Blain EV Troubleshooting Ev - Trouble-Gb

Diunggah oleh

Sylvester SullivanDeskripsi Asli:

Judul Asli

Hak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

Blain EV Troubleshooting Ev - Trouble-Gb

Diunggah oleh

Sylvester SullivanHak Cipta:

Format Tersedia

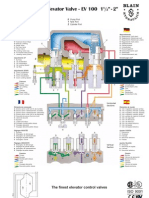

EV 100 Trouble Shooting (2007)

UP Travel

Valves are fully adjusted and tested in the factory. Check electrical operation before changing valve setting.

Problem

Possible cause

Solenoid A not energised or voltage too low.

Recommended

Test: Turn adjustment 5 all the way in. If the elevator now starts upwards the problem is at solenoid A. See

A

below.

No Up-Start (Elevator remains

Solenoid A tube not screwed down tight. Solenoid valve A: Dirt or damage between needle AN and seat AS. Adjustment 2 not far enough open.

Tighten Solenoid A tube. Clean or change needle and seat. Turn out adjustment 2. Turn in adjustment 1 with the pump running. Set relief valve higher. Turn out adjustment 8.

Insert smaller bypass ow guide (see ow guide charts at EV catalogue).

at oor) Adjustment 1 too far back (open). Not enough pilot pressure. Pressure relief S valve is set too low. Adjustment 8 turned in too far (car sits on the buffer). Bypass ow guide U is too large. Pump running in the wrong direction. The pump connection ange is leaking excessively. The pump is undersize or worn.

Install the pump correctly. Seal the pump connection. Select bigger pump or replace pump.

Test: If by turning adjustment 1 with the pump running the pressure does not rise above 5 bar, even with a smaller bypass valve inserted, the problem should be sought at the pump.

Test: Turn adjustment 3 all the way in. If the elevator now travels upwards at full speed the problem is at solenoid B. Solenoid B not energised or voltage too low. Up-Start, but no Full Speed Solenoid B tube not screwed down tight. Solenoid valve B: Dirt or damage between needle AN and seat AS. The pump connection ange is leaking excessively. The pump is undersize or worn. See

A

below.

Tighten Solenoid B tube. Clean or change needle and seat. Seal the pump connection. Select bigger pump or replace pump.

Test: If by turning adjustment 1 with the pump running the pressure does not rise above 5 bar, even with a smaller bypass valve inserted, the problem should be sought at the pump.

Adjustment 1 turned in too far. Adjustment 2 turned out too far. Up-Start too hard Bypass ow guide U too small (slots too narrow). O-Ring UO on Bypass Valve U is leaking. Star to Delta motor switch period is too long. Excessive friction on the guide rails or in the cylinder head. No deceleration into leveling speed

Levelling too fast

Turn out adjustment 1. Turn in adjustment 2. Change to ow guide with wider slots. Change O-Ring see EV Spare Parts List. 0.2-0.3 sec. is sufcient. Can not be eliminated thru valve adjustment.

Lift coil to check magnetic pull. See A below. Slow down switch possibly set to high (late).

Solenoid B does not de-energise. Adjustment 3 turned in too far. O-Ring UO on Bypass Valve U is leaking. Adjustment 4 too far screwed out. Solenoid A is de-energised too late. Adjustment 5 turned in too far. Adjustment 1 turned in too far. Up leveling speed too high. Restriction on the return line. Bypass ow guide U too small (slots too narrow). Solenoid A and B reversed. Up leveling speed too slow. Middle O-Ring FO of ange 4F is leaking. Relief valve is set too low.

Turn out adjustment 3. Turn in adjustment 2. Change O-Ring see EV Spare Parts List. Turn in adjustment 4 to about 0.05 m/s leveling speed. Lift coil to check pull. See Turn out adjustment 5. Turn out adjustment 1. Turn in adjustment 4 to about 0.05 m/s leveling speed. Remove restriction; enlarge return line. Change to ow guide with wider slots. Swap solenoid A and B. See Turn out adjustment 4. Change O-Ring see EV Spare Parts List. Set relief valve higher.

