Aerospace Subassemblies

Diunggah oleh

api-78427664Judul Asli

Hak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

Aerospace Subassemblies

Diunggah oleh

api-78427664Hak Cipta:

Format Tersedia

Roger A.

Smith

1932 Lexington Rd. Residence: (316) 688-5153

Wichita, KS 67218 Cellular: (316) 461-1195

rsc756f2@westpost.net

OBJECTIVE

I am seeking full time employment building aerospace subassemblies.

SUMMARY

Ambitious, dedicated, and experienced individual possessing a manufacturing tech

nology focus in terms of leadership, action oriented, streamlining processes, re

duce flow time, assist with 5S, problem solving, creativity, composure, customer

focused, patient, good peer relationships, perseverance, priority setting, orga

nization, adaptable to change, pro-active solutions, planning strategies, facili

ties management, quality processes, lean manufacturing, safety enhancements, and

diversity engagement. Excellent communication and computer skills with Microsof

t Office applications. Many successful applications in process and ergonomic imp

rovements. Wide range of experience with coordinating projects between functiona

l organizations such as Engineering, Planning, Industrial Engineering, Facilitie

s, Safety, Security, Quality Assurance, Materiel, Procurement, Change Board, Man

ufacturing Operations, Tooling, Tool Cribs, Parts Control Area (PCA), and Manage

ment at all levels.

PROFESSIONAL EXPERIENCE

HAWKER BEECHCRAFT, Wichita, KS

Jul. 2007-Oct. 2009

Manufacturer of Aircraft

Industrial Engineering

* Develop process improvements for shop employees in order for them to become mo

re efficient.

Final Line Assembly

* Installation of parts/components for 11 months on the Hawker 4000 airplane.

WICHITA PUBLIC SCHOOLS a" USD 259, Wichita, KS

Mar. 2007-May 2007

Emergency Substitute Teacher K-12

GLOBAL ENGINEERING AND TECHNOLOGY, INC., Goddard, KS Apr. 2005-Dec.

2006

Manufacturer of airplane furniture.

Inspector

* Inspection of furniture including cabinetry and upholstery items starting at t

he beginning stages to the final finished product. First Article Inspections (FA

I) were documented upon changes to engineering drawings.

* Inspected detail sheet metal parts and assemblies to engineering drawings ensu

ring a quality product. FAIas were documented regularly.

Receiving Inspector

* Received in and inspected all parts and materials for form, fit, function, and

quantity ensuring that a quality product was received for future assembly/insta

llation. I input and managed detailed records of products received so purchasing

could charge suppliers appropriately. I organized and supplied up-to-date copie

s of the Material Safety Data Sheets (MSDS) for the library and distributed copi

es to end users.

* Product was placed in a staging area for future stocking or delivered to areas

for immediate in shop usage.

BOEING COMPANY - WICHITA DIVISION, Wichita, KS J

un. 1982-Jun. 2002

Manufacturer of commercial airplanes, modification of used airplanes, and contra

ctor for military products.

Production Operations Specialist

* Identified, analyzed, and implemented ergonomic improvements in production and

assembly shop areas.

* Developed and implemented lean manufacturing concepts based on the Toyota Prod

uction System for process improvements to reduce the product cost, increase mora

le and support company goals and initiatives.

* Team member of Accelerated Improvement Workshops which achieved savings of 50%

or more in production time, lead time, space consolidation and quality.

* Provided waste elimination techniques using the Toyota Production System conce

pts and practices to add value and eliminate Muda (waste).

* Determined root cause analysisa and implemented solutions.

* Member of Integrated Project Team (IPT) to provide lean initiatives for the 73

7 wing box assembly.

* Enhanced facility layouts and machine/tool rearrangements for improved work ce

ll configurations.

* Developed visibility charts to monitor productivity growth or losses and revie

wed with management.

* Projected workforce requirements in support of budget, schedule, and airplane

work zones for both production and modification programs.

* Coordinated abest practicea solutions and action plans from all other function

al organizations in task team settings for management review.

* Produced barcharts to schedule and sequence of shopas work to be done (planned

jobs).

* Calculated workforce projections/forecasting from budgeted allocations for eac

h work zone of the airplane.

* Performed 5S functions in all work areas involved with (sort, sweep, simplify,

standardize, sustain).

* Reviewed company policies and procedures for complete and accurate information

and submitted update information as needed.

* Worked in finance for one year tracking program costs and status of hours cloc

ked to budgeted amounts.

* Led team meetings in organizing and moving shop equipment and applicable provi

sions.

* Developed, organized, filed, and retained aircraft modification records in a m

odern storage system.

