Foam Over

Diunggah oleh

Mili Bueno RivasDeskripsi Asli:

Hak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

Foam Over

Diunggah oleh

Mili Bueno RivasHak Cipta:

Format Tersedia

Delayed Coker - Coking Safety & Communications

Pgina 1 de 3

Search

Our Mission Home Conference/Seminar USA Germany Training Discussion Forum Blog Products & Services Safety Site Safety Audit EPA/OSHA Bulletin Mgmt of Change Reliability Research Refinery Contacts Person of the Year Contact Us Featured Cokers Testimonials Coker News Refinery News Old Discussion Coker History Links Become a Fan

Who We Are

Logo

Legal Notice

Coke Drum Foam-Overs Causes & Cures

By Norm Lieberman There are two types of coke drum foam-overs - bad and very bad:

Drums that carry-over during filling - Bad Drums that carry-over after being filled -Very Bad

Results of a drum carry-over are quite variable, depending on how much coke has been carried into the fractionator, and now the fractionator is designed to deal with carry-overs. On most newer cokers, a circulating fractionator bottoms pump, and an external filter permit modest amounts of coke (a few tons) to be extracted from the fractionator in a day or two. A typical 12' diameter fractionator can tolerate a single carry-over of 20 or 30 tons of coke. Carry-over amounts greater than these amounts will: 1. Cause cavitation of the heater charge pump 2. Increase heater tube skin temperatures. 3. Knock the fractionator off-line. Carry-Over After Switching I've had a wonderful opportunity to study this problem in great detail last month. My client has four coke drum density level indicators, drum top pressure indicators and the combined drum outlet temperature located on the switch deck. This allowed me to observe the response of the coke drums, as the operators manipulated the drain, steam, switch and vapor valves. This coker has a tendency to carry-over on almost every switch. My observations: Made after watching half a dozen switches indicated.

Visit our sister sites: CatCracking.com SulfurUnit.com

Previous Events Canada - Coker Canada - Sulfur USA - Conference USA - Coker Training USA - FCC Latin America Europe Coker Training Calgary Coker Training Rio

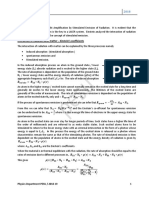

Foam-overs occur from the full drum, due to a loss in drum pressure. Pressures must be measured at the top of the coke drum, not 100 feet away at the pressure gauge located upstream of the vapor valves. For a few minutes after the switch, these pressures may be moving in opposite directions. A drum pressure drop of one psi in two minutes, is sufficient to initiate a foam-over. Once started, foam-overs are harder to suppress, then if never allowed to start in the first place. Rapid coke drum switching, does not necessarily promote an increase in foam front height, if the operators closely controls the full coke drum pressure. A 10% - 15% reduction in coke drum density, at the lower drum level indicators proceeds, by a few minutes, a drum carry-over. However, this cannot be used as a warning for action. It's already too late. The drain valve from the warming drum must be closed before switching drums. However, closing the drain valve 3 or 5 minutes before switching is looking for trouble. The warm-up condensate can fill the feed line to the empty coke drum with lighter hydrocarbons. Then, when the 920F resid hits the 300F to 500F condensate in the feed line, the resulting surge in vapor pressures-up both coke drum. If the pressure in the full coke drum then is permitted to drop back to it's pre-switch pressure, a foamover from the full drum is likely. Naturally, an incompletely drained drum may cause a massive pressure swing. At the now defunct Western Slope Refinery, I observed a 15 psi pressure swing due to a poorly drained drum. The resulting coke drum carry-over knocked the heater charge pumps off-line. Maintaining an ascending pressure at the top of the full coke seemed to be the best way to suppress foam-overs. For a period of 15 minutes, starting with the time the drain valve is closed, the full coke drum pressure ought to be increased by "x" psig. But what does "x" depend on? A typical valve for "x" is one psi per five minutes. However "x', the rate of the increase in the pressure drop profile needed to suppress foam-overs, is a function of:

