Dharmandan TechnoProjects Pvt Ltd

Diunggah oleh

goyalneerajDeskripsi Asli:

Judul Asli

Hak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

Dharmandan TechnoProjects Pvt Ltd

Diunggah oleh

goyalneerajHak Cipta:

Format Tersedia

DHARMANANDAN TECHNOPROJECTS PVT.

LIMITED

ABOUT US (COMPANY PROFILE): Dharmanandan TechnoProjects Pvt. Limited (DTPPL) is founded by the finest and widely experienced Technocrats. Company is having state of the art manufacturing facility backed by immense technical supports from their technical founders. DTPPL is a leading Turnkey project solution provider for the vast and diversified products like Mineral water / Packaged drinking water plant, Cement Plant, Cable Plant, Plywood, Iodized Salt, Tyre and Tube plant, Steel Plant, Waste tyre recycling plant (Pyrolysis Plant), Food processing Plants etc. We are also providing complete ISI consultancy for any products for which ISI license is required. OUR VISION: DTPPL strongly believes in ethical business practices. Progress must be achieved in harmony with the environment. A commitment to community welfare and environmental protection are an integral part of our long term vision. DTPPL shall be professionally managed Indian company, committed to total customer satisfaction. DTPPLs work force shall be innovative, entrepreneurial and empowered team constantly creating value and attaining global benchmarks. DTPPL shall foster a culture of caring, trust and continuous learning while meeting expectations of employees and society. GREEN BUSINESS IDEA FROM DTPPL: DTPPL is constantly thriving on efforts to develop environment friendly technology which will be helpful to society and human beings in long term sustainability. DTPPL has come up with GREEN CONCEPT of BEST OUT OF WASTE technology which is unique in its kind. We are offering PYROLYSIS PLANT with state of the art new generation technology for recycling of waste tyres, rubbers and plastics in an eco friendly manner.

REG. OFFICE: 2nd Floor, Galaxy Point, Near Old Sarthana Jakat Naka, Varachha Road, Surat -395006, Gujarat, India. Ph no: 0261 2578830 (M):9099065245, website:www.dtppl.com E-mail: dtppl.projects@gmail.com

DHARMANANDAN TECHNOPROJECTS PVT. LIMITED

WHAT IS PYROLYSIS OF WASTE TYRES? Pyrolysis is established technology that cooks material in the absence of oxygen, causing it to break down. Emissions from the process are therefore controlled and completely environmentally friendly. The pyrolysis method for recycling of used tyres is an innovative technique that uses a special mechanism to heat the used tires in a closed vessel to melt down the tires into the materials that they were made of. The pyrolysis reaction will produce carbon black, steel wires, gas and furnace oil as by-products of the recycling process.

CURRENT SCENARIO OF WASTE TYRES IN INDIA: A BIG PROBLEM There are around One billion tyres (100 crore nos of tyres) which are thrown away every year in India. Some 300 millions (30 crores) of them are recycled or are used as fuel and the rest are sent to landfill. This is projected to rise by 15 per cent a year, represents potentially 5 million barrels of recoverable diesel fuel. Worldwide almost 20% of the waste stream is Waste Tyre and Waste Plastic, most of which still ends up in landfill or at worst it is incinerated. This is a terrible waste of a valuable resource containing a high level of latent energy. In recent year, this practice has become less and less desirable due to opposition from Government and environmentally conscious community groups. The value of plastics going to landfill is showing a marginal reduction despite extensive community awareness and education programs Once a substance or object has become waste, it will remain waste until it has been fully recovered and no longer poses a potential threat to the environment or to human health. DTPPL provides the only commercial waste tyre process that in reality removes worn tyres from the waste chain. This achievement will have significant environmental and profitability impact.

