Atv71 Controller Inside en v3

Diunggah oleh

Juan Rodriguez ArevaloHak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

Atv71 Controller Inside en v3

Diunggah oleh

Juan Rodriguez ArevaloHak Cipta:

Format Tersedia

Altivar 61 / 71

"Controller Inside" Card VW3 A3 501

User's manual

Retain for future use

Sommaire

Before you begin_____________________________________________________________________________________________ 4 Documentation structure_______________________________________________________________________________________ 5 Introduction _________________________________________________________________________________________________ Presentation _____________________________________________________________________________________________ Description ______________________________________________________________________________________________ Dialog __________________________________________________________________________________________________ Master CANopen communication _____________________________________________________________________________ Communication with a PLC _________________________________________________________________________________ Clock___________________________________________________________________________________________________ Programming ____________________________________________________________________________________________ 6 6 6 7 7 7 8 8

Hardware setup _____________________________________________________________________________________________ 9 Receipt _________________________________________________________________________________________________ 9 Installing the card in the drive ________________________________________________________________________________ 9 Description of terminals ___________________________________________________________________________________ 10 Characteristics __________________________________________________________________________________________ 11 Schemes_______________________________________________________________________________________________ 12 Connection to a CANopen bus ______________________________________________________________________________ 13 Example of connection to a CANopen bus _____________________________________________________________________ 14 Connecting the "Controller Inside" card to a PC_________________________________________________________________ 15 Data backup battery ______________________________________________________________________________________ 16 Configuration ______________________________________________________________________________________________ 17 Configuring the switches___________________________________________________________________________________ 17 Diagnostics ________________________________________________________________________________________________ LEDs __________________________________________________________________________________________________ I/O monitoring ___________________________________________________________________________________________ Card fault ______________________________________________________________________________________________ 18 18 19 20

Operation using the graphic display terminal ______________________________________________________________________ 21 Factory-loaded program ___________________________________________________________________________________ 21 Example of a special program ______________________________________________________________________________ 23 Operation using the integrated display terminal ____________________________________________________________________ 24 Factory-loaded program ___________________________________________________________________________________ 24 Special program _________________________________________________________________________________________ 24

While every precaution has been taken in the preparation of this document, Schneider Electric SA assumes no liability for any omissions or errors it may contain, nor for any damages resulting from the application or use of the information herein. The products and options described in this document may be changed or modified at any time, either from a technical point of view or in the way they are operated. Their description can in no way be considered contractual.

Before you begin

Read and understand these instructions before performing any procedure on this drive.

DANGER

HAZARDOUS VOLTAGE

Read and understand the Installation manual before installing or operating the Altivar 61 / 71 drive. Installation, adjustment, repair, and maintenance must be performed by qualified personnel. The user is responsible for compliance with all international and national electrical standards in force concerning protective grounding of all equipment. Many parts of this variable speed drive, including the printed circuit boards, operate at the line voltage. DO NOT TOUCH. Use only electrically insulated tools. DO NOT touch unshielded components or terminal strip screw connections with voltage present. DO NOT short across terminals PA and PC or across the DC bus capacitors. Install and close all the covers before applying power or starting and stopping the drive. Before servicing the variable speed drive - Disconnect all power - Place a DO NOT TURN ON label on the variable speed drive disconnect - Lock the disconnect in the open position Disconnect all power including external control power that may be present before servicing the drive. WAIT 15 MINUTES to allow the DC bus capacitors to discharge. Then follow the DC bus voltage measurement procedure given in the installation manual to verify that the DC voltage is less than 45 VDC. The drive LEDs are not accurate indicators of the absence of DC bus voltage. Electric shock will result in death or serious injury.

CAUTION

DAMAGED EQUIPMENT

Do not install or operate any drive that appears damaged. Failure to follow this instruction can result in equipment damage.

Documentation structure

Installation manual

This manual describes: Assembly How to connect the drive

Programming manual

This manual describes: The functions The parameters How to use the drive display terminal (integrated display terminal and graphic display terminal)

Communication parameters manual

This manual describes: The drive parameters with specific information (addresses, formats, etc) for use via a bus or communication network The operating modes specific to communication (state chart) The interaction between communication and local control

Modbus, CANopen, Ethernet, Profibus, INTERBUS, Uni-Telway, DeviceNet, Modbus Plus, FIPIO manuals ...

These manuals describe: Connection to the bus or network Configuration of the communication-specific parameters via the integrated display terminal or the graphic display terminal Diagnostics Software setup The communication services specific to the protocol

Altivar 58/58F compatibility manual

This manual describes the differences between the Altivar 71 and the Altivar 58/58F. It explains how to replace an Altivar 58 or 58F, including how to replace drives communicating on a bus or network.

Altivar 38 compatibility manual

This manual describes the differences between the Altivar 61 and the Altivar 38. It explains how to replace an Altivar 38, including how to replace drives communicating on a bus or network.

Introduction

Presentation

The Controller Inside programmable card is used to adapt the variable speed drive to specific applications by integrating control system functions. Various predefined configurable applications are sold by Telemecanique and its partners. The PS 1131 software workshop for PC is used for programming and debugging new applications, quickly and in an open-ended manner. It is not possible to transfer the program from the card to the PC, which enables us to protect our know-how. Only one Controller Inside programmable card can be installed in the Altivar 61 or Altivar 71 drive. It can be combined with another option card (I/O extension or communication). Consult the tables summarizing the possible combinations: drives, options and accessories, see catalogue. The Controller Inside programmable card has: 10 logic inputs, 2 of which can be used for 2 counters or 4 of which can be used for 2 incremental encoders 2 analog inputs 6 logic outputs 2 analog outputs A master port for the CANopen bus A PC port for programming with the PS 1131 software workshop If the power consumption table does not exceed 200 mA, this card can be powered by the drive. Otherwise, an external 24 V c power supply must be used. The Controller Inside programmable card can also use: The drive I/O The I/O extension card I/O The encoder interface card points counter The drive parameters (speed, current, torque, etc)

