Pole

Diunggah oleh

Sreekanth SunkeDeskripsi Asli:

Hak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

Pole

Diunggah oleh

Sreekanth SunkeHak Cipta:

Format Tersedia

CIDCO OF MAHARASHTRA LIMITED. C.A.NO.

CIDCO/EE(ELECT-S)/2010-2011/85

Sl.Pg.No.

221

(20) PARTICULAR SPECIFICATIONS

(ELECTRICAL WORKS)

20.1 GENERAL: The intent of these specifications is to give general guidelines for the equipments / components proposed to be used and best efforts are made to cover all relevant requirements and apart intent specification. However if any addition or alternation is necessitated and directed by the competent Authority the same shall be done without any extra cost of financial implication on the CIDCO as per the directives of Engineer. 20.2 APPLICABLE STANDARDS: All relevant Indian standards shall be made applicable with latest amendments. Also if any other specific application is required by the owners then the same shall be complied too. ITEM NO. 1 & 2 20.3 20.3.1 SPECIFICATIONS FOR 13 MTRS. & 9 MTRS. RSJ POLES The pole for H.T. line shall be 152mm x 152 mm rolled steel joist pole of 13 mtr. height and 9 mtr. height the weight of the pole shall be minimum of 37.1Kg/Mtr. 20.3.2 A base plate made out of CI and of size 300 mm x 300 mm x 10 mm shall be welded continuously at the pole bottom. 20.3.3 Provision for terminating the earthwire coming from the earthing

station shall be made for the pole at a height of 3.0 mtr. from the pole bottom with 16 mm dia, 50 mm long G.I. bolt and G.I. washers.

CIDCO OF MAHARASHTRA LIMITED. C.A.NO. CIDCO/EE(ELECT-S)/2010-2011/85

Sl.Pg.No.

222

20.3.4

The pole shall be erected in a perfectly vertical alignment by excavating a pit of size 0.8 mtr. x 0.6 mtr. x 2.15 mtr. deep with 1:3:6 ratio cement concrete with duly plastered plinth or muffing of width 400 mm and height of 600 mm from the ground level and of appropriate shape. The center to center distance between two consecutive poles shall be as per the I.E. rules & regulations and local Electricity Supply Authority.

20.3.5

The poles shall be subjected to surface treatment with wire brushing and cleaning prior to painting with one coat of red oxide and two coats of black bituminous paint upto 2.5 mtr. height and for remaining portion with alluminium paint of two coats.

ITEM NO. 3 20.4 20.4.1 ALUMINUM CONDUCTOR STEEL REINFORCED CONDUCTOR Scope: Supply and erection of aluminum conductor steel reinforced for overhead line.

This specification provides for Supply & Erection of 0.2 ALUMINIUM CONDUCTOR STEEL REINFORCED (ACSR) Conductor (PANTHER ) for High Voltage overhead lines.

20.4.2

SERVICE CONDITIONS The conductor to be supplied against this specification shall be suitable for satisfactory continuous operation under the following tropical climatic conditions:

CIDCO OF MAHARASHTRA LIMITED. C.A.NO. CIDCO/EE(ELECT-S)/2010-2011/85

Sl.Pg.No.

223

20.4.3

STANDARDS Sr.No. Particulars (a) (b) (c) (d) (e) (f) (g) (h) (i) (j) Maximum Ambient Temperature in open air Maximum Ambient Temperature in shade Minimum Ambient Temperature in shade Relative Humidity Maximum Annual Rainfall Maximum Altitude above Mean Sea level. Maximum Wind Pressure Isoceraunic level Seismic level (Horizontal acceleration ) General nature of climate Values 50 Degree C. 45 Degree C. 3.5 Degree C. 10 % to100% 1450 mm. 1000 metres 150Kg/Sq.m. 50 days/year. 0.3 g Moderately hot and humid tropical climate, conductive to rust and fungus growth Except as modified in this Specification, the conductor shall conform to the following Indian Standards (Amended upto date). Sr.No. 1 Indian Standards IS:398 Part II /1996 IS:1778 / 1980 IS:2629 Title Specification for Aluminum conductors for overhead Transmission purpose. Reels and Drums for Bare conductors. Recommended practice for Hot Dip Galvanising of Iron and Steel. 4 IS:4826 Galvanised Coating on Round Steel Wire.

2 3

CIDCO OF MAHARASHTRA LIMITED. C.A.NO. CIDCO/EE(ELECT-S)/2010-2011/85

Sl.Pg.No.

224

Sr.No. 5

Indian Standards IS:5484

Title EC grade Aluminium rod produced by continuous Revision). casting and rolling (First

20.4.4

PROPERTIES OF CONDUCTOR The details of ACSR Panther conductor are tabulated below: Sr.No. Particulars (a) Stranding and wire diameter (b) Number of Strands (i) Steel Centre (ii) 1st Steel Layer (iii) 1st Aluminium Layer (iv) 2nd Aluminium Layer (c) (d) (e) (f) (g) (h) Sectional area of Aluminium in sq. mm. Sectional area of Steel in sq. mm. Total sectional area in sq.mm. Overall Diameter in mm. Approximate weight in kg/km. Calculated D.C. Resistance at 20 degree Celsius in Ohm/km. (i) (j) Minimum Breaking load in kN Modulus of Elasticity in GN/sq.metre. 89.67 80.00 1 6 12 18 212.1 49.4 261.5 21.00 974 0.139 Values Aluminium: 30/3.00 mm., Steel: 7/3.00 mm.

CIDCO OF MAHARASHTRA LIMITED. C.A.NO. CIDCO/EE(ELECT-S)/2010-2011/85

Sl.Pg.No.

225

20.4.5

THE DETAILS OF ALUMINIUM STRANDS ARE AS BELOW:

Sr.No. (a) (b) (c) stranding in kN

Particulars Minimum Breaking Load of Strand before Minimum Breaking Load of Strand after stranding in kN. Maximum D.C. Resistance of Strand at 20 Degree Celsius in Ohm/km.

Values 1.17 1.11 4.079

20.4.6

THE DETAILS OF STEEL STRANDS ARE AS BELOW: WIRE SIZE Sr. No. (a) (b) (c)

Particulars Minimum Breaking Load of Strand before stranding in kN. Minimum Breaking Load of Strand after stranding in kN. Minimum weight of Zinc Coating after stranding in gm/sq. Metre.

