Transformer Turns Ratio Test

Diunggah oleh

vipulgupta2012Deskripsi Asli:

Judul Asli

Hak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

Transformer Turns Ratio Test

Diunggah oleh

vipulgupta2012Hak Cipta:

Format Tersedia

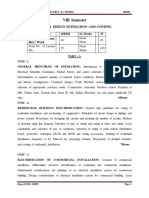

TRANSFORMER TESTING

Transformer Turns Ratio Test

The Transformer Turns Ratio test (TTR) is used to make sure that the Turns Ratio between the windings of the transformer is correct. This ratio decides what the output voltage of the transformer will be with respect to the input voltage. The ratio is calculated under no-load conditions, with ratios calculated at the tap positions for each winding and for the winding as a whole. A voltage is applied to one winding and the voltmeters connected to both low voltage and high voltage windings are read simultaneously. The transformer ratio is the ratio of the HV voltmeter and the LV voltmeter readings. When ratio tests are being made on three-phase transformers, the ratio is taken on one phase at a time, and the measured ratio should be compared with the ratio calculated using nameplate voltages. Any variation should be within 5%.

Power Factor

This test is made to monitor the dryness of transformer insulation. Power factor is defined as the ratio of the power dissipated divided by the input volt-ampere multiplied by 100. The measurement of power factor is made with a capacitance bridge and the connections are the same as for the insulation resistance tests.

Transformer Resistance

The resistance of a transformer winding can be measured after current has not passed through the transformer for several hours, allowing it to reach the same temperature as its surroundings. Winding resistance is calculated by measuring the voltage and current simultaneously, with the current as close to the rated current as possible. Calculating the winding resistance can be helpful as it lets us calculate and compensate for I 2R losses, a major component of load losses as a whole. Winding resistance measurements can be made to determine if any changes have occurred in the current carrying path. The winding resistance measurements should be made with a Wheatstone bridge, Kelvin bridge or similar bridge capable of measuring fractional ohms accurately. For Wye connected values, measurements should be made between each pair of bushings, then summed and multiplied by three-halves to get the comparison value.

Transformer Polarity

This test is an acceptance test and acceptance tests should be performed immediately after the product arrives at the destination. The polarity of a transformer is either additive or subtractive. In order to find out the polarity of a transformer, a voltage is applied between the primary bushings. If the resultant voltage between the secondary bushings is greater than the applied voltage that means that the transformer has additive polarity. If it is lower, the transformer has

subtractive polarity. Polarity is not important for a single connected distribution transformer, but it is a vital concern if transformers are to be paralleled or bank connected. Three phase transformers are also checked for polarity by the same means.

Transformer Phase Relation

This is also an acceptance test. A phase relation test is carried out for polyphase (for instance, three-phase) transformers to make sure that they have been connected in such a way that their phase relationship is correct. A phase relation test calculates the angular displacement and relative phase sequence of the transformer, and can be carried out in conjunction with ratio and polarity tests. The voltages of the phase of primary and secondary can be recorded and comparisons made to get the phase relation.

Visual Inspection

It should be done periodically. This may reveal either present or potential problems that may not be picked up by diagnostic testing. For example, deteriorating gaskets, low oil level or chipped bushing skirts. A standard list of check points should be established for each unit and then a record of each inspection maintained. Excitation Current Test

This is a periodic test. The excitation current is the minimum amount of current needed to maintain the core in a state of magnetic excitation. It is measured at the rated voltage, and usually given as a percentage of the rated current. The test is performed with a single phase supply with, preferably, a voltage rated at approximately 10% of the phase voltage of the winding to which the supply is to be connected, although lower voltages can be used. There are 2 methods that can be used: the first is to connect a single-phase supply to any available winding with an ammeter in the circuit to monitor the exciting current. Three such single-phase tests are necessary for a three-phase transformer. The relationship between the single phase readings is important; it should be as follows:

The readings taken on phase A and C should be within 5% of each other. The reading on phase B should be between 65 and 90% of the readings on phase A and C.

Readings that fall outside of the relationships given above may be indicators of a winding fault. In the other method, the same voltage level and ammeter requirements apply except the following connections should be made:

Short one winding on phase C and apply voltage and read the exciting current on phase A.

Short one winding on phase A and apply voltage and read the exciting current on phase C. Short one winding on phase B and apply voltage and read the exciting current on phase A or phase C.