A A

Deceleration into leveling speed but overtravel of oor level Bypasspressure not adjustable Elevator stops before reaching the oor (no leveling)

below.

below.

A For checking the operation of the solenoids, remove the top nuts. By lifting the coils a few millimeters, the magnetic pull of the coil can be felt.

For testing, the operation of the elevator car can also be controlled by lifting and replacing the coil. If the coil gets too hot, the coil has to be mounted onto the solenoid and the following adjustments have to be carried out on normal travels from oor to oor. Standard settings: Adjustments 1 & 4 approx. level with ange faces. Up to two turns in either direction may then be necessary. Adjustments 2, 3 & 5 all the way in (clockwise) then for EV : all adjustments 1.5 turns out (c-clockwise), for EV 1 1/2 2 : adjustments 3 & 5 two and half turns out (c-clockwise), adjustment 2 two turns out. Small nal adjustments may be necessary.

EV 100 Trouble Shooting (2007)

DOWN Travel

Valves are fully adjusted and tested in the factory. Check electrical operation before changing valve setting.

Problem

No Down Start

Possible cause

Solenoid D not energised or voltage too low. Adjustment 6 turned in too far. Adjustment 8 turned out too far. O-Ring UO on Down Valve X is leaking. Solenoid C not energised or voltage too low.

Recommended

Lift coil to check magnetic pull. See Turn out adjustment 6.

Turn in adjustment 8 cautiously. Attention: Danger of traveling through

A

below.

Change O-Ring see EV Spare Parts List. Lift coil to check magnetic pull. See Turn out adjustment 7. Check insert size (see ow guide charts page 6) Lift coil to check magnetic pull. See

A A

below.

No full speed

Adjustment 7 turned in too far. Down Valve ow guide X too small.

No down leveling. Elevator stops before oor level No down leveling. Elevator travels though oor level Elevator sinks quickly

Solenoid C and D reversed. Adjustment 9 turned in too far. Spring 9F in adjustment 9 is broken. Adjustment 8 turned in too far. Filter of adjustment 8 blocked or adjustment 8 is damaged. Adjustment 9 turned out too far. Solenoid valve C: Dirt or damage between needle DN and seat DS. Inner O-Ring FO on ange 7F is leaking. Solenoid D tube not screwed down tight. Adjustment 8 turned in too far. For possible down leakage points, see Technical Dokumentation System Lenkage. Solenoid valve D: Dirt or damage between needle DN and seat DS. O-Ring XO of Down Valve X is leaking. O-Ring VO of Check Valve V is leaking. O-Ring WO of Leveling Valve W is leaking. Inner O-Ring FO on ange 4F is leaking. O-Ring HO of Manual Lowering H is leaking. HP: Handpump is leaking.

below.

Turn out adjustment 9 to about 0.05 m/s leveling speed. Replace adjustment 9 complete. Turn out adjustment 8 about turn. Turn in adjustment 9 to about 0.05 m/s leveling speed. Clean or change needle and seat. Change O-Ring see EV Spare Parts List. Tighten Solenoid D tube. Turn out adjustment 8 about turn. Replace one seal at a time and test before proceeding to the next point of possible leakage, if still necessary. Clean or change needle and seat.

Change O-Ring see EV Spare Parts List. When Down Valve is compensated, replace Down Valve.

Elevator sinks slowly due to inner leakage (Relevelling)

Change Check Valve see EV Spare Parts List. Change O-Ring see EV Spare Parts List. Change O-Ring see EV Spare Parts List. Replace Manual Lowering.

Remove suction tube and observe if handpump leaks. Replace complete hand pump.

Elevator sinks due to inner leakage of auxiliary equipment

HX/MX : Adjustment 8M turned in too far.

HX/MX: Down valve 9M is leaking. Dirt or damage between the needle DN and seat DS.

Turn out adjustment 8M. Clean or change needle and seat. Change O-Ring see EV Spare Parts List. Replace Manual Lowering. Consider oil cooler if hot oil is a problem.

