MRL Azm161 en

Diunggah oleh

chara0202Deskripsi Asli:

Judul Asli

Hak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

MRL Azm161 en

Diunggah oleh

chara0202Hak Cipta:

Format Tersedia

Operating instructions Solenoid interlock

1 About this document

AZM 161../..

EN

Operating instructions...................... pages 1 to 6

Translation of the original operating instructions

1.1 Function This operating instructions manual provides all the information you need for mounting, set-up, commissionning, the safe operation and disassembly of the safety switchgear. The operating instructions must be available in a legible condition and complete version in the vicinity of the device. 1.2 Target group: authorised qualified personnel All operations described in this operating instructions manual must be carried out only by trained specialist personnel, authorised by the plant operator. Please make sure that you have read and understood these operating instructions and that you know all applicable prescriptions regarding occupational safety and accident prevention prior to installing and putting the component into operation. The machine builder must carefully select the harmonised standards to be complied with as well as other technical specifications for the selection, mounting and integration of the components. 1.3 Explanation of the symbols used Information, hint, note: This symbol is used for identifying useful additional information.

FR

Vous trouverez la version actuelle du mode demploi dans votre langue nationale officielle sur lInternet, www.schmersal. net. U vindt de huidige versie van de gebruikshandleiding in uw officile landstaal op het Internet, www.schmersal.net. EU (www.schmersal.net)

ES

Encontrar el manual de instrucciones actual en su idioma oficial de la UE en nuestra pgina de Internet www. schmersal.net. Il manuale distruzioni aggiornato nella vostra lingua (lingua ufficiale UE) scaricabile in Internet allindirizzo www. schmersal.net.

NL

IT

JP

Content 1 1.1 1.2 1.3 1.4 1.5 1.6 1.7 2 2.1 2.2 2.3 2.4 2.5 About this document Function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1 Target group: authorised qualified personnel. . . . . . . . . . . . . . . . . .1 Explanation of the symbols used . . . . . . . . . . . . . . . . . . . . . . . . . . .1 Appropriate use . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1 General safety instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1 Warning about misuse . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2 Exclusion of liability . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2 Product description Ordering code . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2 Special versions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2 Destination and use . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2 Technical data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3 Safety classification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3

Caution: Failure to comply with this warning notice could lead to failures or malfunctions. Warning: Failure to comply with this warning notice could lead to physical injury and/or damages to the machine. 1.4 Appropriate use The products described in these operating instructions are developed to execute safety-related functions as a part of an entire plant or machine. It is the responsibility of the manufacturer of a machine or plant to ensure the proper functioning of the entire machinery or plant. The safety switchgear must be exclusively used in accordance with the versions listed below or for the applications authorised by the manufacturer. Detailled information regarding the range of application can be found in the chapter Product description. 1.5 General safety instructions The user must observe the safety instructions in this operating instructions manual, the country-specific installation standards as well as all prevailing safety regulations and accident prevention rules. Further technical information can be found in the Schmersal catalogues or in the online catalogue on the Internet: www. schmersal.net. The information contained in this operating instructions manual is provided without liability. Subject to technical modifications. If multiple safety components are wired in series, the Performance Level to EN ISO 13849-1 will be reduced due to the restricted error detection under certain circumstances. The entire concept of the control system, in which the safety component is integrated, must be validated to EN ISO 13849-2. There are no residual risks, provided that the safety instructions as well as the instructions regarding mounting, commissionning, operation and maintenance are observed.

