KRISHAN

Diunggah oleh

shailesh singhDeskripsi Asli:

Hak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

KRISHAN

Diunggah oleh

shailesh singhHak Cipta:

Format Tersedia

TERM PAPER OF ELE ON APPLICATION OF DC SERIES MOTOR

SUBMTTED BY:NAME:- MUNISH SHARMA ROLL NO:- A 04 SECTION:- RB4802A04 REGD. NO:- 10804343 SUBMITTED TO:-

MR. ARVIND CHANDAN

There are four types of DC motor: 1. 2. 3. DC series wound motor DC shunt wound motor DC compound motor - there are also two types: 1. cumulative compound 2. differentially compounded Permanent Magnet DC Motor

History and development:

4.

Modern DC brushless motors range in power from a fraction of a watt to many kilowatts. Larger brushless motors up to about 100 kW rating are used in electric vehicles. They also find significant use in highperformance electric model aircraft.

TYPES OF DC MOTORS : Externally-excited DC motor: Electromagnetic experiment of Faraday The principle:

The conversion of electrical energy into mechanical energy by electromagnetic means was demonstrated by the British scientist Michael Faraday in 1821. A freehanging wire was dipped into a pool of mercury, on which a permanent magnet was placed. When a current was passed through the wire, the wire rotated around the magnet, showing that the current gave rise to a circular magnetic field around the wire .This motor is often demonstrated in school physics classes, but salt water is sometimes used in place of the toxic mercury. This is the simplest form of a class of devices called homopolar motors. This type of DC motor is constructed such that the field is not connected to the armature. This type of DC motor is not normally used. The motor is called a "shunt" motor because the field is in parallel, or "shunts" the armature. The motor field windings for a series motor are in series with the armature. A compounded DC motor is constructed so that it contains both a shunt and a series field. DC motor because the shunt and series fields are aiding one another.

Shunt-Wound Motor :

A shunt-wound DC motor has a decreasing torque when speed increases. The decreasing torque- vsspeed is caused by the armature resistance voltage drop and armature reaction. At a value of speed near 2.5 times the rated speed, armature reaction becomes excessive, causing a rapid decrease in field flux, and a rapid decline in torque until a stall condition is reached.

DC Motors:

A DC motor is designed to run on DC electric power. Two examples of pure DC designs are Michael Faraday's homopolar motor and the ball bearing motor, which is a novelty. By far the most common DC motor types are the brushed and brushless types, which use internal and external commutation respectively to create an oscillating AC current from the DC source so they are not purely DC machines in a strict sense. A: shunt B: series C: compound

Shunt-Wound Motor Applications:

The characteristics of a shunt-wound motor give it very good speed regulation, and it is classified as a constant speed motor, even though the speed does slightly decrease as load is increased. Shunt-wound motors are used in industrial and automotive applications where precise control of speed and torque are required.

SHUNT, SERIES AND COMPOUND MOTORS:

Before variable-voltage supplies became readily available, most d.c. motors were obliged to operate from a single d.c. supply, usually of constant voltage. The armature and field circuits were therefore designed either for connection in parallel (shunt), or in series. As we will see shortly, the operating characteristics of shunt and series machines differ widely, and hence each type tends to claim its particular niche: shunt motors were judged to be good for constant-speed applications, while series motors were (and still are) widely used for traction applications. The operating characteristics of shunt, series and compound (a mixture of both) motors are explored below, but first we should say something of the physical differences. At a fundamental level these amount to very little, but in the detail of the winding arrangement, they are considerable.

unloaded, the motor may "run away" and speed up to the point of mechanical failure. However factors such as external load and internal mechanical resistance may adequately limit the speed. Operating at normal power line frequencies, universal motors are very rarely larger than one kilowatt (about 1.3 horsepower). Universal motors also form the basis of the traditional railway traction motor in electric railways. In this application, to keep their electrical efficiency high, they were operated from very low frequency AC supplies, with 25 and 16.7 hertz (Hz) operation being common. Because they are universal motors, locomotives using this design were also commonly capable of operating from a third rail powered by DC. Universal motors generally run at high speeds, making them useful for appliances such as blenders, vacuum cleaners, and hair dryers where high RPM operation is desirable. They are also commonly used in portable power tools, such as drills, circular and jig saws, where the motor's characteristics work well. Many vacuum cleaner and weed trimmer motors exceed 10,000 RPM, while Dremel and other similar miniature grinders will often exceed 30,000 RPM. "Universal" or "Series-wound" motors generally operate better with DC current, but they have the ability to operate with AC current as well, making them very versatile for a broad range of applications. However, there is little to no means to control the motor's speed accurately. Unlike induction motors, the "goal" of this motor is to run a load at the highest speed possible, which has specific advantages for appliances such as vacuum cleaners and blenders and such. Many automotive starter motors are either series-wound or compound-wound motors because of the high starting torque.

