Pressors

Diunggah oleh

Manoj MisraDeskripsi Asli:

Judul Asli

Hak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

Pressors

Diunggah oleh

Manoj MisraHak Cipta:

Format Tersedia

8.

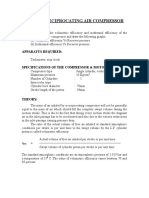

ENERGY PERFORMANCE ASSESSMENT OF COMPRESSORS

8.1 Introduction

The compressed air system is not only an energy intensive utility but also one of the least energy efficient. Over a period of time, both performance of compressors and compressed air system reduces drastically. The causes are many such as poor maintenance, wear and tear etc. All these lead to additional compressors installations leading to more inefficiencies. A periodic performance assessment is essential to minimize the cost of compressed air.

8.2

Purpose of the Performance Test

To find out: Actual Free Air Delivery (FAD) of the compressor Isothermal power required Volumetric efficiency Specific power requirement

The actual performance of the plant is to be compared with design / standard values for assessing the plant energy efficiency.

8.3

Performance Terms and Definitions

Compression ratio : Absolute discharge pressure of last stage Absolute intake pressure : It is the least power required to compress the air assuming isothermal conditions. : The ratio of Isothermal power to shaft power : The ratio of Free air delivered to compressor swept volume

Isothermal Power

Isothermal Efficiency Volumetric efficiency

Specific power requirement: The ratio of power consumption (in kW ) to the volume delivered at ambient conditions.

8.4

8.4.1

Field Testing

Measurement of Free Air Delivery (FAD) by Nozzle method Principle: If specially shaped nozzle discharge air to the atmosphere from a receiver getting its supply from a compressor, sonic flow conditions sets in at the nozzle throat

Bureau of Energy Efficiency

107

8. Energy Performance Assessment of Compressors

for a particular ratio of upstream pressure (receiver) to the downstream pressure (atmospheric) i.e. Mach number equals one. When the pressure in the receiver is kept constant for a reasonable intervals of time, the airflow output of the compressor is equal to that of the nozzle and can be calculated from the known characteristic of the nozzle. 8.4.2 Arrangement of test equipment The arrangement of test equipment and measuring device shall confirm to Figure 8.1. 8.4.3 Nozzle Sizes

The following sizes of nozzles are recommended for the range of capacities indicated below: Nozzle size (mm) 6 10 16 22 33 50 80 125 165 Capacity (m3/hr) 39 9 30 27 90 60 170 130 375 300 450 750 2000 1800 5500 3500 - 10000

Flow Nozzle: Flow nozzle with profile as desired in IS 10431:1994 and dimensions 8.4.4 Measurements and duration of the test. The compressor is started with the air from the receiver discharging to the atmosphere through the flow nozzle. It should be ensured that the pressure drop through the throttle valve should be equal to or twice the pressure beyond the throttle. After the system is stabilized the following measurements are carried out: Receiver pressure Pressure and temperature before the nozzle Pressure drop across the nozzle Speed of the compressor kW, kWh and amps drawn by the compressor

The above readings are taken for the 40%, 60%, 100% and 110% of discharge pressure values. Measuring instruments required for test Thermometers or Thermocouple Pressure gauges or Manometers Differential pressure gauges or Manometers Standard Nozzle

Bureau of Energy Efficiency

108

8. Energy Performance Assessment of Compressors

Psychrometer Tachometer/stroboscope Electrical demand analyser T1

P1 FILTER

P2

AIR COMPRESSOR

RECEIVER

P4

P3

T3

THROTTLE VALVE

Nozzle P3 P4

FLOW STRAIGHTENER

DISCHARGE TO ATMOSPHERE

BY-PASS

Figure 8.1: Test Arrangement for Measurement of Compressed Air Flow

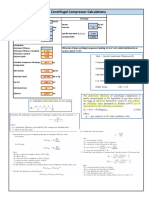

8.5 Calculation Procedure for Nozzle Method

I.

T 2( P3 P4 )( P3 x Ra ) Free air delivered , Q f (m / sec) = k x x d x 1 x 4 P T3 1

s

1/ 2

k d T1 P1 P3 T3 Ra P3-P4

: : :

:

: : : :

Flow coefficient as per IS Nozzle diameter M Absolute inlet temperature oK Absolute inlet pressure kg/cm2 Absolute Pressure before nozzle kg/cm2 Absolute temperature before nozzle oK Gas constant for air 287.1 J/kg k Differential pressure across the nozzle kg/cm2

Bureau of Energy Efficiency

109

8. Energy Performance Assessment of Compressors

II.