3 Mounting 3.1 General mounting instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3 3.2 Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3 4 Electrical connection 4.1 General information for the electrical connection. . . . . . . . . . . . . . . 3 4.2 Contact variants . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3 5 Set-up and maintenance 5.1 Functional testing. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4 5.2 Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4 6 Disassembly and disposal 6.1 Disassembly. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4 6.2 Disposal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4 7 Appendix 7.1 EC Declaration of conformity . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

x.000 / v.A. / 12.2009 / BZ-Nr. 50162-16V900 / Teile-Nr. 1173667-EN / Ausgabe J

EN

Operating Instructions Solenoid interlock

1.6 Warning about misuse In case of inadequate or improper use or manipulations of the safety switchgear, personal hazards or damages to machinery or plant components cannot be excluded. The relevant requirements of the standard EN 1088 must be observed. 1.7 Exclusion of liability We shall accept no liability for damages and malfunctions resulting from defective mounting or failure to comply with this operating instructions manual. The manufacturer shall accept no liability for damages resulting from the use of unauthorised spare parts or accessories. For safety reasons, invasive work on the device as well as arbitrary repairs, conversions and modifications to the device are strictly forbidden; the manufacturer shall accept no liability for damages resulting from such invasive work, arbitrary repairs, conversions and/or modifications to the device. 2 Product description 2.1 Ordering code This operating instructions manual applies to the following types: AZM 161 - K-- No. Option Description CC Cage clamps SK Screw terminals ST M12 x 1 connector 11/03 1NO/4NC with connector 11/12 2NO/3NC with connector 12/03 1NO/5NC 12/11 2NO/3NC with connector 12/12 2NO/4NC Latching force 5 N R Latching force 30 N Power to unlock A Power to lock Lateral manual release ED cover-side EU rear T Emergency exit lateral TD cover-side TU rear N Emergency release 024 Us 24 VAC/DC 110/230 Us 110/230 VAC

AZM 161../.

Interlocks with power to lock principle may only be used in special cases after a thorough evaluation of the accident risk, since the safety guard can be opened immediately on failure of the power supply or upon activation of the main switch. Manual release (for set-up, maintenance, etc.) The manual release is realised by turning the triangular key (M5 triangular key available as accessory), so that the locking bolt is pulled into unlocking position. The normal locking function is only restored after the triangular key has been returned to its original position. After its putting into operation, the manual release must be secured by installing the plastic cover, which is included in delivery. Lateral manual release Manual release on the cover side or on the rear side (ordering suffix -ED/-EU)

Emergency release (mounting only on the outside of the safety guard) To realise an emergency release, turn the orange lever in the direction shown by the arrow until it hits the end stop. In this position, the safety guard can be opened. The lever is latched and cannot be turned back. To cancel the blocked position, the central fixing screw must be unscrewed until the blocked position is neutralised. Return the lever to its original position and firmly retighten the screw. Emergency release (ordering suffix -N)

Only if the conversions described in this operating instructions manual are realised correctly, the safety function and therefore the compliance with the Machinery Directive is maintained. 2.2 Special versions For special versions, which are not listed in the order code below 2.1, these specifications apply accordingly, provided that they correspond to the standard version. 2.3 Destination and use The solenoid interlock AZM 161 has been designed to prevent, in conjunction with the control part of a machine, movable safety guards from being opened before hazardous conditions have been eliminated.

Emergency exit (fitting and actuation only from within the hazardous area) To realise an emergency exit for model T, turn the orange lever in the direction shown by the arrow until it hits the end stop. For the versions TD and TU, the emergency exit is realised by pushing the red latching pushbutton. In this position, the safety guard can be opened. The blocked position is canceled by turning the lever in the opposite direction or by pulling out the pushbutton. In unlocked condition, the safety guard is protected against unintentional closing. Lateral emergency exit (ordering suffix -T) Emergency exit on the cover side or on the rear side (ordering suffix -TD/-TU)