Frequency Response Analysis testing. The main purpose of this test is to determinate the frequency response graph of the equivalent electric / dielectric / magnetic / mechanic altogether evaluated. There are two approaches to this test: Frequency sweep technique. A low voltage sweep generator is used synchronized with a level meter that for each phase registers a frequency response plot. The result is a graph that correlates frequencies in horizontal axis and attenuations per phase in vertical axis Pulse technique. A fast pulse of ~500V is given to the transformer and taken both at the input and output in each phase.

FIG: FRA signature of a test with a problem in transformer windings detected with FRAMIT system

Next and in the computer, are used digital signal processing techniques with mathematic algorithms that change from time domain to frequency domain giving the same results than from sweep technique.. Both techniques give as a result the signature of the transformer with the inside information of the complete electric / dielectric / magnetic / mechanic status. This test is very useful as a complement of the usual tests and can also check that no 10 alterations were derived from transportation, loose windings or displaced, problems in the magnetic core, etc. Diagnosis and trending Each previous test results are changed into the different registered parameters from the transformed that were previously programmed in the test protocol. These parameters will be submitted to a criteria evaluation to the diagnosis emission. Diagnose criteria can change depending on the transformer, depending of the companies, but it exist a minimum values, another normalized and other ones than from an empiric approach conform Expert Diagnose Software that could be a failure criteria interpretation. These software applications give an orientation of the machine status, but must be the maintenance expert who with all the machine data indicates end diagnosis and performs necessary actions: repair, continue operation, program new test, and recommend service limitation. Another scope will come from the historic/trending of the transformer. The parameters evolution could help detecting machines degradation speed and the new maintenance exigencies. ELECTRIC TESTS TO THE DIELECTRIC CIRCUIT It is a group of tests that with measuring electronic instrumentation that can give a punctual status evaluation of the dielectric in the power transformer. They all are off-line (transformer out of service) apart from the indicated exceptions. Dielectric circuit tests Insulation Resistance and Polarization Index (IR, PI) Recovery voltage Measurement (RVM) and time constant Capacitance, Dissipation (power) factor (tan ) and insulation losses in dielectric / bushing Partial Discharge (PD) Insulation Resistance This test has been the most usual historically, being called to megger the transformer (the term comes from the firm of the first Megger system)

This test is performed on a measuring tester able to generate high continuous voltages usually of 5000V that is applied between both dielectric terminals of the power transformer (one terminal to all the bushings joined in high voltage, the other to low voltage and ground) to evaluate the punctual dielectric status inside. The tester has a high voltage tester operating from batteries or from the main. Measuring principle is based on measuring current / voltage in a continuous way that evolves as an answer to a voltage step.

FIG.2: Equivalent diagram of the dielectric circuit of a transformer. Ri is the insulation resistance, Cg the geometric capacitance and the different Ra/Ca emulate the equivalent dielectric absorption circuit. Insulation Resistance will be the quotient between voltage and current at the end of minute 1 of the test (~Ri in figure 2). This parameter should be above a minimum normalized value. It contains direct information from the dielectric system status in the transformer, but is very influenced by temperature (and should be temperature normalized / corrected). So, it is usually another parameter named Polarization Index (PI). To measure it, the test is extended from minute 1 to minute 10, being PI, the quotient of currents in both time instants. This value is now independent from temperature and should be comparable in consecutive tests. Recovery Voltage Measurement (RVM) Other approach to get a generic knowledge of the dielectric status inside the transformer (paper-oil) is with recovery voltage testing. With this test is obtained the polarization spectrum of the dielectric mixing information both of dissolved humidity and components degeneration. Any dielectric can be simulated with an equivalent diagram as from figure 2. Recovery voltage testing pursues determining temporal spectrum of the different circuits Ra/Ca which include information of moisture/degradation in the dielectric. Test is performed with the circuit from figure 3. It has several charge / discharge steps of the dielectric from a continuous voltage source V whose result composes a plot spectrum named polarization spectrum. Each point comes from a charge process while a time T (S1 closed and S2 open) of the sample and discharges in a time T/2 (S1 open

and S2 closed). Finally an electrometer (E= very high impedance voltmeter) registers the point as the maximum of the recovery voltage curve given by the Ra/Ca.

