Frequency of Maintenance Tests

Diunggah oleh

moskin1230 penilaian0% menganggap dokumen ini bermanfaat (0 suara)

58 tayangan3 halamanVisual Circuit Switchers Network Protectors Protective Relays Electromechanical Electronic Instrument Transformers Metering Devices Ground-Fault Protection Systems Rotating Machinery AC Motors DC Motors AC Generators DC Generators Motor Control Mediumand High-Voltage Motor Control Centers Adjustable Speed Drive Systems Direct-Current Systems Batteries Battery Chargers Rectifiers Surge Arresters Low-Voltage Devices Mediumand high-voltage devices Suggested Monthly Frequency of Maintenance Source: MTS-2005

Deskripsi Asli:

Hak Cipta

© Attribution Non-Commercial (BY-NC)

Format Tersedia

PDF, TXT atau baca online dari Scribd

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniVisual Circuit Switchers Network Protectors Protective Relays Electromechanical Electronic Instrument Transformers Metering Devices Ground-Fault Protection Systems Rotating Machinery AC Motors DC Motors AC Generators DC Generators Motor Control Mediumand High-Voltage Motor Control Centers Adjustable Speed Drive Systems Direct-Current Systems Batteries Battery Chargers Rectifiers Surge Arresters Low-Voltage Devices Mediumand high-voltage devices Suggested Monthly Frequency of Maintenance Source: MTS-2005

Hak Cipta:

Attribution Non-Commercial (BY-NC)

Format Tersedia

Unduh sebagai PDF, TXT atau baca online dari Scribd

0 penilaian0% menganggap dokumen ini bermanfaat (0 suara)

58 tayangan3 halamanFrequency of Maintenance Tests

Diunggah oleh

moskin123Visual Circuit Switchers Network Protectors Protective Relays Electromechanical Electronic Instrument Transformers Metering Devices Ground-Fault Protection Systems Rotating Machinery AC Motors DC Motors AC Generators DC Generators Motor Control Mediumand High-Voltage Motor Control Centers Adjustable Speed Drive Systems Direct-Current Systems Batteries Battery Chargers Rectifiers Surge Arresters Low-Voltage Devices Mediumand high-voltage devices Suggested Monthly Frequency of Maintenance Source: MTS-2005

Hak Cipta:

Attribution Non-Commercial (BY-NC)

