Steel Information

Diunggah oleh

Fabio MiguelDeskripsi Asli:

Judul Asli

Hak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

Steel Information

Diunggah oleh

Fabio MiguelHak Cipta:

Format Tersedia

Steel

Information

FACTS ABOUT ALLOYING AND ACCOMPANYING ELEMENTS IN STEEL

C - CARBON:

Carbon is the most important and influential alloying element in steel in addition to carbon every unalloyed steel contains silicon,

manganese, phosphorus and sulphur which occur unintentionally during manufacturing. The addition of further alloying elements

to achieve special effects and intentional increase of manganese and silicon contents, results in alloy steel. With increased carbon

content the strength and hardenability of steel increase but its ductility, forcibility and machinability reduces. The carbon content

in steel has virtually no effect on the steels corrosion resistance to water, acids and hot gases.

CR - CHROMIUM

Chromium increases the hardenability of steel while the ductility is effected minimally. Higher chrome content in steel increases its

corrosion resistance, and by forming carbides the edge holding quality of steel increases. The tensile strength of steel increases by

80 – 100 N/MM² for every 1% chrome added. The yield strength also increases but the notch impact value reduces.

Ni - NICKEL

By adding nickel to steel the notch toughness is increased significantly and is therefore alloyed for increasing toughness in case

hardening, heat-treatable and subzero steels. Nickel combined with chromium ensures good through hardening. Chrome-Nickel

Steels are stainless, heat resistant and resistant to scaling. Nickel does not impair the welding properties of steel.

Mo - MOLYBDENUM

While molybdenum improves the tensile strength and increases the resistance and weldability of steel, the forgability of steel

with a high molybdenum content decreases. When used in combination with chromium and nickel, molybdenum may produce

high yield points and tensile strength values.

Mn - MANGANESE

Manganese increases the strength of steel to a lesser degree than carbon while it favourably influences the forgability, weldability

and markedly increases the hardness penetration depth.

V - VANADIUM

Vanadium is used as a primary grain refiner in the manufacture of steel. It is also a strong carbide former, thus providing increased

wear resistance, edge holding and high temperature strength. Vanadium is therefore used primarily as an alloying element in high

speed steels, hot forming and creep resistant steels.

C - CARBON is found in the following steels:

EN3, EN8, EN9, EN19, EN24, EN26, EN36B, EN30B, 17CRNIM (All hollow bar grades)

CR - CHROMIUM is found in the following steels:

EN19, EN24, EN26, EN36B, EN30B, 17CRNIM06

Ni - NICKEL is found in the following steels:

EN24, EN26, EN36B, EN30B, 17CRNIM06

MO - MOLYBDENUM is found in the following steels:

EN19, EN24, EN226, EN30B, 17CRNIM06

MN - MANGANESE is found in the following steels:

EN3, EN8, EN9, EN19, EN24, EN26, EN36B, EN30B, 17CRNIM06 (All hollow bar grades)

V - VANADIUM is found in the following steels:

Some grades of hollow bar contain vanadium most grades of tool steels

S - SULPHUR

Sulphur is found in all steels

Si - SILICON

Silicon is found in all steels

P - PHOSPHOROUS

Phosphorous is found in all steels

Tel: +27 (0)11 865 4939. Fax: +27 (0)11 902 8995. e-mail: sales@specialsteels.co.za

Anda mungkin juga menyukai

- Online Vegetable StoreDokumen10 halamanOnline Vegetable Storestudent id100% (1)

- Planarch Codex: The Path of Ghosts: An Ancestral Cult Recently Popular Among Thieves & AssassinsDokumen2 halamanPlanarch Codex: The Path of Ghosts: An Ancestral Cult Recently Popular Among Thieves & AssassinshexordreadBelum ada peringkat

- Tulip Dress Pattern Multipage PDFDokumen21 halamanTulip Dress Pattern Multipage PDFEvelina AnileveBelum ada peringkat

- Material & Technology: Alloy: An Alloy Is A Metal Composed of More Than One Element. EngineeringDokumen4 halamanMaterial & Technology: Alloy: An Alloy Is A Metal Composed of More Than One Element. Engineeringapi-19753215Belum ada peringkat