EN

Operating Instructions Solenoid interlock

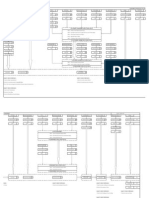

2.4 Technical data Standards: Enclosure: Actuator and locking bolt: Contact material: Protection class: Contact types: Switching system: Positive break travel (unlocked): Positive break force (unlocked): Termination: Cable type: Cable section: Cable entry: Fmax: Latching force: Actuating speed: Actuating frequency: Mechanical life: Ambient temperature: Electrical data: Utilisation category: Ie/Ue: Uimp: Ui : Ithe: U s: Magnet: Power consumption: Max. fuse rating: IEC/EN 60947-5-1; EN ISO 13849-1; EN 1088; BG-GS-ET-19 glass-fibre reinforced thermoplastic, selfextinguishing stainless steel 1.4301 Silver IP 67 change-over contact with double break, type Zb, with galvanically separated contact bridges A to IEC 60947-5-1; slow action, positive break NC contact 10 mm each NC contact 10 N Screw terminals or cage clamps or connector flexible min. 0.25 mm2, max. 1.5 mm2 (including conductor ferrules) 4 x M16 x 1.5 2000 N 30 N for ordering suffix R max. 2 m/s max. 1000 operations / h > 1 million operations 25 C + 60 C AC-15, DC-13 4 A / 230 VAC; 2.5 A / 24 VDC M12 connector, 8 poles: 2 A / 24 VDC Connector, 4 poles: 4 kV Connector, 8 poles: 0.8 kV Connector, 4 poles: 250 V Connector, 8 poles: 60 V Connector, 4 poles: 6 A Connector, 8 poles: 2 A 24 VAC / DC 110 / 230 VAC 100 % ED max. 10 W 6 A gG D-fuse 3.2 Dimensions All measurements in mm.

AZM 161../.

20

32 72

18

22,5

26

30

28 26 130

4 Electrical connection 4.1 General information for the electrical connection The electrical connection may only be carried out by authorised personnel in de-energised condition. At least one magnetic contact with positive break A must be integrated in the safety circuit.

104

For the cable entry, suitable cable glands with an appropriate degree of protection must be used. The thin walls of the mounting holes are removed when the cable gland is screwed in. 4.2 Contact variants Contacts shown in de-energised condition and with the actuator inserted

2.5 Safety classification Standards: B10d (NC contact): Service life:

MTTFd B10d 0,1 x nop nop

EN ISO 13849-1 2,000,000 20 years

d op x h op x 3600 s/h t cycle

Power to unlock

Power to lock

A1 51 71 63

A1 51 71 63

Q

A2 52 72 64 A2 52 72 64

P Q

13 21 41 14 22 42

(Specifications can vary depending on the application-specific parameQ ters hop, dop and tcycle as well as the load.) 72 A1 13 14 21 22 41 42 51 52 63 64A271 5272 64 A2 13 14 21 22 41 42 51 52 63 64 71 72 A1 A2 13 14 AZM 161SK-12/12... 22 21 Q 41 42 AZM 161CC-12/12... 3 Mounting 13 14 21 22 41 42 51 52 63 64 71 72 A1 A2 3.1 General mounting instructions Three mounting holes are provided for fixing the enclosure. The solenoid interlock is double insulated. The use of a protective ground wire therefore is not authorised. The solenoid interlock must not be used as end stop. Any mounting position, provided that the ingression of course dirt in the used opening is avoided. Unused actuator openings must be sealed with slot sealing plugs. Please observe the remarks of the standards EN ISO 12100, EN 953 and EN 1088. EN 3

13 21 41

14 22 42

A1 51 71 63

30

6 25

90

Operating Instructions Solenoid interlock

Power to unlock Power to lock AZM 161ST-12/03...G

21 41 11 YE +24 VDC 63 YE 64 52 72 GN 51 71

AZM 161../.

A1 51 71 63 A2 52 72 64 11 21 41 12 22 42

A1 51 71 63

A1 51 71 63 A2 52 72 64

22 42 12

11 21 41

12 22 42

72 A1 11 12 21 22 41 42 51 52 63 64A2 71 5272 64 A2 11 12 21 22 41 42 51 52 63 64 71 72 A1 A2 13 14 AZM 161SK-12/03... 22 21 Q 41 42 AZM 161CC-12/03... 13 14 21 22 41 42 51 52 63 64 71 72 A1 A2

12 11 21 22 41 42 51 52 63 64 71 72 A1 A2

AZM 161ST-../.. with connector AZM 161ST-12/11...