http://www.coking.com/Foamover.asp

12/06/2011

Delayed Coker - Coking Safety & Communications

Pgina 2 de 3

1. Coke drum outage. A small outage being 18' to 22' 2. Low coke drum top temperature (i.e. less than 815F) promotes unstable foam fronts, which requires a more positive ascending pressure profile to suppress. 3. Lighter coker feeds, slop in feed, low coke drum pressure, high recycle rates, excess steam in the heater passes, and other factors that increase drum vapor velocities, require a larger "x" valve. 4. Many of my clients use a tremendous amount of steam in the coke drum structure, most of which goes into the coke drums, which increases velocity. Many operators will double the amount of anti-foam injection a few minutes before switch time, then reduce it back to normal, when the drum pressures have stabilized (10 or 15 minutes later). I believe this to be a good practice. Total silicon contamination of coker naphtha will only increase by about 3%. On the other hand, this will not compensate for a sudden drop in coke drum pressure of 2 or 3 psi. Also, once the coke bed in the full drum starts to really fluff-up, a coke drum carry-over can't be positively stopped with anti-foam injection. To achieve an ascending pressure profile, the operators have a number of choices. My favorite one is to just pinch-back on the vapor valve from the full drum. This requires a local pressure indication from the top of the coke drum, transmitted down to the vapor valve. A more conventional method is to hold back pressure with the combined vapor line warm-up valve, which is often an HIC control valve. This method however, has the disadvantage of increasing the pressure of both the full and empty drums. That is, five times as much coke drum volume has to be pressured-up, as compared to my favorite method. Increasing the fractionator pressure, by slowing down the wet gas compressor, and/or reducing the HCGO pump around rate also works. But this involves increasing the pressure of the fractionator and both coke drums. This is even less responsive than the previous suggestions. Regardless of the method chosen to obtain an ascending drum pressure after the switch, the hotter the coke drum vapor outlet (upstream of the overhead vapor line quench), the more stable the coke bed will be. Also, as liquid yields increase (about one volume percent for every increase of 8F in drum top temperature), the higher temperature off-sets the loss in liquid yield due to the 40 minutes period, when the coke drum pressure is higher than optimum. (Drum pressure should not be decreased until the steamed drum is lined-up to the blow down system). Steaming out the coke drum When the "little" steam (3,000 - 4,000 lbs./hr) is introduced into the coke drum, the foam front, at first, is actually suppressed. That's because the steam will, for 10 or 15 minutes, cause an increase in the pressure in the drum being steamed. However this effect only lasts a short time. Then, the pressure in the drums will start to fall, unless the operator intervenes, to maintain an ascending pressure profile. If the empty coke drum being switched into is cold (300F condensate outlet), then the tendency to lose pressure, in the full drum being switched out of, is greatly enhanced. That's because the combined vapor flow from both drums will be low, until the empty drum heats to full coking temperatures (790F). The combined effect of steaming a full drum, when the pressure in the drum is falling, can get pretty ugly. But, simply shutting off the "little" steam, once the coke bod begins to expand will - well, start polishing up your resume, because that will accelerate the rate of pressure decline, and pull the drum over. Coke Drum Carry-Over While Filling This occurs less frequently, then a foam-over after the switch. Often, the anti-foam is not added properly; diluent is added, but no silicon; a wrong anti-foam flow is displayed; the antifoam injection point is plugged. Or "your cup runneth over." The gravity of the coker feed (API) drops, and the operators neglects to cut coker feed. The bearings on the drill steam hoist motor of "A" drum are gone, and the "B" drum cycle needs to be extended just a little bit too long.

http://www.coking.com/Foamover.asp

12/06/2011

Delayed Coker - Coking Safety & Communications

Pgina 3 de 3

Properly calibrated K-ray level detectors give adequate warning to the alert operator. Some refiners have vibration probes (like those used to detect pump shaft vibration) on the overhead vapor line. At least for shot coke, this will identify when a coke carry-over begins. Reducing the heater outlet temperature, by 5F to 10F will temporarily stop the carry-over, by reducing the vapor generation in the coke drum. Summary Maintaining a gradually increasing pressure in the drum to be quenched, of several psi, for about 15 minutes after the switch, will off-set to some extent, marginally low drum temperatures; shortened coke drum cycles; low drum outages; higher feeds; low coke drum pressure and rapid coke drum switches. Send mail to Info@Coking.com with questions or comments about this Delayed Coker (www.coking.com) web site. Copyright: April 21, 2011 09:47 AM

http://www.coking.com/Foamover.asp

12/06/2011

Anda mungkin juga menyukai

- Advances in Delayed CokingDokumen8 halamanAdvances in Delayed Cokingjojumathew100% (1)

- Vacuum Making1Dokumen2 halamanVacuum Making1AnkurVermaBelum ada peringkat

- Steam Blowing: Technical BulletinDokumen3 halamanSteam Blowing: Technical BulletinCartila MawratiBelum ada peringkat

