AISC 360-2010 Pin

Diunggah oleh

ihpeterDeskripsi Asli:

Judul Asli

Hak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

AISC 360-2010 Pin

Diunggah oleh

ihpeterHak Cipta:

Format Tersedia

Comm. D5.] PIN-CONNECTED MEMBERS 16.

1–287

D4. BUILT-UP MEMBERS

Although not commonly used, built-up member configurations using lacing, tie

plates and perforated cover plates are permitted by this Specification. The length and

thickness of tie plates are limited by the distance between the lines of fasteners, h,

which may be either bolts or welds.

D5. PIN-CONNECTED MEMBERS

Pin-connected members are occasionally used as tension members with very large

dead loads. Pin-connected members are not recommended when there is sufficient

variation in live loading to cause wearing of the pins in the holes. The dimensional

requirements presented in Specification Section D5.2 must be met to provide for the

proper functioning of the pin.

1. Tensile Strength

The tensile strength requirements for pin-connected members use the same φ and

Ω values as elsewhere in this Specification for similar limit states. However, the

definitions of effective net area for tension and shear are different.

2. Dimensional Requirements

Dimensional requirements for pin-connected members are illustrated in Figure

C-D5.1.

Dimensional Requirements

1. a ≥ 1.33 be

2. w ≥ 2be + d

3. c ≥ a

where

be = 2t + 0.63 in. (16 mm) ≤ b

Fig. C-D5.1. Dimensional requirements for pin-connected members.

Specification for Structural Steel Buildings, June 22, 2010

AMERICAN INSTITUTE OF STEEL CONSTRUCTION

16.1–288 EYEBARS [Comm. D6.

D6. EYEBARS

Forged eyebars have generally been replaced by pin-connected plates or eyebars

thermally cut from plates. Provisions for the proportioning of eyebars contained in

this Specification are based upon standards evolved from long experience with

forged eyebars. Through extensive destructive testing, eyebars have been found to

provide balanced designs when they are thermally cut instead of forged. The more

conservative rules for pin-connected members of nonuniform cross section and for

members not having enlarged “circular” heads are likewise based on the results of

experimental research (Johnston, 1939).

Stockier proportions are required for eyebars fabricated from steel having a yield

stress greater than 70 ksi (485 MPa) to eliminate any possibility of their “dishing”

under the higher design stress.

1. Tensile Strength

The tensile strength of eyebars is determined as for general tension members, except

that, for calculation purposes, the width of the body of the eyebar is limited to eight

times its thickness.

2. Dimensional Requirements

Dimensional limitations for eyebars are illustrated in Figure C-D6.1. Adherence to

these limits assures that the controlling limit state will be tensile yielding of the body;

thus, additional limit state checks are unnecessary.

Specification for Structural Steel Buildings, June 22, 2010

AMERICAN INSTITUTE OF STEEL CONSTRUCTION

Comm. D6.] EYEBARS 16.1–289

Dimensional Requirements

t ≥ 1/2 in. (13 mm) (Exception is provided

in Section D6.2)

w ≤ 8t

d ≥ 7/8w

dh ≤ d + 1/32 in. (1 mm)

R ≥ dh + 2b

2/3w ≤ b ≤ 3/4w (Upper limit is for

calculation purposes only)

Fig. C-D6.1. Dimensional limitations for eyebars.

Specification for Structural Steel Buildings, June 22, 2010

AMERICAN INSTITUTE OF STEEL CONSTRUCTION

Anda mungkin juga menyukai

- SESOC AnchorBolts PDFDokumen33 halamanSESOC AnchorBolts PDFDivesh rahulBelum ada peringkat

- SEV454-Design Project 2Dokumen46 halamanSEV454-Design Project 2Busiku SilengaBelum ada peringkat

- AP Research Survival Guide - RevisedDokumen58 halamanAP Research Survival Guide - RevisedBadrEddin IsmailBelum ada peringkat

- As 1926.1 - 2012 Swimming Pool SafetyDokumen49 halamanAs 1926.1 - 2012 Swimming Pool SafetyrteteBelum ada peringkat

- Design and Analysis of Steel BeamsDokumen35 halamanDesign and Analysis of Steel BeamsLhee Ann Garbo100% (1)