Description

5 6 1 RJ45 connector for connecting the PS 1131 software workshop via an RS 485 serial link. Connection to the PC is via a cable and an RS 232/RS 485 converter included in the PowerSuite for PC connection kit, VW3 A8 106. 4 2 9-way male SUB-D connector for connection to the CANopen bus. 3 Connector with removable screw terminals, 6 contacts at intervals of 3.81 for the 24 V c power supply and 4 logic inputs. 4 3 connectors with removable screw terminals, 6 contacts at intervals of 3.81 for 6 logic inputs, 6 logic outputs, 2 analog inputs, 2 analog outputs and 2 commons. 5 5 LEDs, comprising: 1 to indicate the presence of the 24 V c power supply 1 to indicate a program execution fault 2 to indicate the CANopen bus communication status 1 controlled by the application program 6 Block of 4 configuration switches

Introduction

Dialog

ATV 61 / 71 XBT Magelis

Human-machine dialog with the application programmed in the Controller Inside programmable card is possible using: The Altivar 61 / 71 graphic display terminal A Magelis industrial HMI terminal connected to the drive Modbus port A Magelis industrial HMI terminal connected to the Ethernet TCP/IP network (if the drive is equipped with an Ethernet TCP/IP communication card) One graphic terminal menu is dedicated to the Controller Inside programmable card. This menu can be customized by the card program according to the application. Any industrial HMI terminal which supports the Modbus protocol can be used to display and modify the Controller Inside programmable card parameters. The card Modbus server provides access to 2048 Kwords (% MW, etc).

Modbus bus

Sensors

Independent machine with multiwire system

Master CANopen communication

ATV 61 / 71 XBT Magelis

The master CANopen port on the Controller Inside programmable card can be used to extend the I/O capacity (using CANopen I/O modules) and to control other CANopen slave devices.

Modbus bus

CANopen bus

ATV 31

ATV 31

Advantys STB distributed I/O

FTB 1CN

Independent machine with CANopen bus

Communication with a PLC

Premium XBT Magelis

Ethernet TCP/IP network ATV 61 / 71 ATV 61 / 71

The Altivar 61 / 71 drive equipped with a Controller Inside programmable card fits easily into complex architectures. Regardless of which bus or network is being used (Ethernet TCP/IP, Modbus/ Uni-Telway, FIPIO, Modbus Plus, Profibus DP, InterBus, etc), the PLC can communicate with the Controller Inside programmable card and the drive. The periodic variables can still be configured as required.

CANopen bus

Sensors

ATV 31

FTB 1CN

Modular machine with Ethernet TCP/IP network

Introduction

Clock

A clock backed up by a lithium battery makes it possible to have a log of events that have occurred. When the Controller Inside programmable card is installed in the drive, the drive faults are automatically time and date-stamped without special programming.

Programming

In factory settings mode, the "Controller Inside" card only contains the clock function. For other applications, the program must be loaded: By loading an existing program (procedure described in the PS 1131documentation) Or by loading a custom-built program, with the aid of the PS 1131 software workshop, using the function libraries dedicated to programming the "Controller Inside" card. In order to program the "Controller Inside" card, it is necessary to undergo training. The PS1131 CD-Rom contains: This manual, already available on the CD-Rom supplied with each Altivar 61 / 71 The PS 1131 software workshop The online help The standard function library Program examples The Altivar 61 / 71 parameters manual The standard function library contains: Logic functions (AND, OR, etc) Mathematical functions (Cos, Sin, Exp, etc) Functions dedicated to drives which simplify data exchanges between the drive and the "Controller Inside" programmable card (example: sending the speed reference) Functions for managing the CANopen bus Graphic terminal display functions This manual does not describe programming using PS 1131. Note: PS 1131 is also called CoDeSys. CoDeSys V2.2 can be used on the Controller Inside for Altivar 58 (VW3A581131), but must not be used for programming the Controller Inside for Altivar 61 / 71 (VW3 A3 501).

Hardware setup

Receipt

Check that the card catalog number marked on the label is the same as that on the delivery note corresponding to the purchase order. Remove the option card from its packaging and check that it has not been damaged in transit. Check that the product is complete: the packaging should contain the "Controller Inside" option card and its 4 removable terminals.

Installing the card in the drive

See the Altivar 61 / 71 Installation Manual. Note: If a Controller Inside card and an I/O extension card are installed simultaneously: The I/O extension card must be installed on the drive first Then the Controller Inside card must be installed on the I/O extension card

Hardware setup

Description of terminals

AO52 COM A051 AI52 COM AI51 LO56 LO55 LO54 LO53 LO52 LO51 LI60 LI59 LI58 LI57 LI56 LI55

Terminal 24V

Function Power supply for the "Controller Inside" card, logic outputs and analog outputs. If allowed by the power consumption table (for example if outputs are not being used), the "Controller Inside" card can be powered by the 24 V c power supply in the drive. If you are using an external power supply: The "Controller Inside" card should preferably be turned on before the drive. However, the "Controller Inside" card must without fail be turned on no more than 2s after the drive is turned on. Failure to follow this instruction locks the drive in card fault mode (ILF). This fault cannot be reset, and the only way to acknowledge it is to turn off the drive. Catalog number for a Telemecanique power supply (24 V c, 2A): ABL7 RE 24 02.

COM

Common ground and electrical 0V of the "Controller Inside" card power supply, logic inputs, (LIpp), outputs (LOpp), analog inputs (AIpp) and analog outputs (AOpp). This ground and electrical 0V are common with the drive ground and electrical 0V. There is therefore no point in connecting this terminal to the 0V terminal on the drive control terminals.