- EFFECTS OF COMMON ALLOYING ELEMENTS IN ALUMINIUM AND STEELDokumen4 halamanEFFECTS OF COMMON ALLOYING ELEMENTS IN ALUMINIUM AND STEELamber2211Belum ada peringkat

- Effect of Alloying Elements On Steel PropertiesDokumen5 halamanEffect of Alloying Elements On Steel PropertiesgovimanoBelum ada peringkat

- Effects of Alloying Elements in Steel: A SummaryDokumen4 halamanEffects of Alloying Elements in Steel: A SummaryLakshmi NarayananBelum ada peringkat

- Cast Iron ComposiotionDokumen34 halamanCast Iron ComposiotionMubash AbdBelum ada peringkat

- Alloy Steel and Cast IronDokumen16 halamanAlloy Steel and Cast IronDennis AlvarezBelum ada peringkat

- STEELDokumen13 halamanSTEELAjinkya GholveBelum ada peringkat

- Effect of Elements in SteelDokumen3 halamanEffect of Elements in SteelJayakrishnan Radhakrishnan100% (1)

- Steel ConstructionDokumen24 halamanSteel ConstructionISMA ZAIDA DINBelum ada peringkat

- Steel and Its AlloyDokumen23 halamanSteel and Its AlloyHemang ChopraBelum ada peringkat

- Tratamientos Térmicos: Carlos Bohórquez 2010Dokumen61 halamanTratamientos Térmicos: Carlos Bohórquez 2010procesosun2010Belum ada peringkat

- Effects of Elements On SteelDokumen4 halamanEffects of Elements On SteelmichaelBelum ada peringkat

- SteelDokumen31 halamanSteelumairBelum ada peringkat

- Chromium:-: 21 Chemical Elements and Effects On Steel Mechanical PropertiesDokumen8 halamanChromium:-: 21 Chemical Elements and Effects On Steel Mechanical Propertiesdhoni03Belum ada peringkat

- Effects of Alloying Elements in SteelDokumen12 halamanEffects of Alloying Elements in SteelyatheendravarmaBelum ada peringkat

- Steel TopicDokumen6 halamanSteel Topicazher03Belum ada peringkat

- Alloying Elements of Steels and PropertiesDokumen3 halamanAlloying Elements of Steels and PropertiesdaimaheshBelum ada peringkat

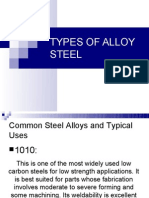

- Types of Steel AlloyDokumen47 halamanTypes of Steel AlloyArpit Thumar100% (2)

- Aircraft Maintenance Ferrous MetalsDokumen8 halamanAircraft Maintenance Ferrous MetalsRocker HuzzBelum ada peringkat

- Properties and applications of carbon and alloy steelsDokumen12 halamanProperties and applications of carbon and alloy steelsananda narayananBelum ada peringkat

- Different Types of Steel Grades and Their PropertiesDokumen9 halamanDifferent Types of Steel Grades and Their PropertiesSyed Shoaib RazaBelum ada peringkat

- Effects of Alloying ElementsDokumen3 halamanEffects of Alloying Elementsdraj1875977Belum ada peringkat

- local_media FILEDokumen7 halamanlocal_media FILEmacksabado78Belum ada peringkat

- NON Ferrous AlloysDokumen37 halamanNON Ferrous AlloysRajan ChaudharyBelum ada peringkat

- 211 2aDokumen33 halaman211 2aMada ChohBelum ada peringkat

- Materials and Alloys for Automotive Exhaust SystemsDokumen4 halamanMaterials and Alloys for Automotive Exhaust SystemsTKBelum ada peringkat

- Alloying Elements ExcelDokumen18 halamanAlloying Elements ExcelRavindra ErabattiBelum ada peringkat

- GCE3135 AssignmentDokumen10 halamanGCE3135 AssignmentBilal MishoryBelum ada peringkat

- MMSE Materials OverviewDokumen30 halamanMMSE Materials OverviewmohansaiBelum ada peringkat

- Commercial Names and Alloying Elements of Stainless SteelDokumen12 halamanCommercial Names and Alloying Elements of Stainless SteelSandi ChaisisBelum ada peringkat