REG. OFFICE: 2nd Floor, Galaxy Point, Near Old Sarthana Jakat Naka, Varachha Road, Surat -395006, Gujarat, India. Ph no: 0261 2578830 (M):9099065245, website:www.dtppl.com E-mail: dtppl.projects@gmail.com

DHARMANANDAN TECHNOPROJECTS PVT. LIMITED

POTENTIAL IMPACTS AT EACH STAGE OF THE LIFE CYCLE OF A TYRE OR OTHER RUBBER PRODUCT ON ENVIRONMENT

LIFE STAGE Raw Material

PROCESS INCLUDED Natural Rubber production Synthetic Rubber production Steel and fabric production Production of various other additives incorporated in tyres Transportation Production of the Basic components (sheet extrusions etc) from which the products are made Building of the tyre or other rubber product Vulcanizing and Finishing Use of the product for design application

IMPACTS Resource depletion Agriculture (for natural rubber) Energy use Greenhouse and Other emissions Solid and Liquid waste Energy use Greenhouse and Other emissions Solid and Liquid waste

Manufacture

Use

Disposal

Disposal to Land Uncontrolled stockpiling Disposal in land filling

Transportation

Transportation of Raw materials Transportation of new tyres Transportation of used tyres to disposal or retreading Transportation of waste tyres

Tyres have significant impact on the operation energy of vehicles resulting in energy use and emissions, dust from wear and tear Leachate to receiving environment Fires Free flow of landfill gas and leached compounds Mosquitoes and other vermin Visual Impact Erosion Energy use, Greenhouse and Other Emissions Noise

REG. OFFICE: 2nd Floor, Galaxy Point, Near Old Sarthana Jakat Naka, Varachha Road, Surat -395006, Gujarat, India. Ph no: 0261 2578830 (M):9099065245, website:www.dtppl.com E-mail: dtppl.projects@gmail.com

DHARMANANDAN TECHNOPROJECTS PVT. LIMITED

WHAT DTPPL OFFERS? DTPPL offers green route of Pyrolysis to re-cycle waste Tyres, Plastic and Rubbers. DTPPLs Tyre pyrolysis plant offers the opportunity to process millions of tyres each year in an economical and genuine environmentally friendly manner without production of waste materials This process will put to an end to some of the uneconomical and extravagant uses of tyres currently in vogue when they reach the end of their useful life. The greatest savings of all will come from recycling the carbon black, oil and steel. Carbon black manufacturer requires the burning of around 1.4 tons of oil for 1 ton of carbon black. Reclaiming the valuable materials used to manufacture, Indian waste tyres would save the needless consumption of a further 6 million barrels of oil and avoid creating around 7, 00, 000 tons of CO2 per year. END PRODUCTS PRODUCED BY PYROLYSIS PROCESS: Pyrolysis of scrap tyres can produce economically viable products (carbon black, oil, gas and steel) in an environmentally sound manner.

Scrap Tyres

Primary products

Secondary Value added products

Pyrolysis Oil 40% - 45%

Virgin Carbon Black

Same yields and quality as the product obtained from petroleum

Scrap Tyres

Pyrolysis Gas 10% - 13%

Refined Fuel Oil

Carbon Black 30% 35%

Activated Carbon 2025%

Steel wires 11% - 15%

REG. OFFICE: 2nd Floor, Galaxy Point, Near Old Sarthana Jakat Naka, Varachha Road, Surat -395006, Gujarat, India. Ph no: 0261 2578830 (M):9099065245, website:www.dtppl.com E-mail: dtppl.projects@gmail.com

DHARMANANDAN TECHNOPROJECTS PVT. LIMITED

WASTE PLASTIC PYROLYSIS OUPUT:

Waste Plastics

Primary products

Secondary Value added products

PE

Pyrolysis Oil 30-70% Depends on Raw material

Refined Fuel Oil

Same yields and quality as the product obtained from petroleum

PP

PVC

Sorted Dried waste Plastic

Pyrolysis Gas 10%

PE

Fuel Stick 10 -20%

CARBON BLACK (Out put 30-35%): Carbon black has applications in a wide variety of rubber and plastic applications. Carbon black can be further processed to produce high value product. It can be GREEN alternative to the carbon black produced from petroleum Industry. It is being used as a raw material in many industries as listed below. Conveyor Belt Carrier Belt Hose and door mat Electrical cable insulation Black Nylon Bag Automotive Industries Tyre Industry Rubber Industry Plastic Industry

REG. OFFICE: 2nd Floor, Galaxy Point, Near Old Sarthana Jakat Naka, Varachha Road, Surat -395006, Gujarat, India. Ph no: 0261 2578830 (M):9099065245, website:www.dtppl.com E-mail: dtppl.projects@gmail.com