Torque motors: Universal motors and series wound DC motors:

A wound field DC motor with the field and armature windings connected in series is called either a "serieswound motor" or a "universal motor," because of its ability to operate on AC or DC power. The ability to operate on AC or DC power is because the current in both the field winding and the armature (and hence the resultant magnetic fields) will alternate (reverse polarity) at the same time, and hence the mechanical force generated is always in the same direction. The torque of a series-wound or universal motor declines slowly with speed. Although this can be advantageous for some applications, it also means that, A torque motor (also known as a limited torque motor) is a specialized form of induction motor which is capable of operating indefinitely while stalled, that is, with the rotor blocked from turning, without incurring damage. In this mode of operation, the motor will apply a steady torque to the load (hence the name). A common application of a torque motor would be the supply- and take-up reel motors in a tape drive. In this application, driven from a low voltage, the characteristics of these motors allow a relativelyconstant light tension to be applied to the tape whether or not the capstan is feeding tape past the tape heads. Driven from a higher voltage, (and so delivering a higher torque), the torque motors can also achieve fastforward and rewind operation without requiring any

additional mechanics such as gears or clutches. In the computer gaming world, torque motors are used in force feedback steering wheels.

A linear motor is essentially an electric motor that has been "unrolled" so that, instead of producing a torque (rotation), it produces a straight-line force along its length by setting up a traveling electromagnetic field. Linear motors are most commonly induction motors or stepper motors. You can find a linear motor in a maglev (Transrapid) train, where the train "flies" over the ground, and in many roller-coasters where the rapid motion of the motorless railcar is controlled by the rail. On a smaller scale, at least one letter-size (8.5" x 11") computer graphics X-Y pen plotter made by HewlettPackard (in the late 1970s to mid 1980's) used two linear stepper motors to move the pen along the two orthogonal axes.

Slip ring:

The slip ring is a component of the wound rotor motor as an induction machine (best evidenced by the construction of the common automotive alternator), where the rotor comprises a set of coils that are electrically terminated in slip rings. These are metal rings rigidly mounted on the rotor, and combined with brushes (as used with commutators), provide continuous unswitched connection to the rotor windings. In the case of the wound-rotor induction motor, external impedances can be connected to the brushes. The stator is excited similarly to the standard squirrel cage motor. By changing the impedance connected to the rotor circuit, the speed/current and speed/torque curves can be altered. (Slip rings are most-commonly used in automotive alternators as well as in synchro angular datatransmission devices, among other applications.) The slip ring motor is used primarily to start a high inertia load or a load that requires a very high starting torque across the full speed range. By correctly selecting the resistors used in the secondary resistance or slip ring starter, the motor is able to produce maximum torque at a relatively low supply current from zero speed to full speed. This type of motor also offers controllable speed. Motor speed can be changed because the torque curve of the motor is effectively modified by the amount of resistance connected to the rotor circuit. Increasing the value of resistance will move the speed of maximum torque down. If the resistance connected to the rotor is increased beyond the point where the maximum torque occurs at zero speed, the torque will be further reduced. When used with a load that has a torque curve that increases with speed, the motor will operate at the speed where the torque developed by the motor is equal to the load torque. Reducing the load will cause the motor to speed up, and increasing the load will cause the motor to slow down until the load and motor torque are equal. Operated in this manner, the slip losses are dissipated in the secondary resistors and can be very significant. The speed regulation and net efficiency is also very poor.

Efficiency:

To calculate a motor's efficiency, the mechanical output power is divided by the electrical input power: , where is energy conversion efficiency, Pe is electrical input power, and Pm is mechanical output power. In simplest case Pe = VI, and Pm = T, where V is input voltage, I is input current, T is output torque, and is output angular frequency.

Implications:

This means that efficiency is highest in the middle of the torque range, so an oversized motor runs with the highest efficiency. This means using a bigger motor than is necessary accounts for extra torque, and allows the motor to operate closest to no load, or peak operating conditions.