Values 9.29 8.83 260

20.4.7

NOMINAL SIZE The aluminium and galvanised steel wires for the stranded conductor covered by this standard shall have diameters specified in Clause 20.4.1. The diameter of the galvanized steel wires shall be measured over the zinc coating.

CIDCO OF MAHARASHTRA LIMITED. C.A.NO. CIDCO/EE(ELECT-S)/2010-2011/85

Sl.Pg.No.

226

20.4.8

TOLERANCE ON NORMAL SIZE (i) ALUMINIUM WIRES: No negative tolerance shall be permitted on the nominal diameter of Al wires. However, positive tolerance in this regards shall be as provided in IS:398 ( part2) amended upto date. (ii) GALVANISED STEEL WIRES: A tolerance of +/2 % is permitted on the nominal diameter.

20.4.9

FREEDOM FROM DEFECTS The wires shall be smooth and free from all imperfections such as spills, spilts, slag inclusion, die marks, scratches, fittings, blowholes, projections, looseness, overlapping of strands, chipping of aluminium layers etc. and all such other defects which may hamper the mechanical and electrical properties of the conductor. Special care should be taken to keep away dirt, grit etc. during stranding.

20.4.10

JOINTS IN WIRES (i) Aluminium Wires: No joints shall be permitted in the aluminium wires in the outermost layer of the ACSR conductor. Joints in the inner layers are permitted, in addition to those made in the base rod or wire before final drawing, but no two such joints shall be less than 15 metre apart in the complete stranded conductor. Such joints shall be made by cold pressure buttwelding. Joints are not permitted in the outermost layer of the conductor in order to ensure a smooth conductor finish. (ii) Galvanised Steel Wires: There shall be no joints except those in the base rod or wire before final drawing, in steel wires forming the core of the steel reinforced aluminium conductor.

CIDCO OF MAHARASHTRA LIMITED. C.A.NO. CIDCO/EE(ELECT-S)/2010-2011/85

Sl.Pg.No.

227

Joints are not permitted in the steel wires after final drawing in order to avoid reduction in the breaking strength of the conduct or that may occur as a result of failure of the joints. 20.4.11 STRANDING (i) The wires used in the construction of galvanised steel reinforced aluminium conductor shall before stranding, satisfy all the relevant requirements of this specification. (ii) The lay ratio of the different layers shall be within the limit given in the following table: 20.4.12 LAY RATIO OF ALUMINIUM CONDUCTORS GALVANISED STEEL REINFORCED PANTHER CONDUCTOR (1) (2) (3) (4) (i) (ii) Number of Wire Ratio of Diameter : : Aluminium : 30 Steel : 7 1.0

Lay Ratio for Steel Core (6 Wire Layer) : Minimum : 13 Maximum : 28 Lay Ratio for Aluminium Wires: Outermost Layer : Minimum : 10 Maximum : 14 Layer immediately beneath outermost Minimum: 10 Layer: Maximum: 16

NOTE:

For the purpose of calculation, the mean lay ratio shall be taken as the arithmetic mean of the relevant minimum and maximum values given in the above table.

(iii)

While stranding, pre forming and post forming method should be used for stranded steel core. In order to relieve the residual tension in core wire to avoid flaring of conductor.

(iv)

In all constructions, the successive layers shall have opposite directions of lay, the outermost layer being righthanded. The wires in each layer shall be evenly and closely stranded.

CIDCO OF MAHARASHTRA LIMITED. C.A.NO. CIDCO/EE(ELECT-S)/2010-2011/85

Sl.Pg.No.

228

(v)

In conductors having multiple layers of aluminium wires, the layratio of any aluminium layer shall not be greater than the layratio of aluminium layer immediately beneath it. Table 20.4/1 Minimum Clearance between Conductors (IS : 4237 1967) Sr. No. 7. 8. 9. 10. 11. 12. Voltage Level (kN) 11 22 33 110 230 400 Clearance in mm Between Phase & Between Phases Earth 460 305 610 915 1675 3350 4000 460 610 1000 1675 3500

20.4.13

The conductor shall be Panther alluminium conductor steel reinforced and size as specified & with generally having current carrying capacity of 325 amps. of 40 degree centigrade and consisting of a bunch of six/ seven stranded alluminium conductors and one steel reinforcing wire at the center. The weight of the conductor shall be 974Kg/Km.

20.4.14

The conductor shall generally conform to I.S. 398 Part-II - 1976 with latest amendments.

20.4.15

STRINGING OF CONDUCTORS: a) Peels of the conductor shall be handled carefully so that there is no cutting, nicking of fraying of the conductor strands. b) The conductor shall be paid out from a rotating red supported on jacks for easy unwinding.

CIDCO OF MAHARASHTRA LIMITED. C.A.NO. CIDCO/EE(ELECT-S)/2010-2011/85

Sl.Pg.No.

229

c)

Alluminium sheaves fitted with ball bearings shall be used at the points of conductor supports for easy pulling and to ensure uniform tension throughout the conductor length.

d) e) f) g) h)

The conductor shall be pulled with proper care along clamp. The conductor should be pulled up to a proper sag in a span at or near the dead end section of the line. The tension should then be adjusted until correct sag is obtained in a span near the pulling end. Generally in straight length cut points shall be provided at a distance of about 1 Km. or as desired by MSEB/CIDCO. The minimum clearances from the conductor shall be as per rule `17 to 79 and 80 of I.E. Rules.

20.4.16

a) b)

Annealed alluminium wire shall be used for fastening the conductors. The anticlimbing device consisting of barbed wire extending upto a minimum length of 38 cms. or any other suitable design shall be provided on all H.T. poles.

c) d) e)

The danger or caution sign board to be displayed on all H.T. Poles shall be as per I.S. 2551 - 1963. All stay wires are required to be properly earthed. At all road crossing points guard wires are required to be used as per rule No.88 of I.E. rules.

20.4.17

Method of Construction : At first the conductor is removed from bundle / drum straighten without knots, bends, etc. Stringing of conductor shall be done with draw vice. Conductor shall not be twisted while stringing. Disc insulators shall be used if the line

CIDCO OF MAHARASHTRA LIMITED. C.A.NO. CIDCO/EE(ELECT-S)/2010-2011/85

Sl.Pg.No.

