Low Cost Digital Thermometer: Department of Biomedical Engineering

Diunggah oleh

systemdllDeskripsi Asli:

Judul Asli

Hak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

Low Cost Digital Thermometer: Department of Biomedical Engineering

Diunggah oleh

systemdllHak Cipta:

Format Tersedia

Low Cost Digital Thermometer

BME 301 Department of Biomedical Engineering University of Wisconsin-Madison March 11, 2009 Natasha Benkovich, BSAC Colleen Farrell, Team Leader Hallie Kreitlow, Communicator Deborah Yagow, BWIG Clients: Amit Nimunkar and Jonathan Baran Advisor: Professor John G. Webster Department of Biomedical Engineering

Table of Contents Abstract...2 Problem Statement..3 Background 3 Competition.........4 Client Requirements6 Ergonomics..6 Common Features7 Design Option 1: Portable with Contained Circuitry and Power Source.8 Design Option 2: Attached Thermometer with Internal Circuitry...9 Design Option 3: Attached Thermometer with Circuitry in MedCal..9 Design Matrix10 Future Work on Final Design ...11 References..12 Appendices.13 Appendix A: Current Patents.13 Appendix B: Cost Estimate14 Appendix C: Project Design Specifications...14

Abstract Thermometers are used to take the core body temperature of patients. Currently, mercury thermometers are used to take temperatures in developing countries (Hackett-Hemwall Foundation 2009). These thermometers no longer work once they are broken and are harmful to the environment and people. With their unpredictable funding, emerging countries cannot always purchase new thermometers. The goal of this project is to meet the needs of emerging countries by creating a functional, low-cost, and durable thermometer, which will operate with the MedCal.

Problem Statement Emerging countries are in need of a durable, low-cost thermometer to operate with the MedCal, a handheld medical output device. The thermometer's incorporated circuitry should produce accurate temperature measurements through the use of a human interface. Background Medecal is a University of Wisconsin initiative to develop an economical medical technology platform to make healthcare technology affordable and available in emerging countries (Baran 2009). The current focus is on respiratory and lung diseases. In addition to the low-cost equipment, an output device called the MedCal is under development. The MedCal (Figure 1) is a compact, handheld medical calculator, which operates with multiple low-cost devices including the thermometer, pulse oximeter, and spirometer. The MedCal will power itself and any devices attached to it using a 9 or 12V lithium-ion battery. The user interface will have a minimal number of inputs to simplify use.

Figure 1: Prototype of MedCal.

Core body temperature is important for determining the physiological state of an individual. It can evaluate various physical conditions including shock and infection (Webster 1998). The proximity of the temperature reading to the actual core temperature differs according

to the site of measurement. For instance, oral measurements are lower than core temperature by ~0.5C and rectal measurements are lower than core temperature by as much as 2C (Webster 2004). Emerging countries differ from more developed countries in several ways. Hospitals in emerging countries often have staff with limited technical knowledge and consequently if something breaks, they will likely not know how to repair it. This causes the equipment to have a reduced useful lifetime. Furthermore, it is unknown if or when funding will be received, which means purchasing parts or disposable parts is not always feasible. Finally, electric power fluctuates and goes out on a regular basis and therefore cannot be depended on to power equipment (Longombe 2000). Competition There are currently a number of options available commercially for thermometers. The first and most basic option available is the mercury thermometer (Figure 2). This is a non-digital thermometer that uses the expansion of mercury contained in a glass tube. The temperature can be read based on calibrated markings that are placed on the sides of the glass. This thermometer uses very low technology and is very cheap. However, the mercury it contains can be very harmful if the glass is broken and therefore released. The glass of this design is not rugged enough for emerging countries and often they do not have the proper disposal for the exposed mercury should the glass break. Another problem with the mercury thermometer is that to read the temperature there is a Figure 2: Mercury Thermometer

wait time of approximately three minutes for the mercury to reach the correct temperature. With short staffing and limited resources, three minutes can be too long to have to wait for a reading.