13 14 21 22 41 42 51 52 63 64 71 72 A1 A2

Legend 12 guard closed 11 +24 VDC 63 0 VDC 64 unlocked AZM 161ST-11/12...

13 14 21 22 41 42 51 52 63 64 71 72 A1 A2

System condition

Solenoid control Power to unlock Power to lock

LED yellow actuator yellow magnet

Contacts

green LED

green LED

21-22

41-42

63-64

51-52 on

1 234

1 234

AZM 161 11/12

Guard open Guard closed, actuator inserted (not locked) Guard closed, actuator inserted and locked

24 V 24 V

0V 0V

on

on

on

on on

AZM 161ST-11/03... AZM 161 12/11

11 12 21 22 41 42 51 52 63 64 71 72 A1 A2

0V

24 V

on

on

on

LED on

1 234

LED off

AZM 161...-G with LED The contacts are shown in closed and locked condition. AZM 161ST-12/12...G

21 41 13 YE 22 42 14 +24 VDC 63 YE 64 52 72 GN 51 71

5 Set-up and maintenance 5.1 Functional testing The safety function of the safety components must be tested. The following conditions must be previously checked and met: 1. Fitting of the solenoid interlock and the actuator 2. Check the integrity of the cable entry and connections 3. Check the switch enclosure for damages 5.2 Maintenance A regular visual inspection and functional test, including the following steps, is recommended: 1. Check for tight installation of the actuator and the switch 2. Remove particles of dust and soiling 3 Check cable entry and connections Damaged or defective components must be replaced. 6 Disassembly and disposal

14 13 21 22 41 42 51 52 63 64 71 72 A1 A2

Legend 14 guard open 13 +24 VDC 63 0 VDC 64 unlocked

System condition Solenoid control Power to unlock Power to lock LED yellow actuator yellow magnet Contacts

green LED

green LED

6.1 Disassembly The safety sensor must be disassembled in de-energised condition only.

13-14 63-64 51-52 71-72

21-22

41-42

Guard open Guard closed, actuator inserted (not locked) Guard closed, actuator inserted and locked

24 V 24 V

0V 0V

on

on

on

on on

6.2 Disposal The safety switchgear must be disposed of in an appropriate manner in accordance with the national prescriptions and legislations.

0V

24 V

on

on

on

on

LED on

LED off

EN

71-72 on

11-12

Operating Instructions Solenoid interlock

7 Appendix

AZM 161../..

7.1 EC Declaration of conformity

EC Declaration of conformity

Translation of the original declaration of conformity

valid as of December 29, 2009

K.A. Schmersal GmbH Industrielle Sicherheitsschaltsysteme Mddinghofe 30 42279 Wuppertal Germany Internet: www.schmersal.com

We hereby certify that the hereafter described safety components both in its basic design and construction conforms to the applicable European Directives Name of the safety component: AZM 161

Description of the safety component:

Interlocking device with electromagnetic interlock for safety functions

Harmonised EC-Directives:

2006/42/EC EC-Machinery Directive 04/108/ EC EMC-Directive Ulrich Loss Mddinghofe 30 42279 Wuppertal

Person authorized for the compilation of the technical dokumentation:

Place and date of issue:

Wuppertal, September 9, 2009

AZM 161-C-EN

Authorised signature

Heinz Schmersal

Managing Director

Note The currently valid declaration of conformity can be downloaded from the internet at www.schmersal.net.

