GM Supplier Evaluation

Diunggah oleh

Agis LiberakisDeskripsi Asli:

Hak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

GM Supplier Evaluation

Diunggah oleh

Agis LiberakisHak Cipta:

Format Tersedia

Supplier Evaluation Criteria for System Sourcing ID 1 2 3 4 5 6 7 8 Company profile: Company global footprint.

Emphasis on powertrain anti-vibration mounts and devices: Company history. Business growth history / plan. Separate anti-vibration molded rubber business. Existing anti-vibration molded rubber business [by OEM / Tier I], especially system responsibility of OEM mount systems. Technical centers, their capabilities, and footprint. SFO vision In business - 10 yrs AVS as core business

other OEM business: components and/or systems homeroom & regional support list (Exel file) Global manufacturing facilities (anti-vibration molded rubber facilities). This includes: SFO vision Locations elastomeric & hydromount. Capabilities Capacities Rubber injection capacity. Hydromount assembly capacity. Elastomeric mount assembly capacity. Available floor space to add capacity.

On-site audit test equipment (dimensional, static & dynamic rate, rubber characteristics, etc.) rubber Rheometer (Lab) rubber Mooney visco meter (Lab) MRE static rate (Online) MRE adhesion (Lab) Glycol Moisture content (Lab) Assembled mount dynamic & static rates (Online) Pre-loaded height of assembled mount (Online) TGA [Thermal Gravimetric Analysis] (proper voluncanization) GD&T - CMM (Lab) Denso Meter (permeability) Rubber mixing facilities. sufficient capacity for GM programs 20 [estimated 170 gms/part] 10 11 12 13 14 15 16 17 18 19 Rubber supply chain & Quality control 21 Company Structure: 22 Global organization chart. 23 Regional organization chart. Global company logistics (information sharing, math data transfer, 24 common learnings and exchange, etc.) Quality Assurance: 23 Customer PPM. Program management: Cradle to grave program management process 24 25 Change control Tools and methods 26 27 28 People Logistics Raw rubber sources (dedicated or open market) Raw rubber quality standards and checks global accountability distinct PD, Mfg, Quality, Sales IT communication structure among the different divisions <1 documented product development & release process trackable process in place MS Office, MS project, product release & change control system dedicated program manager from cradle to grave regional warehouses [All GM Regions] All-GM region account managers homeroom & regional support list (Excel file)

29 Account management and sales Engineering support. 30

Design Development Expertise: Description of in-house capabilities to construct math models of components.

ID Experienced UG designers and seats 31 32 Software used (UG, CATIA, etc.). 33 IT Equipment Math data transfer to GM. [State if connected to GM Team Center 34 (TCAE), if not, what is current data transfer method and what are their future plans to be connected to TCAE.] 2 minimum 3 medium program [ 5 - 8 PT combinations] 5 Large programs [> 8] UG

direct connect to TCAE

Description of in-house capabilities for powertrain mounts system analysis and development. Rigid body modal analysis and optimization. 35 Loads analysis. ADAMS with macros for multiple load cases and PT and mounts displacements integrated PT 6-DOF analysis and optimization with visual capability [MTDES like capability]

36

37 o Vehicle system model integration. o Include description of software used such as ADAMS/MatLab, or 38 proprietary software). Capabilities and tools to manipulate and calculate powertrain inertia data. 39

Not required ADAMS (loads) Proprietary for 6-DOF automated with coordinate system transformation capability Description of in-house capabilities to construct finite element models and perform structural analysis: o o o o o o Experienced CAE specialists Software used for mesh generation. Boundary conditions modeling. Fastened joints modeling and analysis for strength/slippage. Rubber modeling techniques. Large deformation rubber analysis techniques. List Number of CAE Engineers Hypermesh per GM guidelines per GM guidelines automated [PATRAN or equivalent] using ABAQUS with contact modeling Hi standard:analysis code for fatigue prediction based on FEA and appropriate rubber models Minimum standard: formula based rubber fatigue life vs. stress or strain curves using ABAQUS using ABAQUS with stops per GM guidelines Optistruct NASTRAN Linear: NASTRAN non-linear: ABAQUS nCode FEA with fiber orientation Hydraulic mounts modeling and analysis techniques and tools. Elastomeric mount main rubber element stiffness prediction tool. Controlled mounts modeling and analysis techniques and tools. > 5 yrs inclusing castings designs small & large amplitude damping and dynamic stiffness predictions complete elastomeric mounts characterization tools

40 41 42 43 44 45

o Rubber fatigue analysis techniques (considering static pre-load, thermal load, cycling load). 46

47 o Static stiffness predictions for elastomeric mounts. 48 o Load deflection of complete mount assemblies. o Cast and sheet metal brackets FEM techniques [meshing, element 49 types, boundary conditions, tip mass, etc.]. o Cast metal brackets optimization software/techniques [Optistruct or 50 the like]. 51 o Metal components dynamic stiffness (modal) analysis. o Metal components strength analysis (linear and non-linear). 52 53 o o 54 55 56 57 o o o Metal components fatigue analysis. Modeling and analysis of composite plastic brackets.

