04778673

Diunggah oleh

Umai BalanDeskripsi Asli:

Hak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

04778673

Diunggah oleh

Umai BalanHak Cipta:

Format Tersedia

Sensorless Control of IM in Mining Applications

Gregor Edelbaher, Branko Foner, Joe Koreli , Evgen Urlep , Milan Curkovi , Miran Rodi , c c c

University Premogovnik

of Maribor, Maribor, Slovenia Velenje, Velenje, Slovenia would be in the underground or external ventilators and compressor equipment. Speed and position sensors are not a practical solution due to many reasons. Some of them are: any sources of possible sparking should be avoided, the Ex-housing has to be used, any additional cabling introduces additional source of noise and disturbances. Additionally, there are already existing induction motors operating in the mines, which should not be replaced due to their high costs. But of course, there is a drawback of sophisticated control and somewhat deteriorated drive performances over the conventional drive. The main problem with sensorless control of induction motor arises at zero stator frequency and its vicinity. At zero frequency there is no back emf and therefore it is impossible to close the feedback. One can only use open loop control for low frequency region and then at some point change the control structure to closed loop. The idea was to upgrade the existing induction motor drives with the appropriate frequency inverters, which would enable the application of torque or speed control without the additional mechanical sensors mounted on the motor. This was achieved by the development of a new power inverter, which applies speed sensorless control algorithm, also presented in the paper. It is based on the DSP-2 card, developed at the Institute of Robotics. This hardware makes possible a rapid development and testing of induction motor control algorithms. A speed sensorless direct eld oriented control (DFOC) of induction motor was implemented on the test system, which has the nominal power of 132kW and is used for the hydraulic pump in the hydraulic station operating approximately 400m under ground level. In this paper we are presenting our solution for induction motor variable speed drive without the mechanical transducer. Drive is implemented with self developed DSP motor control board DSP2 based on TMS320C32 DSP and Xilinx FPGA. Power electronics stage was built with Semikron IGBT module. The paper is divided in seven sections. Mathematical presentation of the induction motor, a DFOC (Direct Field Oriented Control) control algorithm, back-emf rotor ux estimator and speed calculation are given in Section II. Power inverter is described in Section III, where the schematics are given. Non-linearities of the inverter are presented in Section IV, together with its compensation. Control implementation (software) is presented in Section V. The successful operation of the obtained software is

Abstract A power inverter applying a speed sensorless induction motor control is presented in the paper. It was designed with the goal to be used in applications positioned in the Ex-environment of the underground mines. Direct eld oriented control, using rotor ux and speed observer is used. The speed sensorless observer scheme is based on the back-emf observer. Applied hardware and software are presented. Operation is described with the use of experimental results, which were obtained from the actual application operating in the coal mine. The project is a good example of cooperation between the academia and industry.

I. I NTRODUCTION In the eld of underground coal mining a large amount of the process equipment is being used. All this equipment has to satisfy the process requirements, for which it has to exhibit a high robustness. Most of the machines are driven by the ac electrical motors, usually squirrel-cage induction motors, which is due to their simple construction and low cost. Besides all the good properties this motors also exhibit some bad ones - especially important is the high loading of the power sources in the starting phase, where currents become very high. Usually the induction motors in this kind of applications do not use the speed or position measurement, which is due to the fact, that no feedback control is applied to them. In order to improve the operation preferences and thereby reduce of the power consumption, feedback control has to be applied. At the Institute of Robotics, Faculty of Electrical Engineering and Computer Science, University of Maribor a power inverter applying the speed sensorless control scheme for the possible application in coal mines was developed in the cooperation with a Premogovnik Velenje company (Velenje Lignite Coal mine, Slovenia). The basic motivation for the project was the development of the power inverter in the Ex-environment construction, which would eliminate the negative properties of the classical drives and in the future enable the use of the other features offered by this kinds of equipment. On the basis of feasibility analysis of use of this kind of equipment in Velenje coal mine and other coal mines and heavy industry a very wide spectrum of possible applications was discovered. Main application areas are all kinds of transporters, ranging from chainto belt-driven ones, where the use of this kind of equipment would improve the operation. Further investigations showed another possibility in the pumping application, especially in water and hydraulics pumps. In the fresh air supply applications the interesting and useful possibilities

1-4244-0121-6/06/$20.00 2006 IEEE

1842

EPE-PEMC 2006, Portoro, Slovenia

EMF ctrl.

uqd

yrd

flux ctrl.

d isd

udc

current ctrl.

uss*

pd

dq

wrd

pressure ctrl.

speed ctrl.

