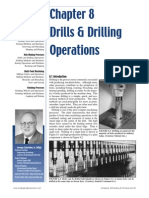

Drilling Process

Diunggah oleh

Naga Surya GDeskripsi Asli:

Hak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

Drilling Process

Diunggah oleh

Naga Surya GHak Cipta:

Format Tersedia

Drilling Process

http://www.scribd.com/doc/4373001/Drilling-Process

Scribd Upload a Document Search Documents Explore

Documents

Books - Fiction Books - Non-fiction Health & Medicine Brochures/Catalogs Government Docs How-To Guides/Manuals Magazines/Newspapers Recipes/Menus School Work + all categories Featured Recent

People

Authors Students Researchers Publishers Government & Nonprofits Businesses Musicians Artists & Designers Teachers + all categories Most Followed Popular Sign Up | Log In

/ 15

ocument for Free

1 of 27 22-06-2011 18:19

Drilling Process

http://www.scribd.com/doc/4373001/Drilling-Process

/ 15

ocument for Free

2 of 27 22-06-2011 18:19

Drilling Process

http://www.scribd.com/doc/4373001/Drilling-Process

/ 15

ocument for Free

3 of 27 22-06-2011 18:19

Drilling Process

http://www.scribd.com/doc/4373001/Drilling-Process

/ 15

ocument for Free

4 of 27 22-06-2011 18:19

Drilling Process

http://www.scribd.com/doc/4373001/Drilling-Process

/ 15

ocument for Free

5 of 27 22-06-2011 18:19

Drilling Process

http://www.scribd.com/doc/4373001/Drilling-Process

/ 15

ocument for Free

6 of 27 22-06-2011 18:19

Drilling Process

http://www.scribd.com/doc/4373001/Drilling-Process

/ 15

ocument for Free

7 of 27 22-06-2011 18:19

Drilling Process

http://www.scribd.com/doc/4373001/Drilling-Process

/ 15

ocument for Free

8 of 27 22-06-2011 18:19

Drilling Process

http://www.scribd.com/doc/4373001/Drilling-Process

/ 15

ocument for Free

9 of 27 22-06-2011 18:19

Drilling Process

http://www.scribd.com/doc/4373001/Drilling-Process

MANUFACTURING AND MATERIALS DEPARTMENT

MME1103 Workshop Technology Manual Drilling

4.3

BASIC FORMULA FOR DRILLING OPERATION

Cutting speeds and RPM calculations are those operations that are strictly drilling operations, but the drilling operation is also used to perform other operations such as reaming, tapping, countersinking and counterboring. The following are the basic formula that are commonly used in the drilling operation.

Cutting speed is the peripheral speed of the cutting edge = D N; where D is the drill diameter and N is the rotational speed (rpm)

The cutting speed selection depends on both the workpiece and cutter materials; N = V x 1000 rpm, where D V is cutting speed N is rotational speed (rpm)

and

* Note that V is in m/min and D in mm

Feed (f) is the distance the drill penetrate per revolution (mm/rev), the share of each cutting edge is = f/2

Depth of cut is taken as half the diameter for drilling = D/2

Drilling time (T) can be given by the equation;

T = L / f N; where f is the feed (mm/rev) N is the rotational speed (rpm) L is the sum of hole depth, approach and over travel distances

*The approach is usually considered as 0.4D while over travel ranges from 1 to 3mm.

Material removal rate (MRR) in drilling is the volume of material removed by the drill per unit time.

MRR = ( D / 4).(f).(N)

/ 15

ocument for Free

10 of 27 22-06-2011 18:19

Drilling Process

http://www.scribd.com/doc/4373001/Drilling-Process

MANUFACTURING AND MATERIALS DEPARTMENT

MME1103 Workshop Technology Manual Drilling

4.3.1 Sample Questions

1) 20 mm diameter drill is on a drilling machine with cutting speed 25. If the feed is 0.25 mm/rev, what is the MRR? What is the MRR is the drill diameter is tripled? 2) The hole of a diameter of 44.7 mm is to be drilled to a depth of 60 mm and reamed to a diameter of 45 mm. The feed is 0.56 mm/rev for drilling. The cutting speed is 70.6 m/min. The reaming approach is 0.55 mm and over travel is 2 mm. Determine :a) b) c) d) The feed and spindle speed for reaming operation. The drilling time The reaming time The MRR for the drilling operation.