- Alloying Elements in SteelDokumen5 halamanAlloying Elements in Steelkihal zohirBelum ada peringkat

- Ferrous Alloys GuideDokumen56 halamanFerrous Alloys Guidejayakrishnan psBelum ada peringkat

- Ferrous Alloys Properties and ApplicationDokumen21 halamanFerrous Alloys Properties and ApplicationMohan RaiBelum ada peringkat

- Anirudha Samant REG NO.-16BME1044 Slot - C1 Alloy SteelsDokumen12 halamanAnirudha Samant REG NO.-16BME1044 Slot - C1 Alloy SteelsAnirudhaBelum ada peringkat

- Structural steelDokumen6 halamanStructural steelZaid HabibuBelum ada peringkat

- Bme - Part 1Dokumen49 halamanBme - Part 1Sumanth ChallaBelum ada peringkat

- Glossary of Metallurgical TermsDokumen1 halamanGlossary of Metallurgical TermsqualidadesiderBelum ada peringkat

- Alloying Elements and Their EffectsDokumen5 halamanAlloying Elements and Their EffectsDimas Anugrah100% (2)

- Hss Tools and AppilcationDokumen17 halamanHss Tools and AppilcationMeena SivasubramanianBelum ada peringkat

- FC-06-Engineering Material & Metallurgy PDFDokumen431 halamanFC-06-Engineering Material & Metallurgy PDFsomnath ghosh100% (1)

- Effects of Alloying Elements in SteelDokumen3 halamanEffects of Alloying Elements in SteelfaizalzolBelum ada peringkat

- Metals 2Dokumen13 halamanMetals 2arooj anjumBelum ada peringkat

- Ferrous Alloy Types and PropertiesDokumen72 halamanFerrous Alloy Types and PropertiesSneha Kriti100% (3)

- Steel ManufacturingDokumen29 halamanSteel ManufacturingNDTInstructor100% (3)

- Metallurgy, Properties, and Uses of FerrousDokumen37 halamanMetallurgy, Properties, and Uses of FerrousAl DrinBelum ada peringkat

- Ch-27.7 Alloying Element of Steel and Alloy SteelDokumen51 halamanCh-27.7 Alloying Element of Steel and Alloy SteelSmruti Ranjan PattanayakBelum ada peringkat

- Steel Types, Properties and Products-1Dokumen20 halamanSteel Types, Properties and Products-1Deepak SahBelum ada peringkat

- Piping MaterialDokumen45 halamanPiping MaterialLcm TnlBelum ada peringkat

- Effects of Alloying Elements in SteelDokumen2 halamanEffects of Alloying Elements in SteelPradeepRajenBelum ada peringkat

- Effects of MN, P, S, SiDokumen2 halamanEffects of MN, P, S, SiAdithya ShourieBelum ada peringkat

- GKDITRDokumen33 halamanGKDITRsenthil muruganBelum ada peringkat

- Effects of Alloying Elements in Steel PDFDokumen2 halamanEffects of Alloying Elements in Steel PDFchowhkBelum ada peringkat

- Hs Stainless SteelDokumen12 halamanHs Stainless SteelKrisna MahendraBelum ada peringkat

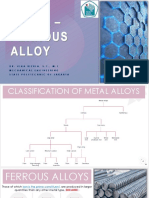

- Dr. Vika Rizkia, S.T., M.T Mechanical Engineering State Polytechnic of JakartaDokumen31 halamanDr. Vika Rizkia, S.T., M.T Mechanical Engineering State Polytechnic of JakartaCANDRA ANDREAN Mahasiswa PNJBelum ada peringkat

- Classification of SteelsDokumen27 halamanClassification of SteelsGAURAV SINGHBelum ada peringkat

- Ch-27.7 Alloying Element of Steel and Alloy SteelDokumen50 halamanCh-27.7 Alloying Element of Steel and Alloy SteelPARESHBelum ada peringkat

- Aircraft Materials and Manufacturing ProcessDokumen125 halamanAircraft Materials and Manufacturing ProcessPalanisamy RajaBelum ada peringkat

- Stainless Steel: Prof. Dr. Heru SusantoDokumen12 halamanStainless Steel: Prof. Dr. Heru SusantoAf'idatun NissaBelum ada peringkat