- Fees Structure For Government Sponsored (KUCCPS) Students: University of Eastern Africa, BaratonDokumen3 halamanFees Structure For Government Sponsored (KUCCPS) Students: University of Eastern Africa, BaratonGiddy LerionkaBelum ada peringkat

- Introduction-Design-Guide 2Dokumen16 halamanIntroduction-Design-Guide 2Sutha100% (1)

- BS5400 Part 4 Training Course - TE EpsomDokumen19 halamanBS5400 Part 4 Training Course - TE EpsomjologscresenciaBelum ada peringkat

- EMC Design Guide For PCBDokumen78 halamanEMC Design Guide For PCBFaruq AhmedBelum ada peringkat

- Design of Concentrically Braced FramesDokumen22 halamanDesign of Concentrically Braced FramesAnonymous iS33V5100% (1)

- SteelDesign Torsion Fu NewDokumen6 halamanSteelDesign Torsion Fu NewRafik Mohamed AlhajiBelum ada peringkat

- AD 337 - Wind Pressures For Buildings With Dominant OpeningsDokumen2 halamanAD 337 - Wind Pressures For Buildings With Dominant Openingssymon ellimacBelum ada peringkat

- Defining Torsion in Master FrameDokumen5 halamanDefining Torsion in Master FramekatoBelum ada peringkat

- Anchor PDFDokumen63 halamanAnchor PDFparhBelum ada peringkat

- The Application of Flexural Methods To Torsional Analysis of Thin-Walled Open SectionsDokumen10 halamanThe Application of Flexural Methods To Torsional Analysis of Thin-Walled Open SectionsRm1262100% (1)

- Anchor Bolt CheckDokumen1 halamanAnchor Bolt CheckihpeterBelum ada peringkat

- Anchor Bolt CheckDokumen1 halamanAnchor Bolt CheckihpeterBelum ada peringkat

- Engineering Structures: SciencedirectDokumen8 halamanEngineering Structures: SciencedirectFeleki AttilaBelum ada peringkat

- Assignment 1 GRAD 2019Dokumen4 halamanAssignment 1 GRAD 2019RamonErnestoICBelum ada peringkat

- CSA S16-09 CSA S16 09: Design of Steel StructuresDokumen20 halamanCSA S16-09 CSA S16 09: Design of Steel StructuresArnold GonzalesBelum ada peringkat

- Coriolis - Atlas CompendiumDokumen62 halamanCoriolis - Atlas CompendiumSquamata100% (2)

- Ford Spot Weld SpecDokumen12 halamanFord Spot Weld SpecJonathan Davies0% (1)

- Simpson Strong-Tie CFS Designer ManualDokumen26 halamanSimpson Strong-Tie CFS Designer Manualdnl_vicarsBelum ada peringkat

- Anchor Design HILTIDokumen14 halamanAnchor Design HILTIRohit GadekarBelum ada peringkat

- RC Detailing To EuroCode 2Dokumen39 halamanRC Detailing To EuroCode 2ahmadBelum ada peringkat

- Steel Members DesignDokumen195 halamanSteel Members DesignStephen JamesBelum ada peringkat

- Structural Steel Standard SANS 50025 / EN 10025:2004: Macsteel Trading Macsteel VRN Tel: 011-871-4600 Tel: 011-861-5200Dokumen11 halamanStructural Steel Standard SANS 50025 / EN 10025:2004: Macsteel Trading Macsteel VRN Tel: 011-871-4600 Tel: 011-861-5200JakesBelum ada peringkat

- Monthly Steel Quiz Tests Your KnowledgeDokumen2 halamanMonthly Steel Quiz Tests Your KnowledgeRajed MaglinteBelum ada peringkat

- RPH Sains DLP Y3 2018Dokumen29 halamanRPH Sains DLP Y3 2018Sukhveer Kaur0% (1)

- Con 1303Dokumen8 halamanCon 1303chef100% (1)

- Audit AP TestsDokumen3 halamanAudit AP TestsSweet Emme100% (1)

- Calculating Length of Reinforcing BarsDokumen3 halamanCalculating Length of Reinforcing BarsswarluBelum ada peringkat

- HCF PDFDokumen68 halamanHCF PDFSushmit SharmaBelum ada peringkat

- Eurocode 3 PDF FreeDokumen2 halamanEurocode 3 PDF FreeBret0% (1)