230

deviates by 30 degrees or more, terminal pole and tri-pole or four pole structure at terminal pole and at junction / cut pole. Parallel double groove clamp having two nut bolts designated to carry full line current shall be used for making Jumper wire connections. Universal parallel double groove clamp having two nut bolts shall be used for Tap Off point. On straight line the conductor shall be bounded on top groove of insulator and at angular position binding shall be done in side groove. Binding wire of 12 SWG shall be of the same metal as that of conductor. 20.4.18 Mode of Measurement : For measurement purpose, sum of the total conductor including jumper connections shall be considered. (i.e. per km)

ITEM NO. : 4 20.5 20.5.1 PIN TYPE INSULATOR 11/22/33 KV Scope: Supplying porcelain Pin type insulator, suitable for 11/22/33 Kv and necessary ancillary materials and complete erection on provided cross arm / bracket and connected to the over-head line as per instructions from the site engineer. Material : Insulator : Distribution class Pin type insulator made from porcelain, suitable for specified voltage level, having ISI mark, with necessary hardware Hardware: Nuts, washers. Etc. Binding Wire : Bare Copper wire or conductor. Clamps : MS Clamps.

CIDCO OF MAHARASHTRA LIMITED. C.A.NO. CIDCO/EE(ELECT-S)/2010-2011/85

Sl.Pg.No.

231

20.5.2

General a) b) All the insulators shall be made out of glazed porcelain or rough glass and suitable for 22KV line voltage. The pin insulators shall generally be as per I.S. 731-1963 and the disc insulators shall be generally as per I.S. 731 1963 and I.S. 3188 1965 with all latest amendments. c) d) 4.3 The manufacturers dimensional drawings should be submitted for pin type insulator. Providing suitable size tension hardware made out of cast alluminium suitable ACSR conductors etc. complete. The work should be carried out as per instructions of the Engineer.

20.5.3

Method of Construction : Distribution class porcelain pin type insulator, suitable for specified voltage level, erected on provided cross arm or bracket with clamps, ancillary materials, and connected to the over-head line. Connection shall be made with bare copper wire of specified gauge.

20.5.4

Mode of Measurement : Executed quantity will be measured on number basis (i.e. each) ITEM NO. : 5

20.6

PORCELAIN DISC. TYPE INSULATOR 11/22/33 KV Supplying and erecting porcelain disc type insulator suitable for 22KV line complete erected with suitable hardware on provided cross arm

20.6.1

Scope: Supplying porcelain disc type insulator, suitable for 11/22/33 KV and necessary ancillary materials, and complete erection on provided cross arm / bracket and connected to the over-head line as per instructions from the site engineer.

CIDCO OF MAHARASHTRA LIMITED. C.A.NO. CIDCO/EE(ELECT-S)/2010-2011/85

Sl.Pg.No.

232

Material: Insulator: Distribution class Disc type insulator made from porcelain, suitable for specified for specified voltage level, having ISI mark, with necessary hardware. Hardware: Nuts, washers, etc. Binding Wire: Bare Copper wire or conductor. Clamps: MS clamps. 20.6.2 Method of construction: Distribution class Disc type insulator made from porcelain, suitable for specified voltage level, erected on provided cross arm or bracket with clamps, ancillary materials, and connected to the over-head line. Connection shall be made with bare copper wire of specified guage. 20.6.3 Mode of Measurement: Executed quantity will be measured on number basis (i.e. each) ITEM NO. : 6 & 7 20.7 PLATE TYPE EARTHING (WITH OR WITHOUT CI COVER, FUNNEL, ETC) 20.7.1 Scope Supplying and erecting galvanised cast iron / copper earth plate type / G.I. pipe type earthing with / without C.I. cover as per instructions from the site engineer. Material: Earth Plate: Galvanised cast iron / Copper earth plate or G.I. pipe as per specifications given in Table No 20.7/1. CI Cover: As per specifications given in Table No 20.7/1. Earthing Conductor: Copper/G.I strip/Annealed bare copper wire/G.I. earth wire of size as per specifications given in Table No 20.7/1.

CIDCO OF MAHARASHTRA LIMITED. C.A.NO. CIDCO/EE(ELECT-S)/2010-2011/85

Sl.Pg.No.

233

GI Pipe: As per specification (CW-PLB/GP) mentioned chapter no. 20.7/1.5 for watering, and as enclosure for Earth wire, refer specifications given in Table No 20.7/1. Hardware: Screw / nut bolts with required washer of dimensions, Rawl plug / clip/ 'U' nails and material as per specifications given in Table No 20.7/1. Filling material: Coal /Charcoal/ salt as per specifications given in Table No 20.7/1.1. Lugs: As per specification (CB-LG/AL, CB-LG/CU) mentioned chapter 20.7/1.9 & 20.7/1.10 Copper/ Aluminum lugs as per specifications given in Table No 20.7/1. Table No. 20.7/1 Detailed Specifications of various types of Earthing Type of earthing S. No. Galvanised cast iron Particulars earth plate type without C. I. cover 1. Depth from top of plate Up to Ground level 2. Size & type of material for pipe / Plate type earthing Cast iron earth plate size 60x60x0.6 cms Copper earth plate size 60x60x0.6 cms Cast iron earth plate size 60x60x0.6 cms 1.5 m Galvanised Copper earth plate type with C. I. cover Galvanised cast iron earth plate type with C. I. cover 1.5 m Galvanised Pipe type earthing without C. I. Cover

1.5 m

B grade G. I. pipe 40 mm dia. 2.5 mtr. Long or 20 mm dia. G. I. Rod

3.

Salt / Charcoal

30 Kg. charcoal and slat

30 Kg. charcoal and salt

40 Kg. charcoal and salt N.A.

CIDCO OF MAHARASHTRA LIMITED. C.A.NO. CIDCO/EE(ELECT-S)/2010-2011/85

Sl.Pg.No.

234

Type of earthing S. No.

Galvanised cast iron earth plate type without C. I. cover each

Copper earth plate type with C. I. cover each

Galvanised cast iron earth plate type with C. I. cover each Double G.I. 6 SWG 12 mm dia. G. I. Pipe 2.5 mtr. long

Pipe type earthing without C. I. Cover

Particulars

4.