EN

K. A. Schmersal GmbH Industrielle Sicherheitsschaltsysteme Mddinghofe 30, D - 42279 Wuppertal Postfach 24 02 63, D - 42232 Wuppertal Telefon Telefax E-Mail: Internet: +49 - (0)2 02 - 64 74 - 0 +49 - (0)2 02 - 64 74 - 1 00 info@schmersal.com http://www.schmersal.com

Anda mungkin juga menyukai

- Shoe Dog: A Memoir by the Creator of NikeDari EverandShoe Dog: A Memoir by the Creator of NikePenilaian: 4.5 dari 5 bintang4.5/5 (537)

- The Yellow House: A Memoir (2019 National Book Award Winner)Dari EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Penilaian: 4 dari 5 bintang4/5 (98)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDari EverandNever Split the Difference: Negotiating As If Your Life Depended On ItPenilaian: 4.5 dari 5 bintang4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDari EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RacePenilaian: 4 dari 5 bintang4/5 (890)

- Grit: The Power of Passion and PerseveranceDari EverandGrit: The Power of Passion and PerseverancePenilaian: 4 dari 5 bintang4/5 (587)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDari EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifePenilaian: 4 dari 5 bintang4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingDari EverandThe Little Book of Hygge: Danish Secrets to Happy LivingPenilaian: 3.5 dari 5 bintang3.5/5 (399)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDari EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FuturePenilaian: 4.5 dari 5 bintang4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDari EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryPenilaian: 3.5 dari 5 bintang3.5/5 (231)

- The Emperor of All Maladies: A Biography of CancerDari EverandThe Emperor of All Maladies: A Biography of CancerPenilaian: 4.5 dari 5 bintang4.5/5 (271)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDari EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersPenilaian: 4.5 dari 5 bintang4.5/5 (344)

- On Fire: The (Burning) Case for a Green New DealDari EverandOn Fire: The (Burning) Case for a Green New DealPenilaian: 4 dari 5 bintang4/5 (73)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDari EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaPenilaian: 4.5 dari 5 bintang4.5/5 (265)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDari EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyPenilaian: 3.5 dari 5 bintang3.5/5 (2219)

- Team of Rivals: The Political Genius of Abraham LincolnDari EverandTeam of Rivals: The Political Genius of Abraham LincolnPenilaian: 4.5 dari 5 bintang4.5/5 (234)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDari EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You ArePenilaian: 4 dari 5 bintang4/5 (1090)

- Rise of ISIS: A Threat We Can't IgnoreDari EverandRise of ISIS: A Threat We Can't IgnorePenilaian: 3.5 dari 5 bintang3.5/5 (137)

- The Unwinding: An Inner History of the New AmericaDari EverandThe Unwinding: An Inner History of the New AmericaPenilaian: 4 dari 5 bintang4/5 (45)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Dari EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Penilaian: 4.5 dari 5 bintang4.5/5 (119)

- Her Body and Other Parties: StoriesDari EverandHer Body and Other Parties: StoriesPenilaian: 4 dari 5 bintang4/5 (821)

- Internship Report-1Dokumen64 halamanInternship Report-1VIJAY SPBelum ada peringkat

- Introduction To Manufacturing Engineering: Lecturer: Ass - Prof.Dr. Nguyen Tien DuongDokumen14 halamanIntroduction To Manufacturing Engineering: Lecturer: Ass - Prof.Dr. Nguyen Tien DuongTOAN Du100% (1)

- DiGas 4000 Light E 08.02Dokumen2 halamanDiGas 4000 Light E 08.02manit1963Belum ada peringkat

- Structural Analysis of Beams Using Moment Distribution MethodDokumen15 halamanStructural Analysis of Beams Using Moment Distribution MethodneetuBelum ada peringkat

- SSP 099 18 Tfsi 132kw 20 Tfsi 162kw Ea888Dokumen60 halamanSSP 099 18 Tfsi 132kw 20 Tfsi 162kw Ea888Jose Ramón Orenes ClementeBelum ada peringkat

- Udayanandan, Notes On Tensors PDFDokumen56 halamanUdayanandan, Notes On Tensors PDFhristos314Belum ada peringkat

- Process Level ChartDokumen2 halamanProcess Level ChartzaidinBelum ada peringkat

- P613 HW # 2 Solutions for a 2D Electron GasDokumen4 halamanP613 HW # 2 Solutions for a 2D Electron GasRakeshBelum ada peringkat

