Accuracy of Ball Screw Mounting Surfaces

Diunggah oleh

adolfovolumetricDeskripsi Asli:

Judul Asli

Hak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

Accuracy of Ball Screw Mounting Surfaces

Diunggah oleh

adolfovolumetricHak Cipta:

Format Tersedia

500-5E0

Point of Selection

Accuracy of the Ball Screw

Accuracy of the Ball Screw

Lead Angle Accuracy

The accuracy of the Ball Screw in the lead angle is controlled in accordance with the JIS standards (JIS B 1192 - 1997). Accuracy grades C0 to C5 are defined in the linearity and the directional property, and C7 to C10 in the travel distance error in relation to 300 mm.

Effective thread length Nominal travel distance

Reference travel distance Target value for reference travel distance Fluctuation/2 Actual travel distance

Travel distance error

Representative travel distance error

Ball Screw

Fluctuation Representative travel distance

Fig.1 Terms on Lead Angle Accuracy

[Actual Travel Distance] An error in the travel distance measured with an actual Ball Screw. [Reference Travel Distance] Generally, it is the same as nominal travel distance, but can be an intentionally corrected value of the nominal travel distance according to the intended use. [Target Value for Reference Travel Distance] You may provide some tension in order to prevent the screw shaft from runout, or set the reference travel distance in "negative" or "positive" value in advance given the possible expansion/ contraction from external load or temperature. In such cases, indicate a target value for the reference travel distance.

[Representative Travel Distance] It is a straight line representing the tendency in the actual travel distance, and obtained with the least squares method from the curve that indicates the actual travel distance. [Representative Travel Distance Error (in )] Difference between the representative travel distance and the reference travel distance. [Fluctuation] The maximum width of the actual travel distance between two straight lines drawn in parallel with the representative travel distance. [Fluctuation/300] Indicates a fluctuation against a given thread length of 300 mm. [Fluctuation/2 ] A fluctuation in one revolution of the screw shaft.

A15-17

500-5E0

Table1 Lead Angle Accuracy (Permissible Value)

Unit: m

Precision Ball Screw Rolled Ball Screw Accuracy grades C0 C1 C2 C3 C5 C7 C8 C10

Effective thread Representa- Fluc- Representa- Fluc- Representa- Fluc- Representa- Fluc- Representa- Fluclength tive travel tuative travel tuative travel tuative travel tuative travel tua-

Above Or less distance error 100 200 315 400 500 630 800 100 200 315 400 500 630 800 1000 3 3.5 4 5 6 6 7 8 9 11

tion

distance error

tion

distance error

tion

distance error

tion

distance error

tion

Travel Travel Travel distance error distance error distance error

3 3 3.5 3.5 4 4 5 6 6 7

3.5 4.5 6 7 8 9 10 11 13 15 18 22 26 30

5 5 5 5 5 6 7 8 9 10 11 13 15 18

5 7 8 9 10 11 13 15 18 21 25 30 36 44 52 65

7 7 7 7 7 8 9 10 11 13 15 18 21 25 30 36

8 10 12 13 15 16 18 21 24 29 35 41 50 60 72 90 110

8 8 8 10 10 12 13 15 16 18 21 24 29 35 41 50 60

18 20 23 25 27 30 35 40 46 54 65 77 93 115 140 170 210 260

18 18 18 20 20 23 25 27 30 50/ 100/ 210/ 35 300mm 300mm 300mm

1000 1250 1250 1600 1600 2000 2000 2500 2500 3150 3150 4000 4000 5000 5000 6300 6300 8000 8000 10000

40 46 54 65 77 93 115 140

Note) Unit of effective thread length: mm Table2 Fluctuation in Thread Length of 300 mm and in One Revolution (permissible value) Unit: m

Accuracy grades Fluctuation/300 Fluctuation/2

C0 3.5 3

C1 5 4

C2 7 5

C3 8 6

C5 18 8

C7

C8

C10

Table3 Types and Grades

Type For positioning For conveyance

Series symbol Cp Ct

Grade 1, 3, 5

Remarks ISO compliant

1, 3, 5, 7, 10

Note) Accuracy grades apply also to the Cp series and Ct series. Contact THK for details.