Ted

k imr

d isq

3

i1

is

dq

i3

max dc

p

udc

udc ctrl. at braking

qr

^ wr rotor flux ^ yr and

uq

speed observer

^ uss

IM

Emulsion tank

Fig. 1.

Block schematics for DFO control of induction motor

presented in Section VI with the use of experimental results on the actual system. In Section VII a conclusion is given. II. T HEORETICAL BACKGROUND A. Induction Motor Model A three-phase symmetric voltage source inverter driven induction motor is considered to have sinusoidal distributed windings and short-circuited rotor. By neglecting hysteresis, eddy currents, and saturation of the magnetic circuit, the dynamic behavior of the induction motor is expressed by the state equations, viewed from the stator frame (a-b frame), as [1]: 1 dis s = dt Ls d s r = dt Te = us Rs is s s Lm d s r Lr dt (1)

B. Direct Field Oriented Control Field-oriented control (FOC, Fig. 1) is applied to induction motor drives in order to perform a fast decoupled control of torque and ux. A prerequisite for that is the information about the rotor ux angular position calculated in the frame of FOC algorithm. As a consequence it is possible to control torque and rotor ux in a dc motor control fashion, by acting on two separate components of the stator current. The position of the rotor ux is calculated from the air-gap ux vector position, directly measured by suitable ux-sensing devices or calculated from the appropriate rotor ux estimator or observer [2], [3], [4], [5], [6], [7], [8], [9], [10]. In DFO the stator winding is supplied by current (voltage source inverter with digital current control loop). Phase currents are measured by LEM sensors and phase voltages are estimated from PWM duty cycles. Rotor ux estimator estimates rotor ux from these voltages and currents. Estimated rotor ux is then used to maintain rotor eld orientation. The DFO control presents the inner control loop. Reference currents for the DFO control are obtained from the cascaded ux and speed controller. Because the motor shaft speed is not measured, it is estimated from stator frequency and compensated for the slip frequency. The basic assumption of the FOC is: rd = | r | = Lm imR , rq = 0 (5)

Rr Lm s jpr s + Rr i r Lr Lr s 2 Lm s s s p (ra isb rb is ) sa 3 Lr J dr = Te Tl dt

(2)

(3)

(4)

where r is the mechanical rotor angle velocity, two s s dimensional complex space vectors s = sa + jsb , s s s s s s s s s r = ra + jrb , us = usa + jusb , is = isa + jis sb are stator and rotor ux, stator voltage and current, respectively, Te is motor torque and Tl is load torque, J is inertia of the rotor and p is the number of pole pairs.

where imR is so-called magnetizing current. The current in the rotor eld reference frame is presented as: (6) is = isd + jisq

1843

where: isd = isa cos (r ) + isb sin (r ) is the magnetizing and isq = isa sin (r ) + isb cos (r ) (8) (7)

D. Motor Shaft Speed Calculation Motor shaft speed r is calculated from estimated angular frequency of stator current (12) and estimated slip frequency (13) by expression (14). e = s s ra es rb es ra rb s ra

2 2

(12)

is the torque generating component. Rotor ux was calculated using an observer, presented in the following text. The ux angle r was obtained by the use of: (9) r = atan2 rb , ra . C. Back EMF and Rotor Flux Estimation Rotor ux estimator as proposed by Ohtani [10] is used to reduce the stator resistance inuence at low speed. A lag circuit is employed, to which both the motor induced voltage and the rotor ux command are imposed, and therefore it is possible to calculate rotor ux and speed even at very low frequency down to standstill. It employs rotor ux estimator parameter Tf to set the same time constant to the lag circuit as that of the rotor circuit to reduce the inuence of stator resistance. The proposed rotor ux estimator is shown in Fig. 2 and composed of two lag circuits. Rotor induced voltage er is imposed to the lag circuit Tf /(1 + Tf s) and rotor ux command rd is imposed to the other lag circuit 1/(1 + Tf s) and the addition of them becomes the estimated value of the rotor ux. Calculated rotor induced voltage er is obtained from: es = r d s Lr r = dt Lm us Rs is Ls s s dis s dt . (10)