- Answer:: A. B. C. D. EDokumen51 halamanAnswer:: A. B. C. D. EselvakumarBelum ada peringkat

- Analysis and Design of Compression Steel MembersDokumen55 halamanAnalysis and Design of Compression Steel MembersWulandita Prihandini SagarmathaBelum ada peringkat

- Discussion - Design of W-Shapes For Combined Bending and TorsionDokumen2 halamanDiscussion - Design of W-Shapes For Combined Bending and TorsionnaimBelum ada peringkat

- C4-1 Lecture 5-NBCC Provisons - 2018-B&W PDFDokumen47 halamanC4-1 Lecture 5-NBCC Provisons - 2018-B&W PDFYang LiBelum ada peringkat

- Detecting Laminations in Thick Steel PlatesDokumen4 halamanDetecting Laminations in Thick Steel PlatesirmakBelum ada peringkat

- CCL PT Slabs Brochure Eng PDFDokumen15 halamanCCL PT Slabs Brochure Eng PDFSharad BornarkarBelum ada peringkat

- Bolt and Weld Capacity - Red Book 1999 PDFDokumen2 halamanBolt and Weld Capacity - Red Book 1999 PDFWhite_rabbit2885764Belum ada peringkat

- Base Connections Green BookDokumen41 halamanBase Connections Green BookLesego MatojaneBelum ada peringkat

- Prestress Concrete DPDokumen20 halamanPrestress Concrete DPdanielBelum ada peringkat

- Chapter 1 - Introduction To Structural Steel DesignDokumen44 halamanChapter 1 - Introduction To Structural Steel DesignKhaled Khafagy100% (1)

- Section Cut ETABS PDFDokumen2 halamanSection Cut ETABS PDFKimleng KhyBelum ada peringkat

- Ass 1 PDFDokumen2 halamanAss 1 PDFMohammad Saeed KhawamBelum ada peringkat

- 9 Beam DeflectionDokumen34 halaman9 Beam DeflectionBharat JajoriaBelum ada peringkat

- Media File Corrigenda To Connections 12 V2webcolDokumen9 halamanMedia File Corrigenda To Connections 12 V2webcolRC Dela RocaBelum ada peringkat

- Seismicdesign 120341225048028 5Dokumen82 halamanSeismicdesign 120341225048028 5ssbboossBelum ada peringkat

- KKKH3353 - Structural Steel Design - Tension MembersDokumen21 halamanKKKH3353 - Structural Steel Design - Tension MembersZeyad Tareq Al Sarori100% (2)

- Delegated Connection Design-The BasicsDokumen49 halamanDelegated Connection Design-The BasicsJay BawanBelum ada peringkat

- Design of Tension Member LRFDDokumen57 halamanDesign of Tension Member LRFDJerome Angelo B. Baybay100% (1)

- Uniform and Temperature LoadingDokumen2 halamanUniform and Temperature LoadingWessam NourBelum ada peringkat

- Structural Engineering VUDokumen6 halamanStructural Engineering VUshan kumarBelum ada peringkat

- Use of Flat Slabs in Multi-Storey Commercial Building Situated in High Seismic ZoneDokumen14 halamanUse of Flat Slabs in Multi-Storey Commercial Building Situated in High Seismic ZoneZimit SukhadiaBelum ada peringkat

- Assignment 1 Steel Structure DesignDokumen3 halamanAssignment 1 Steel Structure DesignAizat Sera SuwandiBelum ada peringkat

- A Programmable Solution For Stepped Crane ColumnsDokumen4 halamanA Programmable Solution For Stepped Crane ColumnsMohamed Mostafa IbrahimBelum ada peringkat

- Code in Staad ProDokumen6 halamanCode in Staad ProZakaria ZulkifliBelum ada peringkat

- 16542Dokumen7 halaman16542Cnc CamBelum ada peringkat

- Spandrel Flexural Design: Technical NoteDokumen11 halamanSpandrel Flexural Design: Technical Notetomxxx34Belum ada peringkat

- Aci349 06Dokumen157 halamanAci349 06OscarBelum ada peringkat

- Wheel Calculation IDEA Analyzes Wheel Material OptionsDokumen35 halamanWheel Calculation IDEA Analyzes Wheel Material Optionsbambang satryojatiBelum ada peringkat