DHARMANANDAN TECHNOPROJECTS PVT. LIMITED

FUEL OIL (Out Put 40 -45%) Oil produced by pyrolysis is having high aromatic content can be used as a fuel in many industries. It has very high calorific value of more than 10,000 cal/gm. It can replace diesel in many industrial applications. GAS (Out Put 10 13%) Gas produced by pyrolysis is a mixture of hydro carbon gases. They have sufficient calorific value that they can be used in pyrolysis reactors heating system as a fuel. STEEL WIRES (Out put 11 -15%) Steel wires are detached after completion of entire pyrolysis process. These steel wires are pressed and can be sold for recycling or to scrap dealers. There is huge demand for recyclable steel. Hence steel wires are having good commercial value. TECHNICAL PROCESS ROUTE OF OUR PYROLYSIS PLANT: Our Pyrolysis plant is having technologically most advanced reactor system Waste tyres are shredded and possibly combined with other plastic waste streams and fed in to the pyrolyzer. The waste stream is subjected to temperature in the range of 300c to 450c under anaerobic (i.e. oxygen free) conditions. This process causes rubber to break down and the organic component of the oil is converted in to a mixture of organic chemicals and incompressible gases. The vaporized gases will then pass through the heat exchanger and the oil gets condensed in liquid form. Water is being used as cooling media. This water is recirculated again for cooling. The non compressible gas is fed to the heating system as a fuel thus entire reactor is Energy self sufficient. Then the steel wire and carbon black are removed. Entire process is batch process and can be operated continuously

REG. OFFICE: 2nd Floor, Galaxy Point, Near Old Sarthana Jakat Naka, Varachha Road, Surat -395006, Gujarat, India. Ph no: 0261 2578830 (M):9099065245, website:www.dtppl.com E-mail: dtppl.projects@gmail.com

DHARMANANDAN TECHNOPROJECTS PVT. LIMITED

BENEFITS FROM DTPPLs ADVANCED PYROLYSIS TECHNOLOGY: Recover energy and value from waste in the form of fuel and charcoal Reduces plastic and tyre land pollution Eco-friendly recycling of plastic and tyres Commercially viable process End product oil is used as substitute to LDO/Furnace oil Perfect solution for Polymer waste management Raw material (waste tyres, waste plastics) easily available Lower reaction temperature of 350 to 475 degree C (variable depending on raw material type) Zero emission process: no harm to environment Lesser reaction time and more energy savings Optimum conversation of polymer waste into hydrocarbon liquid with negligible wax content Plant is 'Energy self sufficient' PYROLYSIS RECYCLING MACHINE COMPONENTS: Pyrolysis reactor and inner tubes Gas chimney Gas tank Condenser Cooling tower Smoke pipe Oil pipe Oil tank Blower Draft fan Motor Power controller, Gas Collection, Vacuum Tank

REG. OFFICE: 2nd Floor, Galaxy Point, Near Old Sarthana Jakat Naka, Varachha Road, Surat -395006, Gujarat, India. Ph no: 0261 2578830 (M):9099065245, website:www.dtppl.com E-mail: dtppl.projects@gmail.com

DHARMANANDAN TECHNOPROJECTS PVT. LIMITED

TECHNICAL SPECIFICATIONS OF THE PLANT: Equipment Equipment Model Material Structure Capacity for one batch Oil yield Carbon Black Steel wire Gas Work pressure Main engine rotation speed Fuels choice Power Cooling method Cooling water consumption (T/H) Type of drive Heating method Type of installation Operating Mode Reactor dimension (MM) (Diameter*Length) Reactor Weight Total weight Specification BS 007 Waste tyres, Scrap Rubbers, Plastic Horizontal Rotation About 5-6 tons 40 % - 45% 30% - 35% 11% - 15% 10% - 13% Atmospheric pressure 0.4 RPM Coal, Wood, Gas, Oil About 15 HP for 5 MT Water cooling Cyclic External annual gear drive Direct With foundation Intermittent operation 2200x6000 (5 M.T.)