4.4 DRILLING TECHNIQUES

In a standard drilling operation, the following steps are taken (Gupta, 1996): a) Firstly, the workpiece is marked with a centre punch at the centre of the hole to be drilled. b) It is then held firmly in a vice or other suitable clamping device and place on the table of the drilling machine.

c) The socket containing the drill is fitted in the machine spindle. d) The spindle is lowered by the hand lever and it is ensured that the point of the drill is in exact alignment with the previously marked centre of the hole. e) The motor is now started and the rotating drill is gradually pressed into the workpiece to produce the desired hole. f) The pressure should be frequently relived during the drilling operations, otherwise the cutting edges of the drill will be strained and the drill is damaged. g) In order to avoid spoiling the cutting edge of the drill, coolant such as oil or soap water should be used constantly during the drilling operation.

/ 15

ocument for Free

11 of 27 22-06-2011 18:19

Drilling Process

http://www.scribd.com/doc/4373001/Drilling-Process

MANUFACTURING AND MATERIALS DEPARTMENT

MME1103 Workshop Technology Manual Drilling

4.4.1 Cutting Fluids

A large number of coolant and cutting oils are used in drilling operations. A good cutting fluid will cool the workpiece and tool and will also act as a lubricant between the chip and the tool to reduce friction and heat buildup. Table 4.2 lists some of the cutting fluids for different materials.

Materials Dry

Aluminum Brass Bronze Cast iron Steels Low carbon Alloy Stainless Others

Emulsifying or soluble oils mixed in water Animal or mineral oils with added sulfur or chlorine

x x x

Type of cutting fluid Soluble Oil Kerosene Sulfurised Oil x x x x

Mineral oil

x x x

x x x

: :

For main requirement to use inexpensive cooling medium For operations that tend to create more friction and for reaming, counterboring, countersinking and tapping operations

Table 4.2 List of cutting fluids for different materials

4.5

GUIDELINES IN DESIGN

The general design guidelines recommended by Kalpakjian at. (2001) for drilling, reaming and tapping operations are as follows: a) Design should allow holes to be drilled on flat surfaces and perpendicular to the drill motion. Exit surfaces for the drill should also be flat. b) Interrupted hole surfaces should be avoided or minimized for improved dimensional accuracy. c) Hole bottom should if possible match standard drill point angles (Section 4.1.1). Flat bottoms or odd shapes should be avoided.

/ 15

ocument for Free

12 of 27 22-06-2011 18:19

Drilling Process

http://www.scribd.com/doc/4373001/Drilling-Process

MANUFACTURING AND MATERIALS DEPARTMENT

MME1103 Workshop Technology Manual Drilling

d) Through holes are preferred over blind holes. If holes with large diameters are required, the parts should have a pre-existing hole. e) Part should be designed so that all drilling can be done with a minimum of fixturing and without repositioning the workpiece. f) It may be difficult to ream blind or intersecting holes because of the possibility of tool breakage. Extra hole depth should be provided. g) Blind holes must be drilled deeper than subsequent reaming or tapping operations that may be performed.

4.6

TROUBLESHOOTING

A general guideline to the probable causes of problems in drilling operations is listed below Kalpakjian & Schmid, 2001:

Problem Drill breakage

Possible Causes Dull drill; seizing in hole because of chips clogging flutes; feed too high; lip relief angle too small Cutting speed too high; ineffective cutting fluid; rake angle too high; drill burned and strength lost when sharpened Drill misaligned or bend; lips not equal; web not central Same as above; machine spindle loose; chisel edge not central; side pressure on workpiece Dull drill; ineffective cutting fluid; welding of workpiece material on drill margin; improperly ground drill; improper alignment

: :

Excessive drill wear

Tapered hole Oversized hole Poor hole surface finish

: : :

Table 4.3: List of problems and possible causes in drilling operation

Figure 4.4: Causes of oversize drilling: (a) drill lips ground to unequal lengths, (b) drill lips ground to unequal angles, and (c) unequal angles and lengths