- SOP - Start-Up & Shut Down Procedure of Thermal Craker Heater De-CokingDokumen10 halamanSOP - Start-Up & Shut Down Procedure of Thermal Craker Heater De-CokingsaadBelum ada peringkat

- Guidelines On FCC Fractionator Bottoms System Rev2Dokumen5 halamanGuidelines On FCC Fractionator Bottoms System Rev2M Scott GreenBelum ada peringkat

- Aph FireDokumen25 halamanAph Firesekhar_ntpcBelum ada peringkat

- The Boiler HouseDokumen9 halamanThe Boiler Housemeijon pelayerBelum ada peringkat

- Thermal Cracking - Delayed Coking 2Dokumen8 halamanThermal Cracking - Delayed Coking 2Anonymous rUs4PjYo5Belum ada peringkat

- Steam Accumulater 0909fultonwhitepaperDokumen10 halamanSteam Accumulater 0909fultonwhitepaperjmpbarrosBelum ada peringkat

- Bottom Blowdown: Download The (295 KB) Try Answering The For This Tutorial View The Complete Collection ofDokumen8 halamanBottom Blowdown: Download The (295 KB) Try Answering The For This Tutorial View The Complete Collection ofsenaBelum ada peringkat

- Optimising Steam Systems: Part IIDokumen8 halamanOptimising Steam Systems: Part IIbk1234567Belum ada peringkat

- Compressor: Recommended Schedule Maintenance Will Void Warranty and Result in Damage To or Failure of The EquipmentDokumen6 halamanCompressor: Recommended Schedule Maintenance Will Void Warranty and Result in Damage To or Failure of The EquipmentRemmy MushiBelum ada peringkat

- Prepare A Boiler For SurveyDokumen9 halamanPrepare A Boiler For SurveyLakshmikanthBelum ada peringkat

- CFBC Refractory Dryout Along With Atmospheric Boilout FinalDokumen7 halamanCFBC Refractory Dryout Along With Atmospheric Boilout FinalpurvgargBelum ada peringkat

- Cement Plant VIPDokumen51 halamanCement Plant VIPengr kazamBelum ada peringkat

- Foam Control in Crude UnitsDokumen8 halamanFoam Control in Crude UnitsNXVNBelum ada peringkat

- Testing of Engines - 0Dokumen12 halamanTesting of Engines - 0S lenkaBelum ada peringkat

- Tata Steel ProjectDokumen12 halamanTata Steel Projectsp32483Belum ada peringkat

- TD Vs IB TrapDokumen5 halamanTD Vs IB TrapKailas NimbalkarBelum ada peringkat

- Sec 7dDokumen5 halamanSec 7dShin Creed100% (1)

- Boiler Q&A FurtherDokumen7 halamanBoiler Q&A FurtherRachitBelum ada peringkat

- BKLT DeaeratorDokumen24 halamanBKLT Deaeratormalikgaurav01Belum ada peringkat

- Shot CokeDokumen9 halamanShot CokeaminBelum ada peringkat

- Boiler Questions BtechDokumen5 halamanBoiler Questions BtechRishav Raj100% (1)

- Effect of Operating Conditions On COP of VCRDokumen9 halamanEffect of Operating Conditions On COP of VCRSatheesh ChandranBelum ada peringkat

- 13-10-27 Delayed Coker ProcessDokumen37 halaman13-10-27 Delayed Coker Processعزت عبد المنعم100% (1)

- Steam Blowing ProcedureDokumen15 halamanSteam Blowing ProcedureDangol100% (14)

- Alkali Boil Out - ProcedureDokumen4 halamanAlkali Boil Out - ProcedureMourya DevuBelum ada peringkat

- 7 Steam - SafetyDokumen5 halaman7 Steam - SafetyYeshitilaAyalewBelum ada peringkat

- Root Cause On Seal Failure RefineryDokumen8 halamanRoot Cause On Seal Failure RefineryVaibhav SinghBelum ada peringkat

- Section 1.4 - Processing Control EquipmentDokumen35 halamanSection 1.4 - Processing Control EquipmentLakshman Kumar JulapalliBelum ada peringkat

- Chapter 7: Oil Vapor Diffusion Pumps: Theory of OperationDokumen9 halamanChapter 7: Oil Vapor Diffusion Pumps: Theory of OperationGyu BotBelum ada peringkat

- 02.understanding Process Equipment For Operators & Engineers-61Dokumen5 halaman02.understanding Process Equipment For Operators & Engineers-61rahulBelum ada peringkat

