Waistcoat Jacket

Diunggah oleh

Nicholas FeatherstonDeskripsi Asli:

Hak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

Waistcoat Jacket

Diunggah oleh

Nicholas FeatherstonHak Cipta:

Format Tersedia

Steps involved in making a Waistcoat Jacket

A) Required Items: 1) Sewing machine, with cotton line (different colours grey and black used here). 2) Sewing pattern. 3) Jacket material (pure cotton, silk cotton, wool cotton) for front and back of jacket. 4) Inner lining can be satin material. Think of complementary colours for lining and front of jacket as well. 5) Interfacing material for front side of jacket. Choose approporiate colour. 6) Buttons. 7) Scissors, needles, pins, unpicker, marking pen, rotary cutter, cutting board, marking roller, thimble, cotton wheels. 8) Material carbon copy transfer paper 9) Steam iron and ironing board 10) Measuring tape

B) Glossary:

1) Under stitch - used to sew the folds on seam lines to one side, this gives the seam a more defined shape. 2) Stay stitch used to create a temporary stitch line that is easily removable. 3) Back stitch this should be used at the start and end of any standard stitch. 4) Baste stitch -

C) Sequence:

Photo 1 Measure chest, choose correct size from pattern supplied and cut out pattern for back and front, including jacket front material (x2), jacket back material (x2), interfacing for front piece (x2) which is cut 1cm smaller, and the lining (x2).

Photo 2 Fold material for front of jacket piece and pin along the line of grain. If material is poorly cut, then approximate the line. Line up edges when pinning as the idea is to cut two pieces at the same time. Ensure that you are cutting the correct side of the material.

Line of material grain direction

Line up pattern piece to be parallel with edge of material

Photo 3 Material and pattern for jacket Front piece. Pin the cut-out pattern to the material, taking account of the out grain direction of the material in your positioning. Position pattern piece so that grain line is parallel with edge of the material (as pinned in Photo 2).

Photo 4 Material and pattern for jacket back piece. Pin pattern to material, fold double, as per Photo 2. Align pattern according to grain line as per Photo 3.

Photo 5 Use rotary cutter to cut out material along pattern edges. Position cutting board underneath before using rotary cutter.

Photo 6 Back (left side of photo) and front (right side of photo) pieces of material as cut-out. Use as cut-out pattern/rotary cutter to cut lining, interfacing and primary material all at the same time.

Photo 7 Fold lining material in half, line up hems (as per Photo 2) and position front/back pattern pieces so that grain line is parallel with material edge.

Photo 8 Use rotary cutter to cut out lining pieces.

10

Photo 9 Jacket Front pieces (x2). Cut interfacing to a size 1cm smaller than front material. Use steam iron to attach interfacing to jacket Front material. Note that black coloured interfacing has only one glue side which can be used, so check that interfacing is on correct side before using steam iron. Steam iron to be applied carefully to interfacing material.

11

Dart lines

Photo 10 Re-attach paper pattern to front/back material (by pinning). Use marking roller and carbon copy transfer paper to transfer dart lines (as shown) to material.

12

Dart lines transferred to back of material

Photo 11 Install material carbon copy transfer paper between back sides of jacket front material.

13

Photo 12 Mark out lines of welts onto Front jacket piece.

14

Photo 13 Move material carbon copy transfer paper as required to correct position.

15

Photo 14 Mark out darts with marking roller for jacket Back piece (with transfer paper installed).

16

Photo 15 Insert material carbon copy transfer paper in-between lining and transfer dart lines to back of lining.

17

Start (apply backstitch)

End (leave loose and tie by hand)

Photo 16 Fold material along line midway in-between the two dart lines and pin. Insert perpendicular pin at end of the two dart lines.

Photo 17 Use straight stitch with Tension = 4, Stitch length = 2.5, Stitch width = 0 to stitch from start till finish of the dart line. At the start, apply backstitch, at the end, bring stitching as close as possible to the edge and leave loose for tying off by hand (see Photo 16).