HX/MX: O-Ring XO of Down Valve YM is leaking. HX/MX: Manual Lowering is leaking (HX/MX). Contraction of oil during cooling especially from 35C or above.

A For checking the operation of the solenoids, remove the top nuts. By lifting the coils a few millimeters, the magnetic pull of the coil can be felt.

For testing, the operation of the elevator car can also be controlled by lifting and replacing the coil. If the coil gets too hot, the coil has to be mounted onto the solenoid and the following adjustments have to be carried out on normal travels from oor to oor. Standard settings: Adjustments 7 & 9 approx. level with ange faces. Up to two turns in either direction may then be necessary. Adjustments 6 & 8 all the way in (clockwise) then for EV , adjustment 6,1 turn and adjustment 8, 1 turn out (c-clockwise), for EV 1 1/2 2 , adjustments 6 & 8, 1 turns out (c-clockwise). Small nal adjustments may be necessary.

mar 07

Pfaffenstrasse 1 Boellinger Hoefe 74078 Heilbronn Germany

Tel. 07131 2821-0 Fax 07131 485216 http://www.blain.de e-mail:info@blain.de

GmbH

Manufacturer of the Highest Quality: Control Valves for Elevators Tank Heaters - Hand Pumps Pipe Rupture Valves - Ball Valves

Anda mungkin juga menyukai

- Maya Keyboard ShortcutsDokumen0 halamanMaya Keyboard ShortcutsDaryl Gomez TimatimBelum ada peringkat

- Mitchella Partridge Berry Materia Medica HerbsDokumen3 halamanMitchella Partridge Berry Materia Medica HerbsAlejandra GuerreroBelum ada peringkat

- Stavanger Tourist SpotDokumen96 halamanStavanger Tourist Spotregupathi6413Belum ada peringkat

- Hydro Elite Quick Installation ManualDokumen12 halamanHydro Elite Quick Installation ManualMileBelum ada peringkat

- Elevator Apprentice: Passbooks Study GuideDari EverandElevator Apprentice: Passbooks Study GuideBelum ada peringkat

- Synergy Element Brochure LowDokumen16 halamanSynergy Element Brochure Lowangela1590Belum ada peringkat

- MACPUAR S.A. Order DetailsDokumen22 halamanMACPUAR S.A. Order DetailsBjorn De BenBelum ada peringkat

- 1 27Dokumen54 halaman1 27MD Omar FarukBelum ada peringkat

- Elevator History and Functions and The Invention of This Amazing Piece of WorkDokumen69 halamanElevator History and Functions and The Invention of This Amazing Piece of Workjay vallejosBelum ada peringkat

- Configuration & Options List: 30Xw0452 1752 Water Cooled Liquid ChillerDokumen22 halamanConfiguration & Options List: 30Xw0452 1752 Water Cooled Liquid ChillerOctavio Farid Rossi YumhaBelum ada peringkat

- Lift Control System: ManualDokumen180 halamanLift Control System: ManualAfsar HussainBelum ada peringkat

- EE313Dokumen3 halamanEE313Jean Luis Saviñón100% (1)

- High-Speed Elevators Move People Through Time and SpaceDokumen15 halamanHigh-Speed Elevators Move People Through Time and SpaceDemme Abdi Nasa100% (1)

- Elevator Inspector: Passbooks Study GuideDari EverandElevator Inspector: Passbooks Study GuideBelum ada peringkat

- Manuale IV5 (Inglese)Dokumen223 halamanManuale IV5 (Inglese)bmonaandaBelum ada peringkat

- Elevator Mechanic: Passbooks Study GuideDari EverandElevator Mechanic: Passbooks Study GuideBelum ada peringkat

- Wittur NL Spare Part Catalogue Ed2018-1 PDFDokumen308 halamanWittur NL Spare Part Catalogue Ed2018-1 PDFNguyễn Lê Anh KhoaBelum ada peringkat