* Successfully completed 547 hours of non-monitored training classes (ex: JIT, L

ean Academy, Apollo Root Cause Analysis, etc.). And completed 54.5 hours of moni

tored training classes (ex: Ethics, Safety Monitor, CPR, etc.).

* Successfully completed a comprehensive in-house sheet metal assembly course du

ring the 747 commercial airliner modification program converting them to cargo t

ransport aircraft.

* Worked both on military and commercial programs at different times.

CESSNA AIRCRAFT CO. - WALLACE DIVISION, Wichita, KS Jun.

1978-Jun. 1982

Manufacturer of business jets and turbo-prop airplanes.

Industrial Engineer

* Developed time/motion standards for best shop practices.

* Maintained shop schedule visibility for management review at the Prospect Plan

t, the Main Plant, and Flight Operations.

* Studied and proposed a variety of changes to facility layouts.

* Initiated ROI studies for equipment replacement.

* Identified, analyzed, and made improvements to production processes.

EDUCATION

B.S.T., Technology Management, Pittsburg State University, Wichita, KS. 2003-200

4

Key Courses Completed include:

Legal and Social Environment of Business, Industrial Organization and Technology

Management, Facility Maintenance and Management, Industrial Supervision, Presen

tation Skills, Societal Influence of Technology, Quality Control, Industrial Saf

ety, Safety Management, Leadership in the Workplace, Human Relations in Industri

al Settings, Internship in Technology Management, Engineering Materials and Proc

esses, Diversity, Work Measurement and Efficiency Methods.

B.S., Industrial Technology, Emporia State University, Emporia, KS. 1972-1975

Associates in Applied Science - Electrical/Electronics, Cowley County Community

College, Arkansas City, KS.

1970-1972

Anda mungkin juga menyukai

- The Yellow House: A Memoir (2019 National Book Award Winner)Dari EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Penilaian: 4 dari 5 bintang4/5 (98)

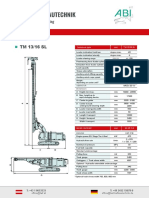

- ABI TM 13 16 SL - EngDokumen1 halamanABI TM 13 16 SL - EngJuan Carlos Benitez MartinezBelum ada peringkat

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDari EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RacePenilaian: 4 dari 5 bintang4/5 (895)

- Existentialism in LiteratureDokumen2 halamanExistentialism in LiteratureGirlhappy Romy100% (1)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDari EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifePenilaian: 4 dari 5 bintang4/5 (5794)

- DCN Dte-Dce and ModemsDokumen5 halamanDCN Dte-Dce and ModemsSathish BabuBelum ada peringkat

- The Little Book of Hygge: Danish Secrets to Happy LivingDari EverandThe Little Book of Hygge: Danish Secrets to Happy LivingPenilaian: 3.5 dari 5 bintang3.5/5 (399)

- Cool Fire Manual 45M620N2UK 01 PDFDokumen198 halamanCool Fire Manual 45M620N2UK 01 PDFPaun MihaiBelum ada peringkat

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDari EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaPenilaian: 4.5 dari 5 bintang4.5/5 (266)

- Lightning Protection Measures NewDokumen9 halamanLightning Protection Measures NewjithishBelum ada peringkat

- Shoe Dog: A Memoir by the Creator of NikeDari EverandShoe Dog: A Memoir by the Creator of NikePenilaian: 4.5 dari 5 bintang4.5/5 (537)

- Manual de Operacion y MantenimientoDokumen236 halamanManual de Operacion y MantenimientoalexBelum ada peringkat

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDari EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FuturePenilaian: 4.5 dari 5 bintang4.5/5 (474)

- Transparency and Digitalization in The Public Administration of RomaniaDokumen8 halamanTransparency and Digitalization in The Public Administration of RomaniaMădălina MarincaşBelum ada peringkat

- Never Split the Difference: Negotiating As If Your Life Depended On ItDari EverandNever Split the Difference: Negotiating As If Your Life Depended On ItPenilaian: 4.5 dari 5 bintang4.5/5 (838)

- Healthymagination at Ge Healthcare SystemsDokumen5 halamanHealthymagination at Ge Healthcare SystemsPrashant Pratap Singh100% (1)

- Grit: The Power of Passion and PerseveranceDari EverandGrit: The Power of Passion and PerseverancePenilaian: 4 dari 5 bintang4/5 (588)

- Advocacy Firm Business Plan by SlidesgoDokumen40 halamanAdvocacy Firm Business Plan by SlidesgoirinaBelum ada peringkat

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDari EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryPenilaian: 3.5 dari 5 bintang3.5/5 (231)

- Lesson 1: Composition: Parts of An EggDokumen22 halamanLesson 1: Composition: Parts of An Eggjohn michael pagalaBelum ada peringkat