Type of Wire

Double G.I. Double G.I. wire 8 SWG 8 SWG 12 mm dia. G. I. Pipe 2 mtr. long 12 mm dia. G. I. Pipe 2 mtr. long

Double G.I. 8 SWG

5.

Wire enclosure

N.A.

6.

Nut bolts

12 mm dia. Cadmium / GI 12 mm dia. Cadmium / N.A.

7. 8.

Washers Watering Pipe

GI 19 mm dia. G. I. Pipe

GI 19 mm dia. G. I. Pipe Yes Yes Yes

GI 19 mm dia. G. I. Pipe Yes Yes Yes

N.A. N.A. Yes N.A. N.A.

9.

Lungs

Yes No No

10. Funnel 11. Brick Masonry

20.7.2

Method of construction: Pit is' to be dug of required dimension and depth for the earthing at site, and laying of Galvanised cast iron / Copper earth plate or G.I. pipe shall be as per Table No 20.7/1. The earth connection to equipment / switch gear and earthing electrode shall be connected as shown in the diagram and as per IS 3043 amender up to-date. The connections shall be made either by strip or double run of earth wire

CIDCO OF MAHARASHTRA LIMITED. C.A.NO. CIDCO/EE(ELECT-S)/2010-2011/85

Sl.Pg.No.

235

with drilling, welding, riveting, brazing and nut bolting to plate or pipe, where ever required in an approved manner. As far as possible continuous strip shall be used, but where ever jointing of strip is unavoidable; the overlap portion must not be less than 21/2 times the width of the strip either welded/ brazed/soldered by all sides or 6 inches overlap with two nut bolts/riveting of adequate size with requited washer and covered by anti-corrosive paint as per approved jointing practice in the industry and as per directives from site engineer in charge. Pit shall then be filled with screened soil with alternate layer of coal and3alt, and if, necessary brick masonry work (Where ever applicable) shall be done as specified in IS: 3043, with laying wires in PVC/ G.I. pipe and watering arrangement and covered with C.I. Cover (Where ever applicable). . Where ever required or as specified by Site Engineer, a Test link shall be provided for facilitating the testing of resistance of earth electrode. 20.7.3 Testing: The value of each earth electrode shall be measured by earth tester in presence of site Engineer and record to be submitted. 20.7.4 Mode of Measurement: Executed quantity will be measured on number basis (i.e. each)

ITEM NO. : 8 20.8 Providing cement Concrete for Foundation or for concrete filling in 1:3:6 ratio with 20 to 25 mm stone metal duly plastered with necessary curing for pole muffing or any other purpose. The work should be carried out as per the instructions of the Engineer. And payment will be made as mentioned in Schedule A.

CIDCO OF MAHARASHTRA LIMITED. C.A.NO. CIDCO/EE(ELECT-S)/2010-2011/85

Sl.Pg.No.

236

ITEM NO. : 9 20.9 20.9.1 VEE CROSS ARM Scope : Supplying Vee cross arm suitable for 22 kV and necessary ancillary materials complete erection on provided pole with necessary painting as per specification and as per instructions from the site engineer. Material : Cross arm : Channel Iron cross arm Hardware : G. I. nut bolts Flat : MS flat 80 x 10 mm thick Clamp : Two clamps made from MS flat of size 80 x 10 mm. Paint : Red oxide, Silver paint 20.9.2 Method of Construction : Fabricating the Vee cross arm for erecting Insulators with channel 75 x 40 mm with 4.4 mm thick web and 7.3 mm thick flange, length of 45 mm for base of insulator, vertical member of suitable length to maintain the clearance of 1530 mm, with angle of 60 degrees to horizontal and M. S. flat of 80 x 10 mm. at centre of cross arm fixed to the pole by means of two M. S. clamps of 80 x 10 mm M. S. flat with 15mm. dia bolts and nuts duly painted with one coat of red oxide paint and two coats of aluminum paint. Table No. 9/1 DETAILS OF IRON CROSS ARM / BRACKET AS PER ITEM IN CSR Item description 100x50 Size of channel Clamps Nut bolts

100x50 mm with 4.7 mm Two

clamps 15 mm. nuts and

channel cross thick web and 7.5 mm thick of 50x6 mm bolts flange channel x 2.7 m length M. S. flat arm

CIDCO OF MAHARASHTRA LIMITED. C.A.NO. CIDCO/EE(ELECT-S)/2010-2011/85

Sl.Pg.No.

237

Item description Vee-cross arm

Size of channel

Clamps

Nut bolts for 15 mm. nuts and

Made out of channel 75 x 40 Clamps and 7.3 mm thick flange with M. S. flat clearance of 1220 mm. between the insulators as per drawing attached here with

mm with 4.4 mm thick web 75x10 mm of bolts

Vee-cross arm 100x50 mm with 4.7 mm Clamps web and 7.5 mm thick flange M. S. flat size suitable with clearance of 1530 mm between the insulators Channel with 75x40 mm with 4.4 mm thick Clamps clamp erection insulators Channel bracket guarding Channel iron 1600 mm in Clamps 4.4 mm thick web and 7.3 M. S. flat mm thick flange for channel. M. S. flat

for 15 mm. nuts and

thick web and 7.5 mm thick 75x10 mm of bolts

for with 3 sets screws

for web and 7.3 mm thick flange 75x10 mm of

11/22 KV pin

for 15 mm. dia nuts earthing mm. clips,

for length and 75x40 mm with 50x6 mm of and bolts with 2 made from 25x3

Angle bracket guarding

iron Angle iron bracket 65 x 65 x Clamps length and 75x40 mm with M. S. flat 4.4 mm thick web and 7.3 mm thick flange.

for 15 mm. dia nuts earthing mm. clips,

for 6 mm. Angle 1600 mm in 50x6 mm of and bolts with 2 made from 25x3

20.9.3

Mode of Measurement : Executed quantity will be measured on number basis (i.e. each)

CIDCO OF MAHARASHTRA LIMITED. C.A.NO. CIDCO/EE(ELECT-S)/2010-2011/85

Sl.Pg.No.

