Senior Manager

Diunggah oleh

api-792601930 penilaian0% menganggap dokumen ini bermanfaat (0 suara)

20 tayangan4 halamanSenior Manager with 21 years experience looking for a Middle Management position.

Hak Cipta

© Attribution Non-Commercial (BY-NC)

Format Tersedia

TXT, PDF, TXT atau baca online dari Scribd

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniSenior Manager with 21 years experience looking for a Middle Management position.

Hak Cipta:

Attribution Non-Commercial (BY-NC)

Format Tersedia

Unduh sebagai TXT, PDF, TXT atau baca online dari Scribd

0 penilaian0% menganggap dokumen ini bermanfaat (0 suara)

20 tayangan4 halamanSenior Manager

Diunggah oleh

api-79260193Senior Manager with 21 years experience looking for a Middle Management position.

Hak Cipta:

Attribution Non-Commercial (BY-NC)

Format Tersedia

Unduh sebagai TXT, PDF, TXT atau baca online dari Scribd

Anda di halaman 1dari 4

I am a detail oriented, customer focused business professional with broad manag

erial leadership in Global Business Partnering, Procurement Operations and Suppl

y Chain Management. A leader with a proven ability to assess and prioritize bus

iness needs, then implement creative solutions. Consistently exceeds organizati

onal goals by lowering operational costs, improving process efficiencies and exe

rcising partner relationships.

PROFESSIONAL STRENGTHS / SKILLS

Global Partnership Building

Vendor / OEM Management

Cost Reduction / TCO

BPI - Six Sigma Green Belt

Direct & Indirect Procurement

Negotiating

Team Building / Coaching

Strategic Planning

Materials Mgmt. / Outsourcing

Budgeting / Planning

Supply Chain Management

Program / Project Mgmt.

Profile

* Comfortable interfacing with senior level executives and all functional groups

* Conducted quarterly Business Reviews and annual Executive Reviews

* Extensive management experience along with individual contributor roles

* Led both Programs and Projects on varying levels of complexity

* Versed in Business Process tools and practices; Six Sigma Green Belt

* Managed both Direct and Indirect commodities, products, and services

* IT engagement on EDI protocol, Web based applications, and re-engineering of a

n Ariba based tool for Indirect Procurement

* Experienced in Financial Planning and Budgeting

* Extensive knowledge of Procurement process / tools ... Spend Management, Costi

ng, Data Analysis, Process Audits, Forecasting, Negotiating, Blanket POs

* Solid experience in Business Partnering and Vendor Relationship Management

* Well versed in Business Acumen, Strategic Agility, Dealing with Ambiguity, Esc

alation Management

* Core Personal traits Organization abilities, Detail oriented, Team leader and

player

EMPLOYMENT HISTORY

DELL INC., Round Rock, Texas October 1999 to March 2009

Sr. Global Commodity Mgr. (Indirect) (3+ Years)

* Managed Software & Peripherals commodity spend of $ 500M

* Focused on aggressive Cost Reductions and reduced Total Cost of Ownership

* Managed Strategic and Core partners on a Global basis

* Interfaced with Sales and Marketing groups on product offerings and Merchandis

ing

* Outlined commodity Strategic planning and roadmap development

* Negotiated contracts of varying levels and degree of complexity

* Active member of a team developing new Ariba tools and processes to support In

direct OPS

* Business Process Improvement Six Sigma Green Belt

Sr. Global Procurement Mgr. (Direct) (1+ Years)

* Managed Enterprise SAN Interconnect commodities Fibre Channel (FC), SCSI, iSC

SI, SAS

* Procurement Lead responsible for New Product planning and Sustaining operation

s

* Conducted Strategic and Tactical commodity planning, roadmap and pricing

* Drove industry leading costing efforts and Supply Chain optimization

* Negotiated contracts with technology providers: HW, SW, Warrants, Escrow

* Supported Order Entry and Demand Planning processes

* Conducted Executive Business Reviews with senior department heads and vendor m

anagement

Sr. Global Notebook Supply Chain Mgr. (Direct) (5+ Years)

* Managed global notebook Supply Chain planning New Product & Sustaining OPS

* Procurement Lead on Global Core Teams comprised of all functional groups

* Coordinated detailed project schedules, actions and budgets

* Supported Order Entry and Demand Planning processes

* Focused on global NB supply chain optimization and platform component costing

* Re-engineered the Phased Preview Process OEM engagement model, flow and proces

ses

* Conducted Executive Business Reviews with senior department heads and vendor m

anagement

COMPAQ COMPUTER CORPORATION, Houston, Texas

March 1995 to October 1999

Sr. Operations Mgr. (4+ Years)