Another thermometer design that is currently available is the thermistor digital thermometer (Figure 3). This design uses a thermistor contained within a metal probe to detect temperature change due to the resistance change proportional to the temperature. This resistance change produces a change in the voltage output of the system and a temperature can be detected. This design uses basic technology to keep the cost relatively low, but there are still additional parts that make it unsuitable for emerging countries. The sound and LCD display features add unnecessary cost and the watch battery used for power would not be easily replaced in many emerging countries, making the Figure 3: Digital Thermistor Thermometer. thermometer useless once the battery died.

The final type of thermometer that is currently available utilizes infrared technology (Figure 4). This thermometer measures the infrared energy from the tympanic membrane in the ear and converts it to an electrical signal. It allows for a quick, non-invasive measurement. A major disadvantage of this technology is that it is more expensive and more complex. For emerging countries, it is important that the design be simple and rugged to withstand rough conditions. The design is complicated and the moving parts involved could be broken and would not be easily repaired. Figure 4: Infrared Thermometer.

Finally, in Appendix A, a few relevant patents involving thermistor temperature sensors are listed. Client Requirements The main factor of the design is that the thermometer must be low-cost. Current goal aims to keep the cost below three dollars. The client is willing to sacrifice aesthetics and extra bells and whistles that are unnecessary in the MedCal application. The device needs to be durable to survive the shipment to these countries and be able to withstand high temperatures, being dropped, and years of operation. It must be simple with little or no maintenance, or will quickly go unused. The required accuracy is 1 C, and the most accurate range of detection should be within 32 to 42 C. The device must be calibrated for both oral detection on adults and rectal detection on children. Finally, it must interface with the MedCal via a cord and port to input temperature information. Ergonomics In order to be sure this product would be usable by all patients and physicians, it is important to consider ergonomics in the design. By incorporating the human factors during the design phase, it will hopefully prevent errors in the medical recording and injuries of the patients or doctors. This product will be used in foreign countries, and therefore the language and literacy barrier is important. A person should be able to successfully use the thermometer regardless of his or her native language. A series of universal symbols or colors will be incorporated to indicate the function or mode of the thermometer. Also, it is important to be able to have different modes of use in order to accommodate both oral and rectal measurements. The design must be simple and intuitive. By having a simple design, it will cut down on the number of parts, which will cut down on the overall cost. Having it be intuitive would aid in

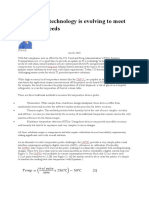

the ease of use by the foreign physicians as well. Finally, and most importantly, the thermometer must be safe. There must be a tolerance of error built into the design to ensure safety regardless of use. If, for example, the patient bites the probe there should not be any harm to the patient or the probe. Common Features The three design options for the thermometer have many common features. They all utilize a thermistor as the temperature sensor. Thermistors are temperature-sensing elements made of semiconductor material that has been sintered in order to display large changes in resistance in proportion to small changes in temperature. This resistance can be measured by using a small and measured direct current, or dc, passed through the thermistor in order to measure the voltage drop produced. The resistance of an NTC thermistor will decrease as the temperature increases (Ametherm). The thermistor runs leads into the rest of the circuitry, as shown below in Figure 5. This analog voltage information then enters a microcontroller either in the portable device (Design Option 1) or through a cord into the MedCal (Design Options 2 and 3). The programming language C will be used to encode a calibration curve into the microcontroller that extrapolates 20 seconds worth of temperature readings to predict the final temperature, which would usually take about three minutes. There will be two calibration curves, one for oral use and one for rectal temperature readings. Figure 5: Circuitry utilizing Differential Op-Amp.