10

/ 15

ocument for Free

13 of 27 22-06-2011 18:19

Drilling Process

http://www.scribd.com/doc/4373001/Drilling-Process

MANUFACTURING AND MATERIALS DEPARTMENT

MME1103 Workshop Technology Manual Drilling

4.7 SAFETY RULES

Poor work habits will lead to injuries. Chip flying into unprotected eyes, dropping heavy tools, getting hair or clothing caught in a rotating drill are among many hazards that can be avoided through safe work habits. The list below denotes a safety rules that student/ machinist need to be follow when doing the drilling operation: a) Workpieces should always be secured with bolts and strap clams, C-clamps or fixtures. A drill press vise should be used when drilling small parts. If a clamp should come loose and a merry go round result, do not try to stop it from turning with your hands. Turn of the machine quickly. b) Ensure all parts are properly secured and safe to run before starting the machine. c) Never clean the taper in the spindle when the drill is running, since this could result in broken fingers or worse injuries. d) Always remove the chuck key immediately after using it. A key left in the chuck will be thrown out at high velocity when the machine is turned on. e) Never stop the drill press spindle with your hand after you have turned off the machine, sharp chips often collect around the chuck or spindle. Do not reach around, near or behind a revolving drill. f) Do not leave the machine running unattended. g) Remove and clear all metal chips in between machine parts before and after usage. h) Do not change gear when the machine is running. i) Use a brush instead of your hands to clean chips off the machine. Never use an air jet for removing chips as this will cause the chips to fly at a high velocity and may lead to cuts and eye injuries. Do not clean chips or wipe oil while the machine is running. j) When moving the head or table on sensitive drill presses, make sure a safety clamps is set just below the table or head on the column; this will prevent the table from suddenly dropping if the column clamp is prematurely released.

4.8 PROJECT DRILLING

To be supplied by Sis Tuti

11

/ 15

ocument for Free

14 of 27 22-06-2011 18:19

Drilling Process

http://www.scribd.com/doc/4373001/Drilling-Process

MANUFACTURING AND MATERIALS DEPARTMENT

MME1103 Workshop Technology Manual Drilling

REFERENCES

Groover M.P., (1996), Fundamentals of Modern Manufacturing, Materials, Processes and Systems, International Editions, Prentice Hall. Gupta J.K. (1996), Basic Workshop Practice, S. Chand & Company Ltd. Kalpakian, S & Schmid, S.R. (2001), Manufacturing Engineering and th Technology - 4 International Edition, Prentice Hall International. Kibble R.R, Neely J.E, Meyer R.O & White W.T. (2002). Machine Tool Practiceth 7 Edition, Prentice Hall.

12

Drilling Process

/Download this Document for FreePrintMobileCollectionsReport Document 15 This is a private document.

ocument for Free

15 of 27 22-06-2011 18:19

Drilling Process

http://www.scribd.com/doc/4373001/Drilling-Process

Info and Rating

Education engineering workshop IIUM UIAM Education-Course-Material Ahmad Faridi

Follow

Share & Embed Related Documents

PreviousNext

1. p.

p.

p. / 15

ocument for Free

16 of 27 22-06-2011 18:19

Drilling Process

http://www.scribd.com/doc/4373001/Drilling-Process

2. p.

p.

p.

3. p.

p.

p.

4. p.

p. / 15

ocument for Free

17 of 27 22-06-2011 18:19

Drilling Process

http://www.scribd.com/doc/4373001/Drilling-Process

p.

5. p.

p.

p.

6. p.

p.

p.

7. p. / 15

ocument for Free

18 of 27 22-06-2011 18:19

Drilling Process

http://www.scribd.com/doc/4373001/Drilling-Process

p.

p.

8. p.

p.

p.

9. p.

p.

p. / 15

ocument for Free

19 of 27 22-06-2011 18:19

Drilling Process

http://www.scribd.com/doc/4373001/Drilling-Process

10. p.

p.

p.

11. p.

p.

p.

12. p.

p. / 15

ocument for Free

20 of 27 22-06-2011 18:19

Drilling Process

http://www.scribd.com/doc/4373001/Drilling-Process

p.

13. p.

p.

p.

14. p.

p.

p.

15. p. / 15

ocument for Free

21 of 27 22-06-2011 18:19

Drilling Process

http://www.scribd.com/doc/4373001/Drilling-Process

p.

p.

16. p.

p.

p.

17. p.

p.

p. / 15

ocument for Free

22 of 27 22-06-2011 18:19

Drilling Process

http://www.scribd.com/doc/4373001/Drilling-Process

18. p.

p.

More from this user

PreviousNext

1. 26 p.

6 p.

5 p.

2. 15 p.

13 p. / 15

ocument for Free

23 of 27 22-06-2011 18:19

Drilling Process

http://www.scribd.com/doc/4373001/Drilling-Process

2 p.

3. 24 p.

2 p.

8 p.

4. 10 p.

7 p.

15 p.

5. 10 p. / 15

ocument for Free

24 of 27 22-06-2011 18:19

Drilling Process

http://www.scribd.com/doc/4373001/Drilling-Process

14 p.

46 p.

6. 371 p.