- HSVF HSVF HSVF HSVF Adjustment Manual Adjustment Manual Adjustment Manual Adjustment ManualDokumen20 halamanHSVF HSVF HSVF HSVF Adjustment Manual Adjustment Manual Adjustment Manual Adjustment ManualJesús David Diaz MontesBelum ada peringkat

- Tac 32 ICON 32 ManualDokumen220 halamanTac 32 ICON 32 ManualOnebigunicornBelum ada peringkat

- Carrier 30GTN PDDokumen38 halamanCarrier 30GTN PDBudhi HermawanBelum ada peringkat

- Maintenance and service manual for elevator control valve EV 100 blainDokumen13 halamanMaintenance and service manual for elevator control valve EV 100 blaindragishabl100% (1)

- QuickGuide PDFDokumen32 halamanQuickGuide PDFRibeiroFrancesBelum ada peringkat

- KLEEMANN Lift Modernisation SolutionsDokumen18 halamanKLEEMANN Lift Modernisation SolutionsKleemmann Hellas SABelum ada peringkat

- Maintenance and Service Manual For Elevator Control Valve: EV 100 BlainDokumen13 halamanMaintenance and Service Manual For Elevator Control Valve: EV 100 Blainsuk2010Belum ada peringkat

- Unidrive PDFDokumen209 halamanUnidrive PDFAlejandra PerezBelum ada peringkat

- Blain Service Manual GBDokumen40 halamanBlain Service Manual GBsmsobhanBelum ada peringkat

- Goat Milk Marketing Feasibility Study Report - Only For ReferenceDokumen40 halamanGoat Milk Marketing Feasibility Study Report - Only For ReferenceSurajSinghalBelum ada peringkat

- Nexus 3rd Generation Lift Controller - Programming ManualDokumen14 halamanNexus 3rd Generation Lift Controller - Programming ManualSam WildBelum ada peringkat

- Modernize Elevators with MCS 220 M ControllerDokumen1 halamanModernize Elevators with MCS 220 M ControllerTaha AlkibsiBelum ada peringkat

- 07 Dover 139-172Dokumen34 halaman07 Dover 139-172apuhapuh_153349Belum ada peringkat

- Lift control technical folder hydraulic systemDokumen6 halamanLift control technical folder hydraulic systemAidolan UlrichBelum ada peringkat

- Elevator and Escalator Guide Rollers CatalogDokumen21 halamanElevator and Escalator Guide Rollers CatalogManuel Hernandez0% (1)

- Schindler 3300 Ca Product Family Brochure PDFDokumen32 halamanSchindler 3300 Ca Product Family Brochure PDFjorge barrerBelum ada peringkat

- JSW Energy Plant Maintenance BBPDokumen46 halamanJSW Energy Plant Maintenance BBPSandeep Kumar PraharajBelum ada peringkat

- 239 ManDokumen158 halaman239 Mancristian gonzalezBelum ada peringkat

- Mia fst2XT XTs 2015-07 enDokumen129 halamanMia fst2XT XTs 2015-07 enMagtanggol RelucioBelum ada peringkat

- Elevator Drives - Past, Present and FutureDokumen41 halamanElevator Drives - Past, Present and FutureNuraimi Hamid100% (1)

- Power Unit Inst - Instructions EngDokumen46 halamanPower Unit Inst - Instructions Engvaleriu.bosneaga6798100% (1)

- SCM Go Flex: Product Technical SheetDokumen8 halamanSCM Go Flex: Product Technical SheetKen LeeBelum ada peringkat

- Arcode Load Sensor Function User Manual.V100.enDokumen6 halamanArcode Load Sensor Function User Manual.V100.enAhmedBelum ada peringkat

- ARL-300 Lift Control Panel Electrical DiagramsDokumen29 halamanARL-300 Lift Control Panel Electrical DiagramsBrahim CherguiBelum ada peringkat

- ILC2 Installation and Programming GuideDokumen1 halamanILC2 Installation and Programming GuideJose Almeida100% (1)