- IPENZ PN19-SeismicResistancePressureEquipmentFinalDokumen148 halamanIPENZ PN19-SeismicResistancePressureEquipmentFinalFabio Miguel0% (1)

- Frangible RoofDokumen2 halamanFrangible RoofFabio MiguelBelum ada peringkat

- AsdasdafdsdafaDokumen1 halamanAsdasdafdsdafaFabio MiguelBelum ada peringkat

- Sdadsadasdasdfagsdg GZXCDokumen1 halamanSdadsadasdasdfagsdg GZXCFabio MiguelBelum ada peringkat

- Sdafsdgsvxcvgerg - Ssdasss CosdapyDokumen2 halamanSdafsdgsvxcvgerg - Ssdasss CosdapyFabio MiguelBelum ada peringkat

- Ewedqweqwe SddsadpyDokumen1 halamanEwedqweqwe SddsadpyFabio MiguelBelum ada peringkat

- SdafsdgsvxcvgergDokumen2 halamanSdafsdgsvxcvgergFabio MiguelBelum ada peringkat

- 1204 1980Dokumen6 halaman1204 1980Fabio MiguelBelum ada peringkat

- Sdafsdgsvxcvgerg - Ssdasss CosdapyDokumen2 halamanSdafsdgsvxcvgerg - Ssdasss CosdapyFabio MiguelBelum ada peringkat

- MitchDokumen1 halamanMitchFabio MiguelBelum ada peringkat

- Cxcxcxxcxcxcxcxcsdfsa DSADokumen1 halamanCxcxcxxcxcxcxcxcsdfsa DSAFabio MiguelBelum ada peringkat

- SvdsdfsaerDokumen1 halamanSvdsdfsaerFabio MiguelBelum ada peringkat

- DasdasdasdasDokumen1 halamanDasdasdasdasFabio MiguelBelum ada peringkat

- Dadsdasdasdasdfafw 2 EfwfrDokumen1 halamanDadsdasdasdasdfafw 2 EfwfrFabio MiguelBelum ada peringkat

- Smith VDRDokumen1 halamanSmith VDRFabio MiguelBelum ada peringkat

- Smith VDRDokumen1 halamanSmith VDRFabio MiguelBelum ada peringkat

- YoDokumen5 halamanYoFabio MiguelBelum ada peringkat

- Smith VDRDokumen1 halamanSmith VDRFabio MiguelBelum ada peringkat

- Loftus LocalityDokumen1 halamanLoftus LocalityFabio MiguelBelum ada peringkat

- Q1028Dokumen9 halamanQ1028Fabio MiguelBelum ada peringkat

- Community NewsDokumen3 halamanCommunity NewsFabio MiguelBelum ada peringkat

- Loftus Park BrochureDokumen17 halamanLoftus Park BrochureFabio MiguelBelum ada peringkat

- Above Ground Applications For PE PipeDokumen22 halamanAbove Ground Applications For PE PipebugerkngBelum ada peringkat

- 18 Capitani PDFDokumen10 halaman18 Capitani PDFFabio MiguelBelum ada peringkat

- UF##index.G-R Petroleum Docs WeblinksDokumen9 halamanUF##index.G-R Petroleum Docs WeblinksFabio MiguelBelum ada peringkat

- Esl redCZDokumen6 halamanEsl redCZFabio MiguelBelum ada peringkat

- 04 Immigration Questionnaire - Work Permit (Waiver)Dokumen7 halaman04 Immigration Questionnaire - Work Permit (Waiver)Fabio MiguelBelum ada peringkat

- UF##index.G-R ES Docs WeblinksDokumen33 halamanUF##index.G-R ES Docs WeblinksFabio MiguelBelum ada peringkat

- Nozzle Load File Creation GuideDokumen22 halamanNozzle Load File Creation GuideFabio MiguelBelum ada peringkat

- Gaskets App GD2Dokumen6 halamanGaskets App GD2Fabio MiguelBelum ada peringkat

- Film Analysis Glas by Bert Haanstra: Hrithik Ameet Surana 1810110081Dokumen3 halamanFilm Analysis Glas by Bert Haanstra: Hrithik Ameet Surana 1810110081hrithikBelum ada peringkat