58 In-house bracket design development experience.

ID Alternate propulsion systems (Hybrid, Fuel Cell, Electric, etc.) mounting system expertise. o Benchmarking. Previous and current programs with OEMs. Design and requirements best practices.

59

60 o o 61

1 per PT architecture type (similar system) 1 system documented learnings from previous experience and/or benchmarking elastomeric & hydraulic bushing, conical, and caged (box) mounts. tightly decoupled & fully coupled minimum standard: Dry filling; EPDM Hi standard: min plus

62

Passive mounts expertise: style of mounts previously/currently developed and produced

Advanced hydraulic mounts [dual tracks, tightly decoupled, double isolated,..] Alternate technologies [Dry filling, air damping, silicone, EPDM, special 64 designs,.] 63 Controlled mounts expertise: Demonstrate complete portfolio of active, adaptive, or switchable noise & vibration control devices integrated into and separate from the powertrain 65 mounts. [Specify technology development status, applicability, where used.] 66 67 68 Description of in-house expertise in electrical controllers and software for controlling active N&V control devices. Past experiences in the development of actively controlled devices for powertrain N&V cancellation. In-house testing capabilities to characterize performance attributes of controlled mounts. NVH expertise: Internal personnel with vehicle, subsystem, and component level NVH expertise. Measuring instruments. Measuring methods. Data analysis. Performance and validation testing capabilities: Description of in-house capabilities to perform mount performance characterization at varied operating conditions (e.g., tri-axis rate testing under preload, > 600 Hz. low stroke dynamic rate testing, low frequency damping and dynamic stiffness characterization, active mounts displacement cancelling capability as a function of voltage, etc.).

66 67 68 69

2 MTS 833

70 71 72 73

2 MTS 831 <1000 Hz. 1 MTS 831 1000 Hz. > 1 over 1000 Hz. 15 single axis durability (medium programs)

74

Description of in-house capabilities to perform single and multi-axis component durability testing under varying temperature conditions [equipment owned and used; how equipment is used; limitations on testing]

75 76

25 single axis durability (large programs) tri-axis component durability (20 week utilization): = 3 for small programs (Lambda) tri-axis component durability (20 week utilization): = 5 for medium programs (Zeta) tri-axis component durability (20 week utilization): = 7 for large programs (Epsilon,Gamma)

77

78

ID 79 80 81 Corrosion testing capabilities. 82 Contaminant resistance testing (Ozone, Others: oil, anti-freeze) 83 84 Aging resistance Manufacturing processes and expertise: 85 source of rubber formulations (internal or external) Rubber mixing capability (parts capacity / % utilized) 86 87 ISO certifications. Materials and fastener engineering: 88 Materials engineering 89 Fastener engineering 90 Types of protection coatings available and used. 91 Type of metal to rubber adhesives used (in-mold and post volcanization). 92 93 Metal preparation process for proper rubber adhesion. Internal and competitive benchmarking: 94 Competitive component and subsystem benchmarking activities: 95 96 97 98 99 100 101 102 bedplate subassembly tri-axis durability 0 subsystem rig (MAST) 1 corrosion chamber Ozone: 1 chamber Other contaminants: 1 3 chambers All internal support program volume with existing facilities ISO/TS 16949, ISO14001 in-house Materials Engineers in-house Fasteners Engineers A-coat capable E-coat capable water based and Lord compatible

parts library technical analysis cost analysis reports library Golden standard: electronic database electronic database Internal design release and retrieval system (data management) subsystem attributes Competitive vehicle benchmarking activities [1 target vehicle per program]: vehicle level testing components analysis Intangibles [C: area of concern; M: Meets expectations; E: Exceeds expectations] Attitude: eager to grow technical capability Attitude: eager to grow global footprint Communication - Inter company Communication - Intra company Cutting edge! Work place environment Can do attitude

103 104 105 106 107 108 109

Anda mungkin juga menyukai

- Measuring Defect Levels and Calculating Process YieldDokumen16 halamanMeasuring Defect Levels and Calculating Process YieldDiego FloresBelum ada peringkat

- Optimizing Purchasing Processes Saves 1 MillionDokumen4 halamanOptimizing Purchasing Processes Saves 1 MillionMargara PerezBelum ada peringkat