s + rb

sl =

Rr isq Lm Lr rd e sl p

(13) (14)

m =

III. P OWER I NVERTER The role of the power inverter is to produce the desired voltage on the stator windings with the switching of switch elements T1-T6, Fig. 3. Inverter inputs are the control signals of transistors, controlled by the PWM modulator. Its task is to transform desired voltage vectors into the relative time intervals in which transistors should be turned on. Hardware conguration of the power inverter is the following: DSP2 board (oating point DSP motor control board) SKiiP 603GD122-3DUW three phase IGBT module made by Semikron (UCES = 1200V, Ic = 600A) 2 x LEM current transducer DC link capacitor bank heat sink with fan cooling power supply & Skiip interface board Inverter nominal power: P = 164kW Power grid voltage: 3 500Vrms Maximal DC-link voltage: 800V Maximal current: 190Arms Water cooling Switching frequency: 5kHz Ex-housing IV. C OMPENSATION OF B RIDGE N ON -L INEARITY Since the switching times of the existing transistors are not innitely short the necessary blanking time to avoid

R

D7 D8 D9

T7 T8 T9 T1

D1 T2 T3

Estimated rotor ux is then obtained from: s (s) = r Tf 1 es (s) + d (s) r 1 + Tf s 1 + Tf s r (11)

where Tf is the time constant of the lag circuit. It is shown in [10] that when Tf = Tr , the phase error caused from the resistive parameters is reduced to a smaller level, at low speed or almost standstill. From rotor ux space vector the rotor ux angle is calculated, which becomes transformation angle for transformations between synchronous d-q and stationary - reference frames.

us is

Rs +sLs s

d r

er

Mains

Tf

Tf

^ yr

D2

D3

C

T4 T5 T6

y

qr

D10 D11 D12

D4

D5

D6

ej

qr

Tf

M 3~

Fig. 3. Power inverter conguration

Fig. 2.

Rotor ux estimator

1844

DC link short circuiting during commutations must be introduced. This small time delay, also called dead time is the most important cause of the inverter non-linearity and introduces a magnitude and phase error in the output voltage. The dead-time introduced by the inverter causes serious waveform distortion and fundamental voltage drop when the switching frequency is high compared to the fundamental output frequency. One way of dealing with inverter imperfections is to use nonlinear inverter model to compensate for the dead time [11]. The voltage drop caused by the dead-time effects can be approximated by a xed threshold voltage uc and a current dependant component Rd is , where the Rd is modelled inverter resistance for one branch and the is is the branch current, as shown in Fig. 4. While not very accurate, this method still offers good results and is easy to implement in an industrial drive. V. C ONTROL I MPLEMENTATION Software for DSP board is coded mainly in C-language. Because selected DSP has oating point capabilities, software implementation is much easier than it would be on a xed point processor. Program structure is the following (Fig. 5): "main" function, which takes care mostly about initialization and user interface, "interrupt0" function, which takes care about the motor control, with cycle time of 200s, "interrupt1" function, providing CAN communication and calculating pressure controller, with cycle time of 10ms. Pulse width modulator, which is implemented inside of XILINX FPGA, is source of interrupts and it triggers A/D conversions as well. Control algorithm is executed inside of "interrupt0" function, which is triggered by PWM module. Current and voltage sampling is made at the beginning of switching cycle, when none of IGBTs is switching. Current and voltage sampling and A/D conversions are implemented locally on XILINX FPGA and no assistance from DSP is needed for these actions. After all A/D channels are converted, results are available in corresponding FPGA registers that are located inside of DSP memory map. User interface is available only when PC computer is connected with controller via RS232 link, but is needed only during the development phase since all of the ap