Figure 6: Thermistor. The thermistor (Figure 6) will be located at the tip of the thermometer probe. At the junction between the thermistor and the area for temperature detection, a thermally conducting material is needed (seen as gray in Figure). The material will be a metal and it is likely to be stainless steel. Stainless steel does not corrode with the use of bleach for sterilization and it is a relatively low cost metal that is often used in medical applications. Inside the thermometer probe, some type of material will need to fill the empty space as to ensure a lack of movement among the circuit elements (seen as light green in Figure 6). The light blue material seen in Figure 6 will be a thermally conducting material to make sure heat can transfer between stainless steel and thermistor head. Design Option 1: Portable with Contained Circuitry and Power Source Design Option 1 (Figure 7) is independent of the MedCal in terms of power and circuitry. The power source is from a battery, likely AA or AAA because that is what is most available in emerging countries (Hackett-Hemwall Foundation 2009). After taking a temperature measurement, the thermometer is plugged into the MedCal to obtain an output. A microcontroller inside of the thermometer stores the value of the temperature given from the circuit and then later relays that information to the MedCal. This device is very similar to that of a digital thermometer purchased at a drug store except that it does not have a digital display keeping the price low.

Figure 7: Design Option 1, Portable Thermometer. 8

Design Option 2: Attached Thermometer with Internal Circuitry Another option (Figure 8) has the circuitry contained within the thermometer device itself while connected to the MedCal. This option is connected to the MedCal as a source of power, but houses its own internal circuitry. The value of the temperature reading goes directly to the MedCal and provides a reading immediately after detection. An advantage of this design is that less internal parts are necessary for operation, simplifying the probe.

Figure 8: Design Option 2, Attached Thermometer with Internal Circuitry Design Option 3: Attached Thermometer with Circuitry in MedCal The last option (Figure 9) considered is that of a thermometer with circuitry in the MedCal. This design employs the simplest thermometer probe containing only the thermistor circuit element. The power source and the circuitry are contained in the MedCal. The thermistor lies at the end of the thermometer probe contacting a thermal conducting material, likely to be a metal. The thermistor then has leads, which are kept separate, that connect to the circuit through a wire that attaches to the MedCal. An advantage of this device is that the circuitry can be kept safer through encasement within the MedCal. The thermometer probe is cheaper this way and a replacement thermometer could easily be added to the MedCal if needed.

Figure 9: Design Option 3, Attached Thermometer with Circuitry in MedCal 9

Design Matrix When creating a design matrix (Table 1) the most important elements to consider were cost and durability. Accuracy, usability, size, weight, safety and feasibility were also considered. The completely portable device scored the lowest due to its relatively high cost, lower rate of durability, and difficulty to fabricate. The third design option displayed above scored slightly higher than the second due the circuitry being housed in the MedCal, which is beneficial for many reasons. The circuitry is safer in the MedCal, keeping the thermometer probe casing cost low. In the end the simplest, cheapest, and most durable design was chosen.

Table 1: Design Matrix

WeightsDesign Accuracy Options Portable w/ internal circuitry Attached w/ internal circuitry Attached w/ circuitry in MedCal 3 4 3 5 5 4 Yes 4.25 3 3 3 4 4 4 Yes 3.55 3 2 4 2 3 2 Yes 2.5 Durability Usability Cost Size/Weight Feasibility Safety Total 0.1 0.2 0.15 0.4 0.1 0.05 Y/N

10

Future Work on Final Design For the rest of the semester, it will be important to bring this design to the phase of an operable prototype. First, it will be necessary to simplify the current circuitry employed to measure the temperature change. This could be done by either cutting down on the number of operational amplifiers that are being used or by using a quad operational amplifier or by using a variation of the Wheatstone bridge with a potentiometer. This simplification will be done to cut down the cost of the circuitry. It will then be important to do testing on the final design and obtain calibration values in order to later program the device to output a temperature reading from the given voltage. In order for this to become a workable prototype, the external casing must be developed as well as the circuitry. It must be determined which materials are best to use for both the probe and the cord connecting the probe to the MedCal. It will also be important to decide the best way to secure the device together to ensure it is water tight and safe for use on patients.