- Differentiate Between Supplier Positioning Model and Supplier Preferencing ModelDokumen4 halamanDifferentiate Between Supplier Positioning Model and Supplier Preferencing ModelSharon ZweiBelum ada peringkat

- Pilot Run Report 0702Dokumen23 halamanPilot Run Report 0702Greg MackeyBelum ada peringkat

- Global Sourcing Strategies To Achieve Long-Term Success: Brandon Spear Senior Vice President - OperationsDokumen16 halamanGlobal Sourcing Strategies To Achieve Long-Term Success: Brandon Spear Senior Vice President - OperationsannapurnachigurupatiBelum ada peringkat

- Quality Function DeploymentDokumen8 halamanQuality Function DeploymentNivedh VijayakrishnanBelum ada peringkat

- Performance-Management in LogisticsDokumen8 halamanPerformance-Management in LogisticstravellBelum ada peringkat

- 1448 Data Gmet6 25eph Pfep Tuggers Forkfree 191022Dokumen121 halaman1448 Data Gmet6 25eph Pfep Tuggers Forkfree 191022Gustavo FerrerBelum ada peringkat

- Supplier Benchmarking Tool EnglishDokumen11 halamanSupplier Benchmarking Tool EnglishAnonymous hAiENTeytBelum ada peringkat

- Assembly LinesDokumen34 halamanAssembly LineshabtamuBelum ada peringkat

- HA CEDAC Workshop INDO Kaizen PartDokumen16 halamanHA CEDAC Workshop INDO Kaizen PartHardi BanuareaBelum ada peringkat

- Format For Work Instruction MatrixDokumen2 halamanFormat For Work Instruction MatrixKodhansBelum ada peringkat

- Presentation On Lean Manufacturing: Course Title: Ergonomics and Productivity Engineering Sessional Course Code: IPE 3202Dokumen26 halamanPresentation On Lean Manufacturing: Course Title: Ergonomics and Productivity Engineering Sessional Course Code: IPE 3202Ayman Sajjad AkashBelum ada peringkat

- First Pass Yield ReportDokumen8 halamanFirst Pass Yield ReportBrian GrantBelum ada peringkat

- Prds & Piping QapDokumen2 halamanPrds & Piping QapPavul RajBelum ada peringkat

- Supplier Assessment Report-Shenzhen Illuman Photoelectronic Co., LTDDokumen29 halamanSupplier Assessment Report-Shenzhen Illuman Photoelectronic Co., LTDAdam Andrew OngBelum ada peringkat

- Daily Production Report "Title & Graphic of Show": List Scene Numbers and DescriptionsDokumen4 halamanDaily Production Report "Title & Graphic of Show": List Scene Numbers and DescriptionsSergio Quisbert P.Belum ada peringkat

- Understanding Takt TimeDokumen10 halamanUnderstanding Takt TimeRohit VishwakarmaBelum ada peringkat

- Lecture1 - Robust DesignDokumen31 halamanLecture1 - Robust Designds_srinivasBelum ada peringkat

- WCM Roi PDFDokumen20 halamanWCM Roi PDFjackpedro_surf2Belum ada peringkat

- Sasi BenchmarkingDokumen13 halamanSasi BenchmarkingapplebjBelum ada peringkat

- APQP - in ProgressDokumen19 halamanAPQP - in ProgressreshunkBelum ada peringkat

- Measuring operational performance with Operational Ratio (OPRDokumen10 halamanMeasuring operational performance with Operational Ratio (OPRSunny DayBelum ada peringkat

- Undstg Core Tools-APQP & PPAPDokumen2 halamanUndstg Core Tools-APQP & PPAPrajivBelum ada peringkat

- 6W2H For Side Wrinkles MY17 - RearDokumen4 halaman6W2H For Side Wrinkles MY17 - RearVishvendra Pratap SinghBelum ada peringkat

- MeasureDokumen51 halamanMeasureAshwani KumarBelum ada peringkat

- Application of Fmea Method in A Manufacturing Organization Focused On QualityDokumen7 halamanApplication of Fmea Method in A Manufacturing Organization Focused On QualityRudra DasBelum ada peringkat

- Audit Process - How ToDokumen144 halamanAudit Process - How ToVenkateswarlu BharathulaBelum ada peringkat

- Value Stream Mapping - TQMDokumen27 halamanValue Stream Mapping - TQMyashar2500Belum ada peringkat

- Process of EB, QB Samples ShipmentDokumen9 halamanProcess of EB, QB Samples ShipmentBự BụngBelum ada peringkat