About 8100kg About 30 MT

REG. OFFICE: 2nd Floor, Galaxy Point, Near Old Sarthana Jakat Naka, Varachha Road, Surat -395006, Gujarat, India. Ph no: 0261 2578830 (M):9099065245, website:www.dtppl.com E-mail: dtppl.projects@gmail.com

DHARMANANDAN TECHNOPROJECTS PVT. LIMITED

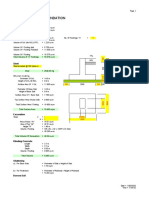

FINANCIAL ASPECTS OF THE PROJECT: Land Requirement Construction shade Water requirement Power Requirement Manpower requirement 1500 square meters 600 square meters Approx. 100 litres per day 15 Hp 2 Managers, 1 Technical, 4 Workers

CAPITAL INVESTMENT: PARTICULARS Land and Building Pyrolysis Plant Price Oil Storage Tank, Crusher Foundation TOTAL (A) INTEREST AND DEPRICIATION: PARTICULARS Interest on Capital Investment @ 15% per annum (Excluding Land and Building) Depreciation on machineries@15% per annum TOTAL (B) EMPLOYMENT COST: PARTICULARS Managers Technical Workers TOTAL (C ) NOS. 2 1 4 MONTHLY SALARY Rs. 0.15 Lacks Rs. 0.10 Lacks Rs. 0.05 Lacks ANNUAL SALARY Rs. 3.6 Lacks Rs. 1.2 Lacks Rs. 2.4 Lacks Rs. 7.2 Lacks AMOUNT Rs. 5.85 Lacks INVESTMENT As per Location Rs.35 Lacks Rs. 2.5 Lacks Rs. 1.5 Lacks Rs. 39 lacks

Rs. 5.85 Lacks Rs. 11.70 Lacks

REG. OFFICE: 2nd Floor, Galaxy Point, Near Old Sarthana Jakat Naka, Varachha Road, Surat -395006, Gujarat, India. Ph no: 0261 2578830 (M):9099065245, website:www.dtppl.com E-mail: dtppl.projects@gmail.com

DHARMANANDAN TECHNOPROJECTS PVT. LIMITED

PRODUCTION COST (BASED ON 5 TONS/DAY & 300 WORKING DAYS/YEAR): PARTICULARS Waste tyres (5tonsX300 days) Employment cost (C) Fuel for initial firing Electricity + Water Misc. Expenses TOTAL (D) REVENUE (INCOME)GENERATION : Volume of waste tyre processed per year: 1500 tons PRODUCT Carbon Black Furnace Oil Steel wire Gas TOTAL (E) % OUTPUT 35 40 12 13 OUTPUT (TONS) 525 600 180 195 PRICE / TON Rs.7,000 Rs.25,000 Rs.12,000 --TOTAL INCOME Rs. 36.75 lacks Rs. 150 Lacks Rs. 21.6 Lacks --Rs. 208.10 Lacks QTY 1500 tons /Year -------225 tons woods /year PRICE Rs.7000 /ton -------Rs.5000/ton TOT. AMOUNT Rs. 105 lacks Rs. 7.2 lacks Rs. 11.25 lacks Rs. 10 Lacks Rs. 12 Lacks Rs. 145.45 Lacks

PROFITABILITY: PARTICULARS Production cost (D) Income (E) Gross Profit ( E D) Interest and Depreciation (B) AMOUNT Rs. 145.45 Lacks Rs. 208.10 Lacks Rs. 62.65 Lacks Rs. 11.70 Lacks

Net Profit (Gross profit Int & deprc.B)

Rs.50.95 Lacks

REG. OFFICE: 2nd Floor, Galaxy Point, Near Old Sarthana Jakat Naka, Varachha Road, Surat -395006, Gujarat, India. Ph no: 0261 2578830 (M):9099065245, website:www.dtppl.com E-mail: dtppl.projects@gmail.com

10

DHARMANANDAN TECHNOPROJECTS PVT. LIMITED

TERMS & CONDITIONS: Price mentioned in Reports: Ex-works Payment: 50% Advance along with confirmed Purchase order and Rest before shipment against proforma Transportation: Extra as actual Local Taxes: Extra as actual Insurance: On customers account Delivery: Within 30 to 45 days after receipt of purchase order and payment Errection & Commisioning: On customers scope. Customer has to pay to & fro air fare of two engineers, lodging, boarding and local conveyance during entire installation period. Installation Time: 15 days Validity: 30 days