A15-18

500-5E0

Point of Selection

Accuracy of the Ball Screw

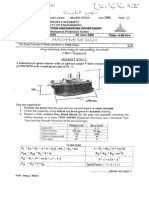

Example: When the lead of a Ball Screw manufactured is measured with a target value for the reference travel distance of 9 m/500 mm, the following data are obtained.

Table4 Measurement Data on Travel Distance Error Unit: mm

Command position (A) Travel distance (B)

Travel distance error (A B)

0 0 0 200 199.995 0.005 400 399.983 0.017

50 49.998 0.002 250 249.993 0.007 450 449.981 0.019

100 100.001 +0.001 300 299.989 0.011 500 499.984 0.016

150 149.996 0.004 350 349.885 0.015

Command position (A) Travel distance (B)

Travel distance error (A B)

Command position (A) Travel distance (B)

Travel distance error (A B)

The measurement data are expressed in a graph as shown in Fig.2. The positioning error (A-B) is indicated as the actual travel distance while the straight line representing the tendency of the (A-B) graph refers to the representative travel distance. The difference between the reference travel distance and the representative travel distance appears as the representative travel distance error.

Measurement point on the thread (mm) 100 0 10 20 30 Fluctuation 8.8m Actual travel distance AB Representative travel distance

Fig.2 Measurement Data on Travel Distance Error

Ball Screw

Travel distance error (m)

+10

200

300

400

500

Target value for reference travel distance 9m/500mm Representative travel distance error 7m

[Measurements] Representative travel distance error: -7 m Fluctuation: 8.8 m

A15-19

500-5E0

Accuracy of the Mounting Surface

The accuracy of the Ball Screw mounting surface complies with the JIS standard (JIS B 1192-1997).

Table 9 C

Square nut

Table 6 EF

Table 7 G

Table 4 EF

Table 5 EF

Note EF

Table 8 C

Table 6 EF

Note) For the overall radial runout of the screw shaft axis, refer to JIS B 1192-1997. Fig.3 Accuracy of the Mounting Surface of the Ball Screw

A15-20

500-5E0

Point of Selection

Accuracy of the Ball Screw

[Accuracy Standards for the Mounting Surface] Table5 to Table9 show accuracy standards for the mounting surfaces of the precision Ball Screw.

Table5 Radial Runout of the Circumference of the Thread Root in Relation to the Supporting Portion Axis of the Screw Shaft Unit: m

Screw shaft outer diameter (mm) Above 8 12 20 32 50 80 Or less 8 12 20 32 50 80 100 C0 3 4 4 5 6 7

Runout (maximum) C1 5 5 6 7 8 9 10 C2 7 7 8 9 10 11 12 C3 8 8 9 10 12 13 15 C5 10 11 12 13 15 17 20 C7 14 14 14 20 20 20 30

Note) The measurements on these items include the effect of the runout of the screw shaft diameter. Therefore, it is necessary to obtain the correction value from the overall runout of the screw shaft axis, using the ratio of the distance between the fulcrum and measurement point to the overall screw shaft length, and add the obtained value to the table above.

Ball Screw

Example: model No. DIK2005-6RRGO+500LC5

L=500 E1 E-F E2 E-F

Measurement point

L1=80

Surface table V block

E1 = e + e

e e : Standard value in Table5 (0.012) : Correction value

e =

=

L1 L

E2

E2 : Overall radial runout of the screw shaft axis (0.06)

80 0.06 500 = 0.01 E1 = 0.012 + 0.01 = 0.022

A15-21

500-5E0

Table6 Perpendicularity of the Supporting Portion End of the Screw Shaft to the Supporting Portion Axis Unit: m

Table7 Perpendicularity of the Flange Mounting Surface of the Screw Shaft to the Screw Shaft Axis Unit: m

Screw shaft outer diameter (mm) Above 8 12 20 32 50 80 Or less 8 12 20 32 50 80 100

Perpendicularity (maximum) C0 2 2 2 2 2 3 C1 3 3 3 3 3 4 4 C2 3 3 3 3 3 4 5 C3 4 4 4 4 4 5 6 C5 5 5 5 5 5 7 8 C7 7 7 7 7 8 10 11