- FRENIC Lift CatalogDokumen20 halamanFRENIC Lift CatalogtejoBelum ada peringkat

- Material Hoist - Spare Parts ManualDokumen42 halamanMaterial Hoist - Spare Parts ManualRajesh PanchalBelum ada peringkat

- EV4 User Manual: Software Versions 1310, 3310, 3350, 3351Dokumen64 halamanEV4 User Manual: Software Versions 1310, 3310, 3350, 3351sanvae123Belum ada peringkat

- InvDokumen5 halamanInvKs Bharathiyar100% (1)

- Motala 2000 en Tekniskt BladDokumen4 halamanMotala 2000 en Tekniskt BladStacey HayesBelum ada peringkat

- Cibes Catalogue PDFDokumen31 halamanCibes Catalogue PDFNold AlburoBelum ada peringkat

- Instruction Manual: LM2A SeriesDokumen73 halamanInstruction Manual: LM2A SeriesроманBelum ada peringkat

- Sky302 User ManualDokumen16 halamanSky302 User ManualAhmedBelum ada peringkat

- Machine Room-Less (MRL)Dokumen13 halamanMachine Room-Less (MRL)rishi070881Belum ada peringkat

- Line Powered ADA Phone ManualDokumen17 halamanLine Powered ADA Phone ManualAnonymous zSpR5jUdBelum ada peringkat

- Start-Up Guide of LSLV-M100: Download ManualDokumen8 halamanStart-Up Guide of LSLV-M100: Download ManualArief FibonacciBelum ada peringkat

- سیستم کنترل newlift PDFDokumen4 halamanسیستم کنترل newlift PDFAliRouyouBelum ada peringkat

- Aybey Disply Dd2 - EngDokumen7 halamanAybey Disply Dd2 - EngAl Fakhamah Lifts100% (2)

- Lift Control SLC4 Information For The Expert I Subranges of The Main Card of Central Unit - AZE0Dokumen6 halamanLift Control SLC4 Information For The Expert I Subranges of The Main Card of Central Unit - AZE0raymon janszenBelum ada peringkat

- Feel the Advantages of KLEEMANN Atlas Basic MRL LiftsDokumen9 halamanFeel the Advantages of KLEEMANN Atlas Basic MRL Liftsprocurement maharconBelum ada peringkat

- Elevator C5000 ManualDokumen13 halamanElevator C5000 ManualAlejandro Gonzalez GonzalezBelum ada peringkat

- Arkel Seriële RS232 AansluitingDokumen6 halamanArkel Seriële RS232 AansluitingHenri KleineBelum ada peringkat

- Datasheet Aritco 6000 enDokumen2 halamanDatasheet Aritco 6000 enBuzaareBelum ada peringkat

- Application Note AN-LM2A-0005v120EN: Vector Control With Peripheral PG (Synchronous Motor)Dokumen12 halamanApplication Note AN-LM2A-0005v120EN: Vector Control With Peripheral PG (Synchronous Motor)TroubleshootingBelum ada peringkat

- Iastar Door DriveDokumen75 halamanIastar Door DriveSyed iliyasBelum ada peringkat

- Lift Inverter Series L A: For Modernization and New InstallationDokumen12 halamanLift Inverter Series L A: For Modernization and New InstallationTroubleshootingBelum ada peringkat

- 3 Coil Valve AdjustmentDokumen6 halaman3 Coil Valve Adjustmentvasansulo100% (1)

- Manual For EncoderDokumen2 halamanManual For EncodermohammedalathwaryBelum ada peringkat

- Elevator and Escalator BrandsDokumen13 halamanElevator and Escalator BrandsjajaBelum ada peringkat

- Trouble Ev eDokumen2 halamanTrouble Ev eSylvester SullivanBelum ada peringkat

- Trouble KV eDokumen2 halamanTrouble KV eSylvester SullivanBelum ada peringkat

- Blain Sys Leak KVDokumen1 halamanBlain Sys Leak KVSylvester SullivanBelum ada peringkat

- Troubleshooting GuideDokumen8 halamanTroubleshooting GuideSylvester SullivanBelum ada peringkat