* OPS Lead of a team challenged with implementing an Outsourcing business model

for Consumer

* Managed the Operations Program detailing Supply Chain, Logistics, IT interface

and metrics

* Executed detailed Project schedules, timelines, actions, mitigations and mater

ials

* Required direct vendor management of Asian based OEM manufacturers on a Global

footprint

* Coordinated the implementation of a Direct Ship Program for finished products

* Leveraged Compaqs operational strengths to greatly improve OEM processes and p

roduct Quality

TEXAS INSTRUMENTS, INC., Dallas, Texas

November 1979 to March 1995

Product Planning Mgr. (15+ Years)

* Held numerous Managerial positions with increasing levels of responsibility

* Responsible for PC and Printer product planning and materials management

* Manufacturing Lead on a team chartered with startup of a new site based on JIT

/ LEAN

* Provided Planning and Budgeting for the Plastics molding operation supporting

Printers & PCs

* Implemented numerous process improvements impacting, quality, costs, and opera

ting efficiency

CAREER HIGHLIGHTS

Indirect Purchasing Supply Chain Management (Dell). Overhauled the existing ful

fillment model supporting the Intelligent Classroom initiative in the K-12 / Hig

h Education business segments. Utilizing Reverse Auction tools consolidated mul

tiple distributors to one core distributor for inventory management and shipment

consolidation while re-defining the cost structure with core suppliers. Result

s: Improved on-time shipping performance by 40%, captured 15% aggregate cost re

duction, and reduced third party installation downtime by 30%.

Indirect Purchasing / Vendor Relations Management (Dell). Implemented a Preferr

ed Partnership program within the Software & Peripherals organization focusing o

n the top tier suppliers with brand strength, product breadth, and stable financ

ials who represented 80% of annual spend. Established guidelines on supplier me

rchandising, Marketing Development funding, and advantaged costs. Results: Cre

ated a better win-win environment with suppliers who increased their average qua

rterly MDF funding by 25%.

Indirect Purchasing Cost Reduction (Dell). Instituted a combination of direct n

egotiation and live Internet / Reverse auction to drive savings for selected Sof

tware & Peripherals commodities. Results: Increased annual savings over 20% re

lative to total spend of $ 500M.

Indirect Purchasing Process Improvement (Dell). Analyzed lost margin dollars a

ssociated with Software & Peripherals Consumer promotional events. Interlocked

with internal organizations, suppliers and distributors to derive a fishbone dia

gram of problem areas with implementation of a revised cost verification process

. Results: Cost accuracy improved 30% with 20% improvement in net promotional

margins.

Indirect Purchasing Negotiations (Dell). Coordinated with the Legal support te

am to streamline the number and level of contractual templates in support of Sof

tware & Peripherals assessing core Legal / Business needs, Terms and Conditions

and associated fallback languages. Results: Reduced the Supplier Agreement fro

m six to three pages, while restructuring the Direct agreement to be a global, u

mbrella agreement with regional attachments versus separate regional master agre

ements. Improved new supplier on-boarding cycle time by 33%.

Indirect Purchasing - BPI (Dell). Team Lead chartered to determine a simple, bu

t efficient process to quickly evaluate 3rd party branded products for considera

tion to Dell branding. Results: Engaged with various Business Unit, Marketing

and Finance teams to establish a set of simple business hurdles to gauge initial

investigation with an internal Web repository followed by process steps to defi

ne and capture resource funding.

Direct Purchasing - BPI (Dell). Enhanced the supplier scorecard for Quarterly B

usiness Reviews from simple reporting to an integrated tool with metrics, cross-

functional inputs, and track-able action items. Results: Delivered a multi-fac

eted tool for performance reporting. Improved core supplier quarterly ratings f

rom 62 to 75 basis points on a scale of 100 over two business quarters.

Direct Purchasing - Product Sourcing. (Dell) Selected to manage a team of senio

r Procurement professionals in a newly created Supply Chain group to directly su

pport notebook computer supply chain planning and new product execution. Establ

ished procedures, communication protocol and reporting tools on a Global basis.

Results: Deployed many of the tools and procedures as best practices with othe

r supply chain organizations.

Indirect Purchasing - Cost Management / Global Negotiation / BPI (Dell). Collab

orated with Direct Procurement to define and implement a new DRAM memory model f

or the Software & Peripherals memory upgrade program. Negotiated with one of th

e core Production memory suppliers to leverage OEM production level component pr

icing. Implement in the US / Canada regions with model fan-out to other regions

. Results: Captured incremental savings in the US region of $ 24M on an annual

spend of $ 120M.