- General Solution Eccentric Loads Weld Groups PDFDokumen10 halamanGeneral Solution Eccentric Loads Weld Groups PDFclam2014Belum ada peringkat

- Ansys Analysis-Trolley Beam 3T1Dokumen13 halamanAnsys Analysis-Trolley Beam 3T1Ye Wint ThuBelum ada peringkat

- Mechanics of Solids: Shearing Stresses in Beams and Thin-Walled MembersDokumen23 halamanMechanics of Solids: Shearing Stresses in Beams and Thin-Walled MembersZabid UllahBelum ada peringkat

- Aisi S100-7 1 PDFDokumen32 halamanAisi S100-7 1 PDFAli ÇELİKBelum ada peringkat

- S - 11 - Concrete 04 Beam Slab Development LengthDokumen152 halamanS - 11 - Concrete 04 Beam Slab Development LengthEngr. Gazi Golam SarwarBelum ada peringkat

- The Development of A New Design Procedure For Conventional Single-Plate Shear ConnectionsDokumen12 halamanThe Development of A New Design Procedure For Conventional Single-Plate Shear ConnectionsMiguelBelum ada peringkat

- Is 5429Dokumen7 halamanIs 5429Yogesh RohillaBelum ada peringkat

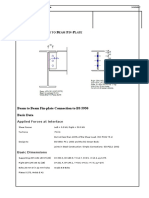

- 11Dokumen3 halaman11ihpeterBelum ada peringkat

- SBBDokumen3 halamanSBBihpeterBelum ada peringkat

- Hilti Design Report PDFDokumen6 halamanHilti Design Report PDFihpeterBelum ada peringkat

- Fin Plate Connection DesignDokumen3 halamanFin Plate Connection DesignihpeterBelum ada peringkat

- Fin Plate Connection DesignDokumen3 halamanFin Plate Connection DesignihpeterBelum ada peringkat

- 20180923Dokumen13 halaman20180923ihpeterBelum ada peringkat

- Portal Output 20180718 R2Dokumen60 halamanPortal Output 20180718 R2ihpeterBelum ada peringkat

- RRDokumen6 halamanRRihpeterBelum ada peringkat

- Expo Favoriteroom 5Dokumen1 halamanExpo Favoriteroom 5ihpeterBelum ada peringkat

- Conn DetailDokumen1 halamanConn DetailihpeterBelum ada peringkat

- 20170303Dokumen4 halaman20170303ihpeterBelum ada peringkat

- 1 Input Data: Profis Anchor 2.6.1Dokumen6 halaman1 Input Data: Profis Anchor 2.6.1ihpeterBelum ada peringkat

- UB457 End PlateDokumen4 halamanUB457 End PlateihpeterBelum ada peringkat

- Conn ForcesDokumen2 halamanConn ForcesihpeterBelum ada peringkat

- Circular Skylight Splice DetailDokumen1 halamanCircular Skylight Splice DetailihpeterBelum ada peringkat

- Software licensed structural analysis reaction forcesDokumen1 halamanSoftware licensed structural analysis reaction forcesihpeterBelum ada peringkat

- UB 254 146 31 B B F - P: X X EAM TO EAM IN LateDokumen7 halamanUB 254 146 31 B B F - P: X X EAM TO EAM IN LateihpeterBelum ada peringkat

- 1 Input Data: Profis Anchor 2.6.4Dokumen6 halaman1 Input Data: Profis Anchor 2.6.4ihpeterBelum ada peringkat

- 1 Input Data: Profis Anchor 2.6.4Dokumen6 halaman1 Input Data: Profis Anchor 2.6.4ihpeterBelum ada peringkat

- ADokumen9 halamanAihpeterBelum ada peringkat

- UB 356 171 45 B B F - P: X X EAM TO EAM IN LateDokumen6 halamanUB 356 171 45 B B F - P: X X EAM TO EAM IN LateihpeterBelum ada peringkat

- UB 457 152 52 B B F - P: X X EAM TO EAM IN LateDokumen6 halamanUB 457 152 52 B B F - P: X X EAM TO EAM IN LateihpeterBelum ada peringkat

- SHS120 Post FixingDokumen6 halamanSHS120 Post FixingihpeterBelum ada peringkat

- SHS120 Post FixingDokumen6 halamanSHS120 Post FixingihpeterBelum ada peringkat

- ADokumen7 halamanAihpeterBelum ada peringkat

- ADokumen7 halamanAihpeterBelum ada peringkat

- UB 254 146 31 B B F - P: X X EAM TO EAM IN LateDokumen7 halamanUB 254 146 31 B B F - P: X X EAM TO EAM IN LateihpeterBelum ada peringkat