FIG 3: Operation diagram of the recovery voltage meter (RVM). The final plot (figure 4) follows the equivalent spectra of all the Ra/Ca related to the circuit in figure 2. The appearance of the plot and the position of the maximum are indicative of the final quality of the dielectric paper / oil. Greater moisture = bigger deflection of the maximum to the left in the time axis.

FIG 4: Test screen from Unitronics RVM UM2B.

Test voltage has standardized in 2kV to be comparable and applicable to all power / distribution oil submerged transformers. In figure 4 screen there is a horizontal axis cycle and in vertical axis maximum per cycle of recovery voltage. Capacitance / Tan delta (Dissipation Factor) & dielectric losses /bushings) Another usual approach when performing dielectric evaluation is tan delta. This test uses AC and pursues to know loss angle of the tested element. This test system is usually more bulky because in order to generate current enough by AC voltage it is necessary to use a greater power source. This measurement technique is again off-line although there are systems that allow an on-line approach. This measurement includes information of the moisture and contamination degree and emulates (greater voltage) the behaviour and voltage aggressions similar to service ones. It is important to take note of transformer temperature and environmental moisture (surface leakage).

FIG 6: Diagram of currents flowing through dielectric, IR resistive is in phase to voltage and capacitive IC out of phase by 90. Total IT, defines angle and tangent. Partial Discharge test It is possible to make partial discharge testing on power transformers, most of all on the most powerful or critical units. Partial discharges are small discharges that appear inside of the dielectric as a sign of its degeneration. They appear as a result of the increase of the electric field in small gaseous voids inside the oil and also inside the paper, epoxy or as a result of the presence of metallic contamination, etc. This discharge accelerates the thermal degradation effects and though the oil is autoregenerable, leads sometimes exponentially to the power transformer destruction. There are two usual detection systems, acoustic and electric. Acoustic system seeks sound mechanic manifestation (in ultrasonic range) of discharges even enabling ecolocation. Electric systems should allow determinate discharges and correlate them with other parameters. This test can be made online or offline if a source apart is used to energize the machine (difficult chance in field). In this test it is important again to take note of the temperature of the machine and environmental conditions.

Other Transformer Tests: Core Loss Test Under no-load conditions, a transformer will continue to drain sources of electrical energy. The chief source of this drain is core loss, which occurs in the magnetic core through a combination of hysteresis and eddy current losses, among others. Core-loss is calculated by applying the rated voltage and frequency to a transformer under no-load conditions. The resultant current is then measured, from which the loss of energy can be extrapolated. Load Loss Test Load loss is a combination of I2R losses, stray losses and eddy losses, all of which contribute to the loss of electrical energy that is seen as current transferred from one winding to another. Load loss changes with the magnitude of the load: that is to say, higher loads see higher rates of loss. The load loss is therefore generally calculated for the rated load, while the transformer is under fullload conditions. It can be measured by applying a voltage to one winding while the other winding is short-circuited. The voltage is adjusted until the current flowing through the circuit is the same as the rated current. The power loss measured at this time is the load loss. Impedance Test Impedance is a measure of the resistance that leads to the loss of electrical energy in a transformer at full load, causing the ratio of the input and output voltages to differ from the Turns Ratio. It can be measured at the same time as load loss. Impedance is found by measuring the voltage required to pass the rated current through one winding of the transformer, while the other winding is short-circuited. This voltage is called the impedance voltage. Applied Potential Test The applied potential test is used to see how well the transformer's insulation deals with voltages higher than the rated voltage, for given periods of time. The applied potential test checks the insulation between individual windings; and between windings and ground by applying voltages to each of these areas. Induced Potential Test The induced potential test is used to test the quality of the transformer's insulation, as with the applied potential test above. It tests the insulation of the individual windings of the transformer by applying voltages between turns, between layers and between lines. Quality control impulse test Quality control impulse tests are made on transformers in order to simulate lightning; to see how well they withstand such high bursts of voltage. The electric impulses applied here can include reduced full-wave tests, chopped-wave tests and front-of-wave tests, to simulate a range of extreme voltage situations. Pressure Leak Test A transformer can be checked for pressure leaks by pressurizing the tank and then leaving it alone for several hours. If the pressure drops during the intervening time, or if there are signs of liquid leakage, then a leak is present. Otherwise, the transformer is leakage free.