3 p.

10 p.

7. 7 p.

46 p.

14 p. / 15

ocument for Free

25 of 27 22-06-2011 18:19

Drilling Process

http://www.scribd.com/doc/4373001/Drilling-Process

8. 8 p.

Recent Readcasters

Add a Comment

Characters: 400 This document has made it onto the Rising list! 02 / 03 / 2010

ocument for Free

26 of 27 22-06-2011 18:19

Drilling Process

http://www.scribd.com/doc/4373001/Drilling-Process

Upload a Document Search Documents Follow Us! scribd.com/scribd twitter.com/scribd facebook.com/scribd About Press Blog Partners Scribd 101 Web Stuff Scribd Store Support FAQ Developers / API Jobs Terms Copyright Privacy Copyright 2011 Scribd Inc. Language: English

/ 15

ocument for Free

27 of 27 22-06-2011 18:19

Anda mungkin juga menyukai

- Pneumatic Circit For Cylinder IiDokumen12 halamanPneumatic Circit For Cylinder IiAjay NishadBelum ada peringkat

- Abs Braking SystemDokumen63 halamanAbs Braking SystemSathiya UdumalpetBelum ada peringkat

- Workshop Report 2Dokumen6 halamanWorkshop Report 2Muhd Ariff100% (1)

- Lab Sheet MillingDokumen5 halamanLab Sheet MillingLalang Laut BestBelum ada peringkat

- Duty English " Drilling Machine": Mechanical Engineering Faculty of EngineeringDokumen14 halamanDuty English " Drilling Machine": Mechanical Engineering Faculty of EngineeringElfa Noprianri PutraBelum ada peringkat

- Engineering Practices-I: An Introduction To The CourseDokumen26 halamanEngineering Practices-I: An Introduction To The CourseSelena ParyBelum ada peringkat

- Exp No 10 DrillingDokumen11 halamanExp No 10 DrillingM IRFANBelum ada peringkat

- Lab 5 Fareez (Grinding Operation)Dokumen12 halamanLab 5 Fareez (Grinding Operation)s231311024Belum ada peringkat

- Extrusion PressDokumen17 halamanExtrusion PresssydengBelum ada peringkat

- 1 DR Abobaker ProductionDokumen20 halaman1 DR Abobaker ProductionKhaled AhmedBelum ada peringkat

- Unit 5Dokumen8 halamanUnit 5Narendra YadavBelum ada peringkat

- Machining Shop TheoryDokumen20 halamanMachining Shop TheoryManjunatha Babu N.sBelum ada peringkat

- Class Notes ManufacturingDokumen13 halamanClass Notes ManufacturingRajangam VeeruchinnanBelum ada peringkat

- Machining WorkshopDokumen8 halamanMachining WorkshopMuhammad Syakir SulimanBelum ada peringkat

- Unit 2 - Drilling 29Dokumen41 halamanUnit 2 - Drilling 29normanjames966Belum ada peringkat

- MFT2 Lab 2Dokumen48 halamanMFT2 Lab 2dellibabu509Belum ada peringkat

- PresentationDokumen33 halamanPresentationkumarpiyush9675Belum ada peringkat

- Fabrication of G-Clamp Lab ReportDokumen6 halamanFabrication of G-Clamp Lab ReportPei Shan Choong100% (2)

- HMT Mandrel Bending 101Dokumen80 halamanHMT Mandrel Bending 101zaiofracassadoBelum ada peringkat

- Chap 8Dokumen11 halamanChap 8Michael Chuquiruna MuñozBelum ada peringkat

- 018 Fab Indexing Table For Vertical Milling 2010MCDokumen40 halaman018 Fab Indexing Table For Vertical Milling 2010MCSelva GanapathyBelum ada peringkat

- CHAPTER 1 2 (Boring Knurling)Dokumen18 halamanCHAPTER 1 2 (Boring Knurling)hudarusliBelum ada peringkat

- Material Removal - Processes - Theory - of Metal MachiningDokumen25 halamanMaterial Removal - Processes - Theory - of Metal Machiningkurniashk13Belum ada peringkat

- ADDITIVE MANUFACTURING NotesDokumen15 halamanADDITIVE MANUFACTURING Notesvara prasadBelum ada peringkat

- 2 هندسة الانتاج والمعادن ملزمة طرق تصنيع مرحلةDokumen23 halaman2 هندسة الانتاج والمعادن ملزمة طرق تصنيع مرحلةAhmed KhalidBelum ada peringkat