- VIP Activity Plan & Status for Qavi BrothersDokumen5 halamanVIP Activity Plan & Status for Qavi BrothersMurtaza AhmedBelum ada peringkat

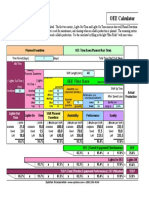

- Six big losses and OEE calculationDokumen2 halamanSix big losses and OEE calculationrotorsanBelum ada peringkat

- Toyota Production SystemDokumen33 halamanToyota Production SystemMohit SharmaBelum ada peringkat

- Different Types of Time in ManufacturingDokumen15 halamanDifferent Types of Time in ManufacturingkazuBelum ada peringkat

- Detailed Project CostingDokumen38 halamanDetailed Project CostingKhaledBelum ada peringkat

- LEAN SCM Hidden FactoryDokumen33 halamanLEAN SCM Hidden FactoryJulian KalacBelum ada peringkat

- Swot Analysis of Go AirDokumen2 halamanSwot Analysis of Go Airmangesh_7735100% (1)

- OEE Calculation USDokumen3 halamanOEE Calculation USBenjamin MossoBelum ada peringkat

- Sec 04 Quality Control ProcessDokumen37 halamanSec 04 Quality Control Processapi-3699912Belum ada peringkat

- Heizer Om12 Ch06 FinalDokumen73 halamanHeizer Om12 Ch06 FinalBahri Karam KhanBelum ada peringkat

- Planning and Decision MakingDokumen132 halamanPlanning and Decision MakingGleiza Two BaguioBelum ada peringkat

- Simple Oee SpreadsheetDokumen2 halamanSimple Oee SpreadsheetadeBelum ada peringkat

- Apqp PQP Flow ChartDokumen1 halamanApqp PQP Flow ChartmjapmgBelum ada peringkat

- Jakarta Plant Engineering Standard: B. General Rules of PFMEA B.1. ScopeDokumen24 halamanJakarta Plant Engineering Standard: B. General Rules of PFMEA B.1. ScopeLeonardoViannaBelum ada peringkat

- Moudling Operation GSIC Process: MouldingDokumen13 halamanMoudling Operation GSIC Process: MouldingBalakumaran MurugesanBelum ada peringkat

- Lean in Service Industry by MG. Kanakana (Corresponding Author)Dokumen10 halamanLean in Service Industry by MG. Kanakana (Corresponding Author)Kun HarjiyantoBelum ada peringkat

- What Are The Best Kpis For Purchasing DepartmentsDokumen6 halamanWhat Are The Best Kpis For Purchasing DepartmentsAKHILESH BirlaBelum ada peringkat

- Warehouse KPI MetricsDokumen41 halamanWarehouse KPI MetricsABU YEROMEBelum ada peringkat

- OP-PSU-050 5 Fuel ManualDokumen179 halamanOP-PSU-050 5 Fuel ManualskynorthBelum ada peringkat

- CostingDokumen2 halamanCostingbanapte59Belum ada peringkat

- Value Stream MapTemplateDokumen6 halamanValue Stream MapTemplatebuddy-20087751Belum ada peringkat

- Preventive Methods in Logistics Poka-Yoke and Failure Mode and Effect Analysis (FMEA)Dokumen5 halamanPreventive Methods in Logistics Poka-Yoke and Failure Mode and Effect Analysis (FMEA)Lukman Wan Mat DaudBelum ada peringkat

- OEE Calculator - Sylution - 2010 - 01 - 21Dokumen1 halamanOEE Calculator - Sylution - 2010 - 01 - 21metugaBelum ada peringkat

- 10 MovementDokumen26 halaman10 MovementjvanandhBelum ada peringkat

- VSM 5WorkstationEd.a TrialVersionDokumen3 halamanVSM 5WorkstationEd.a TrialVersionMani Rathinam RajamaniBelum ada peringkat

- OEE Template Version 01 PHDokumen11 halamanOEE Template Version 01 PHAjitBelum ada peringkat

- Why Process Management Delivers Superior ResultsDokumen26 halamanWhy Process Management Delivers Superior ResultstdeviyanBelum ada peringkat

- Computer Aided EngineeringDokumen30 halamanComputer Aided EngineeringPedro CamargoBelum ada peringkat

- CAE Presentation Covers Analysis Types & Real-World ExampleDokumen30 halamanCAE Presentation Covers Analysis Types & Real-World ExampleSalam FaithBelum ada peringkat

- NcodeDokumen8 halamanNcodesefaydesBelum ada peringkat

- ERIKS Dynamic SealsDokumen28 halamanERIKS Dynamic Sealsdd82ddBelum ada peringkat