Nut diameter (mm) Above 20 32 50 80 125 160 Or less 20 32 50 80 125 160 200

Perpendicularity (maximum) C0 5 5 6 7 7 8 C1 6 6 7 8 9 10 11 C2 7 7 8 9 10 11 12 C3 8 8 8 10 12 13 14 C5 10 10 11 13 15 17 18 C7 14 14 18 18 20 20 25

Table8 Radial Runout of the Nut Circumference in Relation to the Screw Shaft Axis Unit: m

Table9 Parallelism of the Nut Circumference (Flat Mounting Surface) to the Screw Shaft Axis Unit: m

Nut diameter (mm) Above 20 32 50 80 125 160 Or less 20 32 50 80 125 160 200 C0 5 6 7 8 9 10

Runout (maximum) C1 6 7 8 10 12 13 16 C2 7 8 10 12 16 17 20 C3 9 10 12 15 20 22 25 C5 12 12 15 19 27 30 34 C7 20 20 30 30 40 40 50

Mounting reference length (mm) Above 50 100 Or less 50 100 200 C0 5 7

Parallelism (maximum) C1 6 8 10 C2 7 9 11 C3 8 10 13 C5 10 13 17 C7 17 17 30

[Method for Measuring Accuracy of the Mounting Surface]

Radial Runout of the Circumference of the Part Mounting Section in Relation to the Supporting Portion Axis of the Screw Shaft (see Table5 on A15-21)

Support the supporting portion of the screw shaft with V blocks. Place a probe on the circumference of the part mounting section, and read the largest difference on the dial gauge as a measurement when turning the screw shaft by one revolution.

Dial gauge

V block Surface table

V block

A15-22

500-5E0

Point of Selection

Accuracy of the Ball Screw

Radial Runout of the Circumference of the Thread Root in Relation to the Supporting Portion Axis of the Screw Shaft (see Table5 on A15-21)

Support the supporting portion of the screw shaft with V blocks. Place a probe on the circumference of the nut, and read the largest difference on the dial gauge as a measurement when turning the screw shaft by one revolution without turning the nut.

Dial gauge

V block Surface table

V block

Perpendicularity of the Supporting Portion End of the Screw Shaft to the Supporting Portion Axis (see Table6 on A15-22)

Support the supporting portion of the screw shaft with V blocks. Place a probe on the screw shaft's supporting portion end, and read the largest difference on the dial gauge as a measurement when turning the screw shaft by one revolution.

Ball Screw

Dial gauge

V block Surface table

V block

Perpendicularity of the Flange Mounting Surface of the Screw Shaft to the Screw Shaft Axis (see Table7 on A15-22)

Support the thread of the screw shaft with V blocks near the nut. Place a probe on the flange end, and read the largest difference on the dial gauge as a measurement when simultaneously turning the screw shaft and the nut by one revolution.

Dial gauge

V block Surface table

V block

A15-23

500-5E0

Radial Runout of the Nut Circumference in Relation to the Screw Shaft Axis (see Table8 on A15-22)

Support the thread of the screw shaft with V blocks near the nut. Place a probe on the circumference of the nut, and read the largest difference on the dial gauge as a measurement when turning the nut by one revolution without turning the screw shaft.

Dial gauge

V block Surface table

V block

Parallelism of the Nut Circumference (Flat Mounting Surface) to the Screw Shaft Axis (see Table9 on A15-22)

Support the thread of the screw shaft with V blocks near the nut. Place a probe on the circumference of the nut (flat mounting surface), and read the largest difference on the dial gauge as a measurement when moving the dial gauge in parallel with the screw shaft.

Dial gauge

V block Surface table

V block

Overall Radial Runout of the Screw Shaft Axis

Support the supporting portion of the screw shaft with V blocks. Place a probe on the circumference of the screw shaft, and read the largest difference on the dial gauge at several points in the axial directions as a measurement when turning the screw shaft by one revolution.

Dial gauge

V block Surface table

Note) For the overall radial runout of the screw shaft axis, refer to JIS B 1192-1997.