LI51 to LI60

24 V c logic inputs Inputs LI51 and LI59 can be configured as counter. Inputs LI51 and LI52 can be configured for an incremental encoder (channel A = LI51, channel B = LI52). 24 V c logic outputs 0 ... 20mA analog inputs

LO51 to LO56 AI51 and AI52

AO51 and AO52 0 ... 20mA analog outputs

10

24V COM LI51 LI52 LI53 LI54

Hardware setup

Characteristics

Electrical characteristics

Power Current consumption Voltage Maximum No-load Using logic output Analog inputs AI51, AI52 V A mA mA 24 c (min. 19, max. 30) 2 80 200 maximum (1) 2 current analog inputs 020 mA, impedance 250 Resolution: 8 bits Accuracy: 1% for a temperature variation of 60C Linearity: 0.4% of the maximum value Common point for all the card I/O (2) 2 current analog outputs 020 mA, impedance 500 Resolution: 10 bits Accuracy: 1% for a temperature variation of 60C Linearity: 0.2% of the maximum value Common point for all the card I/O (2) 10 logic inputs, 2 of which can be used for 2 counters or 4 of which can be used for 2 incremental encoders Impedance 4.4 k Maximum voltage: 30 V c Switching thresholds: State 0 if y 5 V or logic input not wired State 1 if u 11 V Common point for all the card I/O (2) Six 24 V c logic outputs, positive logic open collector type (source), compatible with level 1 PLC, standard IEC 65A-68 Maximum switching voltage: 30 V Maximum current: 200 mA Common point for all the card I/O (2) Screw, at intervals of 3.81 mm2 mm2 Nm 1.5 (AWG 16) 0.25 8 years approx.

Analog outputs

AO51, AO52

Logic inputs

LI51LI60

Logic outputs

LO51LO56

I/O connection

Type of contact Maximum wire Tightening torque

Lithium battery

Life

Characteristics of the application program

Compiled program (saved in flash memory) Data Maximum size Maximum size Size accessible by Modbus Kb 320

Kword 64 Kword 2

Saved size (NVRAM) Kword 4

Characteristics of the CANopen communication port

Structure Connector Network management Transmission speed Address (Node ID) Services CANopen application layer Channel config. PDO SDO Error check Other services Configuration Diagnostics Using LEDs One 9-way male SUB-D connector Master Configurable via the program: 50 kbps, 125 kbps, 250 kbps, 500 kbps or 1 Mbps 32 slaves maximum DS 301 V4.02 DSP 405 9 receive and transmit PDOs in total for each slave 2 client SDOs per slave (1 read and 1 write). Block transfer Node Guarding, producer and consumer Heartbeat Emergency, Boot-up, Sync The CANopen network configurator is integrated in the PS1131 software workshop. 2 LEDs: RUN and ERROR, conforming to CIA DR303 version 1.0

(1) If the power consumption table does not exceed 200 mA, this card can be powered by the drive. Otherwise, an external 24 V c power supply must be used. (2) This common point is also the drive 0 V (COM).

11

Hardware setup

Schemes

Card powered by the drive

Only if the power consumption is less than 200 mA; otherwise use an external power supply.

ATV 61/71ppppp VW3 A3 501

SW1

LO5p

LO5p

Source

+ 24 V

0-20 mA 0-20 mA

Card powered by external power supply

VW3 A3 501

AO51

AO52

LO5p

LO5p

COM

COM

COM

24 V

AI51

AI52

LI5p

Sink Ext. Int.

+ 24 V

0V

24 V c supply

0-20 mA 0-20 mA

0-20 mA 0-20 mA

12

COM

24 V

AI51

AI52

LI5p

Hardware setup

Connection to a CANopen bus

Pinout for the CANopen 9-way SUB-D connector

Terminal 1 2 3 4 5 6 7 8 9

Description not connected CAN_L CAN_GND not connected not connected CAN_GND CAN_H not connected not connected

Use a straight connector (catalog number TSX CAN KCDF 180T) to connect the "Controller Inside" card to the CANopen bus. This connector integrates a line terminator that must be activated if the "Controller Inside" card is at one end of the CANopen bus. It is not possible to use an angled connector because of the terminals located to the right of the CANopen connector. The 9-way SUB-D connector on the "Controller Inside" card is linked to the card ground and the drive ground. The shielding must be connected to the connector ground. The CANopen signals on the "Controller Inside" card are isolated.

Speed and length of the CANopen bus

It is essential to make sure that all devices connected to the CANopen bus operate at the same transmission speed. The CANopen transmission speed of the "Controller Inside" card is configured from the PS 1131 software workshop. The maximum length of the CANopen bus depends on the transmission speed on this bus. The table below indicates the maximum lengths permitted according to the transmission speed: Transmission speed Max. length of bus 50 kbps 1000m 125 kbps 500m 250 kbps 200m 500 kbps 100m 1 Mbps 5m

13

Hardware setup

Example of connection to a CANopen bus

Description Altivar 61 / 71 drive equipped with a "Controller Inside" card CANopen connector 9-way female SUB-D connector with line terminator (can be deactivated) 2 CANopen cables can be connected 180 cable outlet CAN-H, CAN-L, CAN-GND connection LSZH CANopen cable CE certified CANopen cable. Low smoke emission, non halogen and flame retardant (IEC 60332-1). UL/IEC332-2 CANopen cable UL certified CANopen cable. Flame retardant (IEC 60332-2).