Format Tersedia

Unduh sebagai PDF, TXT atau baca online dari Scribd

Anda di halaman 1dari 3

Suggested Monthly Frequency of Maintenance

Source: MTS-2005 NETA

Section Description Visual Visual & Visual &

Mechanical Mechanical

& Electrical

7.1 Switchgear & Switchboard Assemblies 12 12 24

7.2 Transformers

7.2.1.1 Small Dry-Type Transformers 2 12 36

7.2.1.2 Large Dry-Type Transformers 1 12 24

7.2.2 Liquid-Filled Transformers 1 12 24

Sampling - - 12

7.3 Cables

7.3.2 Low-Voltage Cables 2 12 36

7.3.3 Medium- and High-Voltage Cables 2 12 36

7.4 Metal-Enclosed Busways 2 12 24

Infrared Only - - 12

7.5 Switches

7.5.1.1 Low-Voltage Air Switches 2 12 36

7.5.1.2 Medium-Voltage Metal-Enclosed Switches - 12 24

7.5.1.3 Medium- and High-Voltage Open Switches 1 12 24

7.5.2 Medium-Voltage Oil Switches 1 12 24

7.5.3 Medium-Voltage Vacuum Switches 1 12 24

7.5.4 Medium-Voltage SF6 Switches 1 12 24

7.5.5 Cutouts 12 24 24

7.6 Circuit Breakers

7.6.1.1 Low-Voltage Insulated-Case/Molded-Case CB 1 12 36

7.6.1.2 Low-Voltage Power CB 1 12 36

7.6.1.3 Medium-Voltage Air CB 1 12 36

7.6.2.1 Medium-Voltage Oil CB 1 12 36

Sampling - - 12

7.6.2.2 High-Voltage Oil CB 1 12 12

Sampling - - 12

7.6.3.1 Medium-Voltage Vacuum CB 1 12 24

7.6.4.1 Extra-High-Voltage SF6 1 12 24

Suggested Monthly Frequency of Maintenance

Source: MTS-2005 NETA

Section Description Visual Visual & Visual &

Mechanical Mechanical

& Electrical

7.7 Circuit Switchers 1 12 12

7.8 Network Protectors 12 12 24

7.9 Protective Relays

Electromechanical 1 12 12

Electronic 1 12 12

7.10 Instrument Transformers 12 12 36

7.11 Metering Devices 12 12 36

7.12 Regulating Apparatus

7.12.1.1 Step-Voltage Regulators 1 12 24

Sample Liquid - - 12

7.12.1.2 Induction Regulators 12 12 24

7.12.2 Current Regulators 1 12 24

7.12.3 Load-Tap-Changers 1 12 24

Sample Liquid - - 12

7.13 Grounding Systems 2 12 24

7.14 Ground-Fault Protection Systems 2 12 12

7.15 Rotating Machinery

7.15.1 AC Motors 1 12 24

7.15.2 DC Motors 1 12 24

7.15.3 AC Generators 1 12 24

7.15.4 DC Generators 1 12 24

7.16 Motor Control

7.16.1.1 Low-Voltage Motor Starters 2 12 24

7.16.1.2 Medium-Voltage Motor Starters 2 12 24

7.16.2.1 Low-Voltage Motor Control Centers 2 12 24

7.16.2.2 Medium-Voltage Motor Control Centers 2 12 24

7.17 Adjustable Speed Drive Systems 1 12 24

7.18 Direct-Current Systems

7.18.1 Batteries 1 12 12

7.18.2 Battery Chargers 1 12 12

7.18.3 Rectifiers 1 12 24

7.19 Surge Arresters

7.19.1 Low-Voltage Devices 2 12 24

7.19.2 Medium- and High-Voltage Devices 2 12 24

Suggested Monthly Frequency of Maintenance

Source: MTS-2005 NETA

Section Description Visual Visual & Visual &

Mechanical Mechanical

& Electrical

7.20 Capacitors and Reactors

7.20.1 Capacitors 1 12 12

7.20.2 Capacitor Control Devices 1 12 12

7.20.3.1 Reactors – Dry-Type 2 12 24

7.20.3.2 Reactors- Liquid-Filled 1 12 24

Sampling - - 12

7.21 Outdoor Bus Structures 1 12 36

7.22 Emergency Systems

7.22.1 Engine Generator 1 2 12

Functional Testing - - 2

7.22.2 Uninterruptible Power Systems 1 12 12

Functional Testing - - 2

7.22.3 Automatic Transformer Switches 1 12 12

Functional Testing - - 2

7.23 Telemetry/Pilot Wire SCADA 1 12 12

7.24 Auto. Circuit Reclosers & Line

Sectionalizers

7.24.1 Automatic Circuit Reclosers, Oil/Vacuum 1 12 24

Sample - - 12

7.24.2 Automatic Line Sectionalizers, Oil 1 12 24

Sample - - 12

7.27 EMF Testing 12 12 12

The following matrix is to be used as a multiplier with the above schedule based on equipment

condition and reliability. Specific condition, criticality, and reliability must be determined to

correctly apply the matrix. Application of the matrix, along with the culmination of historical

testing data and trending, should provide a quality electrical preventive maintenance program.

Maintenance Frequency Matrix

Equipment Condition

Poor Average Good

Equipment Low 1.0 2.0 2.5

Reliability Medium 0.50 1.0 1.5

Requirement High 0.25 0.50 0.75

Anda mungkin juga menyukai

- UL Bulletin On Electrical Connections PDFDokumen2 halamanUL Bulletin On Electrical Connections PDFbhaskarinvuBelum ada peringkat

- 18 Yaskawa p1000 Guia Rapida de Inicio Toepyaip1u01Dokumen252 halaman18 Yaskawa p1000 Guia Rapida de Inicio Toepyaip1u01taniaBelum ada peringkat

- Air Circuit Breakers Technical SpecsDokumen28 halamanAir Circuit Breakers Technical SpecsDerargh100% (1)

- P64x EN AP A11Dokumen92 halamanP64x EN AP A11Sakthi Krishnan0% (1)

- Ilnas-En Iec 62485-2:2018Dokumen9 halamanIlnas-En Iec 62485-2:2018Haja A0% (1)

- 8BK88PLUSDokumen8 halaman8BK88PLUSSwapnil PatilBelum ada peringkat

- Reconectador GVRDokumen16 halamanReconectador GVRjuanete29100% (1)

- CBGS0 Technical SCH-En PresentationDokumen33 halamanCBGS0 Technical SCH-En PresentationShah Aizat RazaliBelum ada peringkat