Materials:

There is an impending shortage of many rare raw materials used in the manufacture of hybrid and electric cars (Nishiyama 2007) (Cox 2008). For example, the rare earth element dysprosium is required to fabricate many of the advanced electric motors used in hybrid cars (Cox 2008). However, over 95% of the world's rare earth elements are mined in China (Haxel et al. 2005), and domestic Chinese consumption is expected to consume China's entire supply by 2012 (Cox 2008).

[citation needed]

Linear motors:

Uses:

Electric motors are used in many, if not most, modern machines. Obvious uses would be in rotating machines

such as fans, turbines, drills, the wheels on electric cars, locomotives and conveyor belts. Also, in many vibrating or oscillating machines, an electric motor spins an irregular figure with more area on one side of the axle than the other, causing it to appear to be moving up and down. Electric motors are also popular in robotics. They are used to turn the wheels of vehicular robots, and servo motors are used to turn arms and legs in humanoid robots. In flying robots, along with helicopters, a motor causes a propeller or wide, flat blades to spin and create lift force, allowing vertical motion. In industrial and manufacturing businesses, electric motors are used to turn saws and blades in cutting and slicing processes, and to spin gears and mixers (the latter very common in food manufacturing). Linear motors are often used to push products into containers horizontally. Many kitchen appliances also use electric motors to accomplish various jobs. Food processors and grinders spin blades to chop and break up foods. Blenders use electric motors to mix liquids, and microwave ovens use motors to turn the tray food sits on. Toaster ovens also use electric motors to turn a conveyor in order to move food over heating elements

Anda mungkin juga menyukai

- VB Rol24Dokumen18 halamanVB Rol24shailesh singhBelum ada peringkat

- VB Roll24Dokumen6 halamanVB Roll24shailesh singhBelum ada peringkat

- Term Paper Topic:"Parking Management System"Dokumen8 halamanTerm Paper Topic:"Parking Management System"shailesh singhBelum ada peringkat

- Term Paperof SadDokumen12 halamanTerm Paperof Sadshailesh singhBelum ada peringkat

- Ticket WindowDokumen5 halamanTicket Windowshailesh singhBelum ada peringkat

- Tutorial 1Dokumen21 halamanTutorial 1shailesh singhBelum ada peringkat

- Utpal Term SoftDokumen16 halamanUtpal Term Softshailesh singhBelum ada peringkat

- The Classic Snake Gam4Dokumen22 halamanThe Classic Snake Gam4shailesh singh100% (1)

- Telephone DirectryDokumen41 halamanTelephone Directryshailesh singhBelum ada peringkat

- Term Paper of Operating SystemDokumen7 halamanTerm Paper of Operating Systemshailesh singhBelum ada peringkat

- Term Paper CSE-101: Submitted To Submitted byDokumen14 halamanTerm Paper CSE-101: Submitted To Submitted byshailesh singhBelum ada peringkat

- Term Paper RajanDokumen36 halamanTerm Paper Rajanshailesh singhBelum ada peringkat

- Software Engineerinng CSE314Dokumen34 halamanSoftware Engineerinng CSE314Ajay KumarBelum ada peringkat

- Term PaperPPMDokumen10 halamanTerm PaperPPMshailesh singhBelum ada peringkat

- Telephone DirectryDokumen35 halamanTelephone Directryshailesh singhBelum ada peringkat

- TarunDokumen18 halamanTarunshailesh singhBelum ada peringkat

- ShANKey It ProjectDokumen11 halamanShANKey It Projectshailesh singhBelum ada peringkat

- ReviewDokumen2 halamanReviewshailesh singhBelum ada peringkat

- Student Record SystemDokumen9 halamanStudent Record Systemshailesh singhBelum ada peringkat

- Student Record SystemDokumen5 halamanStudent Record Systemshailesh singhBelum ada peringkat

- Railway ReservationDokumen42 halamanRailway Reservationshailesh singh100% (1)

- Design Problem-1 ON: Submitted To: Submitted byDokumen8 halamanDesign Problem-1 ON: Submitted To: Submitted byshailesh singhBelum ada peringkat

- Lovely Professional University: Synopsis of Software Project MGNTDokumen9 halamanLovely Professional University: Synopsis of Software Project MGNTshailesh singhBelum ada peringkat