Reference Length m number

Catalog number ATV61 / 71pppp VW3 A3 501 TSX CAN KCDF 180T

1 2

50 100 300

TSX CAN CA 50 TSX CAN CA 100 TSX CAN CA 300 TSX CAN CB 50 TSX CAN CB 100 TSX CAN CB 300 TSX CAN CD 50 TSX CAN CD 100 TSX CAN CD 300 VW3 CAN TAP 2

50 100 300

LSZH HD flexible CANopen cable CANopen cable for intensive use and moving applications. Flame retardant (IEC 60332-1). Non halogen. Oil resistant. Junction box for CANopen bus 2 RJ45 connectors for connecting 2 drop cables VW3 CAN CA RRpp 1 RJ45 connector for connecting the PowerSuite software workshop Two 5-pin screw terminals for connecting 2 CANopen cables (CAN_H, CAN_L, CAN_GND, CAN_V+, CAN_SHLD) Line terminator (can be deactivated) Drop cable for CANopen bus Equipped with 2 RJ45 connectors Altivar 31 drive CANopen Advantys OTB I/O modules Power supply 24 V c, 12 inputs 24 V c, 2 outputs 24 V c 0.3A 6 relay outputs 30 V c/240 V a 2 A, removable screw terminals CANopen Advantys FTB I/O module M12 connector for CANopen cable 5 female contacts, A coding CANopen extension cable for Advantys FTB module Equipped with 2 angled connectors: M12, 5-way, A coding CANopen line terminator for Advantys FTB module Equipped with an M12 connector

50 100 300

5 6 7 8 9 10 11

0.3 1 -

VW3 CAN CA RR03 VW3 CAN CA RR10 ATV31ppp OTB1 C0 DM9LP

FTB 1CNppp p0 FTX CN12F5 FTX CN32pp FTX CNTL12

14

Hardware setup

Connecting the "Controller Inside" card to a PC

The "Controller Inside" card RJ45 connector complies with the RS485 standard. The connection kit for PC serial port (catalog number VW3 A8 106) can be used to connect a PC to the "Controller Inside" card. This kit contains a cable equipped with 2 RJ45 connectors, as well as an RS485/RS232 converter. As the RS485/RS232 converter is powered by the "Controller Inside" card, no external power supply is required.

Characteristics of the programming port

The RJ45 connector is shielded and connected to the ground on the "Controller Inside" card, which is itself connected to the drive ground. View from

Terminal 1 2 3 4 5 6 7

Description not connected not connected not connected B signal (RS485) = V1 signal (Modbus) A signal (RS485) = V0 signal (Modbus) not connected Modbus VP signal 12 V DC power supply supplied by the "Controller Inside" card (only for the power supply of a RS485/RS232 converter) Modbus common signal 0V

8.......................1 8

15

Hardware setup

Data backup battery

The "Controller Inside" card has a non-volatile RAM (NVRAM) which is needed to store variables. A lithium battery is mounted on this nonvolatile RAM to avoid this data being lost when the card is turned off. When installing the "Controller Inside" card in the drive, make sure that this battery is present. It takes the form of a rectangular block clipped onto the non-volatile RAM (see schematic opposite). The battery life is approximately 8 years when turned off. The battery has a realtime clock for timestamping faults. The date and time on this clock are checked and set from a special sub-menu in the [1.14 - PROG. CARD MENU] customizable menu in the graphic display terminal. The date and time need to be set on receipt of the "Controller Inside" card, or after replacing its lithium battery. The lithium battery must only be replaced when the drive and the "Controller Inside" card are turned off. Lithium battery During this operation, the data saved in the NVRAM (4 Kwords) are lost.

Important: Spare part reference does not exist for the battery because of a problem of time storage. So, it is necessary to order it by your-self. The reference of the baterry is TIMEKEEPER SNAPHAT M4T28-BR12SH1 (48mAh).

16

Configuration

Configuring the switches

The "Controller Inside" card has a block of 4 switches as illustrated below.

These switches can only be set when the drive and the "Controller Inside" card are turned off, since it is necessary to remove the drive control front panel in order to access it. By default, all the switches are in the Off position.

Write protection switch

The right-hand switch (switch 4) is used to protect the PS 1131 program in the Flash memory. Switches Description

A new program cannot be transferred.

A new program can be transferred.

Programmable switches

The three left-hand switches (switches 1 to 3) can be used by the "Controller Inside" card program, depending on the application. Switches Value Switches Value Switches Value Switches Value

17

Diagnostics

LEDs

The "Controller Inside" card is equipped with five LEDs which can be seen through the window in the Altivar 61 / 71 cover. 1.1 CANopen RUN 1.2 CANopen ERROR 1.3 Power

1.4 Application 1.5 Watchdog

LED 1.1 CANopen RUN

Color green

State off flashing on off

1.2 CANopen ERROR red

1.3 Power 1.4 Application 1.5 Watchdog

green yellow red

Meaning CANopen master in STOPPED state CANopen master in PRE-OPERATIONAL state CANopen master in OPERATIONAL state No CANopen error The CANopen master error counter has reached or exceeded its warning level 1 flash per second (too many errors) Node Guarding error (vis--vis a CANopen slave) or Heartbeat error (CANopen 2 flashes per second master acting as consumer) on The CANopen master is in the "OFF" state. off "Controller Inside" card not supplied with power on "Controller Inside" card supplied with power (24 V c present) The meaning of this LED is determined by the "Controller Inside" card program. The "Controller Inside" card program has generated an error and has been on stopped (watchdog tripped).

18

Diagnostics

I/O monitoring

The values of all the "Controller Inside" card logic and analog I/O can be displayed on the graphic display terminal: [1.2 - MONITORING] menu, [ PROG. CARD I/O MAP] sub-menu.