11

References Ametherm. 2009. What is an NTC thermistor [Online] http://www.ametherm.com/ntcthermistor-probes/what_is_an_ntc_thermistor.htm Baran, Jonathan. 2009. Medecal Project. Rep. v. 4. Bioinstrumentation, 4th edition. John G. Webster (ed.), John Wiley & Sons. New York, 2004 ECE Lab. 2006. Differential Instrumentation Amplifier with a Bridge Transducer [Online] http://www.ecelab.com/circuit-diff-in-amp.htm Focus Technology Co. 2009. Infrared Ear Thermometer (ET-100B) [Online] http://www.madein-china.com/image/2f0j00pCBtnTUfIEikM/Infrared-Ear-Thermometer-ET-100B-.jpg Germes LLC. 2005. Digital Thermometer [Online] http://www.global-b2bnetwork.com/direct/dbimage/50066780/Digital_Thermometer__waterproof_.jpg Hackett-Hemwall Foundation. Engineering World Heath Seminar. 2009. LatNet Internet Business News. 2007. Google Flu Trends Thermometer [Online] http://latnet.biz/wp-content/uploads/2008/11/mercury_thermometer.jpg Longombe, MD, PhD, Ahuka Ona. Appropriate Medical Technology for Developing Countries: Experience for CME Nyankunde. Centre Medical Evangelique of Nyankunde, D.R. Congo. 2000. Medical Instrumentation: Application and Design, 3rd edition. John G. Webster (ed.). John Wiley & Sons. New York, 1998.

12

Appendix A: Current Patents US Patent #7,497,615 Digital temperature sensor, and system and method for measuring temperature. A digital temperature sensor and a system and a method for measuring a temperature are provided. The system includes a reference signal generator including one or more resistance elements; a temperature sensor including a plurality of discrete resistance elements arranged parallel with one another; a multiplexer multiplexing the plurality of discrete resistance elements and the reference resistance element so that the plurality of discrete resistance elements sequentially distribute a power voltage together with the reference resistance element; a comparator having the voltages distributed by the reference resistance element and a discrete resistance element selected by the multiplexer; and a counter counting sequential switchings of the multiplexer. The counter information of the output level transit time of the comparator is provided to the controller, and the system obtains temperature information according to temperature change information from turn information of the discrete resistance elements according to the counter information. US Patent #7,496,469 Temperature sensor adaptors and methods. A temperature sensor adaptor assembly and method having a conversion circuit configured for receiving an input characteristic of an input temperature sensor and generating a pulse width signal having a pulse width that varies in response to the received input characteristic. The assembly also includes an output circuit coupled to the conversion circuit for receiving the pulse width signal, coupled to an output, and configured for providing impedance at the output responsive to the pulse width of the received pulse width signal. The provided impedance at the output corresponds to an impedance of a synthesized temperature sensor that is different from the input temperature sensor. US Patent #7,494,274 Electronic thermometers with flex circuit location. An electronic thermometer is configured for ease and accuracy in construction. A probe of the thermometer includes a flex circuit containing electronic components used to measure temperature and transmit signals to a calculating unit of the thermometer. A locating member supported by the probe can function to pre-position the flex circuit prior to final fixation so that the electronic components are reliably positioned in manufacture. US Patent #2938385 Thermistor Thermometer System. The present invention relates to the field of quick, accurate temperature measurement and more particularly to thermistor thermometer systems which are extremely well adapted for clinical temperature measurements and also relates to improved compensated thermistor temperature sensing assemblies and sensitive rugged thermistor probes and protective coverings for thermometer bulbs.

13

Appendix B: Cost Estimate Single Thermometer Part 10 kOhm thermistor Casing Epoxy Tip Cord Port connection Total: Circuitry in MedCal Part Quantity 10 kOhm resistor 7 Wire ~10 cm Op Amp 3 Total:

Price 0.7 0.5 0.01 0.04 0.5 1 2.75

Price 0.004 0.01 0.25 0.788

Overall Total:

3.538

Appendix C: Project Design Specifications Product Design Specification for BME 301-Group 52: Digital Thermometer (March 5, 2009) Group Members: Tasha Benkovich, Colleen Farrell, Hallie Kreitlow, Deborah Yagow Problem Statement: Emerging countries are in need of a durable, low-cost thermometer to operate with the MedCal, a handheld medical output device. The thermometer's incorporated circuitry should produce accurate temperature measurements through the use of a human interface. Client Requirements: Interface with hub, which connects to laptop via analog signal Should not introduce cross contamination between patients Handheld device Sturdy and durable Calibrated according to international standards