- Calculate Cable Size and Voltage Drop Electrical Notes Articles PDFDokumen10 halamanCalculate Cable Size and Voltage Drop Electrical Notes Articles PDFRavi SharmaBelum ada peringkat

- 508A Supplement SA 3-30-22Dokumen58 halaman508A Supplement SA 3-30-22JE HERERABelum ada peringkat

- D-AAA-TRAFO-ATR-EXP-11 - 200 (Rev.0-2011)Dokumen7 halamanD-AAA-TRAFO-ATR-EXP-11 - 200 (Rev.0-2011)virasamirBelum ada peringkat

- h07rn F en 50525 2 21 Flexible Rubber CableDokumen5 halamanh07rn F en 50525 2 21 Flexible Rubber CableBradBelum ada peringkat

- IEC 60898-1-2003 (Page 109 - Clause 9.12) PDFDokumen1 halamanIEC 60898-1-2003 (Page 109 - Clause 9.12) PDFHop0% (1)

- I-LINE II Busway Installation Manual - CFD - Compact EditionDokumen24 halamanI-LINE II Busway Installation Manual - CFD - Compact Editionvo100% (1)

- 695 Power To The Pump-MHDokumen4 halaman695 Power To The Pump-MHJOSE LUIS FALCON CHAVEZBelum ada peringkat

- IEEE STD C37.20.2b-1994 Suplemento PDFDokumen3 halamanIEEE STD C37.20.2b-1994 Suplemento PDFDaniel Gonzalez LucianiBelum ada peringkat

- Installing and Maintaining Panelboards: NECA 407-2009Dokumen38 halamanInstalling and Maintaining Panelboards: NECA 407-2009Ahmed OmarBelum ada peringkat

- Manual de Supresor de TransitoriosDokumen8 halamanManual de Supresor de TransitoriosAlkaEnergy EnergyBelum ada peringkat

- SEPAM 2000 ModbusDokumen50 halamanSEPAM 2000 Modbuslam9021Belum ada peringkat

- Schneider Electric P3U30 LED labels printoutDokumen2 halamanSchneider Electric P3U30 LED labels printoutPeter Paul Condinato100% (1)

- BUS BAR Sizing CalculationDokumen2 halamanBUS BAR Sizing Calculationmohan babuBelum ada peringkat

- Steam Drum InspectionDokumen3 halamanSteam Drum Inspectionyogacruise100% (1)

- ABB Ability and Digital Services 2018Dokumen44 halamanABB Ability and Digital Services 2018Shefian Md Dom100% (1)

- Hathaway CBT 400 ManualDokumen8 halamanHathaway CBT 400 Manualbeerbatov09700% (1)

- Info Iec60364-5-52 (Ed2.0) en D PDFDokumen7 halamanInfo Iec60364-5-52 (Ed2.0) en D PDFFahrul MuhamadBelum ada peringkat

- Relay Applications PDFDokumen52 halamanRelay Applications PDFRM HaroonBelum ada peringkat

- SQ-300®i Automatic Voltage Control: Proven Electrostatic Precipitator SolutionsDokumen2 halamanSQ-300®i Automatic Voltage Control: Proven Electrostatic Precipitator SolutionsRafael Paiva100% (1)

- Record Plus Catalogue EnglishDokumen256 halamanRecord Plus Catalogue EnglishluxofBelum ada peringkat

- 36kV Indoor VCB & GCB Circuit BreakersDokumen2 halaman36kV Indoor VCB & GCB Circuit BreakersRamesh AnanthanarayananBelum ada peringkat

- DCR Web PDFDokumen4 halamanDCR Web PDFMahmoud AyadBelum ada peringkat

- Nema PB 1-2011Dokumen36 halamanNema PB 1-2011Kamal ArreazaBelum ada peringkat

- Manual Mantenimiento Celdas 8BK20Dokumen16 halamanManual Mantenimiento Celdas 8BK20Alejandro Garay Moreno100% (1)

- Reb 611Dokumen76 halamanReb 611Adil KhanBelum ada peringkat

- HI-POT Setup and TestingDokumen10 halamanHI-POT Setup and Testingsaghaee.rezaBelum ada peringkat

- Qcs 2010 Section 21 Part 4 Motor StartersDokumen6 halamanQcs 2010 Section 21 Part 4 Motor Startersbryanpastor106100% (1)

- Caterpillar Alternator DatasheetDokumen1 halamanCaterpillar Alternator DatasheetFerhat KahveciBelum ada peringkat