- Term Paper OF System Analysis AND Design Theory Topic:-Indentification OF Computer Output S Submitted ToDokumen21 halamanTerm Paper OF System Analysis AND Design Theory Topic:-Indentification OF Computer Output S Submitted Toshailesh singhBelum ada peringkat

- Design Problem-1 ON: Submitted To: Submitted byDokumen8 halamanDesign Problem-1 ON: Submitted To: Submitted byshailesh singhBelum ada peringkat

- SoftwareDokumen26 halamanSoftwareshailesh singhBelum ada peringkat

- Reg No 10812279Dokumen25 halamanReg No 10812279shailesh singhBelum ada peringkat

- Railway Reservation 1Dokumen16 halamanRailway Reservation 1shailesh singhBelum ada peringkat

- Topic:: Software Project ManagementDokumen20 halamanTopic:: Software Project Managementshailesh singhBelum ada peringkat

- Sachin Term PaperDokumen20 halamanSachin Term Papershailesh singhBelum ada peringkat

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDari EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifePenilaian: 4 dari 5 bintang4/5 (5784)

- The Little Book of Hygge: Danish Secrets to Happy LivingDari EverandThe Little Book of Hygge: Danish Secrets to Happy LivingPenilaian: 3.5 dari 5 bintang3.5/5 (399)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDari EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RacePenilaian: 4 dari 5 bintang4/5 (890)

- Shoe Dog: A Memoir by the Creator of NikeDari EverandShoe Dog: A Memoir by the Creator of NikePenilaian: 4.5 dari 5 bintang4.5/5 (537)

- Grit: The Power of Passion and PerseveranceDari EverandGrit: The Power of Passion and PerseverancePenilaian: 4 dari 5 bintang4/5 (587)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDari EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FuturePenilaian: 4.5 dari 5 bintang4.5/5 (474)

- The Yellow House: A Memoir (2019 National Book Award Winner)Dari EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Penilaian: 4 dari 5 bintang4/5 (98)

- Team of Rivals: The Political Genius of Abraham LincolnDari EverandTeam of Rivals: The Political Genius of Abraham LincolnPenilaian: 4.5 dari 5 bintang4.5/5 (234)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDari EverandNever Split the Difference: Negotiating As If Your Life Depended On ItPenilaian: 4.5 dari 5 bintang4.5/5 (838)

- The Emperor of All Maladies: A Biography of CancerDari EverandThe Emperor of All Maladies: A Biography of CancerPenilaian: 4.5 dari 5 bintang4.5/5 (271)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDari EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryPenilaian: 3.5 dari 5 bintang3.5/5 (231)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDari EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaPenilaian: 4.5 dari 5 bintang4.5/5 (265)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDari EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersPenilaian: 4.5 dari 5 bintang4.5/5 (344)

- On Fire: The (Burning) Case for a Green New DealDari EverandOn Fire: The (Burning) Case for a Green New DealPenilaian: 4 dari 5 bintang4/5 (72)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDari EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyPenilaian: 3.5 dari 5 bintang3.5/5 (2219)

- Rise of ISIS: A Threat We Can't IgnoreDari EverandRise of ISIS: A Threat We Can't IgnorePenilaian: 3.5 dari 5 bintang3.5/5 (137)

- The Unwinding: An Inner History of the New AmericaDari EverandThe Unwinding: An Inner History of the New AmericaPenilaian: 4 dari 5 bintang4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDari EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You ArePenilaian: 4 dari 5 bintang4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Dari EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Penilaian: 4.5 dari 5 bintang4.5/5 (119)

- Her Body and Other Parties: StoriesDari EverandHer Body and Other Parties: StoriesPenilaian: 4 dari 5 bintang4/5 (821)

- S10332200-3001 Electrical Engineering StandardDokumen64 halamanS10332200-3001 Electrical Engineering Standardappril26Belum ada peringkat

- A Train Travelling at 40 M / S Takes 2.0 S To Pass The Man. What Is The Length of The Train? M MC 40 MD 80 MDokumen4 halamanA Train Travelling at 40 M / S Takes 2.0 S To Pass The Man. What Is The Length of The Train? M MC 40 MD 80 MDaniel CannywoodBelum ada peringkat

- Is It Time For Industrial UPS Systems in Data Centers?: White Paper PCS100 UPSDokumen2 halamanIs It Time For Industrial UPS Systems in Data Centers?: White Paper PCS100 UPSAhmedBelum ada peringkat