plication related data is readily available over the CAN bus. VI. E XPERIMENTAL R ESULTS Regarding the current trends in the development of vital construction elements for equipment, appropriate for the use in the proposed systems with 500V and 1000V voltage level and powers, higher than 150kW, only recently reached the acceptable level (also in size), the rst model was tested under the realistic coal mine conditions in the year 2004. After the certication for the use in Ex-environment it was introduced into the test operation in 2005. From many possible applications, the one of the highpressure pumping facility for the production of the hydraulic medium for the control of the mining supporters was chosen. Simplied scheme of the controlled water pump system incorporated into the existing high-pressure pumping facility system is shown on Fig. 6. Fig. 7 is showing the picture of the used hydraulic pump and Fig. 8 the picture of the power inverter used. The results of the inverter-driven system, based on DSP-2 card with oating point capabilities, which was used to drive and control the pump operation, were in the expected range. Schematic block diagram of the DSP-2 board is shown on Fig 9. The system was supervised from the companys centre for supervision. For the measurement, processing and transfer of the data a program CANDEX, produced by the Velenje Coal Mine company, was used. For the supervision of operation program package INTOUCH was applied. Fig. 10 is showing approximately 30min of the system operation, presenting system pressure (Fig. 10a), motor electrical torque (Fig. 10b), motor speed (Fig. 10c) and DC-link voltage (Fig. 10d) during operation. Parameters of the induction motor driving hydraulic pump were:

main

hardware initialization

interrupt0

interrupt1

current and voltage measurements

reference values

CAN data receieve

reference values

variables initialization

interrupts initialization

protections

pressure controller

interface to PC

control algorithm

CAN data send

uss*

inverter model

PWM

IM

data sending data receiving

return

modulator

^ u

Fig. 4.

s s

uc

Rd

is

interface

data acquisition

return

Stator voltage estimation using nonlinear inverter model

Fig. 5.

The basic software structure

1845

PS

Hydraulic grid 310 bar

Pump bypass valve

El. grid 500V, 50 Hz

Inverter

Legend:

Pn P2 P1

P - Pump PS pressure sensor M AC motor

Emulsion tank

Fig.6. Simplified scheme of hydraulic system

Fig. 7.

Hydraulic pump

Fig. 8.

Power inverter in Ex-housing

Rs = 0.037 Rr = 0.037 Ls = Lr = 0.01H Lm = 0.0096H p = 2. The starting-point was the control of constant pressure of 310bar. The pressure was measured with the use of the pressure sensor. Due to the highly dynamic behavior of the hydraulic grid consumption, a high dynamics of the pressure controller, cascaded to the speed controller, had to be assured. The output of the pressure controller was used for the control of electric motor - rotation speed (Fig. 10c) and torque (Fig. 10b). The control range was related to the range of the pump and lubrication. It was between 1000 and 1500 rpm. The dynamics of controller responses was suitable for the control of pressure in hydraulic grid. If sufcient quantity of the medium is produced by one pump (approx. 210l/min), pressure control is satisfactory. When the consumption increases, the pressure drops, even if the speed of electric motor rotation is minimal. In this case an additional pump has to be started, which results in the lower requirements for the torque and speed of the

controlled pump operation. In this case the controlled pump operates on the lower boundary of the working range, even though it should be rotating with the speed lower than 1000rpm. However, this is not possible due to the lubrication requirements of the pump (problems at lower speed), which was one of the important limitations of the applied system. Since the power inverter can operate in generative mode only for short periods of time, DC-link voltage during speed decreasing has to be held under 800V by the usage of the DC-link voltage controller applied to the braking torque level limit. Fig. 10d is showing DC-link voltage level during the operation. Voltage spikes occurred during braking periods, but their maximum values are well under rated 800V of the DC-link voltage capacitors. VII. C ONCLUSION There are many reasons to use speed sensorless controlled induction motors in the mining applications. The main motivation is the reduction of the power consumption, which results in the reduced energy costs and thereby increased cost-efciency of the enterprise. A speed sensorless induction motor application was