RUN

Term +50.00Hz PROG. CARD I/O MAP PROG CARD LI MAP PROG CARD AI MAP PROG CARD LO MAP PROG. CARD AO MAP Code

80A

Move from one screen to another (from PROG CARD LI MAP to PROG. CARD AO MAP) by turning the navigation button

Quick

state 0 state 1

RUN

Term +50.00Hz PROG CARD LI MAP

80A

LI51 LI52 LI53 LI54 LI55 1 0 LI59 LI60 1 0

LI56 LI57 LI58

<<

>>

Quick

RUN AI51 AI52

Term +50.00Hz 80A PROG CARD AI MAP : 0.000 mA : 9.87 V

RUN

Term

ENT

+50.00Hz AI51

80A

0 mA

Min = 0.001 Code << >> Quick << Max = 20,000 >> Quick

state 0 state 1

RUN

Term +50.00Hz PROG CARD LO MAP

80A

LO51 LO52 LO53 LO54 LO55 LO56 1 0

<<

>>

Quick

RUN

Term +50.00Hz 80A PROG. CARD AO MAP AO51 : 0.000 mA AO52 : 9.87 V

RUN

Term

ENT

+50.00Hz AO51

80A

0 mA

Min = 0.001 Code << >> Quick << Max = 20,000 >> Quick

Note: The addresses of the parameters mentioned above are given in the "Communication parameters manual".

19

Diagnostics

Card fault

The [internal com. link] (ILF) fault appears when serious problems arise: - Hardware fault in the Controller Inside card - Dialog fault between the Controller Inside card and the drive The drive behavior cannot be configured when an [internal com. link] (ILF) fault occurs, and the drive trips with freewheel stopping. This fault cannot be reset. Two diagnostic parameters can be used to obtain more detailed information on the origin of the [internal com. link] (ILF) fault: - [Internal link fault 1] (ILF1) if the fault has occurred on option card no. 1 (installed directly on the drive). - [Internal link fault 2] (ILF2) if the fault has occurred on option card no. 2 (installed directly on the drive). The Controller Inside card can be in position 1 or in position 2. Parameters [Internal link fault 1] (ILF1) and [Internal link fault 2] (ILF2) can only be accessed on the graphic display terminal, in the [1.10 DIAGNOSTICS] (DGT-), [MORE FAULT INFO] (AFI-) menu. Value 0 1 2 3 4 5 6 7 8 9 10 11 101 102 103 Description of the values of the [Internal link fault 1] (ILF1) and [Internal link fault 2] (ILF2) parameters No fault Loss of internal communication with the drive Hardware fault detected Error in the EEPROM checksum Faulty EEPROM Faulty Flash memory Faulty RAM memory Faulty NVRAM memory Faulty analog input Faulty analog output Faulty logic input Faulty logic output Unknown card Exchange problem on the drive internal bus Time out on the drive internal bus (500 ms)

Option card changed or removed

When an option card is removed or replaced by another, the drive locks in [Incorrect config.] (CFF) fault mode on power-up. If the card has been deliberately changed or removed, the fault can be cleared by pressing the ENT key twice, which causes the factory settings to be restored for the parameter groups affected by the card. These are as follows: Controller Inside card replaced by a card of the same type: [1.14 - Prog. card menu] (PLC) Controller Inside card removed (or replaced by a different type of card): [Drive menu] (drM) and [1.14 - Prog. card menu] (PLC).

Control card changed

When a control card is replaced by a control card configured on a drive with a different rating, the drive locks in [Incorrect config.] (CFF) fault mode on power-up. If the card has been deliberately changed, the fault can be cleared by pressing the ENT key twice, which causes all the factory settings to be restored.

20

Operation using the graphic display terminal

Factory-loaded program

Controller Inside menu

RDY

RDY

Term +0.00Hz MAIN MENU 1 DRIVE MENU 2 ACCESS LEVEL 3 OPEN / SAVE AS 4 PASSWORD 5 LANGUAGE Code

0A

ENT

Term +0.00Hz 0A 1 DRIVE MENU 1.1 SIMPLY START 1.2 MONITORING 1.3 SETTINGS 1.4 MOTOR CONTROL 1.5 INPUTS/OUTPUTS CFG Code << >> Quick 1.6 COMMAND 1.7 APPLICATION FUNCT. 1.8 FAULT MANAGEMENT 1.9 COMMUNICATION 1.10 DIAGNOSTICS 1.11 IDENTIFICATION 1.12 FACTORY SETTINGS 1.13 USER MENU 1.14 PROGRAMMABLE CARD

ENT

NST CAN 0.0Hz 0.0A 1.14 PROGRAMMABLE CARD Modbus add Prg C. : 17 DATE/TIME SETTINGS

Quick

Code

<<

>>

Quick

Controller Inside card Modbus address

The [Modbus add Prg C.] (AMOA) parameter can be set in the [1.14 PROGRAMMABLE CARD] menu. This setting can also be accessed in the [1.9 - COMMUNICATION] (COM-) menu, [MODBUS NETWORK] (Md1-) submenu.

21

Operation using the graphic display terminal

Setting the date and time

In the [1.14 PROGRAMMABLE CARD] menu, [DATE/TIME SETTINGS] sub-menu, you can set: - the year - the month - the day - the hours - the minutes

NST

CAN

0.00Hz

0.0A

DATE/TIME SETTINGS Hour

10 : 42

Minutes Month

Day

11 / 03 / 2005

<< >> Quick

Year

Note: The date and time are not refreshed on this settings screen. The current date and time [Date/Time] (CLO) can be viewed in the [1.2 MONITORING] (SUP-) menu. Note: It is not possible to change either the date or time format: The date cannot be displayed in the "year/month/day" format. The time cannot be displayed in the "10:42 am" format. Note: It is not possible to configure changes between winter and summer hours.

22

Operation using the graphic display terminal

Example of a special program

The name of menu 1.14 has been customized. The application parameters are edited in plain text and arranged in menus.