Anda mungkin juga menyukai

- Short Circuit TestDokumen4 halamanShort Circuit TestHassan AbdoBelum ada peringkat

- Testing & Maintenance of Transformers: Listing Type Test, Routine Test & Special Test As Per I.S. 2026-1981Dokumen14 halamanTesting & Maintenance of Transformers: Listing Type Test, Routine Test & Special Test As Per I.S. 2026-1981PKBelum ada peringkat

- Method No: 2 (Current Voltage Method of Measurement of Winding Resistance)Dokumen6 halamanMethod No: 2 (Current Voltage Method of Measurement of Winding Resistance)Hassan AbdoBelum ada peringkat

- Polarity / Vector Group TestDokumen6 halamanPolarity / Vector Group TestHassan AbdoBelum ada peringkat

- Partial DischargeDokumen11 halamanPartial DischargeDavid_Allen_007100% (1)

- Testing Procedures for Power TransformersDokumen6 halamanTesting Procedures for Power TransformersSamsudin AhmadBelum ada peringkat

- Transformer Voltage Withstand and Insulation TestsDokumen7 halamanTransformer Voltage Withstand and Insulation Testskanchan206100% (1)

- Voltage Drop Control in Transmission Line Atbara-Portsudan 220 KVDokumen72 halamanVoltage Drop Control in Transmission Line Atbara-Portsudan 220 KVirfanWPKBelum ada peringkat

- Transformer BookDokumen48 halamanTransformer BookAloyalole AloyaloleBelum ada peringkat

- Introduction To Switch Gear and ProtectionDokumen12 halamanIntroduction To Switch Gear and ProtectionKrishna PrasadBelum ada peringkat

- Contoh Pengisian Enrollment FormDokumen3 halamanContoh Pengisian Enrollment FormAbu Akhtar Aira AlthafBelum ada peringkat

- Academic Projects For B.Tech/M.TechDokumen45 halamanAcademic Projects For B.Tech/M.TechhaleemforyouBelum ada peringkat

- Measuring Leakage Inductance PDFDokumen8 halamanMeasuring Leakage Inductance PDFaocalayBelum ada peringkat

- E570-97 Flux Leakage Ferro TubularDokumen6 halamanE570-97 Flux Leakage Ferro TubularAsif HameedBelum ada peringkat

- Transformer Winding Resistance Meter TRMDokumen15 halamanTransformer Winding Resistance Meter TRMSyed Haider FaizanBelum ada peringkat

- Testing and Commissioning ProceduresDokumen8 halamanTesting and Commissioning Proceduresbhukya lachiramBelum ada peringkat

- Validating Surge TestDokumen9 halamanValidating Surge Testquality10Belum ada peringkat

- 132kv Grid Station FNF, SheikhupuraDokumen18 halaman132kv Grid Station FNF, Sheikhupurasyed waheedBelum ada peringkat

- EHV - Grounding TransformerDokumen23 halamanEHV - Grounding Transformerm kh100% (1)

- Saturable ReactorDokumen2 halamanSaturable ReactorGilberto ManhattanBelum ada peringkat

- Maintaining Electrical SystemsDokumen8 halamanMaintaining Electrical SystemsHealthyCut FarmsBelum ada peringkat

- VT Guard Pro Protects VTs from Harmful Ferroresonance EffectsDokumen4 halamanVT Guard Pro Protects VTs from Harmful Ferroresonance EffectsAdemir DzanicBelum ada peringkat

- Lecture 02Dokumen20 halamanLecture 02AminaHaiderBelum ada peringkat

- Commissioning Service Department Commissioning Standard Test Formats Description: Functional Test - FeederDokumen8 halamanCommissioning Service Department Commissioning Standard Test Formats Description: Functional Test - FeedererstendrainBelum ada peringkat

- Eee Viii Electrical Design Estimation and Costing 10ee81 Notes PDFDokumen113 halamanEee Viii Electrical Design Estimation and Costing 10ee81 Notes PDFKaran Murthy33% (3)

- Testing and Monitoring of High Voltage Equipment InsulationDokumen43 halamanTesting and Monitoring of High Voltage Equipment InsulationGOKUL GBelum ada peringkat

- Rectifier O and M Manual - Nuberg - FluoderDokumen59 halamanRectifier O and M Manual - Nuberg - FluoderAnujGargBelum ada peringkat

- Open Circuit TestDokumen1 halamanOpen Circuit TestFatima MirBelum ada peringkat