1846

SRAM 0WS 128K x 32

32

DSP TM S320C32-60

CAN 16 GP I/O

EEPROM 4...256kb

2 I C

16

EEPROM interface

XDS510 MPSD Port

SAE81C90

H/W INTERLOCK MIN. DEADTIME

RS232

ADM232A

RS232 interface

PERIOD

JTAG RS485

LTC485

RS485 interface

INCR. ENC. interface

RS422

Boundary Scan Logic

A/D interface

D/A interface

I/O

10 GP I/O PINS INC.ENC.

XilinX XCS40PQ240

INVERTER

CAN interface

DT

SERIAL PORT

FLASH 256 x 8

Power supply supervisor

Regardless the presented limitations a desired operation was achieved with the presented inverter system. This is especially shown by the following facts: starting current of the pump electric motor was reduced, the consumption of electrical energy was reduced, the life expectancy of the pump is increased, the damaging pressure spikes in the grid, which occur due to the starting of pump bypass valve operation in the classical operation, are reduced. Regarding all this facts and the fact that the user is satised with the results we can claim, that the application is successful. ACKNOWLEDGMENT The project entitled "Modern Control Technologies for Improving Competitiveness" is approved and subsidized by European Fund for Regional Development. The work was done in the frame of the development project "Automation of machines and equipment" (Ak3-3/DP3: Development and realization of the induction motor speed sensorless control system). The authors gratefully acknowledge the contributions of Ministry of Economy, Slovenia and Premogovnik Velenje (Velenje Coal mine), Velenje, Slovenia. R EFERENCES

[1] J. Holtz, The Representation of AC Machine Dynamics by Complex Signal Flow Graphs, IEEE Transactions on Industrial Electronics, vol. 42, no. 3, June 1995, pp. 263271. [2] W. Leonhard, Control of Electric Drives, 2nd ed., Springer Verlag, Berlin, Germany, 1997. [3] P. Vas, Sensorless Vector and Direct Torque Control, Oxford University Press, 1998. [4] J. Holtz, Methods for speed sensorless control of ac drives, Sensorless control of ac motors, ed. K. Rajashekara, IEEE Press Book, 1996. [5] K.M.H. Kubota and T. Nakano, DSP-based speed adaptive ux observer of induction motor, IEEE Trans. Ind. Appl., vol.29, 1993, pp.344-348. [6] A. Consoli, G. Scarcella, and A. Testa, Slip-Frequency Detection for Indirect Field-Oriented Control Drives, IEEE Transactions on Industry Applications, Vol. 40, No. 1, January/February 2004. [7] R. D. Consoli, G. Scarcella, A. Testa, and T. A. Lipo, Air-gap ux position estimation of inaccessible neutral induction machines by zero sequence voltage, Elect. Mach. Power Syst. Journal, vol. 30, no. 1, pp. 77-88, Jan. 2002. [8] M. Rodic, K. Jezernik, A. Sabanovic, Speed sensorless sliding mode torque control of induction motor, Conf. Rec. IEEE-IAS Ann. Meeting, 2000, pp.1820-1827. [9] J. Holtz and J. Quan, Sensorless Vector Control of Induction Motors at Very Low Speed Using a Nonlinear Inverter Model and Parameter Identication, IEEE transactions on Industry Applications, vol. 38, no. 4, Jul./Aug. 2002. [10] T. Ohtani, N. Takada, and K. Tanaka, Vector control of induction motor without shaft encoder, IEEE Trans. Ind. Applicat., vol. 28, pp. 157-165, Jan./Feb. 1992 [11] A. R. Munoz and T. A. Lipo, On-Line Dead-Time Compensation Technique for Open-Loop PWM-VSI Drives, IEEE Transactions on Power Electronics, vol. 14, pp. 683-689, Jul. 1999.

A/D A/D A/D A/D 400kS/s 12bit 12bit 12bit 12bit

D/A D/A 12bit 12bit

+-

MUX

LPF

LPF

LPF

LPF

8x 10V

0..10V 10V 10V

0..5V -5..5V 0..5V

3xIN 1xOUT

Fig. 9.

340

Simplied block diagram of the DSP-2 board

(a)

320

p(bar)

300

280

260

400

200

600

800

1000 t(s)

1200

1400

1600

1800

2000

800

(b)

600

T(Nm)

400

200

0 0 200 400 600 800 1000 t(s) 1200 1400 1600 1800 2000

160

140

wr w

(c)

w(rad/s)

120

100

80

0

200

400

600

800

1000 t(s)

1200

1400

1600

1800

2000

800

(d)

U (V)

750 700 650

dc

200

400

600

800

1000 t(s)

1200

1400

1600

1800

2000

Fig. 10.

Experimental results

presented, the applied equipment was described and presentation of experimental results was given. Presented application is an example of the cooperation between the industry and academia, leading to new products and improvement of the competitive position of the company on the world market.