V block

A15-24

500-5E0

Point of Selection

Accuracy of the Ball Screw

Axial Clearance

[Axial Clearance of the Precision Ball Screw] Table10 shows the axial clearance of the precision Screw Ball. If the manufacturing length exceeds the value in Table11, the resultant clearance may partially be negative (preload applied).

Table10 Axial Clearance of the Precision Ball Screw Unit: mm

Clearance symbol Axial clearance

G0 0 or less

GT 0 to 0.005

G1 0 to 0.01

G2 0 to 0.02

G3 0 to 0.05

Unit: mm

Table11 Maximum Length of the Precision Ball Screw in Axial Clearance

Overall thread length Screw shaft outer diameter Clearance GT C0 to C3 4 to 6 8 to 10 12 to 16 18 to 25 28 to 32 36 to 45 50 to 70 80 to 100 80 250 500 800 900 1000 1200 C5 100 200 400 700 800 800 1000 Clearance G1 C0 to C3 80 250 500 800 1100 1300 1600 1800 C5 100 250 500 700 900 1000 1300 1500 C0 to C3 80 250 700 1000 1400 2000 2500 4000 Clearance G2 C5 100 300 600 1000 1200 1500 2000 3000 C7 120 300 500 1000 1200 1500

Ball Screw

2000 3000

* When manufacturing the Ball Screw of precision-grade accuracy C7 with clearance GT or G1, the resultant clearance is partially negative.

[Axial Clearance of the Rolled Ball Screw] Table12 shows axial clearance of the rolled Ball Screw.

Table12 Axial Clearance of the Rolled Ball Screw Unit: mm

Screw shaft outer diameter Axial clearance (maximum) 6 to 12 14 to 28 30 to 32 36 to 45 50 0.05 0.1 0.14 0.17 0.2

A15-25

500-5E0

Preload

A preload is provided in order to eliminate the axial clearance and minimize the displacement under an axial load. When performing a highly accurate positioning, a preload is generally provided.

[Rigidity of the Ball Screw under a Preload] When a preload is provided to the Ball Screw, the rigidity of the nut is increased. Fig.4 shows elastic displacement curves of the Ball Screw under a preload and without a preload.

Without a preload

Axial displacement

2 ao Parallel

ao

With a preload

0 Ft=3Fao Axial load

Fig.4 Elastic Displacement Curve of the Ball Screw

A15-26

500-5E0

Point of Selection

Accuracy of the Ball Screw

Fig.5 shows a double-nut type of the Ball Screw.

Nut B Fa0 Spacer Nut A Axial load Fa0

pla

cem

ent

of n ut A

of n ut B

Dis

D is c pla em ent

Ft FaFa' Fa Fa' FA Fa0 FB

External load: 0

Nut B FB

Spacer

Nut A Fa FA a A B a0 a0 Nut A Nut B Axial displacement

Fig.6

External load: Fa

Fig.5

Nuts A and B are provided with preload Fa0 from the spacer. Because of the preload, nuts A and B are elastically displaced by a0 each. If an axial load (Fa) is applied from outside in this state, the displacement of nuts A and B is calculated as follows.

A = a0 + a

B = a0 - a Ball Screw

In other words, the loads on nut A and B are expressed as follows:

FA = Fa0 + (Fa -- Fa') FB = Fa0 -- Fa'

Therefore, under a preload, the load that nut A receives equals to Fa - Fa'. This means that since load Fa', which is applied when nut A receives no preload, is deducted from Fa, the displacement of nut A is smaller. This effect extends to the point where the displacement ( a0) caused by the preload applied on nut B reaches zero. To what extent is the elastic displacement reduced? The relationship between the axial load on the Ball Screw under no preload and the elastic displacement can be expressed by aFa2/3. From Fig.6, the following equations are established.

a0 = KFa0 2/3 2a0 = KFt

2/3

Kconstant

( )

Ft Fa0

2 3

= 2 Ft = 2

3/2

Fa0 = 2.8Fa0

3Fa0

Thus, the Ball Screw under a preload is displaced by a0 when an axial load (Ft) approximately three times greater than the preload is provided from outside. As a result, the displacement of the Ball Screw under a preload is half the displacement (2 a0) of the Ball Screw without a preload. As stated above, since the preloading is effective up to approximately three times the applied preload, the optimum preload is one third of the maximum axial load. Note, however, that an excessive preload adversely affects the service life and heat generation. As a guideline, the maximum preload should be set at 10% of the basic dynamic load rating (Ca) at a maximum.

