Pipe Data

Diunggah oleh

Pawan Kumar GangwarDeskripsi Asli:

Hak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

Pipe Data

Diunggah oleh

Pawan Kumar GangwarHak Cipta:

Format Tersedia

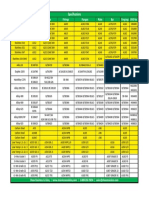

Pipe Data spreadsheet for MS Excel

Pipe Data Version 1.19h Input Data Pipe Size 1" (40) Schedule 40 ### ### ### Weights Flange Class 150 Material A106 Gr B Temperature Insulation Thickness 30/65 C 0 mm ### ### Pipe Water Insulation 4.054 kg/m 1.313 kg/m kg/m Pipe Pipe O/D Wall Thk 48.3 mm 3.683 mm WN Flange Bolts Spec Blind Blind Flange Gate Globe ### Material Properties Density ### Sc Sh SG of 1.000 ### contents Information Information Warning For Category 'M' Fluids, one of maytemperaturestaken Warning The Category 'M' Fluids, one of the temperatures that For temperatures that you input may have been taken The temperatures that you input the have been that Informationtemperatures that has minimum iftemperature Information temperature One Ambient temperature that has been input isisoutside below The been inputCheck the temperature and necessary, One formula. may the beyond below hasabeen inputCheck the that the minimum if necessary, The formula. may be below has been input beyond as aAmbienttemperatures temperature and temperature has of the temperatures that has been input outside below has as of the Warningno elasticforberatethat the been input isismodulus Warning data code for expansion or elastic modulus There istheinexpansionfor thedatathe materialand/orRefer There is no "the"Codetable the materialratesCodeCode for available available expansion Codeexpansion the in the in selected. the for rate for available elastic elastic the minimumdataforaeitherthefor thebeentheinand/orRefer minimum=temperature datathe material the for the tables dataformodulus for materialorinput selected. expansion rate table data the material is for the the code for specified noindataformodulusexpansion ratesCodeRefer to in Modulus expansion rates selected. elastic the tablesin temperatures specified material the outside changeisthe "expansion for thatmaterial selected. Refer to ". specified no the" rateaeither the has beenselected. outside change the elasticfor " tablespecified in selected. Code for =temperature for rates ". OneYoung'stemperatures thatmaterialtheinputselected.the of material similartablein the Code. Code has been OneYoung's Code.material inforSimilarthe Code hassimilar of material inmaterial thehas Code. Use a similar the Modulus" ''Code. the is a been modulus selected. Refer for the323.2.2(b) of B31.3.to thisthisto the Code. Refer to theSimilar materials from the modulus for A for material. A thisthis for thisin material from Use to the to the thisof the material from material selected. B31.3. Refer 323.2.2(b) similar Code. Code. materials from to material. material para. to the Code. thetable for Code. Refer Code. Refer para. Code. the allowable stressexpansion rate. estimate therate and the have been data to estimate to the usedallowable stressexpansion rate. material selected. material estimate used in the modulus.estimate therate and Code to estimate the elastic modulus.material selected. material that has used table Code the Code have been the elastic for the expansion values. used to that has data in the Code to expansion values. to estimate the Refer to the Code. Refer modulus. elasticto the Code. elastic modulus.Steel. Density : Carbon

Expansion Rate: Carbon Steel Carbon-Moly-Low-Chrome (Through 3Cr-Mo). Elastic Modulus: Carbon steels, C <= 0.3%.

RF Flanged Fittings Weight Length -xMisc. SIFs Pipe Spans Butt Weld Fittings Flanged Fittings

Check Red. bore Ball Full bore Ball Wafer Check Butterfly Relief

7,860 kg/m 137.9 N/mm 137.9 N/mm 203.1 kN/mm 200.5 kN/mm 0.046 mm/m 0.446 mm/m 0.400 mm/m

Ea Em @ 30C @ 65C 3065C

Any comments will be appreciated and incorporated as soon as possible. This copy belongs to Malcolm Hutton. Pipe Data Version 1.19 by CN Westwood 1998