- Steam Turbine MaintenanceDokumen3 halamanSteam Turbine Maintenancedreamboy87Belum ada peringkat

- Basf Bm018 Slow Firing AlkaliDokumen4 halamanBasf Bm018 Slow Firing AlkaliRamu NallathambiBelum ada peringkat

- Interstage Coolers A Hot ItemDokumen5 halamanInterstage Coolers A Hot Itemlbh6417320Belum ada peringkat

- Boiler CommissioningDokumen35 halamanBoiler CommissioningNikhil MalhotraBelum ada peringkat

- Precautions To Avoid Barring Gear StallingDokumen2 halamanPrecautions To Avoid Barring Gear StallingSrinivas BudatiBelum ada peringkat

- Why HT Water Temp Should Be Between 75 - 90 Deg. C (Or) Why Preheating of Engine Required?Dokumen14 halamanWhy HT Water Temp Should Be Between 75 - 90 Deg. C (Or) Why Preheating of Engine Required?Ganapathi SankarBelum ada peringkat

- Ball and Tube Mill OpnDokumen5 halamanBall and Tube Mill OpnDevendra PrasadBelum ada peringkat

- Sootblowing Sequence & TroubleshootingDokumen4 halamanSootblowing Sequence & TroubleshootingJunaid BaigBelum ada peringkat

- Boiler OperationDokumen14 halamanBoiler OperationjmayurrBelum ada peringkat

- SR-1054 Serie 40 Applications 2010-10Dokumen14 halamanSR-1054 Serie 40 Applications 2010-10Carlos GutierrezBelum ada peringkat

- Boiler Cooling MethodDokumen7 halamanBoiler Cooling Methodjp mishra100% (1)

- 07.troubleshooting Vacuum Systems-79Dokumen3 halaman07.troubleshooting Vacuum Systems-79Aatish ChandrawarBelum ada peringkat

- Steam Blowing BHELDokumen9 halamanSteam Blowing BHELdnageshm4n244100% (1)

- If One F.D. Fan TripsDokumen9 halamanIf One F.D. Fan TripsAhemad100% (1)

- IC Engine Actual Cycle PreformanceDokumen29 halamanIC Engine Actual Cycle Preformanceمصطفى عبد القادر فايزBelum ada peringkat

- 2.3 Steam SDokumen58 halaman2.3 Steam Saravind grandhiBelum ada peringkat

- Troubleshooting Catalyst Losses in The FCC Unit Kou BASF FCCU Galveston 2016Dokumen31 halamanTroubleshooting Catalyst Losses in The FCC Unit Kou BASF FCCU Galveston 2016GOPALJI SINGHBelum ada peringkat

- Kerala BOE-2014 Paper-1 SolutionDokumen10 halamanKerala BOE-2014 Paper-1 SolutionAlok DoshiBelum ada peringkat

- Boilers OperationDokumen50 halamanBoilers Operationtsrinivasan5083100% (1)

- Preventing Steam Coil FailureDokumen3 halamanPreventing Steam Coil FailureSjeverBelum ada peringkat

- Boiler-Steam Generator Protection PDFDokumen12 halamanBoiler-Steam Generator Protection PDFأمير حارث100% (1)

- Installation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitDari EverandInstallation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitBelum ada peringkat

- Oil and Gas Artificial Fluid Lifting TechniquesDari EverandOil and Gas Artificial Fluid Lifting TechniquesPenilaian: 5 dari 5 bintang5/5 (1)

- Emulsions and Oil Treating Equipment: Selection, Sizing and TroubleshootingDari EverandEmulsions and Oil Treating Equipment: Selection, Sizing and TroubleshootingPenilaian: 5 dari 5 bintang5/5 (3)

- Vestido para El Verano Burdastyle 6004 Patron Gratis InstruccionesDokumen3 halamanVestido para El Verano Burdastyle 6004 Patron Gratis InstruccionesRoxy ParedesBelum ada peringkat

- 2004revconditionscokeform PDFDokumen5 halaman2004revconditionscokeform PDFMili Bueno RivasBelum ada peringkat

- FCE WritingDokumen24 halamanFCE WritingQuil Réjane100% (1)

- Ebook FCE Reading and Use of EnglishDokumen11 halamanEbook FCE Reading and Use of EnglishMaria Del Valle MerinoBelum ada peringkat

- Focus On FCE PT GuidanceDokumen193 halamanFocus On FCE PT Guidancecipri100% (2)