A15-27

500-5E0

[Preload Torque] The preload torque of the Ball Screw in lead is controlled in accordance with the JIS standard (JIS B 1192-1997).

Actual starting torque

Negative actual-torque fluctuation Torque fluctuation Actual torque

(Forward) Reference torque Friction torque Actual torque (minimum) 0

Mean actual torque Effective running distance of the nut

Effective running distance of the nut

Mean actual torque

Actual torque (maximum)

Reference torque

(Backward)

Torque fluctuation Actual starting torque Positive actual torque fluctuation

Actual torque

Fig.7 Terms on Preload Torque

Dynamic Preload Torque

A torque required to continuously rotate the screw shaft of a Ball Screw under a given preload without an external load applied.

Reference Torque

A dynamic preload torque set as a target.

Calculating the Reference Torque

The reference torque of a Ball Screw provided with a preload is obtained in the following equation (5).

Actual Torque

A dynamic preload torque measured with an actual Ball Screw.

Torque Fluctuation

Variation in a dynamic preload torque set at a target value. It can be positive or negative in relation to the reference torque.

Tp = 0.05 (tan)

Tp Fa0 Ph

0.5

Fa0 Ph 2

Coefficient of Torque Fluctuation

Ratio of torque fluctuation to the reference torque.

: Reference torque : Lead angle : Applied preload : Lead

(N-mm) (N) (mm)

A15-28

500-5E0

Point of Selection

Accuracy of the Ball Screw

Example: When a preload of 3,000 N is provided to the Ball Screw model BNFN4010-5G0 + 1500LC3 with a thread length of 1,300 mm (shaft diameter: 40 mm; ball center-to-center diameter: 41.75 mm; lead: 10 mm), the preload torque of the Ball Screw is calculated in the steps below.

Calculating the Reference Torque : Lead angle

tan =

lead 10 = ball center-to-center diameter 41.75

= 0.0762

Fa0 : Applied preload=3000N Ph : Lead = 10mm

Tp

= 0.05 (tan)

0.5

Fa 0 Ph 2

= 0.05 (0.0762)

0.5

3000 10 = 865N mm 2

Calculating the Torque Fluctuation

thread length 1300 = = 32.5 40 screw shaft outer diameter 40

Thus, with the reference torque in Table13 being between 600 and 1,000 N-mm, effective thread length 4,000 mm or less and accuracy grade C3, the coefficient of torque fluctuation is obtained as 30%. As a result, the torque fluctuation is calculated as follows. 865(10.3) = 606 N mm to 1125 N mm

Ball Screw

Result Reference torque : 865 N-mn Torque fluctuation : 606 N-mm to 1125 N-mm

Table13 Tolerance Range in Torque Fluctuation

Effective thread length 4000mm or less Reference torque Nmm Above 4,000 mm and 10,000 mm or less

thread length screw shaft outer diameter

Accuracy grades

40

thread length 40 screw shaft outer diameter

Accuracy grades

60

Accuracy grades

Above 200 400 600 1000 2500 6300

Or less 400 600 1000 2500 6300 10000

C0 35% 25% 20% 15% 10%

C1 40% 30% 25% 20% 15%

C2, C3 45% 35% 30% 25% 20% 15%

C5 55% 45% 35% 30% 25% 20%

C0 45% 38% 30% 25% 20%

C1 45% 38% 30% 25% 20%

C2, C3 55% 45% 35% 30% 25% 20%

C5 65% 50% 40% 35% 30% 25%

C2, C3 40% 35% 30% 25%

C5 45% 40% 35% 30%

A15-29

Anda mungkin juga menyukai

- Torsion in Rods and TubesDokumen14 halamanTorsion in Rods and TubesFengeSolja89% (9)