Direct Purchasing - Cost Control (Dell). Initiated a plan to address cost savin

gs opportunities on the lower 20% of annual spend by combining this spend with c

ore distributors spend of similar products thereby leveraging increased buying p

ower with co-sharing of cost savings. Structured live Internet negotiations dri

ven by the distributor using company tools. Results: Contributed incremental s

avings of $ 12M on annual spend of $ 100M.

Operations / Program Management / Outsourcing (Compaq Computer). Spearheaded a

team of cross functional Operations professionals tasked with implementing a new

global outsourcing model for Consumer computer products. Formulated all aspects

of the business model including but not limited to hardware/ materials supply c

hain, logistics, financial flowchart, IT (EDI) processing, OEM supplier selectio

n and contract negotiation. Results: Completed setup of OEM manufacturing cent

ers in three geographical locations on schedule and budget. After the first yea

r of operation, achieved a 2x growth in unit volume while achieving a 25% improv

ement in direct product and logistical costs.

Project Management / BPI (Texas Instruments). As the Manufacturing lead on a new

site startup team, spearheaded the effort to define, test and implement a new I

ntegrated Manufacturing / Warehouse concept utilizing JIT / KANBAN techniques. R

esults: Reduced combined warehouse and manufacturing space by 40%, eliminated t

he need for material handlers by 20%, and improved manufacturing line efficiency

/ cycle time by 15% due to materials shortages.

Military

October 1975 October 1979, United States Air Force, Strategic Air Command

Combat Crew Commander, Minuteman ICBM

Honorable Discharge

Education

MBA, Management, University of South Dakota (Vermillion, SD), 1979

BBA, Finance/Economics, Texas A&M University (College Station, TX), 1975

Cum Laude

Distinguished Military Graduate from Corps of Cadets

Other

Eagle Scout

Anda mungkin juga menyukai

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDari EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifePenilaian: 4 dari 5 bintang4/5 (5783)

- The Yellow House: A Memoir (2019 National Book Award Winner)Dari EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Penilaian: 4 dari 5 bintang4/5 (98)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDari EverandNever Split the Difference: Negotiating As If Your Life Depended On ItPenilaian: 4.5 dari 5 bintang4.5/5 (838)

- Shoe Dog: A Memoir by the Creator of NikeDari EverandShoe Dog: A Memoir by the Creator of NikePenilaian: 4.5 dari 5 bintang4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerDari EverandThe Emperor of All Maladies: A Biography of CancerPenilaian: 4.5 dari 5 bintang4.5/5 (271)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDari EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RacePenilaian: 4 dari 5 bintang4/5 (890)

- The Little Book of Hygge: Danish Secrets to Happy LivingDari EverandThe Little Book of Hygge: Danish Secrets to Happy LivingPenilaian: 3.5 dari 5 bintang3.5/5 (399)

- Team of Rivals: The Political Genius of Abraham LincolnDari EverandTeam of Rivals: The Political Genius of Abraham LincolnPenilaian: 4.5 dari 5 bintang4.5/5 (234)

- Grit: The Power of Passion and PerseveranceDari EverandGrit: The Power of Passion and PerseverancePenilaian: 4 dari 5 bintang4/5 (587)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDari EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaPenilaian: 4.5 dari 5 bintang4.5/5 (265)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDari EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryPenilaian: 3.5 dari 5 bintang3.5/5 (231)

- On Fire: The (Burning) Case for a Green New DealDari EverandOn Fire: The (Burning) Case for a Green New DealPenilaian: 4 dari 5 bintang4/5 (72)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDari EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FuturePenilaian: 4.5 dari 5 bintang4.5/5 (474)

- Rise of ISIS: A Threat We Can't IgnoreDari EverandRise of ISIS: A Threat We Can't IgnorePenilaian: 3.5 dari 5 bintang3.5/5 (137)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDari EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersPenilaian: 4.5 dari 5 bintang4.5/5 (344)

- The Unwinding: An Inner History of the New AmericaDari EverandThe Unwinding: An Inner History of the New AmericaPenilaian: 4 dari 5 bintang4/5 (45)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDari EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyPenilaian: 3.5 dari 5 bintang3.5/5 (2219)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDari EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You ArePenilaian: 4 dari 5 bintang4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Dari EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Penilaian: 4.5 dari 5 bintang4.5/5 (119)

- Her Body and Other Parties: StoriesDari EverandHer Body and Other Parties: StoriesPenilaian: 4 dari 5 bintang4/5 (821)

- Dunn, David Christopher vs. Methodist Hospital (Court 189)Dokumen1 halamanDunn, David Christopher vs. Methodist Hospital (Court 189)kassi_marksBelum ada peringkat