238

ITEM NO. : 10 20.10 Supplying & Erecting G.I strip of different size used other purpose with necessary G.I clamps fixed on wall painted with bituminous paint is an approved manner. The work should be carried out as per the instructions of the Engineer. And payment will be made as mentioned in Schedule A. ITEM NO. : 11 20.11 22 KV DANGER BOARD: Providing & fixing G.I Caution board fabricated from 16SWG sheet of size 200 x 150 mm (min). The board shall be written in Marathi & English indicating pressure of line danger etc. as required Electricity Rules & Regulation and as per IS: 2551 of 1982. Contractor has to provide to provide 22KV danger board one number on each pole of appropriate size and with proper signals with appropriate painting with approved colours as per IE rules. ITEM NO. : 12 20.12 H.T. STAY SET: Supplying and erecting G.I stay set for poles, complete with anchor plate 300x300x6mm straining screws G.I stay wire 7/8 SWG G.I stay rod 20mm x 1.8 meter length and pole clamps duly erected in provided cement concrete foundation. 20.12.1. G.I Stay set for poles including loop insulators at in-accessible height complete with anchor plate of size 15 x 15 x 0.6 cms, straining screws, G.I Stay wire 7/10 size, G.I. Stay rod 20mm x 1.8 M long and pole clamps etc. Stay sets erected in 1:3:6 cement concrete foundation approx. quantity 0.35 m3 for each set.

CIDCO OF MAHARASHTRA LIMITED. C.A.NO. CIDCO/EE(ELECT-S)/2010-2011/85

Sl.Pg.No.

239

20.12.2

Providing G.I. stay wire for poles of appropriate thickness and length suitable for H.T. line. The work should be carried out as per the instructions of the Engineere.

20.12.3

Providing binding wire for binding the G.I. stay wire of the poles suitable for H.T. overhead line of appropriate tensile strength & thickness. The work should be carried out as per the instructions of the Engineer.

20.12.4

Supplying and erecting anticlimbing devices, fabricated from pole clamps with dropping spikes, welded to it and erected on pole properly. The work should be carried out as per the instructions of the Engineer.

20.12.5

Providing cement concrete foundation for above poles of size 0.8 mtr. x 0.6 mtr. x 2.15 mtr. deep with 1:3:6 cement concrete ratio with duly plastered plinth/muffing or width 400mm. & height of 600 mm. from the ground level with appropriate shape. The plastering should be done with approved quality cement with proper curing etc. complete. The work should be carried out as per the instructions of the Engineer. ITEM NO. 13

20.13

Preparation of schematic & detailed drawings as required by statutory Authority and submission of the same in required sets to the statutory authority on behalf of CIDCO, obtaining the approval for commencement and commissioning of the work. Payment of statutory authority, co-ordination with authority for the site visits etc. and submission of As Built Drawings in 3 sets in the form of prints and in the form of CD. The work also includes obtaining approvals of material, handing over of the installation to the statutory authority on completion of the work under the guidance of Engineer. And payment will be made as mentioned in Schedule A.

CIDCO OF MAHARASHTRA LIMITED. C.A.NO. CIDCO/EE(ELECT-S)/2010-2011/85

Sl.Pg.No.

240

Item No. 20.14 20.15

Description Supplying & erecting anticlimbing devices, fabricated from pole clamps with drooping spikes welded to it and erected on pole. Excavating hard rock or bituminous rod (B.T) by chiseling for preparing pit for poles stay or earth plates or for laying cables, pipes & clearing the site by removing debris & making the site good.

20.16

Supplying and erecting approved make 22KV out door type gang operated air break triple pole switch 200 amperes capacity with 3post pin type insulator per phase mounted in horizontal or vertical position with necessary channels on provided cross arm with adequate length of 'C' class G.I pipe for operating handle erected on extended square shaft. The operating handle provided with lock and key at suitable height from ground level with necessary clamp.

20.17

Supplying and erecting approved make thyrite type lightening arresters suitable for 22KV supply with necessary ancillary materials complete erected on provided cross arm and connected to the overhead line Distribution Class.

20.18

Supplying erecting approved make 22KV outdoor type drop out fuse with insulator complete with fuse holder fuse barrel with metal fitting fuse element mounted on MS channel with working current of 10A capacity complete erected on provided cross arm

20.19

Supplying and laying (including excavation ) 15 cms. Dia full round RCC hume pipe with coupling collar of standard thickness at required depth upto 90 cms. Below road /ground surface, for enclosing provided cable and necessary back filling with light ramming to make the road / ground surface as it was ( except bitumen carpet)

20.20

Providing & laying 75mm dia G.I pipe 'B' grade for enclosing cable below ground / road surface complete.

The work should be carried out as per the instructions of the Engineer. And payment will be made as mentioned in Schedule A.

CIDCO OF MAHARASHTRA LIMITED. C.A.NO. CIDCO/EE(ELECT-S)/2010-2011/85

Sl.Pg.No.

241

ITEM NO. 21 & 22 20.21 TECHNICAL SPECIFICATIONS FOR 22KV/11KV XLPE CABLE SCOPE This technical specification covers design, manufacture, testing at manufacturers works, packing & delivery of High Voltage Cross linked polyethylene insulated PVC Sheathed cables round armoured suitable for 11 KV and 22KV. It is not the intent to specify completely herein all the details of design & construction of the cables. However the cables shall conform to high standards of engineering, design & workman ship. The equipment offered shall be complete with all components necessary for its effective and trouble free operation. STANDARDS Unless otherwise specified elsewhere in its specification, the rating, performance and testing of cables & accessories shall conform to the latest revision of all relevant standards. A list of such standards is enclosed at ANNEXURE I. 20.21.1 PRINCIPAL PARAMETERS The high Voltage Cables and accessories covered in this specification shall meet the technical requirements listed at ANNEXURE II and the following general technical requirement. 20.21.2 20.21.2.1 GENERAL TECHNICAL REQUIREMENT Conductor The conductor shall be made from electrically pure Aluminium wire. The wires shall be stranded together and compacted.

CIDCO OF MAHARASHTRA LIMITED. C.A.NO. CIDCO/EE(ELECT-S)/2010-2011/85

Sl.Pg.No.

242

20.21.2.2 20.21.3

The conductor shall be circular in shape. Conductor Shielding An extruded semi conducting compound shall be provided on the conductor to provide a smooth surface & eliminate electrical stress concentration.

20.21.4

Insulation The core insulation shall be with Cross linked polyethylene unfilled insulation compound. It shall be free from voids and shall withstand all mechanical and thermal stresses under steady state & transient operating conditions. The insulation shall be applied by triple extrusion process.