18

Photo 18 Completed dart line.

19

Photo 19 Repeat for all 8 pieces of material.

20

Photo 20 Use steam iron to fold inside pleat out, towards centre back position.

21

Photo 21 Pin the two straight sides of the lining and the jacket Back material.

Photo 22 Use straight stitch backstitching for lining and sew along line which is 1.5cm from material edge to join the two pieces. Use similar sewing machine requirements as per Photo 17. 22

Photo 23 Use same stitching as per Photo 22 for jacket Back pieces.

Photo 24 Pin the shoulder seams of the Jacket back to the Jacket front. Important to pin the correct sides to each other.

23

Photo 25 Use straight stitching to sew back jacket piece to front jacket piece.

Photo 26 Use same stitching as per Photo 22 for jacket Back pieces. 24

Photo 27 Use same stitching as per Photo 22 for jacket Back pieces.

Photo 28 Use iron to fold all seams open.

25

Fold welt along this line and pin the two sides together

Photo 29 Cut out 2x welt pieces and fold back.

Photo 30 Pin both welts.

26

Photo 31 Sew closure lines on both short edges of welt.

Photo 32 Re-pin welts and use iron to go over permanent fold lines. 27

Pin points

Welt line

Photo 33 Turn over jacket to the inside where welt positions are marked out.

Photo 34 Use pins and pin through jacket to opposite side at welt line. 28

Photo 35 Pin welt to jacket front.

Photo 36 Pin both welts to jacket front. Separate the lining from the jacket material.

29

Photo 37 Sew welts onto the jacket, using a single stitch, 5mm from the welt line. Use backstitching on ends.

Photo 38 Use iron to press welt onto jacket front. 30

Photo 39 Positioning of the two welts.

Cut-outs for arms

Photo 40 Pin entire length of jacket lining to jacket front, except at arm cut-outs. 31

Photo 41 Stitch entire length of jacket using straight stitch, 1.5cm from material edge. Leave out the arm cut-outs.

Photo 42 Layout jacket in front of you (inside out), remove all pins, ready for next step.

32

Triangular cut-outs, spaced at approx 3cm c/c

Photo 43 Cut out triangle shapes along arm edges on both sides of jacket as shown.

Triangular cut-outs along neck line, spaced at approx 3cm c/c

Photo 44 Cut out triangular shapes along neck line from start of curve to end of curve. 33

Photo 45 Turn jacket inside out by putting hand inside open end and drawing material through.

Photo 46 Draw material through until jacket has been completely turned inside out. 34

Photo 47 Change cotton material to grey colour, setup material along seam lines and do Understitching to all seams and inside folds. Ensure that all understitched lines are on the inside of the jacket and that the stitching goes through to the inside fold. Ensure that the inside fold is towards the inside of the jacket. Existing seam line

Outside jacket piece

Understitch line

Inside lining

Photo 48 Position of all understitched lines should be on the inside of the jacket and should be as close as possible to the existing seamline. 35

Understitch lines

Photo 49 There will be some parts of the jacket that you simply cannot get to, but you should be able to put in understitch lines to at least 80% of the seam lines.

36

Anda mungkin juga menyukai

- Never Split the Difference: Negotiating As If Your Life Depended On ItDari EverandNever Split the Difference: Negotiating As If Your Life Depended On ItPenilaian: 4.5 dari 5 bintang4.5/5 (838)

- Shoe Dog: A Memoir by the Creator of NikeDari EverandShoe Dog: A Memoir by the Creator of NikePenilaian: 4.5 dari 5 bintang4.5/5 (537)

- Sednamixer Catalog 180413Dokumen24 halamanSednamixer Catalog 180413Tien Din TranBelum ada peringkat

- HyerPeterson Mines 0052N 11781Dokumen147 halamanHyerPeterson Mines 0052N 11781Nicholas FeatherstonBelum ada peringkat