CONTACT US: DHARMANANDAN TECHNOPROJECTS PVT. LTD. 2nd Floor, Galaxy Point, Above Hotel Amiras, Near Old Sarthana Jakat Naka, Varachha Road, Surat 395006, Gujarat, India. Phone no. 0261 2578830, (M) +91 9099065245 E- mail: dtppl.projects@gmail.com

REG. OFFICE: 2nd Floor, Galaxy Point, Near Old Sarthana Jakat Naka, Varachha Road, Surat -395006, Gujarat, India. Ph no: 0261 2578830 (M):9099065245, website:www.dtppl.com E-mail: dtppl.projects@gmail.com

11

Anda mungkin juga menyukai

- Project RepresentionDokumen13 halamanProject RepresentionDeema sultanBelum ada peringkat

- Final ReportDokumen68 halamanFinal ReportBikash Chandra DasBelum ada peringkat

- Construction Practice 1 For TechnicianDokumen24 halamanConstruction Practice 1 For TechnicianMichael_Mensah_2238Belum ada peringkat

- Engineering Wood in Cold ClimatesDokumen32 halamanEngineering Wood in Cold ClimatesRishabh Parihar0% (1)

- Report Talk FYP ECS356Dokumen10 halamanReport Talk FYP ECS356WHfamilyBelum ada peringkat

- Department of Civil Engineering M.Tech Seminar Report 2021Dokumen22 halamanDepartment of Civil Engineering M.Tech Seminar Report 2021Classic PrintersBelum ada peringkat

- Geography ProjectDokumen19 halamanGeography ProjectSHRAVAN SHINDEBelum ada peringkat

- Experimental Mechanics Laboratory ManualDokumen76 halamanExperimental Mechanics Laboratory Manualprabhaakar100% (1)

- Properties and Uses of Portland Slag CementDokumen3 halamanProperties and Uses of Portland Slag CementRussell Jhegs CuevasBelum ada peringkat

- Visvesavaraya Technological University Jnanasangama, Belgavi-590018Dokumen41 halamanVisvesavaraya Technological University Jnanasangama, Belgavi-590018Hemalata HosamaniBelum ada peringkat

- Rotational viscometer study of vinasse viscosity with temperature and agitationDokumen8 halamanRotational viscometer study of vinasse viscosity with temperature and agitationPatricia J ÁngelesBelum ada peringkat

- Viscosity Lee Eakin Gonzales PG 55Dokumen140 halamanViscosity Lee Eakin Gonzales PG 55Paul Renzo Miranda ZuritaBelum ada peringkat

- Analysis of RCC Structure Using Staad ProDokumen28 halamanAnalysis of RCC Structure Using Staad ProVaibhav VaishBelum ada peringkat

- Site Planning Objectives and ElementsDokumen18 halamanSite Planning Objectives and ElementsShanaia BualBelum ada peringkat

- Material ReportDokumen20 halamanMaterial Reportfirstman31100% (1)

- Water Constraint: Rising Demand and Limited SupplyDokumen22 halamanWater Constraint: Rising Demand and Limited SupplyMuhammad SyahmiBelum ada peringkat

- Statics: Course Instructor: Course TA (Section-A) : Course TA (Section-B)Dokumen23 halamanStatics: Course Instructor: Course TA (Section-A) : Course TA (Section-B)Farjad ShahidBelum ada peringkat

- A Survey of Solid Waste Management in Chennai (A Case Study of Around Koyambedu Market and Madhavaram Poultry Farms)Dokumen4 halamanA Survey of Solid Waste Management in Chennai (A Case Study of Around Koyambedu Market and Madhavaram Poultry Farms)Peertechz Publications Inc.100% (1)

- Organic Soils: BY Roaa Monam FadhilDokumen18 halamanOrganic Soils: BY Roaa Monam FadhilroaaBelum ada peringkat

- Faculty of Engineering and Science MAEN 1000: Engineering Materials Lab Report Cover SheetDokumen18 halamanFaculty of Engineering and Science MAEN 1000: Engineering Materials Lab Report Cover SheetPanadol PanadolBelum ada peringkat