- B2 English Unlimited Coursebook PDFDokumen164 halamanB2 English Unlimited Coursebook PDFDave87% (30)

- Resolver Vs EncoderDokumen7 halamanResolver Vs EncoderAmirtha swamy.nBelum ada peringkat

- The Haber Process: N + 3H > 2NH ΔH = −92 kJ molDokumen2 halamanThe Haber Process: N + 3H > 2NH ΔH = −92 kJ molShaeBelum ada peringkat

- Condition Assessment of Power Transformers and Assessment IndicesDokumen50 halamanCondition Assessment of Power Transformers and Assessment IndicesSKS_2014Belum ada peringkat

- BS en 1057 Tube Sizes - Crane Copper TubeDokumen2 halamanBS en 1057 Tube Sizes - Crane Copper TubestarykltBelum ada peringkat

- Spare Parts List: Chain Saws 562 XP/XPGDokumen37 halamanSpare Parts List: Chain Saws 562 XP/XPGbbeisslerBelum ada peringkat

- Axpert MKS Off-Grid Inverter Selection GuideDokumen1 halamanAxpert MKS Off-Grid Inverter Selection GuideTony OkinyiBelum ada peringkat

- 4 Lasers 2 PDFDokumen10 halaman4 Lasers 2 PDFDark WolfBelum ada peringkat

- Cl60 Rooftop Iom 0213 eDokumen94 halamanCl60 Rooftop Iom 0213 emikexiiBelum ada peringkat

- Cpa Bill Sample 2019 - WcagDokumen8 halamanCpa Bill Sample 2019 - WcagAmina chahalBelum ada peringkat

- Pract 05Dokumen2 halamanPract 05Timothy CBelum ada peringkat

- 1 Copert MainDokumen18 halaman1 Copert MaindpmgumtiBelum ada peringkat

- Dokumentacja Wciągnika PDFDokumen24 halamanDokumentacja Wciągnika PDFmatianBelum ada peringkat

- EE 465 Lecture 8Dokumen25 halamanEE 465 Lecture 8hshjxcbzBelum ada peringkat

- Aes - Mcqs - Unit - 1 To 5Dokumen9 halamanAes - Mcqs - Unit - 1 To 5KumarJinneBelum ada peringkat

- Om Manual C0179439 PDFDokumen154 halamanOm Manual C0179439 PDFAle AleBelum ada peringkat

- The Bicol Development PlanDokumen49 halamanThe Bicol Development PlanGilbert MendozaBelum ada peringkat

- Standard Precision Pyranometer: SpecificationsDokumen1 halamanStandard Precision Pyranometer: Specificationsgaston amayaBelum ada peringkat

- Ieee C57.135 (2001)Dokumen50 halamanIeee C57.135 (2001)Daniel PaniaguaBelum ada peringkat

- GEW Method Statement PDFDokumen2 halamanGEW Method Statement PDFAzhar MushtaqBelum ada peringkat

- MIL-H-5440G Hydraulic Systems, AircraftDokumen49 halamanMIL-H-5440G Hydraulic Systems, AircraftRonny Valero Montoya0% (1)

- DCC ChecklistDokumen1 halamanDCC Checklistluci_camBelum ada peringkat

- Checklist For Engineer On DutyDokumen14 halamanChecklist For Engineer On DutyEzhil AnBelum ada peringkat

- Twinflex Fire AlarmDokumen72 halamanTwinflex Fire AlarmAnt OSheaBelum ada peringkat

- C075 Aq SPC 0006 - 3Dokumen12 halamanC075 Aq SPC 0006 - 3Mingyu SongBelum ada peringkat

- c7 Acert Injection TestDokumen2 halamanc7 Acert Injection TestCristhianBelum ada peringkat

- Gang SawDokumen55 halamanGang SawAstri NgentBelum ada peringkat

- Complete Solar Panel Installation DesignDokumen7 halamanComplete Solar Panel Installation DesignAnietie Udofia100% (2)

- Data Sheet - KM01Dokumen4 halamanData Sheet - KM01Jose Manuel Carcamo SaezBelum ada peringkat

- Tài liệu bồi dưỡng HSG tiếng Anh lớp 11Dokumen14 halamanTài liệu bồi dưỡng HSG tiếng Anh lớp 11xuannghiatandaBelum ada peringkat

- Geiger Counter Neon LampDokumen3 halamanGeiger Counter Neon LampClaudio Oliveira TavaresBelum ada peringkat