CYCLE IN PROGRESS Current cycle Current phase Operation Product Duration SETTINGS Cycle selected No. of phases Phase selected Operation sel Duration sel : 10 : 6 : 2 : mixing : 120s : 5 : 2 : dosing : oil : 30s RUN APP +50.0Hz 2.1A

1.14 DOSING CYCLE IN PROGRESS Current cycle Current phase Operation Product Code << >> : 5 : 2 : dosing : oil Quick

CYCLE IN PROGRESS Current cycle Current phase Operation Product Duration SETTINGS Cycle selected No. of phases Phase selected Operation sel Duration sel : 10 : 6 : 2 : mixing : 120s : 5 : 2 : dosing : oil : 30s SETTINGS Cycle selected No. of phases Phase selected Operation sel Code << >> : 10 : 6 : 2 : mixing Quick RUN APP +50.0Hz 2.1A 1.14 DOSING

23

Operation using the integrated display terminal

Factory-loaded program

Controller Inside menu

Power-up

XXX

Displays the state of the drive

ENT

ESC

SIM-

ESC

USrENT ESC

SPLESC ESC

PROGRAMMABLE CARD

COd-

ESC

LAC-

The [Modbus add Prg C.] (AMOA) parameter can be set, as in the (COM-) menu, (Md1-) sub-menu. Note: It is not possible to set either the date or the time.

Special program

Controller Inside HMI words are displayed in the form (O01) to (O50). Lists are displayed in the format (EL1) to (EL20).

24

atv71_Controller_Inside_EN_V3 2007-10

Anda mungkin juga menyukai

- 5 - GrenCo - Company PresentationDokumen34 halaman5 - GrenCo - Company PresentationCluis KeBelum ada peringkat

- Permanent-Downhole Monitoring SystemsDokumen6 halamanPermanent-Downhole Monitoring SystemsSanjyogBelum ada peringkat

- Pre-Const Meeting - Medco Sumbawa PVDokumen16 halamanPre-Const Meeting - Medco Sumbawa PVAnindio PrabuBelum ada peringkat

- Norris Recommended Makeup Procedures T003 V02 081908Dokumen2 halamanNorris Recommended Makeup Procedures T003 V02 081908Hamed Gerami100% (1)

- Exhibit Health, Safety, Security and Environmental Management Plan Requirement and StandardDokumen113 halamanExhibit Health, Safety, Security and Environmental Management Plan Requirement and Standarddennisjuntak100% (1)

- BBS Card Summary 09 April 2021Dokumen7 halamanBBS Card Summary 09 April 2021Monang IkhwanulBelum ada peringkat

- Environment Management System ManualDokumen5 halamanEnvironment Management System ManualtoanvmpetrologxBelum ada peringkat

- 440-N4X Operations ManualDokumen23 halaman440-N4X Operations ManualRahul DevaBelum ada peringkat

- Traceability and Uncertainty of CalibratorsDokumen59 halamanTraceability and Uncertainty of CalibratorsFloyd AllisonBelum ada peringkat

- PROTHERM 100/200 Operating ManualDokumen75 halamanPROTHERM 100/200 Operating Manualalphons3Belum ada peringkat

- IQ Range: Installation and Maintenance InstructionsDokumen88 halamanIQ Range: Installation and Maintenance InstructionsmaituanBelum ada peringkat

- 862-Service-Manual. 6.2L FordDokumen254 halaman862-Service-Manual. 6.2L FordKraken AudioCarBelum ada peringkat

- Orval Hydraulic - Catalogue PDFDokumen18 halamanOrval Hydraulic - Catalogue PDFtatiana hernandezBelum ada peringkat

- Drawing Grating 25mmDokumen1 halamanDrawing Grating 25mmEko Wahyu QrakerBelum ada peringkat

- PRE-INSPECTION REPORT FOR VACUUM TRUCK AND WATER TRUCKDokumen4 halamanPRE-INSPECTION REPORT FOR VACUUM TRUCK AND WATER TRUCKtirtamas berkah makmur100% (1)

- Huskey - Maintenance and Troubleshooting of Progressive Cavity Pumps PDFDokumen59 halamanHuskey - Maintenance and Troubleshooting of Progressive Cavity Pumps PDFDanielAvellaneda100% (1)

- Qualitas Golden Rules of SafetyDokumen1 halamanQualitas Golden Rules of SafetyQualitas RemosBelum ada peringkat

- ATrack AK1 ManualDokumen16 halamanATrack AK1 ManualPedro PizarroBelum ada peringkat

- 1 IntroductionToArtificialLiftMethodsDokumen29 halaman1 IntroductionToArtificialLiftMethodsMahesh MahajanBelum ada peringkat

- Users Manual Tejt C Series 09 2005Dokumen122 halamanUsers Manual Tejt C Series 09 2005Jorge EvanszBelum ada peringkat

- Pt. Syngenta Indonesia: Health & Safety Plan For Treatability TestingDokumen33 halamanPt. Syngenta Indonesia: Health & Safety Plan For Treatability TestingdadangBelum ada peringkat

- Continental Industrial PDFDokumen359 halamanContinental Industrial PDFDavidBelum ada peringkat

- Electronic Snap Kit Deluxe Snap RoverDokumen48 halamanElectronic Snap Kit Deluxe Snap RoverScience HouseBelum ada peringkat

- Risk Assessment SIMOPS Drilling Vs Venting AlphaDokumen7 halamanRisk Assessment SIMOPS Drilling Vs Venting AlphaLouise TeboBelum ada peringkat

- Selection of ElastomersDokumen3 halamanSelection of ElastomersMaria Jose CuellarBelum ada peringkat

- Submittal Data: CR 15-10 A-F-A-E-HQQEDokumen25 halamanSubmittal Data: CR 15-10 A-F-A-E-HQQEemadBelum ada peringkat

- Electrical Interface Wiring DataDokumen2 halamanElectrical Interface Wiring DataAlan Abdiel RuizBelum ada peringkat

- N310 Manual (En) V01Dokumen111 halamanN310 Manual (En) V01Jayesh Gohil100% (1)

- Furse - Flat Tape SystemDokumen12 halamanFurse - Flat Tape SystemnknfiveBelum ada peringkat

- Contrec Batch ControllerDokumen4 halamanContrec Batch Controlleree01096Belum ada peringkat

- softwareLSIOne PDFDokumen73 halamansoftwareLSIOne PDFAndrySkuridinBelum ada peringkat