07/28/2011 09:16:18

Version 1.19g By Clive N Westwood

PipeData.xls

Notes

1 The databases have been checked to B31.3, but knowing Sod and Murphy there is bound to be a mistake somewhere. If you come across it, please tell us so that we can rectify it as soon as possible. 2 This will be kept as a MS Excel V5.00 spreadsheet as it is not an illegal program and companies should have no problems with you using it. Then again.... The spreadsheet will be kept to a single sheet to ease use. 3 Do we have your E-mail address so that we can send you updates when they are available? Or other address! Send queries/comments to CNW, 19 Barnfield, Sussex, TN6 2RX. This is in the UK, if this ever gets abroad! 4 You can turn off the 'Information' and 'Warning' messages, but at your own peril. 5 Some materials have only used the Stress data at 100F intervals. The intermediate values (50F intervals) may not be accurate. (Copper, Titanium & Zirconium). Refer to the Code. 6 This spreadsheet was created for a 17" 1024 x 768 screen. Other screens may produce odd results. You can resize the window to suit your own screen or change the fonts to fit. The screen can be maximised by selecting 'Maximise'. 7 The top line (Cell B2) can be used for titles, etc., if you wish to print out the sheet. (You can also use cells F2 & M2). 8 Updates should be on going, with several improvements already planned, among them are:Other Codes. External databases so you can create your own. Larger range of pipe sizes. FF & RTJ flange dimensions. Flange allowable pressures, maybe. Separate data base for Aluminium, Copper, Titanium and Zirconium. (50F intervals) 9 Also, whenever the Codes are updated, we will endeavour to update the database as soon as possible. 10 Span Deflections are either Diameter/factor with a maximum value or Length/factor without a maximum limit. 11 Finally, the usual get out clauses:It is intended that those who use this spreadsheet are conversant with the Code and only use this as an aid. This does not replace the Code. This is intended to be used as a quick reference for data and all data should be checked against final documentation. Whilst every effort has been undertaken to ensure the accuracy of the data of this spreadsheet, we can accept no responsibility for the use of the data derived from it.

Page 2

Anda mungkin juga menyukai

- Aspen FLARENET Getting StartedDokumen62 halamanAspen FLARENET Getting StartedAde Nurisman100% (7)

- Material List For Vessel Standard DWGDokumen1 halamanMaterial List For Vessel Standard DWGrustamriyadiBelum ada peringkat

- Australian Standard: Metal Finishing - Preparation and Pretreatment of Surfaces Part 0: Method Selection GuideDokumen17 halamanAustralian Standard: Metal Finishing - Preparation and Pretreatment of Surfaces Part 0: Method Selection GuidedilrangiBelum ada peringkat

- Thk. S.F. K.R.: Dish - Dish 2100Dokumen3 halamanThk. S.F. K.R.: Dish - Dish 2100jayvant jadhavarBelum ada peringkat

- Heat Ex Changers EstimationDokumen46 halamanHeat Ex Changers Estimationshankarbt83Belum ada peringkat

- Volume Calculation For Pressure VesselDokumen2 halamanVolume Calculation For Pressure VesselVikas NaikBelum ada peringkat

- Global Marketing For Tube & PipeDokumen4 halamanGlobal Marketing For Tube & PipedsyashankaBelum ada peringkat

- Pipe SpecificationsDokumen5 halamanPipe Specificationsbabar.muetBelum ada peringkat

- Specs Chart PDFDokumen1 halamanSpecs Chart PDFsojeckBelum ada peringkat

- Pump and Line CalcDokumen1 halamanPump and Line CalcPRATIK P. BHOIRBelum ada peringkat

- CS Pipe Data PKK1Dokumen2 halamanCS Pipe Data PKK1Amrit Singh KalsiBelum ada peringkat

- Binoy's Engg DatasDokumen29 halamanBinoy's Engg DatasSreejith GBelum ada peringkat

- Preliminary Conical StrainersDokumen1 halamanPreliminary Conical StrainersrodolfostiBelum ada peringkat

- Ejemplo Tubesheet Asme UHXDokumen14 halamanEjemplo Tubesheet Asme UHXPedro Montes MarinBelum ada peringkat

- ASME B31.3 CalculatorDokumen144 halamanASME B31.3 CalculatorLeoBelum ada peringkat

- Sizing Steam PipesDokumen2 halamanSizing Steam PipesjoeljdiazBelum ada peringkat

- PSV Sizing (Steam)Dokumen2 halamanPSV Sizing (Steam)Saeid Rahimi Mofrad100% (1)

- CalcDokumen3 halamanCalcZoebairBelum ada peringkat

- Pipe Calc, Wall Thick B31.3-4&12 Inch Pipe J4NDokumen1 halamanPipe Calc, Wall Thick B31.3-4&12 Inch Pipe J4Nsaravoot_jBelum ada peringkat

- UT-CPF1-2016-V13220A-035 HP-COMP-PK13210A-SUCTION SCRUBBER (1st Stage) V-13220A 20170111Dokumen5 halamanUT-CPF1-2016-V13220A-035 HP-COMP-PK13210A-SUCTION SCRUBBER (1st Stage) V-13220A 20170111Jinlong SuBelum ada peringkat

- Shell & Dish ThicknessDokumen3 halamanShell & Dish Thicknesskirandas_mullasseryBelum ada peringkat

