What Is A Composite

Diunggah oleh

Joel DanielDeskripsi Asli:

Judul Asli

Hak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

What Is A Composite

Diunggah oleh

Joel DanielHak Cipta:

Format Tersedia

What is a composite?

A composite is a material which is made up of two or more distinct (i.e. macroscopic, not microscopic) materials. A familiar composite is concrete, which is basically made up of sand and cement. Many common materials could be classed as composites, but this website is concerned with fibre reinforced polymer composites. Polymer composites are plastics within which there are embedded fibres or particles. The plastic is known as the matrix, and the fibres or particles, dispersed within it, are known as the reinforcement. The reinforcement is usually stiffer than the matrix, thus stiffening the composite material. This stiffer reinforcement will usually be laid in a particular direction, within the matrix, so that the resulting material will have different properties in different directions. This characteristic is usually exploited to optimise the design. Polymer matrix composites (PMCs) are materials that use a polymer based resin as a matrix material with some form of fibres embedded in the matrix, as a reinforcement. Both thermosetting and thermoplastic polymers can be used for the matrix material. Common polymer composite thermosetting matrix materials include polyester, vinyl ester and epoxy. Polymer composite thermoplastic matrix materials include PEEK, PEI and PPS. Reinforcements include glass, carbonand aramid fibres. Why use polymer composites?

There can be many secondary reasons why polymer composites may be chosen for the manufacture of particular articles or components, but the primary reason is because of weight saving for their relative stiffness and strength. As an example we can compare a carbon fibre reinforced composite with its steel counterpart. The carbon fibre composite can be five times stronger than 1020 grade steel while having only one fifth the weight. Aluminium (6061 grade) is much nearer in weight to carbon fibre composite (though still somewhat heavier), but the composite can have twice the modulus and up to seven times the strength. When should polymer composites be used?

Polymeric composites are one class of engineering material. As with all other engineering materials, they have particular strengths and particular weaknesses. The matrix protects the strong stiff fibres and together the composite material improves on the properties of either the matrix material or the fibres alone. A major driving force behind the development of composites has been to produce materials with improved specific mechanical properties over existing materials. Specific stiffness can be defined as the stiffness of a material divided by the density of material and specific strength can be defined as the strength of a material divided by the density of the material. It is these good specific properties of composites that allow the design of high performance structural components. Polymer composite material structures can also be engineered so that the directionality of the reinforcement material is arranged so as to match the loading on a given component or structure. In addition, polymer composites are useful in applications where the environment would be detrimental to other materials. A wide selection of resins and coatings are available to match appropriate environmental conditions. Cost is ever present in the engineering equation and it is the balance of cost and performance that determine whether or not to use polymer composites over an alternative structural material option Can polymer composites directly replace metals?

Many metal articles or components can instead be made from composites, but there are important differences which mean that direct substitution should be made with care. Most engineering materials are essentially isotropic. That is, they have the same properties such as strength and modulus, in any direction. There may be 'grain' in some metals due to the manufacturing process, but it is only in critical applications that this matters. Most machining or casting processes do not have to take directional differences into account. Most composites will have very different properties in different directions. This is because, although the matrix material is isotropic, the reinforcement is not. Carbon fibres may be up to 100 times stronger under tension than they are in shear, and the stiffness may differ in the two directions by similar ratios. The properties of the composite will reflect the properties of the reinforcement, so that it can have greatly different properties in different directions. This is exploited in design as manufactured articles rarely require to be equally strong in all directions, and composites can achieve this by particular arrangements of the reinforcement. However, a different design procedure is required for composites compared to that required for metals. . What type of polymer composites are available?

Polymer composites can be classified according to the type of MATRIX material, and the type of REINFORCEMENT material. Because the size of the reinforcement particles, or the type and length of the fibres can be varied, and because the directions in which they can be placed within the matrix can be varied, a very wide variety of properties can be achieved. Where necessary the composite can have different properties in different directions. When we include the possibility of changing the matrix material, it can be seen that polymer composites form a vast family of engineering materials. Click here for matrix options Click here for reinforcement options

What are the main factors determining the costs?