- Rubric 5th GradeDokumen2 halamanRubric 5th GradeAlbert SantosBelum ada peringkat

- Easa Management System Assessment ToolDokumen40 halamanEasa Management System Assessment ToolAdam Tudor-danielBelum ada peringkat

- BenchmarkDokumen4 halamanBenchmarkKiran KumarBelum ada peringkat

- Learning Activity Sheet: 3 Quarter Week 1 Mathematics 2Dokumen8 halamanLearning Activity Sheet: 3 Quarter Week 1 Mathematics 2Dom MartinezBelum ada peringkat

- Mosfet 101Dokumen15 halamanMosfet 101Victor TolentinoBelum ada peringkat

- Baobab MenuDokumen4 halamanBaobab Menuperseverence mahlamvanaBelum ada peringkat

- Audio - Questions: Safety Equipment Reliability Handbook (SERH) 4th EditionDokumen29 halamanAudio - Questions: Safety Equipment Reliability Handbook (SERH) 4th EditionLuc SchramBelum ada peringkat

- AD Chemicals - Freeze-Flash PointDokumen4 halamanAD Chemicals - Freeze-Flash Pointyb3yonnayBelum ada peringkat

- Composite Structures: A. Grimaldi, A. Sollo, M. Guida, F. MaruloDokumen15 halamanComposite Structures: A. Grimaldi, A. Sollo, M. Guida, F. MaruloSharan KharthikBelum ada peringkat

- GS16 Gas Valve: With On-Board DriverDokumen4 halamanGS16 Gas Valve: With On-Board DriverProcurement PardisanBelum ada peringkat

- A Database of Chromatographic Properties and Mass Spectra of Fatty Acid Methyl Esters From Omega-3 ProductsDokumen9 halamanA Database of Chromatographic Properties and Mass Spectra of Fatty Acid Methyl Esters From Omega-3 ProductsmisaelBelum ada peringkat

- Duca Industries March 2023 pay slip for Dipankar MondalDokumen1 halamanDuca Industries March 2023 pay slip for Dipankar MondalPritam GoswamiBelum ada peringkat

- Combined Set12Dokumen159 halamanCombined Set12Nguyễn Sơn LâmBelum ada peringkat

- Maharashtra Auto Permit Winner ListDokumen148 halamanMaharashtra Auto Permit Winner ListSadik Shaikh50% (2)

- Ielts Practice Tests: ListeningDokumen19 halamanIelts Practice Tests: ListeningKadek Santiari DewiBelum ada peringkat

- Breaking NewsDokumen149 halamanBreaking NewstigerlightBelum ada peringkat

- SolBridge Application 2012Dokumen14 halamanSolBridge Application 2012Corissa WandmacherBelum ada peringkat

- Allan S. Cu v. Small Business Guarantee and FinanceDokumen2 halamanAllan S. Cu v. Small Business Guarantee and FinanceFrancis Coronel Jr.Belum ada peringkat

- Checklist of Requirements For OIC-EW Licensure ExamDokumen2 halamanChecklist of Requirements For OIC-EW Licensure Examjonesalvarezcastro60% (5)

- SOP-for RecallDokumen3 halamanSOP-for RecallNilove PervezBelum ada peringkat

- N4 Electrotechnics August 2021 MemorandumDokumen8 halamanN4 Electrotechnics August 2021 MemorandumPetro Susan BarnardBelum ada peringkat

- Extrajudicial Settlement of Estate Rule 74, Section 1 ChecklistDokumen8 halamanExtrajudicial Settlement of Estate Rule 74, Section 1 ChecklistMsyang Ann Corbo DiazBelum ada peringkat

- CFO TagsDokumen95 halamanCFO Tagssatyagodfather0% (1)

- Galaxy Owners Manual Dx98vhpDokumen10 halamanGalaxy Owners Manual Dx98vhpbellscbBelum ada peringkat

- Tutorial 1 Discussion Document - Batch 03Dokumen4 halamanTutorial 1 Discussion Document - Batch 03Anindya CostaBelum ada peringkat

- Master SEODokumen8 halamanMaster SEOOkane MochiBelum ada peringkat

- White Box Testing Techniques: Ratna SanyalDokumen23 halamanWhite Box Testing Techniques: Ratna SanyalYogesh MundhraBelum ada peringkat

- Technical specifications for JR3 multi-axis force-torque sensor modelsDokumen1 halamanTechnical specifications for JR3 multi-axis force-torque sensor modelsSAN JUAN BAUTISTABelum ada peringkat

- U2 All That You Can't Leave BehindDokumen82 halamanU2 All That You Can't Leave BehindFranck UrsiniBelum ada peringkat