- Flicker Analysis and Methods For Electric Arc Furnace Flicker (EAF) MitigationDokumen6 halamanFlicker Analysis and Methods For Electric Arc Furnace Flicker (EAF) MitigationIndah PermataBelum ada peringkat

- Measuring Viscosity at High Shear Rate by Tapered Bearing Simulator Viscometer at 100 °CDokumen13 halamanMeasuring Viscosity at High Shear Rate by Tapered Bearing Simulator Viscometer at 100 °Cmohammed karasnehBelum ada peringkat

- ElectrostaticsDokumen16 halamanElectrostaticsSuparnaBelum ada peringkat

- Semiconductor ParametersDokumen40 halamanSemiconductor ParameterssulaimanBelum ada peringkat

- TDA7286 Single Chip Preamplifier For Double Deck Radio CasseDokumen6 halamanTDA7286 Single Chip Preamplifier For Double Deck Radio CasseDunatoMBelum ada peringkat

- Audible Milliohm Meter Circuit Collection and Build GuideDokumen4 halamanAudible Milliohm Meter Circuit Collection and Build GuideakashBelum ada peringkat

- Network Theorems LabDokumen7 halamanNetwork Theorems LabUmer FarooqBelum ada peringkat

- Report on blade failure of LP last stages in a 210 MW steam turbineDokumen5 halamanReport on blade failure of LP last stages in a 210 MW steam turbinemanojpuru100% (1)

- Lecture # 05Dokumen14 halamanLecture # 05Rahil BalochBelum ada peringkat

- SPM Physics Wave Oscillation Damping ResonanceDokumen4 halamanSPM Physics Wave Oscillation Damping ResonanceIVAN TIONG WEI JUN MoeBelum ada peringkat

- AUX Air Conditioner Service ManualDokumen60 halamanAUX Air Conditioner Service Manualrock_music75% (4)

- Test4-Reading Passage 3Dokumen2 halamanTest4-Reading Passage 3vanpham248Belum ada peringkat

- Diac and Triac ExperimentsDokumen10 halamanDiac and Triac ExperimentsAbhishekBelum ada peringkat

- Projectile Worksheet 2 EdexcelDokumen3 halamanProjectile Worksheet 2 EdexcelSetiawan TanadiBelum ada peringkat

- NPT16 Transformer ControlDokumen16 halamanNPT16 Transformer ControlElver MesaBelum ada peringkat

- 18 Civ 142Dokumen3 halaman18 Civ 142Ayushman RaiBelum ada peringkat

- Double Cage Rotor Motor StructureDokumen2 halamanDouble Cage Rotor Motor Structuresalma100% (1)

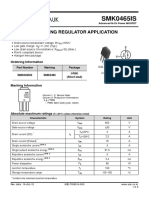

- smk0465 Nchannel MosfetDokumen8 halamansmk0465 Nchannel MosfetharshBelum ada peringkat

- Doepke-Specifying RCD Protection PDFDokumen3 halamanDoepke-Specifying RCD Protection PDFAN.ADAMMSBelum ada peringkat

- Stenton Community TurbineDokumen13 halamanStenton Community TurbineEttie SpencerBelum ada peringkat

- Convection Tutorial Sheet 3Dokumen4 halamanConvection Tutorial Sheet 3Charlotte BBelum ada peringkat

- Unit Ii Multi-Stage Amplifiers: Types of CouplingDokumen58 halamanUnit Ii Multi-Stage Amplifiers: Types of Couplingcinthu chizhian22Belum ada peringkat

- Answers To Saqs: Cambridge International A Level PhysicsDokumen1 halamanAnswers To Saqs: Cambridge International A Level PhysicsharshanauocBelum ada peringkat

- 3PBO-M: Oil-Lubricated Rotary Vane Vacuum PumpDokumen2 halaman3PBO-M: Oil-Lubricated Rotary Vane Vacuum PumpAir-center CompresoresBelum ada peringkat

- 15 November 2020 SSC CGL MAINS MATHS ALL QUESTIONSDokumen9 halaman15 November 2020 SSC CGL MAINS MATHS ALL QUESTIONSNITINBelum ada peringkat

- IGBT Module Selection and ApplicationDokumen7 halamanIGBT Module Selection and Applicationvdsantos74Belum ada peringkat

- Thermal Chemistry Calorimeter Problem AnswersDokumen3 halamanThermal Chemistry Calorimeter Problem AnswersrkvermBelum ada peringkat