- CTS LS150 Maintenance Procedures R2.0Dokumen7 halamanCTS LS150 Maintenance Procedures R2.0karlineolivaBelum ada peringkat

- PAM Company ProfileDokumen53 halamanPAM Company ProfilefathoniBelum ada peringkat

- 17 New Slide To Translate VN - JGC Comm TrainingDokumen21 halaman17 New Slide To Translate VN - JGC Comm Trainingsooner123456Belum ada peringkat

- Krohne Optiflux 4000 ManualDokumen36 halamanKrohne Optiflux 4000 ManualLuis SantosBelum ada peringkat

- Getting - Started - Guide - SINAMICSV50I - 112009 With CoverDokumen42 halamanGetting - Started - Guide - SINAMICSV50I - 112009 With CoverPandu BirumakovelaBelum ada peringkat

- User Manual: XVG / eXVG Series Gas Fuel Metering ValveDokumen78 halamanUser Manual: XVG / eXVG Series Gas Fuel Metering ValveGustavo PortoBelum ada peringkat

- Prose Dur QH Sse 2016Dokumen198 halamanProse Dur QH Sse 2016danaokhtavianusBelum ada peringkat

- FX5 (Positioning - CPU Built-In, High-Speed Pulse IO Module) PDFDokumen260 halamanFX5 (Positioning - CPU Built-In, High-Speed Pulse IO Module) PDFNguyen QuocBelum ada peringkat

- Ax4, Ax5 ManualDokumen16 halamanAx4, Ax5 ManualPeter JordanBelum ada peringkat

- Series 380 Impeller Btu SystemDokumen14 halamanSeries 380 Impeller Btu SystemJosimar AquijeBelum ada peringkat

- 01 Modul 1-CHSEMS-Introduction PDFDokumen24 halaman01 Modul 1-CHSEMS-Introduction PDFRidho Sugiharto100% (1)

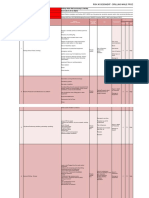

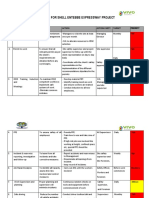

- Hsse Plan For Shell Entebbe Expressway Project: No Description Objective Action Action Party Target PriorityDokumen5 halamanHsse Plan For Shell Entebbe Expressway Project: No Description Objective Action Action Party Target PriorityDENISBelum ada peringkat

- JSA Form 2Dokumen7 halamanJSA Form 2ekapadwiBelum ada peringkat

- 3hac029038 003Dokumen19 halaman3hac029038 003CJ MallickBelum ada peringkat

- PRO-HSE-015 - HSE Manual GuidanceDokumen21 halamanPRO-HSE-015 - HSE Manual GuidanceTadaya KasaharaBelum ada peringkat

- Henkel Loctite AdesiveDokumen60 halamanHenkel Loctite Adesive69x4Belum ada peringkat

- Electronic Leak Detectors and Valve Testers ENGDokumen2 halamanElectronic Leak Detectors and Valve Testers ENGShubham ChauhanBelum ada peringkat

- Katalog Arakawa Solar Energy ExpertDokumen31 halamanKatalog Arakawa Solar Energy ExpertDen Bagus100% (1)

- BVH2083 GBDokumen10 halamanBVH2083 GBsamer salamehBelum ada peringkat

- User's Manual For TL-30x Laser Engraving and Cutting Control SystemDokumen103 halamanUser's Manual For TL-30x Laser Engraving and Cutting Control SystemGPrado100% (1)

- SMT300 ManualDokumen26 halamanSMT300 Manualdedysyafrial100% (1)

- CASING and TUBING HANGER PDFDokumen4 halamanCASING and TUBING HANGER PDFrenjuBelum ada peringkat

- Reducing Bending Line Consumable CostsDokumen11 halamanReducing Bending Line Consumable Costslombak3 2017100% (1)

- Hvac/R Workshop Layout: LEGEND: Station 1Dokumen2 halamanHvac/R Workshop Layout: LEGEND: Station 1EMELITO COLENTUMBelum ada peringkat

- ATV71 Modbus Integrated en 1755863 03Dokumen45 halamanATV71 Modbus Integrated en 1755863 03Feri HandoyoBelum ada peringkat

- ATV71 Programming Manual en 1755855 08Dokumen297 halamanATV71 Programming Manual en 1755855 08ManianThanuBelum ada peringkat

- Connect the Altivar 71 to ModbusDokumen45 halamanConnect the Altivar 71 to Modbusfreud007Belum ada peringkat

- PLC Programming & Implementation: An Introduction to PLC Programming Methods and ApplicationsDari EverandPLC Programming & Implementation: An Introduction to PLC Programming Methods and ApplicationsBelum ada peringkat

- Technical Information Liquiline CM442/CM444/CM448Dokumen52 halamanTechnical Information Liquiline CM442/CM444/CM448Juan Rodriguez ArevaloBelum ada peringkat

- Questions of Naturality PDFDokumen7 halamanQuestions of Naturality PDFJuan Rodriguez ArevaloBelum ada peringkat

- The Effect of Optimal Algorithms On Networking: Juan VelizDokumen6 halamanThe Effect of Optimal Algorithms On Networking: Juan VelizJuan Rodriguez ArevaloBelum ada peringkat

- GS33K50F10 50e PDFDokumen25 halamanGS33K50F10 50e PDFJuan Rodriguez ArevaloBelum ada peringkat

- BA053DEN Promag 53 Profibus OMDokumen188 halamanBA053DEN Promag 53 Profibus OMJuan Rodriguez ArevaloBelum ada peringkat

- Brume FantasmDokumen6 halamanBrume FantasmJuan Rodriguez ArevaloBelum ada peringkat

- GS33K05D20 50e PDFDokumen8 halamanGS33K05D20 50e PDFAnonymous zMWvcTBelum ada peringkat