20.21.5

Insulation Shielding The insulation shielding shall consist of non-metallic semi-conducting compound in combination with non-metallic screening of copper. It shall be possible to strip the insulation screening without applying heat. The screen shall be capable to carry single line to ground fault current for a duration of one second.

20.21.6

The conductor screen and XLPE insulation screen shall all be extruded in one operation by extrusion to ensure perfect bonding.

20.21.7

Armouring G.I. round steel wire armouring shall be provided over the inner sheath.

20.21.8

Outer Sheath An outer sheath shall be applied on the cable by extrusion over armouring. The outer sheath shall be of PVC compound confirming to Type ST2. The PVC compound shall be suitable for protection against rodent and termite attack.

CIDCO OF MAHARASHTRA LIMITED. C.A.NO. CIDCO/EE(ELECT-S)/2010-2011/85

Sl.Pg.No.

243

20.21.9

In addition to the above, binder tape, filler, core identification tape shall be provided. ANNEXURE-I 22KV/11KV XLPE CABLE APPLICABLE STANDARDS

The cables shall comply with the latest edition of the following standards: Sr. No. 1. Indian Standard Spec. No. IS 7098 (Part-II) Cross-linked Polyethylene insulated PVC Title

sheathed cables : Part II for working voltages form 3.3KV upto and including 33KV. 2. IS:8130 Conductors for insulated electric cables and flexible cords. 3. 4. IS:5831 IS:3975 PVC insulation and sheath of electrical cables. Mild steel wires, strips and tapes for armouring of cables. 5. IS:2633 Methods of testing weight, thickness and uniformity of coating on hot dipped galvanized articles. 6. 7. 8. IS:209 IS:1753 IEC:502 Specification for Zinc Aluminium conductors for insulated cables. Extruded solid dielectric insulated power cables for rated voltages form 11KV upto 30 KV.

CIDCO OF MAHARASHTRA LIMITED. C.A.NO. CIDCO/EE(ELECT-S)/2010-2011/85

Sl.Pg.No.

244

Sr. No. 9.

Indian Standard Spec. No. IEC:540 & 540A

Title

Test methods for insulation and sheaths of electric cables and cords.

ANNEXURE-II 22KV/11KV XLPE CABLES DESIRED TECHNICAL PARTICULARS Sr. No. 1. 2. 3. 4. 5. 6. 7. 8. 9. Description Cable Size System Voltage Type of cable Conductor material Minimum No. of strands Nominal thickness of XLPE insulation Minimum thickness of common covering Armouring - round Minimum thickness of outer sheath 10. Approximate overall diameter 11. Approximate net weight kg/km 10400 13850 mm 81 87.5 mm mm 3.15 mm dia 2.84 4mm dia 3.00 mm 0.7 0.7mm mm 3.6 6.00 mm No. Unit Core x Sq.mm. kV 11kV Particulars Upto 3C x 300 & 1C x 1000 sq.mm. 11 XLPE Insulated Aluminium 30 22kV Particulars 31C x 300 sq.mm. 22 XLPE Insulated Aluminium 37

CIDCO OF MAHARASHTRA LIMITED. C.A.NO. CIDCO/EE(ELECT-S)/2010-2011/85

Sl.Pg.No.

245

Sr. No. 12.

Description Normal Delivery Length

Unit m

11kV Particulars 250

22kV Particulars 250

13. 14. 15. 16.

Max. DC Resistance at 20 deg C Approximate AC Resistance Approximate reactance at 50 Hz. Approximate Capacitance per phase

Ohms/km Ohms/km Ohms/km Mfd/km

0.1 0.13 0.095 0.475

As per IS 7098 Paer-II 0.130 0.97 0.319

17. 18. 19.

Current rating Short time current rating Permissible short circuit temperature ITEM NO. 23

Amps kA Deg.C

355 (in ground) 450 (in air 28.2 250

350 (in ground) 455 (in air 28.3 250

20.23 20.23.1

CABLE TRENCHES (EXCAVATED): The cable trenches shall be excavated 1000 mm below the finished ground level and shall have a minimum width of 300 mm. for laying of single cable. When more than one cables are laid in the same trench, the width of the trench shall be increased such that the spacing between the cables is 25 cms. and the end cables are at minimum 15 cms. from the side of the trenches. At the turning of the cable route the trench shall be dug with radius equal to 15 times the cable diameter.

CIDCO OF MAHARASHTRA LIMITED. C.A.NO. CIDCO/EE(ELECT-S)/2010-2011/85

Sl.Pg.No.

246

20.23.2

The trenches shall be cut square with vertical side walls and with uniform depth. Suitable shoring and propping may be done to avoid caving in of trench walls. The floor of the trench shall be rammed and leveled. The bottom of the cable trench shall be prepared with 100mm. sand bed for laying the cables.

20.23.3

The cables shall be laid in trenches over the rollers. After the cable is laid and straightened it shall be covered with sand, and RCC half round/semi circular pipe of appropriate strength & size.

20.23.4

The cable trench then shall be refilled with excavated materials after removing the stones and other sharp materials and the refilled materials shall be compacted with light ramming.

20.23.5

Approved cable markers made of G.I. with 15 cms crown shall be provided along the route of cables at a spacing of 40 50 meters and also at both ends of road crossings or at the cable turning points. The class, type and No. of cables shall be indicated on the markers.

20.23.6

Cable shall be laid in hume pipes at all road crossings and in GI pipes at the wall entries.

ITEM NO. 24 20.24.0 Outdoor/Indoor end termination Kit : LT/HT Cables Before providing end termination kit to the cable, the cable end of the equivalent length of the moulds, shall be prepared by removing the outer PVC insulation along with the steel armouring. The ferrule shall then be inserted over the bare core of the cable, and shall be crimped with hydraulic / mechanical type heavy duty crimping tool. The crimping shall be done in such a manner that there shall be no air gap. Then the crimped portion shall be wrapped first with the PVC

CIDCO OF MAHARASHTRA LIMITED. C.A.NO. CIDCO/EE(ELECT-S)/2010-2011/85

Sl.Pg.No.