- AnalysisofInternationalStandardsonConcrete ReinforcingSteelBarDokumen13 halamanAnalysisofInternationalStandardsonConcrete ReinforcingSteelBarhoustonhimselfBelum ada peringkat

- Lect 32Dokumen16 halamanLect 32Nicholas FeatherstonBelum ada peringkat

- Guidelines for Design and Construction of Precast Pre-tensioned GirdersDokumen24 halamanGuidelines for Design and Construction of Precast Pre-tensioned GirdersNicholas FeatherstonBelum ada peringkat

- Glue Ear - Symptoms, Causes, Treatment, and PreventionDokumen11 halamanGlue Ear - Symptoms, Causes, Treatment, and PreventionNicholas FeatherstonBelum ada peringkat

- Tannerite ' .: Brand Binary Exploding Rifle Target Material Safety Data Sheet CationDokumen4 halamanTannerite ' .: Brand Binary Exploding Rifle Target Material Safety Data Sheet CationNicholas FeatherstonBelum ada peringkat

- NCHRP RPT 543Dokumen163 halamanNCHRP RPT 543Jorge PalominoBelum ada peringkat

- Steel-Concrete Composite Bridges: Design, Life Cycle Assessment, Maintenance, and Decision-MakingDokumen14 halamanSteel-Concrete Composite Bridges: Design, Life Cycle Assessment, Maintenance, and Decision-MakingNicholas FeatherstonBelum ada peringkat

- Sukhoi Su-35Dokumen30 halamanSukhoi Su-35Nicholas FeatherstonBelum ada peringkat

- Electrohemical Study of Corrosion Rate of Steel in Soil Barbalat2012Dokumen8 halamanElectrohemical Study of Corrosion Rate of Steel in Soil Barbalat2012Nicholas FeatherstonBelum ada peringkat

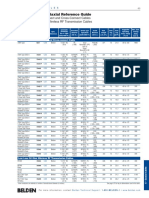

- RG Coaxial and Triaxial Reference GuideDokumen13 halamanRG Coaxial and Triaxial Reference GuideNicholas FeatherstonBelum ada peringkat

- Why Do Your Wings Have Dihedral - BoldmethodDokumen9 halamanWhy Do Your Wings Have Dihedral - BoldmethodNicholas FeatherstonBelum ada peringkat

- VESC ProjectDokumen5 halamanVESC ProjectNicholas FeatherstonBelum ada peringkat

- Aluminum Alloys For AerospaceDokumen2 halamanAluminum Alloys For AerospaceNicholas Featherston100% (1)

- Thesis Ault ReportDokumen167 halamanThesis Ault ReportNicholas FeatherstonBelum ada peringkat

- Ask Us - 400 HZ Electrical SystemsDokumen5 halamanAsk Us - 400 HZ Electrical SystemsNicholas FeatherstonBelum ada peringkat

- Is 5G Safe? Is 5G Safe?: An Easy To Understand GuideDokumen20 halamanIs 5G Safe? Is 5G Safe?: An Easy To Understand GuideDorian GrayBelum ada peringkat

- Jesus Nut - WikipediaDokumen2 halamanJesus Nut - WikipediaNicholas FeatherstonBelum ada peringkat

- Dihedral Effect - An Overview - ScienceDirect TopicsDokumen8 halamanDihedral Effect - An Overview - ScienceDirect TopicsNicholas FeatherstonBelum ada peringkat

- HSF - The ShuttleDokumen8 halamanHSF - The ShuttleNicholas FeatherstonBelum ada peringkat

- HyFlyer - EMEC - European Marine Energy CentreDokumen5 halamanHyFlyer - EMEC - European Marine Energy CentreNicholas FeatherstonBelum ada peringkat

- Excel Advanced ManualDokumen32 halamanExcel Advanced ManualNicholas FeatherstonBelum ada peringkat

- Dihedral (Aeronautics) - WikipediaDokumen7 halamanDihedral (Aeronautics) - WikipediaNicholas FeatherstonBelum ada peringkat