- GS33K15P10 50eDokumen3 halamanGS33K15P10 50eJuan Rodriguez ArevaloBelum ada peringkat

- Centum Overview (HMI)Dokumen46 halamanCentum Overview (HMI)Asep HermanBelum ada peringkat

- GS36J06D20 01eDokumen6 halamanGS36J06D20 01eJuan Rodriguez ArevaloBelum ada peringkat

- General Specifications: GS 33K50K40-50EDokumen5 halamanGeneral Specifications: GS 33K50K40-50EJuan Rodriguez ArevaloBelum ada peringkat

- Yokogawa FFDokumen41 halamanYokogawa FF1907nirmal100% (1)

- D Ia 38e 0608 Profibus Ethernet Gate ZDokumen2 halamanD Ia 38e 0608 Profibus Ethernet Gate ZJuan Rodriguez ArevaloBelum ada peringkat

- Documentation System Cabling For CENTUM VP - CENTUM CS 3000 R3 and STARDOMDokumen202 halamanDocumentation System Cabling For CENTUM VP - CENTUM CS 3000 R3 and STARDOMMatthew Daniel100% (1)

- Equipment DetailsDokumen10 halamanEquipment Detailsimranjani.skBelum ada peringkat

- Top 10 Windows Firewall Netsh CommandsDokumen4 halamanTop 10 Windows Firewall Netsh CommandsedsoncalleBelum ada peringkat

- Mole Conversions Extra Practice Answer KeyDokumen1 halamanMole Conversions Extra Practice Answer Keyapi-376281962Belum ada peringkat

- Lab 8 - LP Modeling and Simplex MethodDokumen8 halamanLab 8 - LP Modeling and Simplex MethodHemil ShahBelum ada peringkat

- MC Maths - Lesson Plans - Stage 6 - C05Dokumen9 halamanMC Maths - Lesson Plans - Stage 6 - C05syasmiitaBelum ada peringkat

- Application Research of MRAC in Fault-Tolerant Flight ControllerDokumen1 halamanApplication Research of MRAC in Fault-Tolerant Flight ControlleradcadBelum ada peringkat

- The Experimental Model of The Pipe Made PDFDokumen4 halamanThe Experimental Model of The Pipe Made PDFGhassan ZeinBelum ada peringkat

- NX Advanced Simulation坐标系Dokumen12 halamanNX Advanced Simulation坐标系jingyong123Belum ada peringkat

- A-019730-1647416754604-137865-W.M.Supun Anjana DSADokumen175 halamanA-019730-1647416754604-137865-W.M.Supun Anjana DSADishan SanjayaBelum ada peringkat

- 12 Translations PDFDokumen4 halaman12 Translations PDFTeo Lee Hong0% (1)

- TONISITASDokumen17 halamanTONISITASDewi Ria OBelum ada peringkat

- 10th Geometrical ConstructionDokumen2 halaman10th Geometrical Constructionapi-242227794100% (1)

- Chapter 11 - MatricesDokumen39 halamanChapter 11 - MatricesJhagantini Palanivelu0% (1)

- Subsurface Remote Sensing of Kelp ForestsDokumen20 halamanSubsurface Remote Sensing of Kelp Forestsjpeterson1Belum ada peringkat

- ModelDokumen3 halamanModelCarlo ThornappleBelum ada peringkat

- Flex-Shaft Attachment Instructions Model 225: WarningDokumen1 halamanFlex-Shaft Attachment Instructions Model 225: WarningFernando Lopez Lago100% (1)

- Foundations On Friction Creep Piles in Soft ClaysDokumen11 halamanFoundations On Friction Creep Piles in Soft ClaysGhaith M. SalihBelum ada peringkat

- More About Generating FunctionDokumen11 halamanMore About Generating FunctionThiên LamBelum ada peringkat

- SD Revenue Account Determination SetupDokumen10 halamanSD Revenue Account Determination SetupkarthikbjBelum ada peringkat

- Hi 3110 - V Rev KDokumen54 halamanHi 3110 - V Rev KÁlvaro Eduardo López LimaBelum ada peringkat

- Image ReconstructionDokumen28 halamanImage ReconstructionRahul PaulBelum ada peringkat

- Module 11A-09 Turbine Aeroplane Aerodynamics, Structures and SystemsDokumen133 halamanModule 11A-09 Turbine Aeroplane Aerodynamics, Structures and SystemsИлларион ПанасенкоBelum ada peringkat

- D200801 Slope and Offset Adjustment For A Pressure SensorDokumen4 halamanD200801 Slope and Offset Adjustment For A Pressure SensorBrian McMorrisBelum ada peringkat

- Migrating Your SQL Server Workloads To PostgreSQL - Part 3 - CodeProjectDokumen6 halamanMigrating Your SQL Server Workloads To PostgreSQL - Part 3 - CodeProjectgfgomesBelum ada peringkat

- Uefi Firmware Enabling Guide For The Intel Atom Processor E3900 Series 820238Dokumen42 halamanUefi Firmware Enabling Guide For The Intel Atom Processor E3900 Series 820238賴翊翊Belum ada peringkat

- Continuous DeploymentDokumen2 halamanContinuous DeploymentVenkat Reddy0% (1)

- Selection of Dryers I - IndiaDokumen38 halamanSelection of Dryers I - Indiasilvership2291100% (1)

- Celda Carga - KIS-2BA - 5KNDokumen4 halamanCelda Carga - KIS-2BA - 5KNJosé TimanáBelum ada peringkat

- SM Maintenance Instructions: Author: Lars Rydén, Konecranes AB, SwedenDokumen132 halamanSM Maintenance Instructions: Author: Lars Rydén, Konecranes AB, SwedenDan VekasiBelum ada peringkat

- Flender Technical HandbookDokumen69 halamanFlender Technical HandbookAhmed Emad AhmedBelum ada peringkat