- Turning Drilling Milling Shaper GrindingDokumen27 halamanTurning Drilling Milling Shaper GrindingphamvanmanhntuBelum ada peringkat

- English Unit 15Dokumen2 halamanEnglish Unit 15Ruth RodriguezBelum ada peringkat

- Lectureslidesondrillingandmilling PPT PDFDokumen25 halamanLectureslidesondrillingandmilling PPT PDFAlagar SamyBelum ada peringkat

- FEG 281 Lathe With Assignment - Engr. JerryDokumen8 halamanFEG 281 Lathe With Assignment - Engr. JerryJoseph Isco OrabuegoBelum ada peringkat

- Manufacturing TechnologyDokumen17 halamanManufacturing TechnologyPeter SamuelBelum ada peringkat

- Mechanical Technology Nov 2013 Memo EngDokumen17 halamanMechanical Technology Nov 2013 Memo EngRiriLil'prettyNBelum ada peringkat

- Grinding Errors and Possible SolutionsDokumen6 halamanGrinding Errors and Possible SolutionsPinak ThankiBelum ada peringkat

- Credit 4 Mill-2003Dokumen33 halamanCredit 4 Mill-2003Gokul Prasad ChettiBelum ada peringkat

- Basic HolemakingDokumen5 halamanBasic HolemakingdramiltBelum ada peringkat

- Lab Session 11Dokumen5 halamanLab Session 11Rahmat aliBelum ada peringkat

- Drill DataDokumen5 halamanDrill DataDOBJANBelum ada peringkat

- EMCO F1 ManualDokumen308 halamanEMCO F1 ManualClinton Koo100% (1)

- Production Technology: Department of Mechanical EngineeringDokumen17 halamanProduction Technology: Department of Mechanical Engineeringrahul bhattBelum ada peringkat

- Workshop Hammer ReportDokumen14 halamanWorkshop Hammer ReportJoshua Chong67% (3)

- Turret LatheDokumen12 halamanTurret LatheK Nallathambi K NallathambiBelum ada peringkat

- Engineering Practices-I: An Introduction To The CourseDokumen25 halamanEngineering Practices-I: An Introduction To The CourseMuhammad Haseeb JavedBelum ada peringkat

- The Advantages of Broaching Have Been Stated As UnderDokumen3 halamanThe Advantages of Broaching Have Been Stated As UnderNishit ParmarBelum ada peringkat

- Bengkel ReportDokumen5 halamanBengkel ReportPaih DtBelum ada peringkat

- Turning - Wikipedia, The Free EncyclopediaDokumen6 halamanTurning - Wikipedia, The Free EncyclopediaKhateeb Ul Islam QadriBelum ada peringkat

- Surface GrindingDokumen14 halamanSurface GrindingariefBelum ada peringkat

- 360 Degree Flexible Drilling Machine ReportDokumen26 halaman360 Degree Flexible Drilling Machine ReportSapna KumariBelum ada peringkat

- Drilling and Technology10Dokumen12 halamanDrilling and Technology10Aryan el-BerwarîBelum ada peringkat

- Hammer Full ReportDokumen9 halamanHammer Full ReportVince Ong100% (3)

- Drilling and Technology9Dokumen12 halamanDrilling and Technology9Aryan el-BerwarîBelum ada peringkat

- Journal - Sumith Cool 3ma19srDokumen8 halamanJournal - Sumith Cool 3ma19srprasanth kumarBelum ada peringkat

- Machining Operations EDokumen15 halamanMachining Operations Ehadyzaky482Belum ada peringkat

- Drilling QuizDokumen7 halamanDrilling QuizKhirasindhu Baruah75% (4)

- Production Lab Viva Question & AnswersDokumen13 halamanProduction Lab Viva Question & AnswersPradeep GsBelum ada peringkat

- Lec 1Dokumen27 halamanLec 1Romany AdelBelum ada peringkat

- Drill 32: Instructions Manual Drilling RigDokumen20 halamanDrill 32: Instructions Manual Drilling RigPungan IonBelum ada peringkat

- Production Engineering: Jig and Tool DesignDari EverandProduction Engineering: Jig and Tool DesignPenilaian: 4 dari 5 bintang4/5 (9)

- International Standard: Iso/Iec 7816-2Dokumen16 halamanInternational Standard: Iso/Iec 7816-2Anwar MohamedBelum ada peringkat

- Tle7 Ict TD M2 V3Dokumen28 halamanTle7 Ict TD M2 V3Rowemar Corpuz100% (1)