- 7 Essential Ways To Make Your Home SafeDokumen19 halaman7 Essential Ways To Make Your Home SafedakrizzzBelum ada peringkat

- 25 Surprisingly TOXIC Everyday Products To STOP Feeding Your BodyDokumen49 halaman25 Surprisingly TOXIC Everyday Products To STOP Feeding Your BodyChompek84Belum ada peringkat

- Excel Intermediate ManualDokumen35 halamanExcel Intermediate ManualNicholas FeatherstonBelum ada peringkat

- 3 Safe Natural Ways to Treat Anxiety Better than XanaxDokumen7 halaman3 Safe Natural Ways to Treat Anxiety Better than XanaxNicholas FeatherstonBelum ada peringkat

- 5G Megaguide by EMF Academy PDFDokumen39 halaman5G Megaguide by EMF Academy PDFSERGIO alarconBelum ada peringkat

- 7 Natural Ways To Repair EMF DamageDokumen8 halaman7 Natural Ways To Repair EMF DamageChristen LeonieBelum ada peringkat

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDari EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifePenilaian: 4 dari 5 bintang4/5 (5794)

- The Yellow House: A Memoir (2019 National Book Award Winner)Dari EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Penilaian: 4 dari 5 bintang4/5 (98)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDari EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RacePenilaian: 4 dari 5 bintang4/5 (894)

- The Little Book of Hygge: Danish Secrets to Happy LivingDari EverandThe Little Book of Hygge: Danish Secrets to Happy LivingPenilaian: 3.5 dari 5 bintang3.5/5 (399)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDari EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FuturePenilaian: 4.5 dari 5 bintang4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDari EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryPenilaian: 3.5 dari 5 bintang3.5/5 (231)

- Grit: The Power of Passion and PerseveranceDari EverandGrit: The Power of Passion and PerseverancePenilaian: 4 dari 5 bintang4/5 (587)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDari EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaPenilaian: 4.5 dari 5 bintang4.5/5 (265)

- On Fire: The (Burning) Case for a Green New DealDari EverandOn Fire: The (Burning) Case for a Green New DealPenilaian: 4 dari 5 bintang4/5 (73)

- The Emperor of All Maladies: A Biography of CancerDari EverandThe Emperor of All Maladies: A Biography of CancerPenilaian: 4.5 dari 5 bintang4.5/5 (271)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDari EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersPenilaian: 4.5 dari 5 bintang4.5/5 (344)

- The Unwinding: An Inner History of the New AmericaDari EverandThe Unwinding: An Inner History of the New AmericaPenilaian: 4 dari 5 bintang4/5 (45)

- Team of Rivals: The Political Genius of Abraham LincolnDari EverandTeam of Rivals: The Political Genius of Abraham LincolnPenilaian: 4.5 dari 5 bintang4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDari EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyPenilaian: 3.5 dari 5 bintang3.5/5 (2219)

- Rise of ISIS: A Threat We Can't IgnoreDari EverandRise of ISIS: A Threat We Can't IgnorePenilaian: 3.5 dari 5 bintang3.5/5 (137)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDari EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You ArePenilaian: 4 dari 5 bintang4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Dari EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Penilaian: 4.5 dari 5 bintang4.5/5 (119)

- Her Body and Other Parties: StoriesDari EverandHer Body and Other Parties: StoriesPenilaian: 4 dari 5 bintang4/5 (821)

- Crochet Sampler AfghanDokumen8 halamanCrochet Sampler Afghanandiscrbd100% (1)

- Quilt Print DressDokumen25 halamanQuilt Print DressNhãKhanhBelum ada peringkat

- Garment Manufacturing Project ReportDokumen64 halamanGarment Manufacturing Project ReportAVANTIKA VERMABelum ada peringkat