- Modular Home Hipot Testing ComparisonDokumen1 halamanModular Home Hipot Testing ComparisonTTaanBelum ada peringkat

- Transformer Testing SafetyDokumen8 halamanTransformer Testing SafetyAvoor KhanBelum ada peringkat

- TransformerDokumen6 halamanTransformerrasheed313Belum ada peringkat

- Earthing system types and their characteristicsDokumen8 halamanEarthing system types and their characteristicsTony KontisBelum ada peringkat

- Protect Electrical Equipment from Over VoltagesDokumen16 halamanProtect Electrical Equipment from Over VoltagesSweqZBelum ada peringkat

- Transformer ProtectionDokumen29 halamanTransformer ProtectionSathish Kumar100% (1)

- Transformer Oil TestDokumen3 halamanTransformer Oil TestROYAL GAMINGBelum ada peringkat

- Rule 48 Precautions Against Leakage Before ConnectionDokumen23 halamanRule 48 Precautions Against Leakage Before ConnectionRK KBelum ada peringkat

- Find 3-Phase Transformer Impedance with Short Circuit TestDokumen2 halamanFind 3-Phase Transformer Impedance with Short Circuit TestAhsan KaziBelum ada peringkat

- Conductor Size, General: Table C-2 NEC References For Conductor SizingDokumen4 halamanConductor Size, General: Table C-2 NEC References For Conductor SizingYashwanth NBelum ada peringkat

- Class PSDokumen9 halamanClass PSAdeel RazaBelum ada peringkat

- Experiment 2: Level Transmitter CalibrationDokumen13 halamanExperiment 2: Level Transmitter CalibrationMuhammad FawwazBelum ada peringkat

- Generator Electrical Test #3Dokumen2 halamanGenerator Electrical Test #3Santoshkumar GuptaBelum ada peringkat

- How To Test The High Voltage CapacitorDokumen3 halamanHow To Test The High Voltage CapacitorShonBelum ada peringkat

- Chapter 1 Circuit Variables and ElementsDokumen10 halamanChapter 1 Circuit Variables and ElementsAli AjamiBelum ada peringkat

- Power System Analysis: Merger TestDokumen8 halamanPower System Analysis: Merger TestAnonymous mNQq7ojBelum ada peringkat

- Transmission line stringing guideDokumen15 halamanTransmission line stringing guidemarcelo3e3Belum ada peringkat

- 12.testing of High Voltage Equipment and Insulation CoordinationDokumen53 halaman12.testing of High Voltage Equipment and Insulation CoordinationumeshBelum ada peringkat

- Psps Ut 2 QBDokumen6 halamanPsps Ut 2 QBNaveen RajBelum ada peringkat

- Polarization Index TestDokumen3 halamanPolarization Index TestShahriar AhmedBelum ada peringkat

- Mapping The Electrostatic Potential and Electric FieldDokumen5 halamanMapping The Electrostatic Potential and Electric Fieldmende5100% (1)

- On Grid Sizing - 1Dokumen16 halamanOn Grid Sizing - 1Mohamed KhaledBelum ada peringkat

- Relay Coordination Chapter3Dokumen13 halamanRelay Coordination Chapter3Chân Gà NướngBelum ada peringkat

- Seminar Topic On: Circuit Breaker-IDokumen25 halamanSeminar Topic On: Circuit Breaker-IParameshwar TummetiBelum ada peringkat

- Reasons of Failures of CvtsDokumen5 halamanReasons of Failures of CvtsLalit Kumar JainBelum ada peringkat

- Idmt RelayDokumen3 halamanIdmt RelayTinku ChoudhuryBelum ada peringkat

- Distribution Transformer SpecificationDokumen21 halamanDistribution Transformer Specificationddhar633Belum ada peringkat

- Psps Unit 1 QBDokumen9 halamanPsps Unit 1 QBNaveen RajBelum ada peringkat

- Basic Electrical Machines (Eceg132) Laboratory Manual: Department of Electrical and Computer EngineeringDokumen158 halamanBasic Electrical Machines (Eceg132) Laboratory Manual: Department of Electrical and Computer EngineeringRonan Rojas100% (1)

- Knowledge is "Real Power": Introduction to Power QualityDari EverandKnowledge is "Real Power": Introduction to Power QualityBelum ada peringkat