247

insulation tape and then with the insulation tape used for wrapping HT conductor. The above method shall be carried out for all the cores strictly using the epoxy spacer, for having sufficient gap in-between the leads. The earth continuity lead shall be clamped to theends of the cable. After covering the cable leads with the PVC moulds, the edges shall be clipped after applying the adhesive on the inside face of the epoxy compound shall not spill out. Now the duly stirred epoxy compound shall be poured and fill till the compound rises through the risers provided on the moulds. After completing the above procedure, the joint shall be allowed to dry out for at least 8 to 10 hours (for epoxy compound to get hardened) depending upon the size of cable. Before connecting to supply, the dry and hardened joint shall be tested for its insulation level with 1000 V/ 5000 V Meggar. ITEM NO. 25 20.25 Straight through joint Kit: L T/HT Cables Before providing joint to the cable, the cable ends of the equivalent length of the joint moulds, shall be prepared by removing the outer PVC insulation along with the steel armouring. The ferrule shall then be inserted over the bare core of the cable, and shall be crimped with hydraulic I mechanical type heavy duty crimping tool. The crimped portion shall be wrapped first with the PVC insulation tape and then with the insulation tape used for wrapping HT conductor. The above method shall be carried out for all the cores strictly following the colour code. The leads of the both the cables now shall be placed into the mould by using the epoxy spacer, for having sufficient gap in-between the leads. The earth continuity lead shall be

CIDCO OF MAHARASHTRA LIMITED. C.A.NO. CIDCO/EE(ELECT-S)/2010-2011/85

Sl.Pg.No.

248

clamped to the both ends of the cable. After covering the cable leads with the PVC moulds, the edges shall be clipped after applying the adhesive on the inside face of the moulds. The pasting of moulds shall be rigid and as far as possible leak proof, so that the epoxy compound shall not spill out. Now the duly stirred epoxy compound shall be poured and fill till the compound rises through the risers provided on the moulds.

After completing the above procedure, the joint shall be allowed to dry out for at least 8 to 10 hours (for epoxy compound to get hardened) depending upon the size of cable. Before connecting to supply, the dry and hardened joint shall be tested for its insulation level with 1000 VI 5000 V Meggar. The cable should be fixed or laid in such manner that there should not be pressure on end of moulds or on jointing position of cables.

Signature of Tenderer Date.:

Chief Engineer & General Manager(T) Date :

Anda mungkin juga menyukai

- Hrudaya Dhyanam PDFDokumen13 halamanHrudaya Dhyanam PDFNitin AgrawalBelum ada peringkat

- Course Content and DetailsDokumen6 halamanCourse Content and DetailsSreekanth SunkeBelum ada peringkat

- IGNOU's Motorcycle Technician Certification ProgramDokumen12 halamanIGNOU's Motorcycle Technician Certification ProgramSreekanth SunkeBelum ada peringkat

- Hrudaya Dhyanam PDFDokumen13 halamanHrudaya Dhyanam PDFNitin AgrawalBelum ada peringkat

- Vajra - 309Dokumen1 halamanVajra - 309Sreekanth SunkeBelum ada peringkat

- Line ProtectionDokumen37 halamanLine ProtectionRameez ZafarBelum ada peringkat

- Directional Earth Fault BasicsDokumen7 halamanDirectional Earth Fault BasicsNillutpal BoruahBelum ada peringkat

- Installation Instructions: 256 Series Paralleling & Reverse Power Protector Trip RelayDokumen2 halamanInstallation Instructions: 256 Series Paralleling & Reverse Power Protector Trip RelaySreekanth SunkeBelum ada peringkat

- Symmetrical ComponentsDokumen2 halamanSymmetrical ComponentsHamayoun Murtaza100% (1)

- JNNSM Technical Specifications W-LED Solar SystemsDokumen13 halamanJNNSM Technical Specifications W-LED Solar SystemslotchanBelum ada peringkat

- Solar Bidders ListDokumen10 halamanSolar Bidders ListSreekanth SunkeBelum ada peringkat

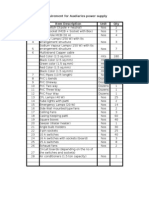

- Material Requirement For Auxilaries Power Supply S.No Item Description Unit QtyDokumen2 halamanMaterial Requirement For Auxilaries Power Supply S.No Item Description Unit QtySreekanth SunkeBelum ada peringkat

- Photovoltaic Cell AnDokumen4 halamanPhotovoltaic Cell AnSreekanth SunkeBelum ada peringkat

- Standards: Sanelec Excitation Systems PVT LTD., Sanelec Excitation Systems PVT LTD.Dokumen1 halamanStandards: Sanelec Excitation Systems PVT LTD., Sanelec Excitation Systems PVT LTD.Sreekanth SunkeBelum ada peringkat

- Four exercises to strengthen your lower back and reduce painDokumen3 halamanFour exercises to strengthen your lower back and reduce painSreekanth SunkeBelum ada peringkat

- 1 Solar Power Plant HMI FinalXDokumen10 halaman1 Solar Power Plant HMI FinalXSreekanth SunkeBelum ada peringkat

- DPR Mayank 29.04.11 To 30.04.11Dokumen3 halamanDPR Mayank 29.04.11 To 30.04.11Sreekanth SunkeBelum ada peringkat

- ACSR Some Equal Standards-Indian StandardDokumen20 halamanACSR Some Equal Standards-Indian StandardHabib EmamiBelum ada peringkat

- Electrical: Section - V Technical SpecificationsDokumen7 halamanElectrical: Section - V Technical SpecificationsSreekanth SunkeBelum ada peringkat

- Shoe Dog: A Memoir by the Creator of NikeDari EverandShoe Dog: A Memoir by the Creator of NikePenilaian: 4.5 dari 5 bintang4.5/5 (537)

- Grit: The Power of Passion and PerseveranceDari EverandGrit: The Power of Passion and PerseverancePenilaian: 4 dari 5 bintang4/5 (587)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDari EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RacePenilaian: 4 dari 5 bintang4/5 (890)

- The Yellow House: A Memoir (2019 National Book Award Winner)Dari EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Penilaian: 4 dari 5 bintang4/5 (98)

- The Little Book of Hygge: Danish Secrets to Happy LivingDari EverandThe Little Book of Hygge: Danish Secrets to Happy LivingPenilaian: 3.5 dari 5 bintang3.5/5 (399)