- Manual of Engineering Drawing: British and International StandardsDari EverandManual of Engineering Drawing: British and International StandardsPenilaian: 3.5 dari 5 bintang3.5/5 (4)

- Lead Wire TestDokumen9 halamanLead Wire Testshani5573100% (1)

- ChartsDokumen1 halamanChartsravikumarmgowdaBelum ada peringkat

- Selection of Ball Screws 1Dokumen4 halamanSelection of Ball Screws 1Minh Trí KnightBelum ada peringkat

- Ballscrew Product Specifications 9 10Dokumen2 halamanBallscrew Product Specifications 9 10harryBelum ada peringkat

- Gear Accuracy Standards and Error MeasurementDokumen8 halamanGear Accuracy Standards and Error MeasurementAnonymous uL3JlWfhBelum ada peringkat

- Involute Gear ProfileDokumen8 halamanInvolute Gear ProfiledressfeetBelum ada peringkat

- Arbol de Levas Como MedirloDokumen9 halamanArbol de Levas Como Medirloariel avalosBelum ada peringkat

- Petervanoossanen - Further Computer Analyzed Data of The Wageningen B-Screw SeriesDokumen13 halamanPetervanoossanen - Further Computer Analyzed Data of The Wageningen B-Screw SeriesLucas ReisBelum ada peringkat

- Ballscrew Product Specifications 11 12Dokumen2 halamanBallscrew Product Specifications 11 12harryBelum ada peringkat

- Static Calculation For FansDokumen4 halamanStatic Calculation For FansBadrul HishamBelum ada peringkat

- Features of The Ball ScrewDokumen8 halamanFeatures of The Ball ScrewTurbosMixerBelum ada peringkat

- J-Bolt Edge System For LHD TramsDokumen8 halamanJ-Bolt Edge System For LHD TramsfernandojBelum ada peringkat

- Ballscrew Product Specifications 7 8Dokumen2 halamanBallscrew Product Specifications 7 8harryBelum ada peringkat

- Involute Gear Tooth Profile vs Cycloidal Gear Tooth ProfileDokumen12 halamanInvolute Gear Tooth Profile vs Cycloidal Gear Tooth ProfileBalvinderBelum ada peringkat

- SEBF 8057 обмер распредваловDokumen12 halamanSEBF 8057 обмер распредваловJone BaneBelum ada peringkat

- C7.1 Generator Set Connecting Rod InspectionDokumen4 halamanC7.1 Generator Set Connecting Rod InspectionbejoythomasBelum ada peringkat

- Link BeamDokumen8 halamanLink BeamNeil SonBelum ada peringkat

- An818 Rev-20 2Dokumen5 halamanAn818 Rev-20 2Senthil KumarBelum ada peringkat

- Preliminary Steel Composite Bridge Design Charts User ManualDokumen11 halamanPreliminary Steel Composite Bridge Design Charts User Manualmamad66Belum ada peringkat

- CR BearingsDokumen24 halamanCR Bearingsharshal161987Belum ada peringkat

- ME5350 METROLOGY AND COMPUTER AIDED INSPECTION END SEMESTER EXAMDokumen6 halamanME5350 METROLOGY AND COMPUTER AIDED INSPECTION END SEMESTER EXAMRahul AhujaBelum ada peringkat

- Saej 1459Dokumen6 halamanSaej 1459Nicole KeithBelum ada peringkat

- MS9483CDokumen6 halamanMS9483CBryan MartinezBelum ada peringkat

- Ansi Agma 2000 A88Dokumen4 halamanAnsi Agma 2000 A88vijaykumarn0% (1)

- Study Concerning The Ball Joint Functionality of A Vehicle Steering SystemDokumen6 halamanStudy Concerning The Ball Joint Functionality of A Vehicle Steering SystemnicusorbarBelum ada peringkat

- Lecture No.4BDokumen163 halamanLecture No.4BNambi HarishBelum ada peringkat

- Ballscrew Product Specifications 13 14Dokumen2 halamanBallscrew Product Specifications 13 14harryBelum ada peringkat

- Talyrond 51 Operating InstructionsDokumen44 halamanTalyrond 51 Operating InstructionsAnenomeBelum ada peringkat