- Factors Affecting Fluid ViscosityDokumen12 halamanFactors Affecting Fluid ViscosityBF3nobelBelum ada peringkat

- Water Resources GuideDokumen32 halamanWater Resources Guidevineet_knwr100% (1)

- 04-01 Water ResourcesDokumen74 halaman04-01 Water ResourcesAindrila Ganguly100% (1)

- Construction Site Layout & SecurityDokumen3 halamanConstruction Site Layout & SecurityCHARLES MAINABelum ada peringkat

- Three-Point Flexural TestDokumen3 halamanThree-Point Flexural TestBassey Okon100% (1)

- Chapter 1 - Quantity of WaterDokumen13 halamanChapter 1 - Quantity of WaterAzhar farooqueBelum ada peringkat

- Expt 4b.flexure TestDokumen5 halamanExpt 4b.flexure TestVishwasVerma100% (1)

- Lab #10: Dissolved Oxygen Levels in Natural Waters: Date: Name: Student Id: Co-WorkerDokumen5 halamanLab #10: Dissolved Oxygen Levels in Natural Waters: Date: Name: Student Id: Co-WorkerCuong NguyenBelum ada peringkat

- Envisci Lesson 8water Use and ManagementDokumen30 halamanEnvisci Lesson 8water Use and ManagementMaria100% (1)

- Final Report - 2008 - 10 - 27Dokumen81 halamanFinal Report - 2008 - 10 - 27jarrydBelum ada peringkat

- Timber Properties and Uses in 37 CharactersDokumen10 halamanTimber Properties and Uses in 37 CharactersJane Carnisel PasionBelum ada peringkat

- Exp 4result Discussion For FaDokumen4 halamanExp 4result Discussion For FanasuhaBelum ada peringkat

- Just What Does A Quantity Surveyor Do?Dokumen4 halamanJust What Does A Quantity Surveyor Do?jihaadfadilBelum ada peringkat

- 98965-XX CP VersionDokumen53 halaman98965-XX CP VersionJack DanielBelum ada peringkat

- Work ReportDokumen6 halamanWork ReportAmit Karmakar100% (1)

- Criteria Plant LayoutDokumen30 halamanCriteria Plant LayoutDeepak ThapliyalBelum ada peringkat

- Unit 3 - Construction Site Selection Criteria Assignment 08-05-20Dokumen7 halamanUnit 3 - Construction Site Selection Criteria Assignment 08-05-20Rob PageBelum ada peringkat

- Consumptive Use of WaterDokumen16 halamanConsumptive Use of WaterMonde NuylanBelum ada peringkat

- Mechanical PropertiesDokumen57 halamanMechanical PropertiesElmedin Gluhic100% (1)

- Result & DiscussionDokumen8 halamanResult & DiscussionAkuwh SyaSyaBelum ada peringkat

- BOQ-of FoundationDokumen8 halamanBOQ-of FoundationJohn Carlo AbalaBelum ada peringkat

- Al Falaj (Autosaved)Dokumen18 halamanAl Falaj (Autosaved)Cacai GariandoBelum ada peringkat

- Engineering Mechanics 1 LabDokumen4 halamanEngineering Mechanics 1 LabZiyad RazaliBelum ada peringkat

- 1.explain The Following Types of Distribution Systems : (A) Dead EndDokumen15 halaman1.explain The Following Types of Distribution Systems : (A) Dead EndMichael LangatBelum ada peringkat

- 14.0 Experiment On Determination of Total Solids in Water: Sl. NoDokumen12 halaman14.0 Experiment On Determination of Total Solids in Water: Sl. NoLely CasTroBelum ada peringkat

- Fiber Reinforced ConcreteDokumen14 halamanFiber Reinforced ConcreteYogesh KotiyalBelum ada peringkat

- E-Waste Presentation For CollegesDokumen20 halamanE-Waste Presentation For CollegesManjunaths GowdaBelum ada peringkat

- DEMOLITION OF BUILDINGS GUIDEDokumen21 halamanDEMOLITION OF BUILDINGS GUIDEbhavaniBelum ada peringkat

- Research Seminar Topics on Green ConcreteDokumen12 halamanResearch Seminar Topics on Green ConcreteSuraj Deb BarmaBelum ada peringkat

