8D

Diunggah oleh

RedBeatDeskripsi Asli:

Hak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

8D

Diunggah oleh

RedBeatHak Cipta:

Format Tersedia

Tracking Number:

Customer Number:

Response Due Date:

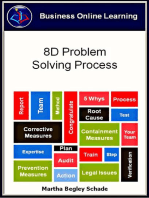

8-D is a quality management tool and is a vehicle for a cross-functional team to articulate thoughts and provides scientific determination to details of problems and provide solutions. Organizations can benefit from the 8-D approach by applying it to all areas in the company. The 8-D provides excellent guidelines allowing us to get to the root of a problem and ways to check that the solution actually works. Rather than healing the symptom, the illness is cured, thus, the same problem is unlikely to recur.

Step Actio n 0 The Planning Stage 1 Establishi ng the Team 2 Problem Definition / Statement & Descriptio n 3 Developing Interim Containme nt Action 4 Identifyin g& Verifying Root Cause 5 Identifying Permanen t Corrective Actions (PCA) 6 Implemen ti n g & V al i d a ti n g P C A 7 Preventin g Recurrenc e 8 Recognizi ng Team Efforts

8D :: Problem Solving Worksheet

The Planning Stage:

The 8-D method of problem solving is appropriate in "cause unknown" situations and is not the right tool if concerns center solely on decision-making or problem prevention. 8-D is especially useful as it results in not just a problem-solving process, but also a standard and a reporting format. Does this problem warrant/require an 8D? If so comment why and proceed.

Is an Emergency Response Action Needed?

(If needed document actions in Action Item Table)

Establishing the Team:

Team Goals: Team Objectives: Skills Responsibility

Establish a small group of people with the process/ product knowledge, allocated time, authority and skill in the required technical disciplines to solve the problem and implement corrective actions. Department Name

Problem Definition

2A

Provides the starting point for solving the problem or nonconformance issue. Need to have correct problem description to identify causes. Need to use terms that are understood by all.

Part Number(s): Customer(s): List all of the data and documents that might help you to define the problem more exactly? Action Plan to collect additional information:

Sketch / Photo of Problem

Prepare Process Flow Diagram for problem use a separate sheet if needed

Page 1 of 6

8D :: Problem Solving Worksheet

2B

IS

Who is affected by the problem? Who first observed the problem? To whom was the problem reported?

IS NOT

Who is not affected by the problem? Who did not find the problem?

Who

What type of problem is it? What has the problem (part id, lot #s, etc)?

What does not have the problem? What could be happening but is not? What could be the problem but is not?

What

What is happening with the process & with containment? Do we have physical evidence of the problem? Why is this a problem (degraded performance)?

Why is it not a problem?

Why

Is the process stable?

Where was the problem observed?

Where could the problem be located but is not? Where else could the problem be located but is not?

Where

Where does the problem occur?

When was the problem first noticed?

When could the problem have been noticed but was not?

When

When has it been noticed since?

How Much/ Many

Quantity of problem (ppm)? How much is the problem costing in dollars, people, & time?

How many could have the problem but dont? How big could the problem be but is not?

How Often

What is the trend (continuous, random, cyclical)? Has the problem occurred previously?

What could the trend be but is not?

Problem Description

(based on the information gathered so far, provide a concise problem description)

2C

Page 2 of 6

8D :: Problem Solving Worksheet

Developing Interim Containment Actions

Temporary actions to contain the problem and fix until permanent correction is in place - document actions in Action Item Table

Identifying & Verifying Root Cause

Analyze for Root Cause of the problem. Identify and verify the Escape Point

4A

Brainstorm the possible causes of the problem

Cause and Effect Diagram 4A How is it made?

Why did it get out? Machine Problem People Materials Machine

People

Materials

Method

Environment

Measurement

Method

Environment

Measurement

circle the most likely contributors (a maximum of three) from each side.

4B

5 Why Analysis

Ask Why did this happen?

Ask Why did this happen?

Ask Why did this happen?

Ask Why did this happen?

Ask Why did this happen?