- Body Systems Portfolio - Tommy JDokumen8 halamanBody Systems Portfolio - Tommy Japi-554072790Belum ada peringkat

- The Emperor of All Maladies: A Biography of CancerDari EverandThe Emperor of All Maladies: A Biography of CancerPenilaian: 4.5 dari 5 bintang4.5/5 (271)

- E-Mobility and SafetyDokumen77 halamanE-Mobility and SafetySantosh KumarBelum ada peringkat

- Women Are Better Managers Than MenDokumen5 halamanWomen Are Better Managers Than MenCorazon ValdezBelum ada peringkat

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDari EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyPenilaian: 3.5 dari 5 bintang3.5/5 (2259)

- Clint Freeman ResumeDokumen2 halamanClint Freeman ResumeClint Tiberius FreemanBelum ada peringkat

- On Fire: The (Burning) Case for a Green New DealDari EverandOn Fire: The (Burning) Case for a Green New DealPenilaian: 4 dari 5 bintang4/5 (73)

- Project Chalk CorrectionDokumen85 halamanProject Chalk CorrectionEmeka Nicholas Ibekwe100% (6)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDari EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersPenilaian: 4.5 dari 5 bintang4.5/5 (344)

- Fire Prevention Plan Template - FINAL 5-30-08Dokumen5 halamanFire Prevention Plan Template - FINAL 5-30-08Peter GeorgeBelum ada peringkat

- Rise of ISIS: A Threat We Can't IgnoreDari EverandRise of ISIS: A Threat We Can't IgnorePenilaian: 3.5 dari 5 bintang3.5/5 (137)

- Procter and Gamble - MarketingDokumen10 halamanProcter and Gamble - MarketingIvana Panovska100% (5)

- Team of Rivals: The Political Genius of Abraham LincolnDari EverandTeam of Rivals: The Political Genius of Abraham LincolnPenilaian: 4.5 dari 5 bintang4.5/5 (234)

- Erosional VelocityDokumen15 halamanErosional VelocityGary JonesBelum ada peringkat

- Case 3 SectionC Group 1 (Repaired)Dokumen3 halamanCase 3 SectionC Group 1 (Repaired)SANDEEP AGRAWALBelum ada peringkat

- Openvpn ReadmeDokumen7 halamanOpenvpn Readmefzfzfz2014Belum ada peringkat

- The Unwinding: An Inner History of the New AmericaDari EverandThe Unwinding: An Inner History of the New AmericaPenilaian: 4 dari 5 bintang4/5 (45)

- Battery Checklist ProcedureDokumen1 halamanBattery Checklist ProcedureKrauser ChanelBelum ada peringkat

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDari EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You ArePenilaian: 4 dari 5 bintang4/5 (1090)

- Adaptive Leadership: Leadership: Theory and PracticeDokumen14 halamanAdaptive Leadership: Leadership: Theory and PracticeJose Daniel Quintero100% (1)

- Exponential Smoothing - The State of The ArtDokumen28 halamanExponential Smoothing - The State of The ArtproluvieslacusBelum ada peringkat

- Pedagogy MCQS 03Dokumen54 halamanPedagogy MCQS 03Nawab Ali MalikBelum ada peringkat

- Cipet Bhubaneswar Skill Development CoursesDokumen1 halamanCipet Bhubaneswar Skill Development CoursesDivakar PanigrahiBelum ada peringkat

- Generalized Class of Sakaguchi Functions in Conic Region: Saritha. G. P, Fuad. S. Al Sarari, S. LathaDokumen5 halamanGeneralized Class of Sakaguchi Functions in Conic Region: Saritha. G. P, Fuad. S. Al Sarari, S. LathaerpublicationBelum ada peringkat

- Cultural Sensitivity BPIDokumen25 halamanCultural Sensitivity BPIEmmel Solaiman AkmadBelum ada peringkat

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Dari EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Penilaian: 4.5 dari 5 bintang4.5/5 (121)

- RPH Week 31Dokumen8 halamanRPH Week 31bbwowoBelum ada peringkat

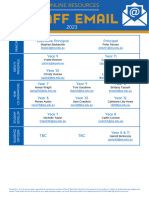

- 2023 Teacher Email ListDokumen5 halaman2023 Teacher Email ListmunazamfbsBelum ada peringkat

- Contemporary Philippine Arts From The Regions: Quarter 1Dokumen11 halamanContemporary Philippine Arts From The Regions: Quarter 1JUN GERONABelum ada peringkat

- Her Body and Other Parties: StoriesDari EverandHer Body and Other Parties: StoriesPenilaian: 4 dari 5 bintang4/5 (821)