- Rational Method Hydologic Calculations With Excel CourseDokumen20 halamanRational Method Hydologic Calculations With Excel Coursesyammc100% (1)

- Oxygen Demand SlidesDokumen8 halamanOxygen Demand SlidesShakir MohyuddinBelum ada peringkat

- High Temperature High Shear Rate Viscometers: TheoryDokumen4 halamanHigh Temperature High Shear Rate Viscometers: TheoryChamuditha BenaragamaBelum ada peringkat

- Role and Responsibilities of QSDokumen3 halamanRole and Responsibilities of QSMuhammad'Izzul100% (1)

- Presentesion Made By: Mukesh KumarDokumen17 halamanPresentesion Made By: Mukesh KumarMukesh Kumar SamotaBelum ada peringkat

- The Chemical Oxygen Demand (Cod)Dokumen7 halamanThe Chemical Oxygen Demand (Cod)arif hilimiBelum ada peringkat

- Group-3: Submitted To-Ar. Meenakshi Singh Ar. Shaan Choudhary Ar. Monika SarafDokumen81 halamanGroup-3: Submitted To-Ar. Meenakshi Singh Ar. Shaan Choudhary Ar. Monika SarafPurvita ShahBelum ada peringkat

- Archimedes' Principle ExplainedDokumen2 halamanArchimedes' Principle ExplainedNg Mei EngBelum ada peringkat

- Tension ReportDokumen14 halamanTension ReportDevruwan Wijetilleke100% (1)

- Sanitary Engineer III: Passbooks Study GuideDari EverandSanitary Engineer III: Passbooks Study GuideBelum ada peringkat

- RUDRA ENVIORNMENTAL SOLUTION (INDIA) LTD. Established On29th July 2009. SinceDokumen6 halamanRUDRA ENVIORNMENTAL SOLUTION (INDIA) LTD. Established On29th July 2009. SinceAbhay ThakurBelum ada peringkat

- Dainik Jagran-25.11.2018 (WWW - Estore33.com)Dokumen14 halamanDainik Jagran-25.11.2018 (WWW - Estore33.com)goyalneerajBelum ada peringkat

- Anchor Intimation Letter - XELPMOCDokumen1 halamanAnchor Intimation Letter - XELPMOCgoyalneerajBelum ada peringkat

- Bhatia Communications & Retail (India) LimitedDokumen22 halamanBhatia Communications & Retail (India) LimitedgoyalneerajBelum ada peringkat

- Banka Bioloo Limited: U90001AP2012PLC082811Dokumen35 halamanBanka Bioloo Limited: U90001AP2012PLC082811goyalneerajBelum ada peringkat

- SEBI Regulations on South West Pinnacle Exploration IPODokumen39 halamanSEBI Regulations on South West Pinnacle Exploration IPOgoyalneerajBelum ada peringkat

- Anchor AllocationDokumen1 halamanAnchor AllocationgoyalneerajBelum ada peringkat

- TDSL - CorrigendumDokumen1 halamanTDSL - CorrigendumgoyalneerajBelum ada peringkat

- Red Herring Prospectus - South West Pinnacle Exploration LimitedDokumen482 halamanRed Herring Prospectus - South West Pinnacle Exploration LimitedgoyalneerajBelum ada peringkat

- TDSL Public Issue DetailsDokumen24 halamanTDSL Public Issue DetailsgoyalneerajBelum ada peringkat

- Business Research On Tubular PolesDokumen65 halamanBusiness Research On Tubular Polesgoyalneeraj0% (1)

- IOCL Vocational Training ReportDokumen27 halamanIOCL Vocational Training ReportAniket BhardwajBelum ada peringkat

- Important:: 7.3L Power Stroke Injector ReplacementDokumen4 halamanImportant:: 7.3L Power Stroke Injector ReplacementIonut-alexandru IordacheBelum ada peringkat

- Propulsion Laboraory Manual DSCE 06AEL68Dokumen58 halamanPropulsion Laboraory Manual DSCE 06AEL68Hareesha N G100% (4)

- List of Figures Figure No Title: Industrial Internship Program 30 Nov 2009 - 9 Jul 2010Dokumen59 halamanList of Figures Figure No Title: Industrial Internship Program 30 Nov 2009 - 9 Jul 2010Azlan Othman60% (5)