- Fast Fur Jacket Fast Fur Jacket Fast Fur Jacket Fast Fur JacketDokumen5 halamanFast Fur Jacket Fast Fur Jacket Fast Fur Jacket Fast Fur JacketamelieBelum ada peringkat

- CONSUMER BUYING BEHAVIOR by MansiDokumen20 halamanCONSUMER BUYING BEHAVIOR by MansiMANSI0% (1)

- Pack Audits ProceduresDokumen5 halamanPack Audits ProceduresAnjali SrivastvaBelum ada peringkat

- Requirements For The May 2021 Students 1. Automotive Department 2. Information Technology DepartmentDokumen21 halamanRequirements For The May 2021 Students 1. Automotive Department 2. Information Technology DepartmentAlexander MugabeBelum ada peringkat

- Mork Borg - Strange Visitors SpreadsDokumen19 halamanMork Borg - Strange Visitors SpreadsSeterianBelum ada peringkat

- Tailoring AnswerDokumen7 halamanTailoring AnswerJocelyn CalasagBelum ada peringkat

- FCZ740 Operation ManualDokumen68 halamanFCZ740 Operation ManualroqueBelum ada peringkat

- MDF069 Woodsia PatternDokumen23 halamanMDF069 Woodsia PatternAlonso SalasBelum ada peringkat

- Fabric requirements and tutorial for sewing a holster bagDokumen1 halamanFabric requirements and tutorial for sewing a holster bagMARÍA JOSÉ COLLAOBelum ada peringkat

- Fun Dip QuiltDokumen6 halamanFun Dip QuiltElizabeth BleierBelum ada peringkat

- Danish Viking SmokkrDokumen16 halamanDanish Viking SmokkrMackenzie67% (3)

- Needlework - English VocabularyDokumen2 halamanNeedlework - English VocabularyMiriam Tõnismägi100% (1)

- Brother VX 1410Dokumen65 halamanBrother VX 1410ducamoris0% (1)

- Kenmore 158.19412 ManualDokumen50 halamanKenmore 158.19412 ManualChristopher Walton83% (12)

- F S Noa Pattern CombinedDokumen46 halamanF S Noa Pattern CombinedSulma DlcruzBelum ada peringkat

- Sailmaker GuidebookDokumen31 halamanSailmaker GuidebookAlfonsobcnBelum ada peringkat

- Repetition Radiation. Gradation.: Pure Colors TintsDokumen4 halamanRepetition Radiation. Gradation.: Pure Colors TintsKathrine MacapagalBelum ada peringkat

- Based On The Study of The History of D, It Is Age-OldDokumen6 halamanBased On The Study of The History of D, It Is Age-OldCattleya Jade JaverleBelum ada peringkat

- Chapter 6 - Basic SailmakingDokumen8 halamanChapter 6 - Basic SailmakingVladislavsŽavtkēvics100% (1)

- Neck FinishingDokumen7 halamanNeck FinishingShresha DasBelum ada peringkat

- Henry The Mallard Duck Crochet Pattern ENDokumen3 halamanHenry The Mallard Duck Crochet Pattern ENashley tohillBelum ada peringkat

- Totoro Bag Sewing PatternDokumen17 halamanTotoro Bag Sewing PatternRoberta AndiBelum ada peringkat

- Cat and Bird Quilt BlocksDokumen14 halamanCat and Bird Quilt Blocksmer84100% (1)

- White IB 4040, 4042, 4041Dokumen68 halamanWhite IB 4040, 4042, 4041babasik11215100% (1)

- Acacia Crossbody Bag-Bagstock Designs-2021Dokumen28 halamanAcacia Crossbody Bag-Bagstock Designs-2021Szilvia Kellóné TóthBelum ada peringkat

- English Baler in ADokumen12 halamanEnglish Baler in AMurielle Gillet-Moreau100% (1)

- How To Create Loomwork Bracelets:: 4 FreeDokumen14 halamanHow To Create Loomwork Bracelets:: 4 FreeTunde Iobbagy100% (2)