1. Design Requirements The device must meet all of the client requirements. a. Performance requirements: The device must run at a maximum of 9-12 V per thermometer. It must require less than 500 mAmps of current. b. Safety: The device must cause no harm to the patient from the circuitry or sensory interface. c. Accuracy and Reliability: It must be 1C to the true temperature. The device must be accurate within 32 to 42C. d. Life in Service: The device must last for a minimum of 5 years under normal operating conditions.

14

e. Shelf Life: Must be able to withstand humid and hot conditions (up to ~47C) as well as any transportation. f. Operating Environment: The device must be able to function properly in high heat. It must be easy to use for untrained persons with minimal maintenance. g. Ergonomics: The handheld structure must be comfortable for both the patient and the operator. h. Size: The device must be small enough to be handheld. i. Weight: The device must be lighter than 1 lb. j. Materials: The device must use low cost materials, non-latex, that can be easily sterilized. k. Aesthetics, Appearance, and Finish: The device must be self-contained and compact. The contact point should be comfortable for the patient. 2. Product Characteristics a. Quantity: One working prototype with goal of cost effective mass production. b. Target Product Cost: The product will sacrifice aesthetics and accuracy for low cost, the goal being below $3. 3. Miscellaneous a. Standards and Specifications: International standards. b. Customer: Requires simplicity, ruggedness, and low maintenance. c. Patient Related Concerns: The device must be sterilized between patients using a 10% bleach solution. d. Competition: Mercury, digital, and infrared thermometers.

15

Anda mungkin juga menyukai

- Handbook of Mechanical and Materials EngineeringDari EverandHandbook of Mechanical and Materials EngineeringPenilaian: 5 dari 5 bintang5/5 (4)

- DIY Thermal ImagerDokumen37 halamanDIY Thermal ImagerPesVis100% (1)

- Stopping by Woods On A Snowy EveningDokumen9 halamanStopping by Woods On A Snowy EveningJulia Garces100% (2)

- Critical Analysis of W.H Auden Poems The PDFDokumen8 halamanCritical Analysis of W.H Auden Poems The PDFMöĤämmĔd äĹ-ŚäÁdï100% (1)

- DJI F450 Construction Guide WebDokumen21 halamanDJI F450 Construction Guide WebPutu IndrayanaBelum ada peringkat

- Reduce Costs by Fixing Electrical and Motor Problems in Factories WHITEPAPERDokumen13 halamanReduce Costs by Fixing Electrical and Motor Problems in Factories WHITEPAPERharigopalk12100% (1)

- Digital LED Thermometer with Microcontroller AVR ATtiny13Dari EverandDigital LED Thermometer with Microcontroller AVR ATtiny13Penilaian: 5 dari 5 bintang5/5 (1)

- Industrial Applications of Infrared Thermography: How Infrared Analysis Can be Used to Improve Equipment InspectionDari EverandIndustrial Applications of Infrared Thermography: How Infrared Analysis Can be Used to Improve Equipment InspectionPenilaian: 4.5 dari 5 bintang4.5/5 (3)

- Ujian 1 THN 4Dokumen13 halamanUjian 1 THN 4Che Shuk ShukaBelum ada peringkat

- Licenta GeorgeDokumen62 halamanLicenta GeorgeGeorgeCristeBelum ada peringkat

- Introduction To Thermographic Analysis SKFDokumen14 halamanIntroduction To Thermographic Analysis SKFTeckelino100% (1)

- Arduino Measurements in Science: Advanced Techniques and Data ProjectsDari EverandArduino Measurements in Science: Advanced Techniques and Data ProjectsBelum ada peringkat

- Infrared ThermographyDokumen20 halamanInfrared ThermographyMohamad Saad50% (2)

- Rachel Joyce - A Snow Garden and Other Stories PDFDokumen118 halamanRachel Joyce - A Snow Garden and Other Stories PDFИгорь ЯковлевBelum ada peringkat