There are four factors determining the direct costs of producing articles from reinforced polymer composites. These are: Material costs Tooling costs Processing costs Finishing costs

Additionally, there may be a number of indirect costs, such as quality control, health and safety considerations, etc. which need to be taken into account but are not dealt with here. Also, there is an increasing emphasis on environmental factors including maintenance , recycling, and disposal, which, over the lifetime of a component, can be important. For many components, the benefits from the use of reinforced polymer composites can become very significant when whole-life costs, rather than just fabrication costs, are included.

What applications are currently fabricated from composites?

Many products in a variety of industries are fabricated from composites, from fighter aircraft to bath tubs. This section gives more examples in different industries including: Boating Automotive and rail General Engineering Aerospace Sporting goods Civil Engineering Domestic Medical

Automotive & rail

Links to other sections Item Typical Fibre Typical Resin Manufacturing

Battery trays Body panels Bumper fascia Drive shafts Radiator grills

Glass SMC Carbon/glass Carbon/ E-glass Glass

PP

Flow/compression moulding Compression moulding

Polyester/rubber VE PBT PP VE/Epoxy/PE PP / Nylon PP / Nylon VE/PW

Compression moulding FW RIM Flow/compression moulding FW, Auto IM Extruded

Instrument panes Glass Leaf springs Engine components Fuel lines Rail car bodies Glass Glass Glass E-glass fabric

Anda mungkin juga menyukai

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDari EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryPenilaian: 3.5 dari 5 bintang3.5/5 (231)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Dari EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Penilaian: 4.5 dari 5 bintang4.5/5 (119)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDari EverandNever Split the Difference: Negotiating As If Your Life Depended On ItPenilaian: 4.5 dari 5 bintang4.5/5 (838)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDari EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaPenilaian: 4.5 dari 5 bintang4.5/5 (265)

- The Little Book of Hygge: Danish Secrets to Happy LivingDari EverandThe Little Book of Hygge: Danish Secrets to Happy LivingPenilaian: 3.5 dari 5 bintang3.5/5 (399)

- Grit: The Power of Passion and PerseveranceDari EverandGrit: The Power of Passion and PerseverancePenilaian: 4 dari 5 bintang4/5 (587)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDari EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyPenilaian: 3.5 dari 5 bintang3.5/5 (2219)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDari EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifePenilaian: 4 dari 5 bintang4/5 (5794)

- Team of Rivals: The Political Genius of Abraham LincolnDari EverandTeam of Rivals: The Political Genius of Abraham LincolnPenilaian: 4.5 dari 5 bintang4.5/5 (234)

- Rise of ISIS: A Threat We Can't IgnoreDari EverandRise of ISIS: A Threat We Can't IgnorePenilaian: 3.5 dari 5 bintang3.5/5 (137)

- Shoe Dog: A Memoir by the Creator of NikeDari EverandShoe Dog: A Memoir by the Creator of NikePenilaian: 4.5 dari 5 bintang4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerDari EverandThe Emperor of All Maladies: A Biography of CancerPenilaian: 4.5 dari 5 bintang4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDari EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You ArePenilaian: 4 dari 5 bintang4/5 (1090)

- Her Body and Other Parties: StoriesDari EverandHer Body and Other Parties: StoriesPenilaian: 4 dari 5 bintang4/5 (821)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDari EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersPenilaian: 4.5 dari 5 bintang4.5/5 (344)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDari EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RacePenilaian: 4 dari 5 bintang4/5 (890)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDari EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FuturePenilaian: 4.5 dari 5 bintang4.5/5 (474)

- The Unwinding: An Inner History of the New AmericaDari EverandThe Unwinding: An Inner History of the New AmericaPenilaian: 4 dari 5 bintang4/5 (45)

- The Yellow House: A Memoir (2019 National Book Award Winner)Dari EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Penilaian: 4 dari 5 bintang4/5 (98)

- Course Outline 21st Century LiteratureDokumen4 halamanCourse Outline 21st Century LiteratureDinalyn VillamangcaBelum ada peringkat

- On Fire: The (Burning) Case for a Green New DealDari EverandOn Fire: The (Burning) Case for a Green New DealPenilaian: 4 dari 5 bintang4/5 (73)

- Perform Mise'en Place: Learning Outcome 1Dokumen38 halamanPerform Mise'en Place: Learning Outcome 1Marichu HipeBelum ada peringkat

- The Spring, Energy Accumulator A Mechanical WatchDokumen5 halamanThe Spring, Energy Accumulator A Mechanical WatchismbllBelum ada peringkat