- 07 Piping BOQDokumen54 halaman07 Piping BOQHRK65Belum ada peringkat

- Top Pipe MomentDokumen2 halamanTop Pipe Momentrsubramani100% (1)

- Dish CalculationDokumen2 halamanDish CalculationRyan Goh Chuang HongBelum ada peringkat

- Memoria ASME-Pressure-Vessel-DesignDokumen143 halamanMemoria ASME-Pressure-Vessel-DesignJuan MendozaBelum ada peringkat

- Common Alloys SpecificationsDokumen1 halamanCommon Alloys SpecificationsSARATH KRISHNAKUMARBelum ada peringkat

- Heat Exchanger Calculation Version 2Dokumen2 halamanHeat Exchanger Calculation Version 2huangjlBelum ada peringkat

- Copia de Unit Converter Ver1Dokumen15 halamanCopia de Unit Converter Ver1Brian TuckerBelum ada peringkat

- Art - 'S TEMA DesignationsDokumen4 halamanArt - 'S TEMA Designationsmuhammad_asim_10Belum ada peringkat

- Standard SpecificationDokumen1 halamanStandard SpecificationĐạt TrầnBelum ada peringkat

- 62577A Calculation of Orifice Coefficient Si UnitsDokumen18 halaman62577A Calculation of Orifice Coefficient Si UnitsUary Buza RegioBelum ada peringkat

- TorqueDokumen6 halamanTorquelucianaBelum ada peringkat

- Dish CalculationDokumen2 halamanDish CalculationRyan Goh Chuang HongBelum ada peringkat

- Detail Dimensi Material GRPDokumen5 halamanDetail Dimensi Material GRPdwi noviana nugrohoBelum ada peringkat

- Calculator - U Tubes - HSA & QtyDokumen4 halamanCalculator - U Tubes - HSA & QtyRey Fiedacan100% (1)

- Heat Exchanger DesignDokumen7 halamanHeat Exchanger Designsiva sankarBelum ada peringkat

- Cone CalculationDokumen3 halamanCone CalculationVicky NtrjnBelum ada peringkat

- Ansi B 1500 PDFDokumen1 halamanAnsi B 1500 PDFMilena Lemus FonsecaBelum ada peringkat

- Dimensions of Bolts and Nuts BS3692Dokumen6 halamanDimensions of Bolts and Nuts BS3692azam RazzaqBelum ada peringkat

- Pressure & Temperature ClassificationDokumen1 halamanPressure & Temperature Classificationkeo85100% (1)

- Equivalent MaterialDokumen1 halamanEquivalent Materialmuhammadf SardarBelum ada peringkat

- Saddle Angle - Formula K - 12.28.20Dokumen2 halamanSaddle Angle - Formula K - 12.28.20Rey FiedacanBelum ada peringkat

- Asme BPVC II Part D Material Strengths 01Dokumen7 halamanAsme BPVC II Part D Material Strengths 01bakellyBelum ada peringkat

- Asme Pipe Wall ThicknessDokumen3 halamanAsme Pipe Wall ThicknessYoke ShuBelum ada peringkat

- ASME B16.5 2013 FlangeRating 1.0Dokumen4 halamanASME B16.5 2013 FlangeRating 1.0sanjaysyBelum ada peringkat

- Dim of Pipes Flanges and FittingsDokumen10 halamanDim of Pipes Flanges and FittingsGeorge Manuel100% (1)

- SuperAlloy Catalog 2013Dokumen5 halamanSuperAlloy Catalog 2013Muhammad SalehBelum ada peringkat

- Name: - ClassDokumen4 halamanName: - Classozil_72Belum ada peringkat

- Wilden Specialty CodesDokumen9 halamanWilden Specialty CodesPump SpesialistBelum ada peringkat

- Sa516 70Dokumen3 halamanSa516 70Thinh ViproBelum ada peringkat

- FRP RF CalcDokumen1 halamanFRP RF CalcmukeshBelum ada peringkat

- Pipe Dimensions: 6 15 6.625" Std. 6 168.28 MM 2 6.065" 2 154.05 MM 2 0.280" 7.11 MMDokumen2 halamanPipe Dimensions: 6 15 6.625" Std. 6 168.28 MM 2 6.065" 2 154.05 MM 2 0.280" 7.11 MMAtul JainBelum ada peringkat

- Studding FlangeDokumen6 halamanStudding FlangeDarshan PanchalBelum ada peringkat

- Nozzle Load CheckDokumen4 halamanNozzle Load CheckpipestressBelum ada peringkat

- FittingsDokumen50 halamanFittingsashokBelum ada peringkat

- Body Flange Thkickness CalculationDokumen2 halamanBody Flange Thkickness CalculationsachmayaBelum ada peringkat