- Ecological Quality RatioDokumen24 halamanEcological Quality RatiofoocheehungBelum ada peringkat

- Underground Equipment SelectionDokumen44 halamanUnderground Equipment SelectionCherotich Silas cheboseiBelum ada peringkat

- A Micocotroller Based Digital Thermometer With Timer DigithermoDokumen10 halamanA Micocotroller Based Digital Thermometer With Timer DigithermoKarthik MohanBelum ada peringkat

- Department of Computer Science & EngineeringDokumen10 halamanDepartment of Computer Science & EngineeringC191235 Sadia IslamBelum ada peringkat

- Machine Overheat Detection and Control System Using ArduinoDokumen37 halamanMachine Overheat Detection and Control System Using ArduinoTemmietope Horpeyemmie80% (5)

- Temperature Sensor ThesisDokumen5 halamanTemperature Sensor Thesiss0kuzej0byn2100% (2)

- Automating Temperature Calibration Baths With Simple Low Cost Image AcquisitionDokumen5 halamanAutomating Temperature Calibration Baths With Simple Low Cost Image AcquisitionNicole FloydBelum ada peringkat

- Design and Implementation of A Digital Thermometer With ClockDokumen11 halamanDesign and Implementation of A Digital Thermometer With Clockadolfo martinezBelum ada peringkat

- Design AND Implementation OF A Digital Thermometer With ClockDokumen10 halamanDesign AND Implementation OF A Digital Thermometer With ClockMuhammad Raza RafiqBelum ada peringkat

- Pyrometer DissertationDokumen4 halamanPyrometer DissertationBuyAPhilosophyPaperUK100% (1)

- Thermocouple Measurement DeviceDokumen3 halamanThermocouple Measurement DeviceylmalaverBelum ada peringkat

- Chapter 1 Basic ElectronicsDokumen25 halamanChapter 1 Basic ElectronicsTanjiro KamadoBelum ada peringkat

- Predictivo Segun La NASADokumen35 halamanPredictivo Segun La NASAedgargarciaBelum ada peringkat

- Clinical ThermometerDokumen33 halamanClinical ThermometerDevraj MandalBelum ada peringkat

- Digital Thermometer Project - BadryaDokumen13 halamanDigital Thermometer Project - BadryaMohammed Abdalla AliBelum ada peringkat

- EnglishDokumen5 halamanEnglishlathifatulBelum ada peringkat

- 5TE ManualDokumen38 halaman5TE ManualJose Luis Alcazar RomeroBelum ada peringkat

- Jinko Manual JK4016Dokumen24 halamanJinko Manual JK4016Gustavo CeschiBelum ada peringkat

- Temperature Measurement of Dynamic ObjectDokumen5 halamanTemperature Measurement of Dynamic Objectbelvinthomas8095Belum ada peringkat

- Engproc 02 00048Dokumen9 halamanEngproc 02 00048Ikechukwu ObiBelum ada peringkat

- Design and Development of Test Rig For Dual Fuel Diesel EngineDokumen5 halamanDesign and Development of Test Rig For Dual Fuel Diesel EngineInternational Journal of Application or Innovation in Engineering & ManagementBelum ada peringkat

- Development of A Temperature ControllerDokumen22 halamanDevelopment of A Temperature ControllerMicu Adrian DanutBelum ada peringkat

- Design of Temperature Measuring Instrument Using NDokumen8 halamanDesign of Temperature Measuring Instrument Using NHải Châu ThanhBelum ada peringkat

- Prototype Development of Temperature and Humidity Monitoring System For Danger BuildingDokumen21 halamanPrototype Development of Temperature and Humidity Monitoring System For Danger BuildingKhurram ShehzadBelum ada peringkat

- Hdwacsuauts V3.1Dokumen51 halamanHdwacsuauts V3.1VALERIE JADE PIAOANBelum ada peringkat