1847

Anda mungkin juga menyukai

- New Sensorless Commutation Technique For Brushless DC MotorsDokumen10 halamanNew Sensorless Commutation Technique For Brushless DC MotorsUmai BalanBelum ada peringkat

- Dynamic Spectrum Allocation in Wireless Cognitive Sensor Networks: Improving Fairness and Energy EfficiencyDokumen5 halamanDynamic Spectrum Allocation in Wireless Cognitive Sensor Networks: Improving Fairness and Energy EfficiencyUmai BalanBelum ada peringkat

- 04153344Dokumen6 halaman04153344Umai BalanBelum ada peringkat

- Power Management Solutions For Energy Management, Power Quality and Environment Using Battery Energy Storage SystemsDokumen1 halamanPower Management Solutions For Energy Management, Power Quality and Environment Using Battery Energy Storage SystemsUmai BalanBelum ada peringkat

- A Self Adaptable Intelligent Battery Charger For Portable ElectronicsDokumen5 halamanA Self Adaptable Intelligent Battery Charger For Portable ElectronicsUmai BalanBelum ada peringkat

- Shoe Dog: A Memoir by the Creator of NikeDari EverandShoe Dog: A Memoir by the Creator of NikePenilaian: 4.5 dari 5 bintang4.5/5 (537)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDari EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifePenilaian: 4 dari 5 bintang4/5 (5794)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDari EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RacePenilaian: 4 dari 5 bintang4/5 (895)

- The Yellow House: A Memoir (2019 National Book Award Winner)Dari EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Penilaian: 4 dari 5 bintang4/5 (98)

- Grit: The Power of Passion and PerseveranceDari EverandGrit: The Power of Passion and PerseverancePenilaian: 4 dari 5 bintang4/5 (588)

- The Little Book of Hygge: Danish Secrets to Happy LivingDari EverandThe Little Book of Hygge: Danish Secrets to Happy LivingPenilaian: 3.5 dari 5 bintang3.5/5 (400)

- The Emperor of All Maladies: A Biography of CancerDari EverandThe Emperor of All Maladies: A Biography of CancerPenilaian: 4.5 dari 5 bintang4.5/5 (271)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDari EverandNever Split the Difference: Negotiating As If Your Life Depended On ItPenilaian: 4.5 dari 5 bintang4.5/5 (838)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDari EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyPenilaian: 3.5 dari 5 bintang3.5/5 (2259)

- On Fire: The (Burning) Case for a Green New DealDari EverandOn Fire: The (Burning) Case for a Green New DealPenilaian: 4 dari 5 bintang4/5 (74)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDari EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FuturePenilaian: 4.5 dari 5 bintang4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDari EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryPenilaian: 3.5 dari 5 bintang3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnDari EverandTeam of Rivals: The Political Genius of Abraham LincolnPenilaian: 4.5 dari 5 bintang4.5/5 (234)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDari EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaPenilaian: 4.5 dari 5 bintang4.5/5 (266)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDari EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersPenilaian: 4.5 dari 5 bintang4.5/5 (345)

- The Unwinding: An Inner History of the New AmericaDari EverandThe Unwinding: An Inner History of the New AmericaPenilaian: 4 dari 5 bintang4/5 (45)

- Rise of ISIS: A Threat We Can't IgnoreDari EverandRise of ISIS: A Threat We Can't IgnorePenilaian: 3.5 dari 5 bintang3.5/5 (137)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDari EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You ArePenilaian: 4 dari 5 bintang4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Dari EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Penilaian: 4.5 dari 5 bintang4.5/5 (121)

- Her Body and Other Parties: StoriesDari EverandHer Body and Other Parties: StoriesPenilaian: 4 dari 5 bintang4/5 (821)

- CCFL - Precautions and Procedures For Accurate Voltage MeasurementsDokumen1 halamanCCFL - Precautions and Procedures For Accurate Voltage MeasurementsSicoe VasileBelum ada peringkat

- Uniquefire Catalog Chapter 09Dokumen4 halamanUniquefire Catalog Chapter 09Lee WenjianBelum ada peringkat

- Medium Voltage Switchgear Room DesignDokumen3 halamanMedium Voltage Switchgear Room DesignSunil ParikhBelum ada peringkat