- Technology and Livelihood Education: Cookery 9Dokumen50 halamanTechnology and Livelihood Education: Cookery 9Julie ArcillaBelum ada peringkat

- 1-Gma Annual Report - 2020 1621409182Dokumen86 halaman1-Gma Annual Report - 2020 1621409182RonEljun Medalla-EnopiaBelum ada peringkat

- Potential Antimicrobial Activity of Red and White Wine Phenolic Extracts Against Strains ofDokumen6 halamanPotential Antimicrobial Activity of Red and White Wine Phenolic Extracts Against Strains ofRafael SoaresBelum ada peringkat

- Holistic NutritionistDokumen3 halamanHolistic Nutritionistmay taurusBelum ada peringkat

- DSTVDokumen3 halamanDSTVMega ByteBelum ada peringkat

- Online Dress Shopping - Modules & DescriptionDokumen3 halamanOnline Dress Shopping - Modules & DescriptionI NoBelum ada peringkat

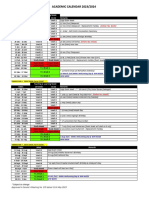

- Academic Calendar 23 24Dokumen1 halamanAcademic Calendar 23 24Jeff KokBelum ada peringkat

- Rapunzel ScriptDokumen4 halamanRapunzel ScriptDyosa siobhieBelum ada peringkat

- 400x HBO MAX BY @k45t0 - 0Dokumen8 halaman400x HBO MAX BY @k45t0 - 0miguewfakeBelum ada peringkat

- Operating Limits and Controls for Hydroplus BoostersDokumen28 halamanOperating Limits and Controls for Hydroplus BoostersPepe PintoBelum ada peringkat

- Acessorios Askool CatalogoDokumen18 halamanAcessorios Askool CatalogoDiogo SilvaBelum ada peringkat

- The Distinctive Musical Styles and Characteristics of Expressionism in Music Through The Elements of MusicDokumen4 halamanThe Distinctive Musical Styles and Characteristics of Expressionism in Music Through The Elements of MusicRoan BodinoBelum ada peringkat

- HirePro Video Proctored Assessment System RequirementsDokumen1 halamanHirePro Video Proctored Assessment System RequirementsKrishna RockBelum ada peringkat

- SMO Project On MI PhoneDokumen67 halamanSMO Project On MI PhoneVishalBelum ada peringkat

- Control Valve Body Assembly (Valve Body) - ALLDATA RepairDokumen6 halamanControl Valve Body Assembly (Valve Body) - ALLDATA RepairgabotoyoBelum ada peringkat

- 293 AzulDokumen7 halaman293 AzulMariel CalhuanteBelum ada peringkat

- In The House Crossword Puzzle Crosswords Icebreakers Oneonone Activities Tests W 40439Dokumen2 halamanIn The House Crossword Puzzle Crosswords Icebreakers Oneonone Activities Tests W 40439Dayani BravoBelum ada peringkat

- Lenovo Laptop Technical SpecificationDokumen2 halamanLenovo Laptop Technical SpecificationJay SathvaraBelum ada peringkat

- Mr Otis and the Canterville GhostDokumen3 halamanMr Otis and the Canterville GhostPatricia Pérez BerradeBelum ada peringkat

- GolgothansDokumen2 halamanGolgothansMike UrsuBelum ada peringkat

- Tactile DematerializationDokumen9 halamanTactile DematerializationchristrombjergBelum ada peringkat

- Attom - DC Power System-Brochure-en-2021v1.2Dokumen5 halamanAttom - DC Power System-Brochure-en-2021v1.2Eleken Login2Belum ada peringkat

- Itw - Within Billy ElliotDokumen1 halamanItw - Within Billy Elliotstregas123Belum ada peringkat

- MFL69365752 01 PDFDokumen292 halamanMFL69365752 01 PDFGeorgescu FlorentinBelum ada peringkat

- Irctcs E-Ticketing Service Electronic Reservation Slip (Personal User)Dokumen1 halamanIrctcs E-Ticketing Service Electronic Reservation Slip (Personal User)Bhanu Pratap ChoudhuryBelum ada peringkat

- SatFlower I6 User Manual V1.0Dokumen62 halamanSatFlower I6 User Manual V1.0Nithin Raj KBelum ada peringkat