- CE 3100: Structural Engineering Lab: February 4Dokumen12 halamanCE 3100: Structural Engineering Lab: February 4Sarankumar ThathuruBelum ada peringkat

- Parametric Modelling of Straight Bevel Gearing System and Analyze The Forces and Stresses by Analytical ApproachDokumen5 halamanParametric Modelling of Straight Bevel Gearing System and Analyze The Forces and Stresses by Analytical ApproachseventhsensegroupBelum ada peringkat

- Parametric Spur GearDokumen11 halamanParametric Spur GearGoutam AcharjeeBelum ada peringkat

- EC210B Spocket InforDokumen3 halamanEC210B Spocket InforKevin Tang Wan FungBelum ada peringkat

- CAJASDokumen16 halamanCAJASDanny PuchaBelum ada peringkat

- Tables of AWG Wire Sizes: Ampacity Stranded Wires Cross Sectional Copper Area °C DC AC Skin EffectDokumen9 halamanTables of AWG Wire Sizes: Ampacity Stranded Wires Cross Sectional Copper Area °C DC AC Skin EffectnambaccucBelum ada peringkat

- Power SkivingDokumen11 halamanPower SkivingahemerlyBelum ada peringkat

- ErectionDokumen20 halamanErectionpulilathaBelum ada peringkat

- Bellows StiffnessDokumen2 halamanBellows StiffnessMesquita JoseBelum ada peringkat

- F,') Er R: Maor+Lne DestqnDokumen3 halamanF,') Er R: Maor+Lne DestqnMostafaBelum ada peringkat

- Morphing BlDE FinalDokumen21 halamanMorphing BlDE FinalSoumian NarayananBelum ada peringkat

- V-belt drive design factorsDokumen12 halamanV-belt drive design factorsPeter IyereBelum ada peringkat

- Internal GearsDokumen4 halamanInternal GearsBranislav DjordjevicBelum ada peringkat

- Spreadsheets To BS 8110: Column InternalDokumen9 halamanSpreadsheets To BS 8110: Column InternalJennifer TangBelum ada peringkat

- Alustar (Perfis & Secções)Dokumen49 halamanAlustar (Perfis & Secções)Jeovani DanielBelum ada peringkat

- Sebf 8269 Привод 3408Dokumen16 halamanSebf 8269 Привод 3408mohamed hamedBelum ada peringkat

- MD Handb2 Belt CalcDokumen5 halamanMD Handb2 Belt Calcoana2507Belum ada peringkat

- Hydraulic Cylinders CH: - Big Bore Sizes To Iso 6020-3 - Nominal Pressure 16 Mpa (160 Bar) - Max 25 Mpa (250 Bar)Dokumen6 halamanHydraulic Cylinders CH: - Big Bore Sizes To Iso 6020-3 - Nominal Pressure 16 Mpa (160 Bar) - Max 25 Mpa (250 Bar)Stoianovici CristianBelum ada peringkat

- Assignment Highway Engg For 2013Dokumen5 halamanAssignment Highway Engg For 2013amareBelum ada peringkat

- Raft DesignDokumen8 halamanRaft Designramesh_madkatte1082Belum ada peringkat

- BendingDokumen10 halamanBendingvalgorBelum ada peringkat

- Fits & TolerancesDokumen6 halamanFits & Tolerancessuperman92makBelum ada peringkat

- Datasheet Amt102 EncoderDokumen8 halamanDatasheet Amt102 EncoderPablo Davila100% (1)

- Worm Gear PDFDokumen15 halamanWorm Gear PDFcemoksz100% (6)

- Engineers Precision Data Pocket ReferenceDari EverandEngineers Precision Data Pocket ReferencePenilaian: 3 dari 5 bintang3/5 (1)

- Structural Steel Design to Eurocode 3 and AISC SpecificationsDari EverandStructural Steel Design to Eurocode 3 and AISC SpecificationsBelum ada peringkat

- Ism Chapter 25Dokumen121 halamanIsm Chapter 25Sergio Serrano ReyesBelum ada peringkat