- Parkinson Hoehn and Yahr ScaleDokumen3 halamanParkinson Hoehn and Yahr ScaleCarol Artigas GómezBelum ada peringkat

- 30 This Is The Tower That Frank BuiltDokumen26 halaman30 This Is The Tower That Frank BuiltAlex BearishBelum ada peringkat

- BronchiolitisDokumen5 halamanBronchiolitisreshianeBelum ada peringkat

- BAFINAR - Quiz 2 ColarDokumen3 halamanBAFINAR - Quiz 2 ColarRonalyn ColarBelum ada peringkat

- Buncefield Volume 2Dokumen208 halamanBuncefield Volume 2Hammy223Belum ada peringkat

- Building Interactive AppsDokumen17 halamanBuilding Interactive AppsJRoman OrtizBelum ada peringkat

- Mitsubishi IC Pneumatic Forklift PDFDokumen5 halamanMitsubishi IC Pneumatic Forklift PDFfdpc1987Belum ada peringkat

- Imamsha Maharaj Na Parcha NewDokumen16 halamanImamsha Maharaj Na Parcha NewNARESH R.PATELBelum ada peringkat

- Catalogue of Palaearctic Coleoptera Vol.4 2007Dokumen471 halamanCatalogue of Palaearctic Coleoptera Vol.4 2007asmodeus822Belum ada peringkat

- The Design and Development of Organic Chemistry Module For College StudentsDokumen6 halamanThe Design and Development of Organic Chemistry Module For College StudentsEight AlykBelum ada peringkat

- Pit Viper 351Dokumen6 halamanPit Viper 351Sebastian Robles100% (2)

- 310 311 320 321 Toilet Warranty Codes PDFDokumen11 halaman310 311 320 321 Toilet Warranty Codes PDFTerri MartinBelum ada peringkat

- Form ConstructionDokumen36 halamanForm ConstructionYhoga DheviantBelum ada peringkat

- Application of Geosynthetics in Pavement DesignDokumen7 halamanApplication of Geosynthetics in Pavement DesignAnonymous kw8Yrp0R5rBelum ada peringkat

- Electricity MagnetismDokumen19 halamanElectricity MagnetismGray Amiel VilarBelum ada peringkat

- Zielinski AnArcheology For AnArchivesDokumen10 halamanZielinski AnArcheology For AnArchivesPEDRO JOSEBelum ada peringkat

- Performance Management Systems and Strategies by Dipak Kumar BhattacharyyaDokumen385 halamanPerformance Management Systems and Strategies by Dipak Kumar Bhattacharyyasayal96amrit100% (3)

- Board Resolution On Assigning Signatories in The Voucher ProgramDokumen2 halamanBoard Resolution On Assigning Signatories in The Voucher ProgramavinmanzanoBelum ada peringkat

- Assignment ProblemDokumen3 halamanAssignment ProblemPrakash KumarBelum ada peringkat

- Ssg-Ng01012401-Gen-Aa-5880-00012 - C01 - Ssags Nigerian Content PlanDokumen24 halamanSsg-Ng01012401-Gen-Aa-5880-00012 - C01 - Ssags Nigerian Content PlanStroom Limited100% (2)

- Specification For Neoprene Coating On The Riser CasingDokumen17 halamanSpecification For Neoprene Coating On The Riser CasingLambang AsmaraBelum ada peringkat

- Amended August 8 2016Dokumen31 halamanAmended August 8 2016lux186Belum ada peringkat

- Tescom Technical Training - Pressure Regulators Explained - Ver1.1Dokumen19 halamanTescom Technical Training - Pressure Regulators Explained - Ver1.1Amod DeshpandeBelum ada peringkat

- Chapter - 1 - Digital - Systems - and - Binary - Numbers EE228 15-16Dokumen81 halamanChapter - 1 - Digital - Systems - and - Binary - Numbers EE228 15-16mohamed hemdanBelum ada peringkat

- Department of Education: Republic of The PhilippinesDokumen6 halamanDepartment of Education: Republic of The PhilippinesLalaine QuitoBelum ada peringkat

- Lab5.ipynb - ColaboratoryDokumen8 halamanLab5.ipynb - ColaboratoryMin YBelum ada peringkat

- Monorail Hoist SystemDokumen17 halamanMonorail Hoist SystemypatelsBelum ada peringkat

- 4th - STD - MM - Kerala Reader Malayalam Vol 1Dokumen79 halaman4th - STD - MM - Kerala Reader Malayalam Vol 1Rajsekhar GBelum ada peringkat