- Fault Detection and Protection of Transformer by Using MicrocontrollerDokumen8 halamanFault Detection and Protection of Transformer by Using MicrocontrollerVelu SamyBelum ada peringkat

- ThermopileDokumen4 halamanThermopilemuzafarBelum ada peringkat

- UV Dosimeter Manual - v08Dokumen37 halamanUV Dosimeter Manual - v08David ShermanBelum ada peringkat

- ECE & ApplicationsDokumen7 halamanECE & ApplicationsSandeep PatilBelum ada peringkat

- Literature Review For Temperature Based Fan Speed ControllerDokumen4 halamanLiterature Review For Temperature Based Fan Speed Controllerc5qxzdj7Belum ada peringkat

- How Sensor Technology Is Evolving To Meet Cold Chain NeedsDokumen3 halamanHow Sensor Technology Is Evolving To Meet Cold Chain NeedschandruuncleBelum ada peringkat

- Chiller Faults Diagnosis A Case StudyDokumen7 halamanChiller Faults Diagnosis A Case StudyBlack SmithBelum ada peringkat

- Selecting The Ideal Temperature Sensor: Microchip Technology Inc. Webseminar: August 25Th, 2004Dokumen23 halamanSelecting The Ideal Temperature Sensor: Microchip Technology Inc. Webseminar: August 25Th, 2004arturo53Belum ada peringkat

- Digital Chemical Thermometers Vs Analog ThermometersDokumen7 halamanDigital Chemical Thermometers Vs Analog ThermometersInternational Journal of Innovative Science and Research TechnologyBelum ada peringkat

- Modern Insulation TestingDokumen49 halamanModern Insulation TestingAdan SolanoBelum ada peringkat

- Temperature Measurement and CalibrationDokumen7 halamanTemperature Measurement and CalibrationMorosanu Andreea-DianaBelum ada peringkat

- Final Report - S & InstrumentationDokumen18 halamanFinal Report - S & InstrumentationJohn ShumanBelum ada peringkat

- Sensirion Humidity SHTC1 Datasheet V3Dokumen14 halamanSensirion Humidity SHTC1 Datasheet V3Marian NiculaeBelum ada peringkat

- Heart Beat Monitoring Using Wireless ConnectionDokumen7 halamanHeart Beat Monitoring Using Wireless ConnectionjosephfelixBelum ada peringkat

- Solidpractices: Thermal Management: Using Electronics Cooling ModuleDokumen14 halamanSolidpractices: Thermal Management: Using Electronics Cooling Modulemlik borhenBelum ada peringkat

- 2 1 2008 James RefomerDokumen16 halaman2 1 2008 James RefomerVipul GuptaBelum ada peringkat

- Micron - Tech Note - TemperatureDokumen14 halamanMicron - Tech Note - TemperatureRavishankarBelum ada peringkat

- Design Strategy For An Infrared Thermometer HND - EetDokumen63 halamanDesign Strategy For An Infrared Thermometer HND - EetAdam QasimBelum ada peringkat

- A Practical Guide To Improving Temperature Measurement Accuracy White Paper Moore IndustriesDokumen5 halamanA Practical Guide To Improving Temperature Measurement Accuracy White Paper Moore IndustriesralexmlBelum ada peringkat

- 5 Temperature Measurement Mistakes With RtdsDokumen17 halaman5 Temperature Measurement Mistakes With RtdsrahulBelum ada peringkat

- Ragini 2Dokumen56 halamanRagini 2Ragini GudelliBelum ada peringkat

- Recovery Act: Electrochromic Glazings Technology: Improved Performance, Lower PriceDokumen49 halamanRecovery Act: Electrochromic Glazings Technology: Improved Performance, Lower PriceRahulSinghRajputBelum ada peringkat

- PDD ProjectReportDokumen21 halamanPDD ProjectReportKhurram ShehzadBelum ada peringkat

- EmiDokumen5 halamanEmidirenBelum ada peringkat

- ICMERE 2013 PI 197awirelessheartbeatandtemperaturemonitoringsystemforremotepatientsDokumen7 halamanICMERE 2013 PI 197awirelessheartbeatandtemperaturemonitoringsystemforremotepatientsOrtyomBelum ada peringkat

