [COLOR EDITION]Penilaian: 5 dari 5 bintang5/5 (1)

- Programming with STM32: Getting Started with the Nucleo Board and C/C++Dari EverandProgramming with STM32: Getting Started with the Nucleo Board and C/C++Penilaian: 3.5 dari 5 bintang3.5/5 (3)

- How to Jailbreak Roku: Unlock Roku, Roku Stick, Roku Ultra, Roku Express, Roku TV with Kodi Step by Step GuideDari EverandHow to Jailbreak Roku: Unlock Roku, Roku Stick, Roku Ultra, Roku Express, Roku TV with Kodi Step by Step GuidePenilaian: 1 dari 5 bintang1/5 (1)

- Amazon Echo Manual Guide : Top 30 Hacks And Secrets To Master Amazon Echo & Alexa For Beginners: The Blokehead Success SeriesDari EverandAmazon Echo Manual Guide : Top 30 Hacks And Secrets To Master Amazon Echo & Alexa For Beginners: The Blokehead Success SeriesBelum ada peringkat

- Windows 10 Mastery: The Complete User Guide to Learn Windows 10 from Beginner to ExpertDari EverandWindows 10 Mastery: The Complete User Guide to Learn Windows 10 from Beginner to ExpertPenilaian: 3.5 dari 5 bintang3.5/5 (6)

- How To Market Mobile Apps: Your Step By Step Guide To Marketing Mobile AppsDari EverandHow To Market Mobile Apps: Your Step By Step Guide To Marketing Mobile AppsBelum ada peringkat

- Patterns in the Machine: A Software Engineering Guide to Embedded DevelopmentDari EverandPatterns in the Machine: A Software Engineering Guide to Embedded DevelopmentPenilaian: 5 dari 5 bintang5/5 (1)

- iPhone 14 Guide for Seniors: Unlocking Seamless Simplicity for the Golden Generation with Step-by-Step ScreenshotsDari EverandiPhone 14 Guide for Seniors: Unlocking Seamless Simplicity for the Golden Generation with Step-by-Step ScreenshotsPenilaian: 5 dari 5 bintang5/5 (1)

- Raspberry Pi | 101: The Beginner’s Guide with Basics on Hardware, Software, Programming & ProjecDari EverandRaspberry Pi | 101: The Beginner’s Guide with Basics on Hardware, Software, Programming & ProjecBelum ada peringkat

- CompTIA A+ Complete Practice Tests: Core 1 Exam 220-1101 and Core 2 Exam 220-1102Dari EverandCompTIA A+ Complete Practice Tests: Core 1 Exam 220-1101 and Core 2 Exam 220-1102Belum ada peringkat

![iPhone Unlocked for the Non-Tech Savvy: Color Images & Illustrated Instructions to Simplify the Smartphone Use for Beginners & Seniors [COLOR EDITION]](https://imgv2-2-f.scribdassets.com/img/audiobook_square_badge/728318688/198x198/f3385cbfef/1714737415?v=1)