- UDR MANUFACTURE ManufacturesDokumen8 halamanUDR MANUFACTURE ManufacturesQuadri Consultancy ServicesBelum ada peringkat

- GameBoy Programming ManualDokumen298 halamanGameBoy Programming Manualdiceman2037100% (4)

- Construction Companies in IndiaDokumen11 halamanConstruction Companies in Indiashobhit.goel33% (3)

- Android Tutorial - Broadcast ReceiversDokumen15 halamanAndroid Tutorial - Broadcast ReceiversTrieu Ngo HuyBelum ada peringkat

- Vernier, Dial, and Electronic Digital Calipers: Session 3Dokumen40 halamanVernier, Dial, and Electronic Digital Calipers: Session 3Emman Bosito100% (1)

- Vismat Material V-Ray For SketchupDokumen19 halamanVismat Material V-Ray For SketchupAmer GonzalesBelum ada peringkat

- STP of Ethifen SyrupDokumen5 halamanSTP of Ethifen SyrupBejoy KarimBelum ada peringkat

- Product Catalog: Ipe ProfilesDokumen2 halamanProduct Catalog: Ipe ProfilesGokul royalveritasBelum ada peringkat

- Metronidazole AnalysisDokumen5 halamanMetronidazole AnalysisHendri WasitoBelum ada peringkat

- IPE 401-Drive SystemDokumen16 halamanIPE 401-Drive SystemElmerBelum ada peringkat

- Rectify Binary Plate Efficiency BubblesDokumen4 halamanRectify Binary Plate Efficiency BubblesCsaba AndrásBelum ada peringkat

- Stoichiometry - Determination of Percent by Mass of NaHCO3 in Alka Seltzer TabletsDokumen6 halamanStoichiometry - Determination of Percent by Mass of NaHCO3 in Alka Seltzer Tabletsgabbal009Belum ada peringkat

- Elective-II: Pavement Analysis & Design: B.E. (Civil Engineering) Eighth Semester (C.B.S.)Dokumen6 halamanElective-II: Pavement Analysis & Design: B.E. (Civil Engineering) Eighth Semester (C.B.S.)Adesh DeshbhratarBelum ada peringkat

- BRAY SERIES 4X HIGH PERFORMANCE BRAY-McCANNLOCK VALVES - Technical ManualDokumen28 halamanBRAY SERIES 4X HIGH PERFORMANCE BRAY-McCANNLOCK VALVES - Technical ManualLuis Daniel ContrerasBelum ada peringkat

- Flyer M 10id 12 ENDokumen2 halamanFlyer M 10id 12 ENTrevor SalazarBelum ada peringkat

- Instructions For Installation, Operating and Maintenance InstructionDokumen30 halamanInstructions For Installation, Operating and Maintenance InstructionmilacronBelum ada peringkat

- Messerschmitt Me 262 - Wikipedia, The Free Encyclopedia3Dokumen5 halamanMesserschmitt Me 262 - Wikipedia, The Free Encyclopedia3beta2009Belum ada peringkat

- What Is A Gantt Chart - Gantt Chart Information, History and SoftwareDokumen3 halamanWhat Is A Gantt Chart - Gantt Chart Information, History and SoftwareShaikh Saeed AlamBelum ada peringkat

- Stop Motion Pre Production - Negotiated BriefDokumen10 halamanStop Motion Pre Production - Negotiated Briefp4nd3m0n1c100% (1)

- Phase Diagrams IntroductionDokumen76 halamanPhase Diagrams IntroductionGikiTopiBelum ada peringkat

- SLTRT Service Level Testing Reporting ToolDokumen110 halamanSLTRT Service Level Testing Reporting ToolChedli Dhouibi50% (2)

- Physicaltestingofrubberrogerbrown2006 Book 150514103634 Lva1 App6892Dokumen389 halamanPhysicaltestingofrubberrogerbrown2006 Book 150514103634 Lva1 App6892AbdelhamidHarratBelum ada peringkat