- Speedaire 10 and 15 HP 2 Stage Air Compressors Owners ManualDokumen84 halamanSpeedaire 10 and 15 HP 2 Stage Air Compressors Owners ManualKeron Trotz100% (1)

- Single Bearing Generator Installation Procedures - LeTourneau, Inc.Dokumen65 halamanSingle Bearing Generator Installation Procedures - LeTourneau, Inc.pevare100% (3)

- 966H-972H - Serv1815 - TXTDokumen233 halaman966H-972H - Serv1815 - TXTBrahim Rabia100% (7)

- Markus FelchnerDokumen2 halamanMarkus FelchnerJuan Cruz TauterysBelum ada peringkat

- Craftsman Mower ManualDokumen31 halamanCraftsman Mower ManualDayton Mickens100% (1)

- Colour Coding Is 9404Dokumen8 halamanColour Coding Is 9404dhoops1988Belum ada peringkat

- 010 Tank Condition 03-05-20Dokumen22 halaman010 Tank Condition 03-05-20Nur SahirohBelum ada peringkat

- Fundamentals of Oil Recovery and Well PerformanceDokumen29 halamanFundamentals of Oil Recovery and Well PerformanceAditya BansalBelum ada peringkat

- Spider 25 We - Technical FolderDokumen2 halamanSpider 25 We - Technical FolderJorge LaraBelum ada peringkat

- The Role of The Plant Engineer in Energy Management 1Dokumen24 halamanThe Role of The Plant Engineer in Energy Management 1Deny AlfonsoBelum ada peringkat

- Astm D4857 - 12Dokumen10 halamanAstm D4857 - 12mancjaBelum ada peringkat

- Smartgen-HGM410 HGM420 V1.6 en PDFDokumen44 halamanSmartgen-HGM410 HGM420 V1.6 en PDFRahmat Nur Ilham100% (4)

- Compressed Gas Cylinders and Related SystemsDokumen26 halamanCompressed Gas Cylinders and Related SystemsPassmore DubeBelum ada peringkat

- Fire Protection TanksDokumen20 halamanFire Protection TankssbmmlaBelum ada peringkat

- Afro 4000 Vossloh ReportDokumen15 halamanAfro 4000 Vossloh ReportLerouxPDF100% (1)

- Chemistry 8402/2: AQA Level 1/2 Certificate June 2013Dokumen28 halamanChemistry 8402/2: AQA Level 1/2 Certificate June 2013BrianChanBelum ada peringkat

- Maximizing Oil Recovery Through Lateral Re-EntryDokumen2 halamanMaximizing Oil Recovery Through Lateral Re-EntryJorge FernandoBelum ada peringkat

- UL Listing Diesel EnginesDokumen1 halamanUL Listing Diesel EnginesDarshAwadBelum ada peringkat

- Nylund 2007-Field Experience With The Wartsila 50DF Dual-FuelDokumen10 halamanNylund 2007-Field Experience With The Wartsila 50DF Dual-FuelsestoubosBelum ada peringkat

- 3512B B 1014bkW 1360bhp 1600rpmDokumen6 halaman3512B B 1014bkW 1360bhp 1600rpmMILADBelum ada peringkat

- Develop India's Next-Gen 6000 HP Diesel-Electric LocomotiveDokumen12 halamanDevelop India's Next-Gen 6000 HP Diesel-Electric LocomotiveviswachandraBelum ada peringkat

- Aircraft Mechanic Section 13 & 28 LogbookDokumen96 halamanAircraft Mechanic Section 13 & 28 LogbookNianga FidricheBelum ada peringkat

- Automotive Applications of Thermoelectric MaterialsDokumen7 halamanAutomotive Applications of Thermoelectric Materialsgljr32941181011Belum ada peringkat

- D12 EngineDokumen57 halamanD12 Enginesergio100% (6)

- Engine Break-In: Recommended ProceduresDokumen3 halamanEngine Break-In: Recommended ProceduresVictor Lo Dastek UnichipBelum ada peringkat

- 140H Update2002 E (43d)Dokumen20 halaman140H Update2002 E (43d)EduardoCalderonBelum ada peringkat