- Invitation to Kids Camp in Sta. Maria, BulacanDokumen2 halamanInvitation to Kids Camp in Sta. Maria, BulacanLeuan Javighn BucadBelum ada peringkat

- Swami Sivananda NewsletterDokumen50 halamanSwami Sivananda NewsletterNaveen rajBelum ada peringkat

- Abyip MagcagongDokumen10 halamanAbyip MagcagongJhon TutorBelum ada peringkat

- CalendarDokumen1 halamanCalendarapi-277854872Belum ada peringkat

- Locked Ideas at QuirkyDokumen22 halamanLocked Ideas at Quirkymasid1Belum ada peringkat

- The Sanctuary Made Simple Lawrence NelsonDokumen101 halamanThe Sanctuary Made Simple Lawrence NelsonSulphur92% (12)

- Elements of Consideration: Consideration: Usually Defined As The Value Given in Return ForDokumen8 halamanElements of Consideration: Consideration: Usually Defined As The Value Given in Return ForAngelicaBelum ada peringkat

- Pooja RasidDokumen3 halamanPooja RasidRajiuBelum ada peringkat

- Course Code: DMGT402: COURSE TITLE: Management Practices & Organizational BehaviorDokumen1 halamanCourse Code: DMGT402: COURSE TITLE: Management Practices & Organizational Behaviortanvirpal singh DhanjuBelum ada peringkat

- Industry Analysis1Dokumen72 halamanIndustry Analysis1Walter InsigneBelum ada peringkat

- Logistics AssignmentDokumen15 halamanLogistics AssignmentYashasvi ParsaiBelum ada peringkat

- 14.30 GrimwadeDokumen32 halaman14.30 GrimwadeJuan QuintanillaBelum ada peringkat

- B2B AssignmentDokumen7 halamanB2B AssignmentKumar SimantBelum ada peringkat

- Instant Download Statistics For Business and Economics Revised 12th Edition Anderson Test Bank PDF Full ChapterDokumen32 halamanInstant Download Statistics For Business and Economics Revised 12th Edition Anderson Test Bank PDF Full Chapteralicenhan5bzm2z100% (3)

- New Jersey V Tlo Research PaperDokumen8 halamanNew Jersey V Tlo Research Paperfvg7vpte100% (1)

- Assignment World Group6 SectionBDokumen3 halamanAssignment World Group6 SectionBWanderer InneverlandBelum ada peringkat

- DH 0526Dokumen12 halamanDH 0526The Delphos HeraldBelum ada peringkat

- Ob Ward Timeline of ActivitiesDokumen2 halamanOb Ward Timeline of Activitiesjohncarlo ramosBelum ada peringkat

- 2023 Whole Bible Reading PlanDokumen2 halaman2023 Whole Bible Reading PlanDenmark BulanBelum ada peringkat

- (Critical Criminological Perspectives) Deborah H. Drake (Auth.) - Prisons, Punishment and The Pursuit of Security-Palgrave Macmillan UK (2012)Dokumen231 halaman(Critical Criminological Perspectives) Deborah H. Drake (Auth.) - Prisons, Punishment and The Pursuit of Security-Palgrave Macmillan UK (2012)Yaeru EuphemiaBelum ada peringkat

- DPTC CMF C P16995 Client 31052023 MonDokumen8 halamanDPTC CMF C P16995 Client 31052023 Monsiddhant jainBelum ada peringkat

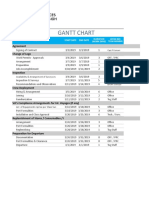

- Gantt Chart TemplateDokumen3 halamanGantt Chart TemplateAamir SirohiBelum ada peringkat

- Aztec CodicesDokumen9 halamanAztec CodicessorinBelum ada peringkat

- Illuminati Confessions PDFDokumen227 halamanIlluminati Confessions PDFberlinczyk100% (1)

- AgricultureDokumen7 halamanAgricultureAhmad CssBelum ada peringkat

- 2 PBDokumen17 halaman2 PBNasrullah hidayahBelum ada peringkat

- Networking and TESOL career goalsDokumen2 halamanNetworking and TESOL career goalsSadiki FltaBelum ada peringkat

- Jack Mierzejewski 04-09 A4Dokumen7 halamanJack Mierzejewski 04-09 A4nine7tBelum ada peringkat

- Writ of Execution - U.S. DISTRICT COURT, NJ - Cv-Writ2Dokumen2 halamanWrit of Execution - U.S. DISTRICT COURT, NJ - Cv-Writ2Judicial_FraudBelum ada peringkat