- 3AH5 Vacuum Circuit Breaker Technical Slides 7078Dokumen18 halaman3AH5 Vacuum Circuit Breaker Technical Slides 7078Ricardo Astupiña FigueroaBelum ada peringkat

- Air Insulated Switchboard: Mcset 17.5 KVDokumen76 halamanAir Insulated Switchboard: Mcset 17.5 KVMIGUEL ALVARO BLASCO MARTINEZBelum ada peringkat

- CA - HD4 - IEC-GOST (EN) E - 1VCP000245 - 10.2017 - Ok PDFDokumen70 halamanCA - HD4 - IEC-GOST (EN) E - 1VCP000245 - 10.2017 - Ok PDFpowerbullBelum ada peringkat

- 7th Edition UL 1008 White PaperDokumen8 halaman7th Edition UL 1008 White PaperMarcelo CamachoBelum ada peringkat

- ZLAC8015 Servo Driver ManualDokumen9 halamanZLAC8015 Servo Driver ManualTHANAWATBelum ada peringkat

- VPS-215-E & VPS-220-E PSU Instructions Rev3 04 10 10Dokumen2 halamanVPS-215-E & VPS-220-E PSU Instructions Rev3 04 10 10tmaiBelum ada peringkat

- Pharos Part 2 - TPCDokumen72 halamanPharos Part 2 - TPCFlorin MandricBelum ada peringkat

- APECB 245 - 300 Instructions NKT 4280,0122,0CDokumen40 halamanAPECB 245 - 300 Instructions NKT 4280,0122,0CWenceslao EscorzaBelum ada peringkat

- ANSI Relay Symbols GuideDokumen2 halamanANSI Relay Symbols Guiderupash_82Belum ada peringkat

- Measurement of Insulation Resistance (IR) - Part 2 PDFDokumen17 halamanMeasurement of Insulation Resistance (IR) - Part 2 PDFvaratharajan g rBelum ada peringkat

- A Standard Format For Power System Studies: Peter E. Sutherland (SM) R. Gerald Irvine (SM)Dokumen8 halamanA Standard Format For Power System Studies: Peter E. Sutherland (SM) R. Gerald Irvine (SM)Ritaban R. BanerjeeBelum ada peringkat

- 32vp297en PDFDokumen112 halaman32vp297en PDFMohamedBelum ada peringkat

- SalzerDokumen37 halamanSalzerabu1882100% (1)

- C NRJED315663EN 030418Dokumen72 halamanC NRJED315663EN 030418bakien-canBelum ada peringkat

- E09-X02 - 0 Medium Voltage Motor Control Center Data SheetDokumen3 halamanE09-X02 - 0 Medium Voltage Motor Control Center Data SheetMuhammad IrfanBelum ada peringkat

- Ansi - c37.20 & Nema SG - 5Dokumen20 halamanAnsi - c37.20 & Nema SG - 5Subrat Das100% (1)

- National Electric Safety Code Ansi c2 NescDokumen44 halamanNational Electric Safety Code Ansi c2 NescLenin NateraBelum ada peringkat

- Knowledge is "Real Power": Introduction to Power QualityDari EverandKnowledge is "Real Power": Introduction to Power QualityBelum ada peringkat

- Frequency of Maintenance Tests MatrixDokumen4 halamanFrequency of Maintenance Tests MatrixAhmed Hasan100% (4)

- Acceptance Testing Guidelines IndexDokumen2 halamanAcceptance Testing Guidelines IndexAsdrubal AraujoBelum ada peringkat

- NETA Test FrequencyDokumen5 halamanNETA Test Frequencytimothynguyen2012Belum ada peringkat

- Selection of Switchyard EquipmentDokumen64 halamanSelection of Switchyard EquipmentkrcdewanewBelum ada peringkat

- RITZ-Medium Voltage Instrument Transformers Standard ENG 2014 01 PDFDokumen40 halamanRITZ-Medium Voltage Instrument Transformers Standard ENG 2014 01 PDFflyzalBelum ada peringkat

- Current Carrying CapacityDokumen1 halamanCurrent Carrying CapacityHassan AbuzidBelum ada peringkat

- Principles of Electric Circuits - FloydDokumen40 halamanPrinciples of Electric Circuits - FloydhdjskhdkjsBelum ada peringkat

- Cathodic Protection RectifiersDokumen12 halamanCathodic Protection RectifiersCyrix.OneBelum ada peringkat

- Operation of An Electric Fan, Parts and Its FunctionsDokumen6 halamanOperation of An Electric Fan, Parts and Its FunctionsAlfie Lariosa100% (1)