- DNR II de HARELDokumen15 halamanDNR II de HARELhenry palmaBelum ada peringkat

- Ubc 1997-0068Dokumen123 halamanUbc 1997-0068Vaibhav ShuklaBelum ada peringkat

- Supplementary Note335Dokumen21 halamanSupplementary Note335Syafiq ArtBelum ada peringkat

- EE719 Tutorial Assigment 1Dokumen24 halamanEE719 Tutorial Assigment 1Siddhesh SharmaBelum ada peringkat

- Tatarko NotesDokumen341 halamanTatarko NotesGrace HeBelum ada peringkat

- 5 2 A A Geometric Constraints 1Dokumen3 halaman5 2 A A Geometric Constraints 1api-248595624Belum ada peringkat

- Angles and Polygons Resit TestDokumen8 halamanAngles and Polygons Resit Testapi-461267688Belum ada peringkat

- MTH 101 - Logic AssignmentDokumen6 halamanMTH 101 - Logic AssignmentMaegan PanaliganBelum ada peringkat

- Assignment Cse 251 TDokumen33 halamanAssignment Cse 251 TPrasoon SrivastavaBelum ada peringkat

- What You Need From Analysis: Appendix ADokumen31 halamanWhat You Need From Analysis: Appendix ACarlos BifiBelum ada peringkat

- 2.8 Index of Refraction LabDokumen4 halaman2.8 Index of Refraction LabsashaBelum ada peringkat

- Everything You Need to Know About AC Drives and VFDsDokumen31 halamanEverything You Need to Know About AC Drives and VFDsAnonymous FKMfvCbBelum ada peringkat

- Deflection Beam Load EndDokumen53 halamanDeflection Beam Load EndRichie BobbyBelum ada peringkat

- SSPC PA2 Measurement of Dry Coating Thickness With Magnetic GagesDokumen11 halamanSSPC PA2 Measurement of Dry Coating Thickness With Magnetic Gageslonglong3003Belum ada peringkat

- Seismic Analysis of Steel Storage Tanks, OverviewDokumen14 halamanSeismic Analysis of Steel Storage Tanks, OverviewRodolfo CBelum ada peringkat

- (AMC8) Permutations and CombinationsDokumen4 halaman(AMC8) Permutations and CombinationsNam NGUYENBelum ada peringkat

- OLGA Server Interface (OSI) Toolbox:: For Use With MATLABDokumen15 halamanOLGA Server Interface (OSI) Toolbox:: For Use With MATLABWaleedSubhanBelum ada peringkat

- Class IX Chemistry Chapter 02Dokumen21 halamanClass IX Chemistry Chapter 02Sam FisherBelum ada peringkat

- The Basis of GlottochronologyDokumen16 halamanThe Basis of GlottochronologyEky SyahrudinBelum ada peringkat

- Unit-6.PDF Analy GeoDokumen21 halamanUnit-6.PDF Analy GeoSudersanaViswanathanBelum ada peringkat

- Prog 3112 Week 11-19Dokumen18 halamanProg 3112 Week 11-19Tanga KaBelum ada peringkat

- Chapter 9 - Areas of Parallelograms and Triangles Revision NotesDokumen8 halamanChapter 9 - Areas of Parallelograms and Triangles Revision NotesHariom SinghBelum ada peringkat

- Equated Yield RateDokumen15 halamanEquated Yield RateAndr Ei100% (1)

- Naive Bayes Classifier: Coin Toss and Fair Dice ExampleDokumen16 halamanNaive Bayes Classifier: Coin Toss and Fair Dice ExampleRupali PatilBelum ada peringkat

- Operations Research - MBA - 2nd SemDokumen225 halamanOperations Research - MBA - 2nd SemA.K.Praveen kumarBelum ada peringkat

- Java Lab ManualDokumen58 halamanJava Lab ManualViswaprem CABelum ada peringkat

- SIMSEN Help FileDokumen89 halamanSIMSEN Help FileSuresh CBelum ada peringkat

- DM - 05 - 04 - Rule-Based Classification PDFDokumen72 halamanDM - 05 - 04 - Rule-Based Classification PDFMohamad ArifBelum ada peringkat