Action Plan

Based on the teams discussions. Begin to complete the Root Cause Action Plan to verify and validate the root causes and test the escape point. Document this on the Action Item Table

4C

Page 3 of 6

8D :: Problem Solving Worksheet

5

Identify Permanent Corrective Actions

solutions that address and correct the root cause. Solutions determined to be the best of all the alternatives. Document and verify the Permanent Corrective Action (PCA) in the Action Item Table

Implementing & Validating the PCA

Implement and validate to ensure that corrective action does what it is supposed to do. Detect any undesirable side effects. Document this on the Action Item Table. Return to root cause analysis, if necessary

Preventing Recurrence

determine what improvements in systems and processes would prevent problem from recurring. Ensure that corrective action remains in place and successful

7A

Address Similar Systems

Process / Item

Who Responsible

When

Page 4 of 6

8D :: Problem Solving Worksheet

7B

Review the following documents / systems

Completion Date Planned Actual

Document Management System Manual Manufacturing Work Instructions Inspection Work Instructions Process Flow Charts Process Control Plans Design FMEA Process FMEA Gages PPAP Engineering Change Approval

Who Responsible

Congratulate Your Team

Use all forms of employee recognition and document as necessary

Celebrate successful conclusion of the problem solving effort

Formally disengage the team and return to normal duties

Was this problem solving exercise effective? Has it been verified with a follow-up?

Yes No Signature / Title / Date Findings

Page 5 of 6

8D :: Problem Solving Worksheet

Action Item Table Actions

Action # Problem Containment / Corrective Action

Implement & Verify Actions

How Verified Action Who Responsible Planned Actual Status

Page 6 of 6

Anda mungkin juga menyukai

- Introduction to 8D Problem Solving: Including Practical Applications and ExamplesDari EverandIntroduction to 8D Problem Solving: Including Practical Applications and ExamplesBelum ada peringkat

- 8D:: Problem Solving Worksheet: The Planning StageDokumen6 halaman8D:: Problem Solving Worksheet: The Planning StagePaula AlviorBelum ada peringkat

- 8D Problem Solving TemplateDokumen6 halaman8D Problem Solving TemplateLinda HansenBelum ada peringkat

- 8D TemplateDokumen7 halaman8D Templatemuhammad_mmd100% (1)

- Problem Solving WorksheetDokumen6 halamanProblem Solving WorksheetAlfredo Jimenez Charles100% (1)

- 8D Problem Solving MethodDokumen8 halaman8D Problem Solving MethodspahicdaniloBelum ada peringkat

- Troubleshooting and Root Cause Failure Analysis: Equipment Problem SolvingDari EverandTroubleshooting and Root Cause Failure Analysis: Equipment Problem SolvingPenilaian: 4.5 dari 5 bintang4.5/5 (3)

- 8D Problem Solving Excel WorksheetDokumen6 halaman8D Problem Solving Excel WorksheetecdtcenterBelum ada peringkat

- 8D Problem SolvingDokumen6 halaman8D Problem SolvingMihai CanaBelum ada peringkat

- Computer Emergency Response Team A Complete Guide - 2020 EditionDari EverandComputer Emergency Response Team A Complete Guide - 2020 EditionBelum ada peringkat

- Problem Solving WorksheetDokumen9 halamanProblem Solving WorksheetCraigBelum ada peringkat

- 8D FormDokumen12 halaman8D Formvu tuan anhBelum ada peringkat

- 8DDokumen8 halaman8DRomie CubalBelum ada peringkat

- Crisis Incident Management Software A Complete Guide - 2020 EditionDari EverandCrisis Incident Management Software A Complete Guide - 2020 EditionBelum ada peringkat

- 8D Form - LongDokumen6 halaman8D Form - LongmaofireBelum ada peringkat

- 8D Problem Solving Worksheet - Long FormDokumen6 halaman8D Problem Solving Worksheet - Long FormDaniela Claudia MogaBelum ada peringkat

- 8D Problem SolvingDokumen7 halaman8D Problem SolvingLokesh Narasimhaiah100% (1)

- Computer Emergency Readiness Team A Complete Guide - 2020 EditionDari EverandComputer Emergency Readiness Team A Complete Guide - 2020 EditionBelum ada peringkat

- Systematic Problem Solving - Radu BotoganDokumen19 halamanSystematic Problem Solving - Radu BotoganIonut EduardBelum ada peringkat

- VDA Volume 4 8D-MethodDokumen23 halamanVDA Volume 4 8D-MethodJuan Egara100% (8)

- 8D Problem-Solving Worksheet Project TrackingDokumen3 halaman8D Problem-Solving Worksheet Project TrackingManish ChristianBelum ada peringkat