- TOS 3rd GradingDokumen8 halamanTOS 3rd GradingRhoda Maron-Gaddi IsipBelum ada peringkat

- Script Story of PaulDokumen2 halamanScript Story of PaulMonica M Mercado100% (2)

- The Fez Owner's Manual: Your Guide to the Shriner FraternityDokumen22 halamanThe Fez Owner's Manual: Your Guide to the Shriner FraternityJay Greenlee100% (1)

- How Did The Augustan Building Programme Help To Consolidate Imperial PowerDokumen4 halamanHow Did The Augustan Building Programme Help To Consolidate Imperial PowerMrSilky232100% (1)

- Outlook 01june 2020 NipponDokumen57 halamanOutlook 01june 2020 NipponKRBelum ada peringkat

- Procreative: Ancient Egyptian Mythology Ra Egyptian Goddesses Hathor Sekhmet Bastet Wadjet MutDokumen2 halamanProcreative: Ancient Egyptian Mythology Ra Egyptian Goddesses Hathor Sekhmet Bastet Wadjet MutRegie Rey AgustinBelum ada peringkat

- Avd ListDokumen7 halamanAvd ListRasheed Basha ShaikBelum ada peringkat

- Message in A Bottle Lesson PlanDokumen8 halamanMessage in A Bottle Lesson PlanKatalin VeresBelum ada peringkat

- Workshop 1 Personal InformationDokumen7 halamanWorkshop 1 Personal InformationConeBelum ada peringkat

- Ibarra Character Analysis in Noli Me TangereDokumen3 halamanIbarra Character Analysis in Noli Me TangereSokchheng Phouk0% (1)

- French SceneDokumen4 halamanFrench Sceneapi-279869756Belum ada peringkat

- Sanskrit 101B Spring 2021 Class PracticeDokumen2 halamanSanskrit 101B Spring 2021 Class PracticeGopal DasaBelum ada peringkat

- Tragedy Fact SheetDokumen1 halamanTragedy Fact SheetSamBuckleyBelum ada peringkat

- What is Rhetoric: The Art of PersuasionDokumen29 halamanWhat is Rhetoric: The Art of PersuasionpaulinaBelum ada peringkat

- Test de Evaluare Initiala A12aDokumen2 halamanTest de Evaluare Initiala A12aRamona AndaBelum ada peringkat

- You Dian TianDokumen5 halamanYou Dian TianWinda AuliaBelum ada peringkat

- Lista Notas Ingles I - DerechoDokumen6 halamanLista Notas Ingles I - DerechoMaria Jose Polanco UrreaBelum ada peringkat

- Stair Details by 0631 - DAGANTADokumen1 halamanStair Details by 0631 - DAGANTAJay Carlo Daganta100% (1)

- Free-Chapter From Born-Again DirtDokumen4 halamanFree-Chapter From Born-Again Dirtmark russellBelum ada peringkat

- ED/-ING Adjectives: Scan To Review Worksheet Expemo Code: 13N3-B6TB-PTE1Dokumen4 halamanED/-ING Adjectives: Scan To Review Worksheet Expemo Code: 13N3-B6TB-PTE1KELLY JOHANNA CUBILLOS VILLALBABelum ada peringkat

- Malaysian Literature Test 2Dokumen5 halamanMalaysian Literature Test 2Na-Thinamalar MagiswaryBelum ada peringkat

- Literary Elements: Self-Learning KitDokumen19 halamanLiterary Elements: Self-Learning KitRoMe LynBelum ada peringkat

- Hexagram 22 YijingDokumen2 halamanHexagram 22 YijingEsperanza TheissBelum ada peringkat

- Dua Lipa - Physical LyricsDokumen2 halamanDua Lipa - Physical LyricsCarolina Jaramillo0% (2)

- R. J. Crum, Roberto Martelli, The Council of Florenece and Medici Palace ChapelDokumen16 halamanR. J. Crum, Roberto Martelli, The Council of Florenece and Medici Palace Chapelgenoveva011Belum ada peringkat

- Abecote 320: Epoxy Enamel CoatingDokumen2 halamanAbecote 320: Epoxy Enamel Coatingengramir07Belum ada peringkat