- Adb Wind ConeDokumen4 halamanAdb Wind ConeSulistyo WidodoBelum ada peringkat

- Bioentry W: Installation GuideDokumen20 halamanBioentry W: Installation GuidePaul CuevaBelum ada peringkat

- Mag B760M Mortar Max Wifi DDR4Dokumen1 halamanMag B760M Mortar Max Wifi DDR4Taewhan JungBelum ada peringkat

- RealmctubeDokumen15 halamanRealmctubeToM100% (6)

- Catalogue of Insulator and Surge Arrester - Orient ChinaDokumen66 halamanCatalogue of Insulator and Surge Arrester - Orient Chinapham thang0% (1)

- 10 III March 2022Dokumen6 halaman10 III March 2022Rehana TahasildarBelum ada peringkat

- Experiment 1 SCRDokumen23 halamanExperiment 1 SCREmry MenezBelum ada peringkat

- Terex Digger Derrick Operators Manual 6Dokumen20 halamanTerex Digger Derrick Operators Manual 6Israel SotoBelum ada peringkat

- MERCURY 30 40 HP Instruktsiya Po Zamene Svechey Zazhiganiya I Rem - Komplekta Pompy Sistemy OhlazhdeniyaDokumen4 halamanMERCURY 30 40 HP Instruktsiya Po Zamene Svechey Zazhiganiya I Rem - Komplekta Pompy Sistemy OhlazhdeniyaScott BakerBelum ada peringkat

- Drawings 04272017Dokumen118 halamanDrawings 04272017Robert TirtaBelum ada peringkat

- 977205PDokumen49 halaman977205PChu QuynhBelum ada peringkat

- DL PU酗尸: Products Ma■UalDokumen24 halamanDL PU酗尸: Products Ma■UalMahmoudBelum ada peringkat

- Running Casing With Weatherford Overdrive System - Best PracticesDokumen1 halamanRunning Casing With Weatherford Overdrive System - Best PracticesYougchu LuanBelum ada peringkat

- BinMaster SensorsDokumen10 halamanBinMaster SensorsdarkpilotBelum ada peringkat

- DEMO LESSON PLAN - Electric Motor&GeneratorDokumen9 halamanDEMO LESSON PLAN - Electric Motor&Generatormary graceBelum ada peringkat

- Chieftec Aps 650cbDokumen26 halamanChieftec Aps 650cbbatamazurBelum ada peringkat

- CableCALC BS 7671 Operating ManualDokumen17 halamanCableCALC BS 7671 Operating Manualjodie_patrickBelum ada peringkat

- XL4015Dokumen9 halamanXL4015Jose M PeresBelum ada peringkat

- Defence Engine: 261-336 KW (350-450 HP) 1491-1850 NM (1100-1364 LB-FT)Dokumen2 halamanDefence Engine: 261-336 KW (350-450 HP) 1491-1850 NM (1100-1364 LB-FT)Aamir ArainBelum ada peringkat

- Group 1 - JFET - NSESP 2021Dokumen16 halamanGroup 1 - JFET - NSESP 2021Sisilia Anabina TariganBelum ada peringkat

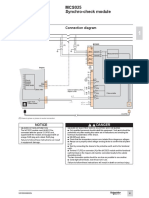

- MCS025 Synchro-Check Module: InstallationDokumen1 halamanMCS025 Synchro-Check Module: Installationوسام وسامBelum ada peringkat

- Service Manual Vox VT40+Dokumen16 halamanService Manual Vox VT40+Marco Antonio Chaparro Acosta100% (2)

- HE800DIQ716CDokumen8 halamanHE800DIQ716CRicardo NunesBelum ada peringkat

- Minutes Bucket Elevator Teleconference October 5 2012Dokumen6 halamanMinutes Bucket Elevator Teleconference October 5 2012Vinod Kumar VermaBelum ada peringkat

- Upmo, Ovcpd Uplb: The Electrical Services SectionDokumen24 halamanUpmo, Ovcpd Uplb: The Electrical Services SectionMickiee OracionBelum ada peringkat

- X1313EX13AX13AFDokumen16 halamanX1313EX13AX13AFCarlos Castillo Urrunaga100% (1)

- Yaskawa SGDB ManualDokumen652 halamanYaskawa SGDB ManualMichael KennaBelum ada peringkat