- Problem Solving - 8disciple Approach (QMS)Dokumen22 halamanProblem Solving - 8disciple Approach (QMS)marlou malabananBelum ada peringkat

- PowerPoint - Problem SolvingDokumen74 halamanPowerPoint - Problem SolvingRonny Tampake100% (1)

- 8D:: Problem Solving Worksheet: Tracking Number: Customer Number: Response Due DateDokumen8 halaman8D:: Problem Solving Worksheet: Tracking Number: Customer Number: Response Due DatePawel WeilBelum ada peringkat

- 8D Form - LongDokumen7 halaman8D Form - LongManoj IllangasooriyaBelum ada peringkat

- Chapter 4-5Dokumen81 halamanChapter 4-5Uves AnsariBelum ada peringkat

- History of 8DDokumen7 halamanHistory of 8DHanieft Nd100% (1)

- 8D Methodology Typical StepsDokumen23 halaman8D Methodology Typical StepsArvind Antony100% (1)

- 8D Process: D0: Prepare For Problem SolvingDokumen4 halaman8D Process: D0: Prepare For Problem SolvingBoby SaputraBelum ada peringkat

- 8D SorularıDokumen3 halaman8D SorularıAdnan KaraerBelum ada peringkat

- Problem Solving Model - 207Dokumen6 halamanProblem Solving Model - 207Cristina GomezBelum ada peringkat

- 8D Corrective Action & Root Cause AnalysisDokumen95 halaman8D Corrective Action & Root Cause AnalysisRawendrraw KuriBelum ada peringkat

- Educational Research (0837) Semester:-Autumn, 2020 Ma (Teacher Education) Assingnment # 2Dokumen26 halamanEducational Research (0837) Semester:-Autumn, 2020 Ma (Teacher Education) Assingnment # 2ZebiButtBelum ada peringkat

- Fix Lean Six Sigma ProblemsDokumen7 halamanFix Lean Six Sigma ProblemsShaheen GulamaniBelum ada peringkat

- 03 - Use of Problem Resolution A3 ModelDokumen4 halaman03 - Use of Problem Resolution A3 ModelJaison LanskiBelum ada peringkat

- ProblemSolving Strategic Plan ReportDokumen2 halamanProblemSolving Strategic Plan ReportKhaled Naseem Abu-SabhaBelum ada peringkat

- Case Analysis Model in 4 StagesDokumen10 halamanCase Analysis Model in 4 StagesRekininternetuBelum ada peringkat

- 8D Work Instructions Rev. A 74FPUR13Dokumen1 halaman8D Work Instructions Rev. A 74FPUR13Boukalmoune IbrahimBelum ada peringkat

- Problem Solving WorksheetDokumen7 halamanProblem Solving WorksheetRaajha MunibathiranBelum ada peringkat

- Pareto Analysis: Using The 80:20 Rule To PrioritizeDokumen6 halamanPareto Analysis: Using The 80:20 Rule To PrioritizeMarjorie España - CamachoBelum ada peringkat

- Introduction To Eight Disciplines of Problem Solving (8D)Dokumen9 halamanIntroduction To Eight Disciplines of Problem Solving (8D)Prasenjit PuriBelum ada peringkat

- Decision Making Problem SolvingDokumen114 halamanDecision Making Problem SolvingwaleedjuttBelum ada peringkat

- Root Cause Analysis Corrective ActionDokumen12 halamanRoot Cause Analysis Corrective ActionAbdulrahman Alkhowaiter100% (2)

- Problem Solving HandoutDokumen13 halamanProblem Solving Handoutabhijit biswasBelum ada peringkat

- Improving Software QualityDokumen6 halamanImproving Software QualityqabalamuraliBelum ada peringkat

- Module 1 RCADokumen85 halamanModule 1 RCACrizzie Mae Aczon PalejoBelum ada peringkat

- Problem Statement - WikipediaDokumen12 halamanProblem Statement - WikipediagumilaokrisselBelum ada peringkat

- Improvement Initiatives Presents: Team-Oriented Problem SolvingDokumen44 halamanImprovement Initiatives Presents: Team-Oriented Problem SolvingCARPENTIERIMAZZABelum ada peringkat

- Basic Problem SolvingDokumen26 halamanBasic Problem SolvingSiti Nur HamizahBelum ada peringkat

- Entrenamiento 8DDokumen23 halamanEntrenamiento 8DRene DurandBelum ada peringkat