- Clear-Com Intercom Systems (Manual)Dokumen17 halamanClear-Com Intercom Systems (Manual)cash flowBelum ada peringkat

- MCCB S.220-224Dokumen5 halamanMCCB S.220-224AM76Belum ada peringkat

- ENG DS OMI 2 Pole Series Relay Data Sheet E 0411Dokumen3 halamanENG DS OMI 2 Pole Series Relay Data Sheet E 0411letterniBelum ada peringkat

- Mitsubishi Freqrol FR Z220 Manual PDFDokumen118 halamanMitsubishi Freqrol FR Z220 Manual PDFJarosław JarosławskiBelum ada peringkat

- Liquid Level Control Device: SSR 02 SSR 03 SSR 04Dokumen2 halamanLiquid Level Control Device: SSR 02 SSR 03 SSR 04ahmedBelum ada peringkat

- QL Innovative Ideas in Illumination Overview 1980Dokumen1 halamanQL Innovative Ideas in Illumination Overview 1980Alan MastersBelum ada peringkat

- Collins Catalog 1961 OCR Page 0014Dokumen1 halamanCollins Catalog 1961 OCR Page 0014Christian CespedesBelum ada peringkat

- Ahg MCC A 001Dokumen22 halamanAhg MCC A 001Yawar QureshiBelum ada peringkat

- Machine Lab 1Dokumen9 halamanMachine Lab 1مالك المجيديBelum ada peringkat

- Lundahl: Amorphous Core Moving Coil Input Transformer LL1931Dokumen1 halamanLundahl: Amorphous Core Moving Coil Input Transformer LL1931Giapy Phuc TranBelum ada peringkat

- Terminal SizeDokumen6 halamanTerminal SizeThanis SribovornmongkolBelum ada peringkat

- A800 Mitshubishi PDFDokumen795 halamanA800 Mitshubishi PDFTruong Minh QuangBelum ada peringkat

- For New Designs: SSC9522S Data SheetDokumen21 halamanFor New Designs: SSC9522S Data Sheetfalla naBelum ada peringkat

- Gigabyte Superb 550P Preview - Forth PageDokumen4 halamanGigabyte Superb 550P Preview - Forth Pagecolorado wildernessBelum ada peringkat

- Siemens Power Engineering Guide 7E 92Dokumen1 halamanSiemens Power Engineering Guide 7E 92mydearteacherBelum ada peringkat

- Split System Air Conditioners Daikin Inverter RZP-DDokumen255 halamanSplit System Air Conditioners Daikin Inverter RZP-Djoko riyantoBelum ada peringkat

- Sofar Hyd User Manual 230115 192131Dokumen51 halamanSofar Hyd User Manual 230115 192131Mhamad ShbeebBelum ada peringkat

- Chapter-4: TransformersDokumen26 halamanChapter-4: TransformersGAGANBelum ada peringkat

- WWW - Iscsemi.cn: Isc 2SC3835GDokumen3 halamanWWW - Iscsemi.cn: Isc 2SC3835GNikita KaplenkoBelum ada peringkat

- Bus PT-1Dokumen2 halamanBus PT-1suraj vishvakarmaBelum ada peringkat

- Manual VeichiDokumen166 halamanManual Veichihicham mahcihBelum ada peringkat

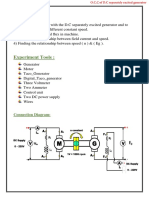

- 4-Electrical Machines-IIDokumen128 halaman4-Electrical Machines-IIBabul PratapBelum ada peringkat

- FAULT CODE 254 - Engine Fuel Shutoff Valve Driver Circuit - Voltage Below Normal or Shorted To Low SourceDokumen7 halamanFAULT CODE 254 - Engine Fuel Shutoff Valve Driver Circuit - Voltage Below Normal or Shorted To Low Sourcemohammed abbasBelum ada peringkat

- Ircp DataDokumen2 halamanIrcp DataHendra Syalala100% (1)

- Location Plan Schedule of Loads: SymbolsDokumen1 halamanLocation Plan Schedule of Loads: SymbolsJim Lesle Valdehuesa Bullecer100% (1)

- DC Motor (RF-300FA-12350, RF-300C-11440, RF-300EA-1D390) China (Mainland) DC MotorDokumen3 halamanDC Motor (RF-300FA-12350, RF-300C-11440, RF-300EA-1D390) China (Mainland) DC MotorMiguel SosaBelum ada peringkat