- On Fire: The (Burning) Case for a Green New DealDari EverandOn Fire: The (Burning) Case for a Green New DealPenilaian: 4 dari 5 bintang4/5 (73)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDari EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifePenilaian: 4 dari 5 bintang4/5 (5794)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDari EverandNever Split the Difference: Negotiating As If Your Life Depended On ItPenilaian: 4.5 dari 5 bintang4.5/5 (838)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDari EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FuturePenilaian: 4.5 dari 5 bintang4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDari EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryPenilaian: 3.5 dari 5 bintang3.5/5 (231)

- The Emperor of All Maladies: A Biography of CancerDari EverandThe Emperor of All Maladies: A Biography of CancerPenilaian: 4.5 dari 5 bintang4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDari EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You ArePenilaian: 4 dari 5 bintang4/5 (1090)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDari EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyPenilaian: 3.5 dari 5 bintang3.5/5 (2219)

- Team of Rivals: The Political Genius of Abraham LincolnDari EverandTeam of Rivals: The Political Genius of Abraham LincolnPenilaian: 4.5 dari 5 bintang4.5/5 (234)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDari EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersPenilaian: 4.5 dari 5 bintang4.5/5 (344)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDari EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaPenilaian: 4.5 dari 5 bintang4.5/5 (265)

- Rise of ISIS: A Threat We Can't IgnoreDari EverandRise of ISIS: A Threat We Can't IgnorePenilaian: 3.5 dari 5 bintang3.5/5 (137)

- The Unwinding: An Inner History of the New AmericaDari EverandThe Unwinding: An Inner History of the New AmericaPenilaian: 4 dari 5 bintang4/5 (45)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Dari EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Penilaian: 4.5 dari 5 bintang4.5/5 (119)

- Her Body and Other Parties: StoriesDari EverandHer Body and Other Parties: StoriesPenilaian: 4 dari 5 bintang4/5 (821)

- Tu 1-5Dokumen8 halamanTu 1-5Made easy classes0% (2)

- Stop Motion Pre Production - Negotiated BriefDokumen10 halamanStop Motion Pre Production - Negotiated Briefp4nd3m0n1c100% (1)

- Phase Diagrams IntroductionDokumen76 halamanPhase Diagrams IntroductionGikiTopiBelum ada peringkat

- Axle, Front - Differential and Carrier - Jee0123251Dokumen3 halamanAxle, Front - Differential and Carrier - Jee0123251Husi NihaBelum ada peringkat

- Plutnicki ResumeDokumen1 halamanPlutnicki ResumeAli PlutnickiBelum ada peringkat

- Multiple-Choice QuestionsDokumen8 halamanMultiple-Choice Questionsvijayganesh pinisettiBelum ada peringkat

- The B-GON Solution: To Mist EliminationDokumen20 halamanThe B-GON Solution: To Mist EliminationDimitris Sardis LBelum ada peringkat

- DiGas 4000 Light E 08.02Dokumen2 halamanDiGas 4000 Light E 08.02manit1963Belum ada peringkat

- P613 HW # 2 Solutions for a 2D Electron GasDokumen4 halamanP613 HW # 2 Solutions for a 2D Electron GasRakeshBelum ada peringkat

- EASA Part 66 Module 7 MCQ and Essay QuestionsDokumen4 halamanEASA Part 66 Module 7 MCQ and Essay QuestionsazadairBelum ada peringkat

- Software TestingDokumen3 halamanSoftware TestingDr. P. N. Renjith Associate Professor - CSEBelum ada peringkat

- P1125P1/P1250E1: Output RatingsDokumen6 halamanP1125P1/P1250E1: Output Ratingsmohsen_cumminsBelum ada peringkat

- CNA09016 SGDokumen8 halamanCNA09016 SGSatyarth SampathBelum ada peringkat

- Twice As Sharp Operators ManualDokumen34 halamanTwice As Sharp Operators ManualLeonardo CHTZBelum ada peringkat

- RTJ Dimension ASME B16.5/B16.47Dokumen1 halamanRTJ Dimension ASME B16.5/B16.47parayilomer0% (1)

- 1,3,3-Trinitroazetidine (TNAZ) - Part I. Syntheses and PropertiesDokumen23 halaman1,3,3-Trinitroazetidine (TNAZ) - Part I. Syntheses and PropertiesThanh XomBelum ada peringkat

- Abbreviations Plumbing Symbols: Fort Worth DistrictDokumen21 halamanAbbreviations Plumbing Symbols: Fort Worth DistrictDenzel NgBelum ada peringkat

- Goodyear Brochure Bandas-48Dokumen1 halamanGoodyear Brochure Bandas-48DavidBelum ada peringkat

- Indian Standards As On 17.01.2004 LatestDokumen19 halamanIndian Standards As On 17.01.2004 LatestSaravana KumarBelum ada peringkat

- Calibration of A Pressure GaugeDokumen6 halamanCalibration of A Pressure GaugeThapelo100% (2)

- Sennheiser MD 441Dokumen2 halamanSennheiser MD 441ndujaBelum ada peringkat

- Cutting A GemDokumen18 halamanCutting A Gemmobsivac100% (1)

- RPVP Puerto PrincesaDokumen8 halamanRPVP Puerto PrincesaRanny LomibaoBelum ada peringkat

- Whatsapp, Viber and Telegram: Which Is The Best For Instant Messaging?Dokumen6 halamanWhatsapp, Viber and Telegram: Which Is The Best For Instant Messaging?Kuningan NesiaBelum ada peringkat

- Canusa GTS - 3LPEDokumen2 halamanCanusa GTS - 3LPEarifin rizalBelum ada peringkat

- Desizing of CottonDokumen16 halamanDesizing of CottonDeepali RastogiBelum ada peringkat

- Internship Report-1Dokumen64 halamanInternship Report-1VIJAY SPBelum ada peringkat

- Checkpoint Physics Notes Chapter 1-5Dokumen5 halamanCheckpoint Physics Notes Chapter 1-5Siddhant Srivastava50% (2)

- Shop Manual WA380-3LE SN A50001Dokumen758 halamanShop Manual WA380-3LE SN A50001Eliecer godoy100% (2)

- Isolation of Caffeine from TeaDokumen6 halamanIsolation of Caffeine from TeaDaisy Joyce Seroje BuslonBelum ada peringkat