- Gilliam - Temp Sensors PDFDokumen6 halamanGilliam - Temp Sensors PDFKarthi SanBelum ada peringkat

- Humidity and Temperature Controller: Ece399 - Community Service Project - Phase IiDokumen18 halamanHumidity and Temperature Controller: Ece399 - Community Service Project - Phase Iiram poisonBelum ada peringkat

- Net Limiter 3Dokumen1 halamanNet Limiter 3systemdllBelum ada peringkat

- KingDokumen2 halamanKingsystemdllBelum ada peringkat

- KingDokumen2 halamanKingsystemdllBelum ada peringkat

- ADC0804Dokumen18 halamanADC0804api-3855288100% (1)

- Ict 2120 Animation NC Ii Week 11 20 by Francis Isaac 1Dokumen14 halamanIct 2120 Animation NC Ii Week 11 20 by Francis Isaac 1Chiropractic Marketing NowBelum ada peringkat

- Asme b16-25Dokumen22 halamanAsme b16-25JamesBelum ada peringkat

- Metal Workers BizHouse - UkDokumen3 halamanMetal Workers BizHouse - UkAlex BekeBelum ada peringkat

- Veronte Autopilot Kit DatasheetDokumen2 halamanVeronte Autopilot Kit DatasheetEkmedzicBelum ada peringkat

- SMAST - 150kW 02190 - 200929091953Dokumen67 halamanSMAST - 150kW 02190 - 200929091953David GarciaBelum ada peringkat

- Test 2 Sku3023 A201 QuestionDokumen8 halamanTest 2 Sku3023 A201 QuestionHafiz HafizanBelum ada peringkat

- SMC VM Eu PDFDokumen66 halamanSMC VM Eu PDFjoguvBelum ada peringkat

- Gujral FCMDokumen102 halamanGujral FCMcandiddreamsBelum ada peringkat

- Islam and Civilization (Analysis Study On The History of Civilization in Islam) Muhammad Hifdil IslamDokumen18 halamanIslam and Civilization (Analysis Study On The History of Civilization in Islam) Muhammad Hifdil IslamLoveth KonniaBelum ada peringkat

- CCNA Training New CCNA - RSTPDokumen7 halamanCCNA Training New CCNA - RSTPokotete evidenceBelum ada peringkat

- Technical Data Sheet: LPI HVSC PlusDokumen2 halamanTechnical Data Sheet: LPI HVSC PlusNguyễn TấnBelum ada peringkat

- VavDokumen8 halamanVavkprasad_56900Belum ada peringkat

- Basics of Population EducationDokumen4 halamanBasics of Population EducationLAILANIE DELA PENABelum ada peringkat

- SOPDokumen16 halamanSOPjerome marquezBelum ada peringkat

- G10Mapeh Exam First QuaterDokumen8 halamanG10Mapeh Exam First QuaterJonas LamcisBelum ada peringkat

- Chap 4 - Basic Principles of ElectricityDokumen31 halamanChap 4 - Basic Principles of ElectricityAdiseshuMiddeBelum ada peringkat

- Keyword 4: Keyword: Strength of The Mixture of AsphaltDokumen2 halamanKeyword 4: Keyword: Strength of The Mixture of AsphaltJohn Michael GeneralBelum ada peringkat

- Chillers VoltasDokumen4 halamanChillers Voltasanil shuklaBelum ada peringkat

- Kelas ChondrichtyesDokumen15 halamanKelas ChondrichtyesanitagustinawatiBelum ada peringkat

- Bravo MRI II Operation ManualDokumen45 halamanBravo MRI II Operation ManualLuis100% (1)

- Sap Ewm OverviewDokumen11 halamanSap Ewm OverviewsachinBelum ada peringkat

- 3 Curvilinear MotionDokumen50 halaman3 Curvilinear Motiongarhgelh100% (1)

- Valdez, Shenny RoseDokumen3 halamanValdez, Shenny Roseyeng botzBelum ada peringkat