- Blain Spare Parts EV KVDokumen2 halamanBlain Spare Parts EV KVSylvester SullivanBelum ada peringkat

- Slack Rope Valve KS For BLAIN EV, KV Down Valve and L10Dokumen1 halamanSlack Rope Valve KS For BLAIN EV, KV Down Valve and L10Sylvester SullivanBelum ada peringkat

- Quick Adj Ev eDokumen2 halamanQuick Adj Ev eSylvester SullivanBelum ada peringkat

- RL RL RL RL RL: R R R R R Amloc Amloc Amloc Amloc AmlocDokumen5 halamanRL RL RL RL RL: R R R R R Amloc Amloc Amloc Amloc AmlocSylvester SullivanBelum ada peringkat

- HPDokumen2 halamanHPSylvester SullivanBelum ada peringkat

- Sys Leak EVDokumen1 halamanSys Leak EVSylvester SullivanBelum ada peringkat

- Slack Rope Valve KS For BLAIN EV, KV Down Valve and L10Dokumen1 halamanSlack Rope Valve KS For BLAIN EV, KV Down Valve and L10Sylvester SullivanBelum ada peringkat

- MD eDokumen4 halamanMD eSylvester SullivanBelum ada peringkat

- Full KV Valves InfoDokumen6 halamanFull KV Valves InfoSylvester Sullivan100% (1)

- EV Spare Parts List: Down Leak Solenoid Valves AdjustmentsDokumen1 halamanEV Spare Parts List: Down Leak Solenoid Valves AdjustmentsSylvester SullivanBelum ada peringkat

- Blain Sys Leak EVDokumen1 halamanBlain Sys Leak EVSylvester SullivanBelum ada peringkat

- Blain Service Manual LowDokumen15 halamanBlain Service Manual LowSylvester SullivanBelum ada peringkat

- Blain Price List 300 Euro 2008Dokumen1 halamanBlain Price List 300 Euro 2008Sylvester SullivanBelum ada peringkat

- Flow - Pressure Chart (US and Metric)Dokumen4 halamanFlow - Pressure Chart (US and Metric)Sylvester SullivanBelum ada peringkat

- Blain CX-EDokumen1 halamanBlain CX-ESylvester SullivanBelum ada peringkat

- EV Poster34Dokumen1 halamanEV Poster34Sylvester SullivanBelum ada peringkat

- Ev eDokumen6 halamanEv eSylvester SullivanBelum ada peringkat

- Blain RL-EDokumen4 halamanBlain RL-ESylvester SullivanBelum ada peringkat

- Blain MD - GBDokumen4 halamanBlain MD - GBSylvester SullivanBelum ada peringkat

- EV Poster1-12Dokumen1 halamanEV Poster1-12Sylvester SullivanBelum ada peringkat

- Blain BVDokumen2 halamanBlain BVSylvester SullivanBelum ada peringkat

- Blain Spare Parts EV KVDokumen2 halamanBlain Spare Parts EV KVSylvester SullivanBelum ada peringkat

- Blain Sys Leak KVDokumen1 halamanBlain Sys Leak KVSylvester SullivanBelum ada peringkat

- Blain KV-GBDokumen6 halamanBlain KV-GBSylvester SullivanBelum ada peringkat

- Blain HP - 4spDokumen2 halamanBlain HP - 4spSylvester SullivanBelum ada peringkat

- Blain KV Trouble-GbDokumen2 halamanBlain KV Trouble-GbSylvester Sullivan100% (1)

- Electrical Machines Multiple Choice Questions - Mcqs - QuizDokumen10 halamanElectrical Machines Multiple Choice Questions - Mcqs - Quiztooba mukhtarBelum ada peringkat

- MUCLecture 2021 10311889Dokumen11 halamanMUCLecture 2021 10311889Ramon Angelo MendezBelum ada peringkat

- Module 37 Nur 145Dokumen38 halamanModule 37 Nur 145Marga WreatheBelum ada peringkat

- Datasheet Optris XI 410Dokumen2 halamanDatasheet Optris XI 410davidaldamaBelum ada peringkat