- ADokumen2 halamanAihpeterBelum ada peringkat

- Chapter 3-The Hospitality & Travel Marketing SystemDokumen14 halamanChapter 3-The Hospitality & Travel Marketing SystemCharis AbadBelum ada peringkat

- CV. Anderson Hario Pangestiaji (English Version)Dokumen5 halamanCV. Anderson Hario Pangestiaji (English Version)Anderson PangestiajiBelum ada peringkat

- Alarm Management Second Ed - Hollifield Habibi - IntroductionDokumen6 halamanAlarm Management Second Ed - Hollifield Habibi - IntroductionDavid DuranBelum ada peringkat

- 01 Lab ManualDokumen5 halaman01 Lab ManualM Waqar ZahidBelum ada peringkat

- Sles-55605 C071D4C1Dokumen3 halamanSles-55605 C071D4C1rgyasuylmhwkhqckrzBelum ada peringkat

- Water 07 02314Dokumen36 halamanWater 07 02314Satyajit ShindeBelum ada peringkat

- Wicks Angela, Roethlein Christopher - A Satisfaction - Based Definition of QualityDokumen1 halamanWicks Angela, Roethlein Christopher - A Satisfaction - Based Definition of Qualityalfdjole0% (1)

- Mumbai Tourist Attractions.Dokumen2 halamanMumbai Tourist Attractions.Guru SanBelum ada peringkat

- Springhill Suites by Marriott / Houston Brookhollow Remit To:2750 N.Loop West, Houston TX 77092 713.290.9242Dokumen1 halamanSpringhill Suites by Marriott / Houston Brookhollow Remit To:2750 N.Loop West, Houston TX 77092 713.290.9242Josué SalazarBelum ada peringkat

- NYU Stern Evaluation NewsletterDokumen25 halamanNYU Stern Evaluation NewsletterCanadianValueBelum ada peringkat

- The Three Key Linkages: Improving The Connections Between Marketing and SalesDokumen5 halamanThe Three Key Linkages: Improving The Connections Between Marketing and SalesRuxandra PopaBelum ada peringkat

- New Pacific Timber v. Señeris, 101 SCRA 686Dokumen5 halamanNew Pacific Timber v. Señeris, 101 SCRA 686Ishmael AbrahamBelum ada peringkat

- List of Psychotropic Drugs Under International ControlDokumen32 halamanList of Psychotropic Drugs Under International ControlRadhakrishana DuddellaBelum ada peringkat

- Eladio Dieste's Free-Standing Barrel VaultsDokumen18 halamanEladio Dieste's Free-Standing Barrel Vaultssoniamoise100% (1)

- Communication Networks Chapter 1 SolutionsDokumen10 halamanCommunication Networks Chapter 1 SolutionsJ PrakashBelum ada peringkat

- Mod. 34 Classic Compact T06Dokumen4 halamanMod. 34 Classic Compact T06Jaime Li AliBelum ada peringkat

- Physics Force and BuoyancyDokumen28 halamanPhysics Force and BuoyancySohan PattanayakBelum ada peringkat

- Flexural Analysis of Beams (Part 2)Dokumen7 halamanFlexural Analysis of Beams (Part 2)Johnnette Nafuerza AggabaoBelum ada peringkat

- Chiller Carrier - 30gn-9siDokumen28 halamanChiller Carrier - 30gn-9siZJ Limited (ZJLimited)Belum ada peringkat

- Move Over G7, It's Time For A New and Improved G11: Long ShadowDokumen16 halamanMove Over G7, It's Time For A New and Improved G11: Long ShadowVidhi SharmaBelum ada peringkat

- Future War in Cities Alice Hills PDFDokumen5 halamanFuture War in Cities Alice Hills PDFazardarioBelum ada peringkat

- JVW 110Dokumen2 halamanJVW 110Miguel Leon BustosBelum ada peringkat

- Investigation Report on Engine Room Fire on Ferry BerlinDokumen63 halamanInvestigation Report on Engine Room Fire on Ferry Berlin卓文翔Belum ada peringkat