- Spec - File Size Description DN NB: Astm A333 Grade 6 Pipe, Asme B36.10Dokumen9 halamanSpec - File Size Description DN NB: Astm A333 Grade 6 Pipe, Asme B36.10jigar_mancityBelum ada peringkat

- Heat ExchangerDokumen11 halamanHeat ExchangerMangesh MandgeBelum ada peringkat

- GRP Piping - Stress AnalysisDokumen5 halamanGRP Piping - Stress Analysisghkashyap1Belum ada peringkat

- Pipe Freeze Protection Design/Install Guide: Page 1 of 16Dokumen16 halamanPipe Freeze Protection Design/Install Guide: Page 1 of 16Cire Lop CastroBelum ada peringkat

- Tabela de MateriaisDokumen1 halamanTabela de MateriaisFabio Peres de LimaBelum ada peringkat

- CH 1 Cylinder Block Cylinder Head, GasketsDokumen49 halamanCH 1 Cylinder Block Cylinder Head, GasketsBogdan Constantin CristeaBelum ada peringkat

- Ch1 Ferrous AlloysDokumen7 halamanCh1 Ferrous Alloysباسمي العشقBelum ada peringkat

- Iso 209-1:1989Dokumen9 halamanIso 209-1:1989davezakBelum ada peringkat

- ASTMDokumen23 halamanASTMchiragpatel6650% (1)

- Astm A 1008-A 1008M-04Dokumen7 halamanAstm A 1008-A 1008M-04NilüferKarayel0% (1)

- Crane Sheave - Early FailuresDokumen14 halamanCrane Sheave - Early FailuresMichael WoodBelum ada peringkat

- SGS MIN TP2008 50 IOCG Recovery in Scandinavia PDFDokumen8 halamanSGS MIN TP2008 50 IOCG Recovery in Scandinavia PDFPedro PabloBelum ada peringkat

- Murex Tig Poster 2008 PDFDokumen1 halamanMurex Tig Poster 2008 PDFPCBelum ada peringkat

- 6 - Industrial MetallurgyDokumen2 halaman6 - Industrial Metallurgyzafar iqbalBelum ada peringkat

- Aeroshell FLUID 41 1Dokumen2 halamanAeroshell FLUID 41 1Hugo SalazarBelum ada peringkat

- Linx® Shielding Gases: Lower Welding CostsDokumen7 halamanLinx® Shielding Gases: Lower Welding CostsMahmoud shawkyBelum ada peringkat

- Vocational Training: Durgapur Steel PlantDokumen28 halamanVocational Training: Durgapur Steel PlantBaptu Roy100% (1)

- 61process of Soft Soldering and Hard SolderingDokumen1 halaman61process of Soft Soldering and Hard Solderingsriram 1814Belum ada peringkat

- Spring Steel InformationDokumen2 halamanSpring Steel InformationDGWBelum ada peringkat

- Combination Flame Arrester & Free VentDokumen4 halamanCombination Flame Arrester & Free Ventyulianus_srBelum ada peringkat

- Install GuideDokumen12 halamanInstall GuidegeroquevBelum ada peringkat

- Sample Peka Sains SPMDokumen15 halamanSample Peka Sains SPMNor Azizah100% (1)

- Understanding Sacrificial Anodes On ShipsDokumen3 halamanUnderstanding Sacrificial Anodes On ShipsVyas SrinivasanBelum ada peringkat

- Ferrochromium: Standard Specification ForDokumen3 halamanFerrochromium: Standard Specification ForhamidharvardBelum ada peringkat

- Attachments For MillingDokumen59 halamanAttachments For MillingLibin AbrahamBelum ada peringkat

- Steels For Quenching and TemperingDokumen39 halamanSteels For Quenching and Temperingjmwalker90Belum ada peringkat

- Materials v1.01Dokumen28 halamanMaterials v1.01plibplib100% (1)

- Strain Ageing PDFDokumen74 halamanStrain Ageing PDFKhalid AkbaryBelum ada peringkat

- Transport and Main Roads Specifications MRTS62 Bridge SubstructureDokumen9 halamanTransport and Main Roads Specifications MRTS62 Bridge SubstructureRAIMUNDO SUHERDINBelum ada peringkat

- Sdgcover Arup HandbookDokumen4 halamanSdgcover Arup Handbookmhan100% (1)

- 500 Materials: 510 Selection of Materials For Service Environment 500-2Dokumen29 halaman500 Materials: 510 Selection of Materials For Service Environment 500-2Mohammed TariqBelum ada peringkat

- Jewelry Plating TermsDokumen2 halamanJewelry Plating TermsELben RescoberBelum ada peringkat

- Vulcraft Roof and Floor Deck SystemsDokumen116 halamanVulcraft Roof and Floor Deck SystemsTitto8528Belum ada peringkat