- OE Spec MTU16V4000DS2250 3B FC 50Hz 1 18Dokumen6 halamanOE Spec MTU16V4000DS2250 3B FC 50Hz 1 18Rizki Heru HermawanBelum ada peringkat

- Pemanfaatan Limbah Spanduk Plastik (Flexy Banner) Menjadi Produk Dekorasi RuanganDokumen6 halamanPemanfaatan Limbah Spanduk Plastik (Flexy Banner) Menjadi Produk Dekorasi RuanganErvan Maulana IlyasBelum ada peringkat

- Kendriya vidyalaya reading comprehension and grammar questionsDokumen7 halamanKendriya vidyalaya reading comprehension and grammar questionsRaam sivaBelum ada peringkat

- Fatigue Life Prediction of A320-200 Aileron Lever Structure of A Transport AircraftDokumen4 halamanFatigue Life Prediction of A320-200 Aileron Lever Structure of A Transport AircraftMohamed IbrahimBelum ada peringkat

- Beckman DxI 800 Prolactin Assay Superiority for Monomeric ProlactinDokumen5 halamanBeckman DxI 800 Prolactin Assay Superiority for Monomeric Prolactindoxy20Belum ada peringkat

- Presentation 123Dokumen13 halamanPresentation 123Harishitha ManivannanBelum ada peringkat

- Common Herbs and Foods Used As Galactogogues PDFDokumen4 halamanCommon Herbs and Foods Used As Galactogogues PDFHadi El-MaskuryBelum ada peringkat

- H. Bateman, A. Erdélyi Et Al. - Higher Transcendental Functions 3 (1955, McGraw-Hill)Dokumen310 halamanH. Bateman, A. Erdélyi Et Al. - Higher Transcendental Functions 3 (1955, McGraw-Hill)ITALO HERRERA MOYABelum ada peringkat

- Fund. of EnterpreneurshipDokumen31 halamanFund. of EnterpreneurshipVarun LalwaniBelum ada peringkat

- Contact GRRSB Team for InquiriesDokumen2 halamanContact GRRSB Team for Inquiriesmsis81Belum ada peringkat

- Shanidham - In-Shanidham Pacify Lord ShaniDokumen3 halamanShanidham - In-Shanidham Pacify Lord ShanisubramanyaBelum ada peringkat

- Spin - 2021Dokumen60 halamanSpin - 2021Tanel LaanemägiBelum ada peringkat

- Screenshot 2023-01-03 at 9.25.34 AM PDFDokumen109 halamanScreenshot 2023-01-03 at 9.25.34 AM PDFAzri ZakwanBelum ada peringkat

- Introduction 3-12-86Dokumen13 halamanIntroduction 3-12-86Roshdy AbdelRassoulBelum ada peringkat

- Jual Sokkia SET 350X Total Station - Harga, Spesifikasi Dan ReviewDokumen5 halamanJual Sokkia SET 350X Total Station - Harga, Spesifikasi Dan Reviewbramsalwa2676Belum ada peringkat

- Fajar Secondary Sec 3 E Math EOY 2021Dokumen16 halamanFajar Secondary Sec 3 E Math EOY 2021Jayden ChuaBelum ada peringkat

- Ca2Dokumen8 halamanCa2ChandraBelum ada peringkat

- The Baptismal Liturgy in The Easter Vigil According To The Sacramentary of Fulda (10th Century)Dokumen7 halamanThe Baptismal Liturgy in The Easter Vigil According To The Sacramentary of Fulda (10th Century)Henry DonascoBelum ada peringkat

- Anxiolytics Sedatives Hypnotics Pharm 3Dokumen38 halamanAnxiolytics Sedatives Hypnotics Pharm 3Peter Harris100% (1)

- AS 1418.2 Cranes, Hoists and Winches Part 2 Serial Hoists and WinchesDokumen31 halamanAS 1418.2 Cranes, Hoists and Winches Part 2 Serial Hoists and WinchesDuy PhướcBelum ada peringkat