Isothermal Efficiency Isothermal power (kW ) = P1 Qf r = = =

Isothermal power / Input power

P x Q f x log e r 1 36.7 Absolute intake pressure kg/ cm2 Free air delivered m3/hr. Pressure ratio P2/P1

III. Specific power consumption at rated disch arg e pressure =

Power consumption, kW Free air delivered , m3 / hr

IV. Volumetric efficiency =

Free air delivered in m3 / min x 100 Compressor displacement in m3 / min

Compressor displacement = D L S n

x D2 x L x S x x n = = = = = Cylinder bore, metre Cylinder stroke, metre Compressor speed rpm 1 for single acting and 2 for double acting cylinders No. of cylinders

8.6 Example

Calculation of Isothermal Efficiency for a Reciprocating Air Compressor. Step 1 : Calculate Volumetric Flow Rate k : Flow coefficient (Assumed as 1) d : Nozzle diameter : 0.08 metre : Receiver Pressure - 3.5 kg / cm2 (a) P2 : Inlet Pressure - 1.04 kg / cm2(a) P1 T1 : Inlet air temperature 30oC or 303oK : Pressure before nozzle 1.08 kg / cm2 P3 T3 : Temperature before the nozzle 40oC or 313oK P3 P4 : Pressure drop across the nozzle = 0.036 kg / cm2 Ra : Gas constant : 287 Joules / kg K

T 2( P3 P4 )( P3 x Ra ) Free air delivered , Q f (m / sec) = k x x d x 1 x 4 P T3 1

s

1/ 2

Free air delivered , Q f (m s / sec) =1 x = 0.391 m3/sec = 1407.6 m3 / h.

x (0.08) 2 x

303 2 x 0.036 x1.08 x 287 x 1.04 313

1/ 2

Bureau of Energy Efficiency

110

8. Energy Performance Assessment of Compressors

Step 2 : Calculate Isothermal Power Requirement

Isothermal power (kW ) =

P x Q f x log e r 1 36.7 = 1.04 kg / cm2 (a) = 1407.6 m3 / h.

P1 - Absolute intake pressure Qf -Free Air Delivered Compression ratio, r = 3.51 = 3.36 1.04

Isothermal power (kW ) =

1.04 x1407.6 x log e 3.36 = 48.34 kW 36.7

Step 3 : Calculate Isothermal Efficiency

Motor input power Motor and drive efficiency Compressor input power Isothermal efficiency

= 100 kW = 86 % = 86 kW = Isothermal Power x 100 Compressor input Power = 48.34 x 100 = 56% 86.0

8.7 Assessment of Specific Power requirement

Specific power consumption = Actual power consumed by the compressor Measured Free Air Delivery In the above example the measured flow is 1407.6 m3/hr and actual power consumption is 100 kW.

Specific power requirement =

100 1407.6

= 0.071 kW/m3/hr

8.8 Measurement of FAD by Pump Up Method

(Note: The following section is a repeat of material provided in the chapter-3 on Compressed Air System in Book-3.) Another way of determining the Free Air Delivery of the compressor is by Pump Up Method - also known as receiver filling method. Although this is less accurate, this can be adopted where the elaborate nozzle method is difficult to be deployed.

Bureau of Energy Efficiency

111

8. Energy Performance Assessment of Compressors

Simple method of Capacity Assessment in Shop floor

Isolate the compressor along with its individual receiver being taken for test from main compressed air system by tightly closing the isolation valve or blanking it, thus closing the receiver outlet. Open water drain valve and drain out water fully and empty the receiver and the pipeline. Make sure that water trap line is tightly closed once again to start the test. Start the compressor and activate the stopwatch. Note the time taken to attain the normal operational pressure P2 (in the receiver) from initial pressure P1. Calculate the capacity as per the formulae given below:

Actual Free air discharge

Q = Where P2 P1 P0 V T = = = = =

P2 P1 V Nm3 / Minute P0 T

Final pressure after filling (kg/cm2 a) Initial pressure (kg/cm2a) after bleeding Atmospheric Pressure (kg/cm2 a) Storage volume in m3 which includes receiver, after cooler, and delivery piping Time take to build up pressure to P2 in minutes

The above equation is relevant where the compressed air temperature is same as the ambient air temperature, i.e., perfect isothermal compression. In case the actual compressed air temperature at discharge, say t20C is higher than ambient air temperature say t10C (as is usual case), the FAD is to be corrected by a factor (273 + t1) / (273 + t2).

EXAMPLE

An instrument air compressor capacity test gave the following results (assume the final compressed air temperature is same as the ambient temperature) Comment? Piston displacement : 16.88 m3/minute Theoretical compressor capacity : 14.75 m3/minute @ 7 kg/cm2 Compressor rated rpm 750 : Motor rated rpm : 1445 Receiver Volume : 7.79 m3 Additional hold up volume, i.e., pipe / water cooler, etc., is : 0.4974 m3 Total volume : 8.322 m3 Initial pressure P1 : 0.5 kg/cm2 : 7.03 kg/cm2 Final pressure P2

Bureau of Energy Efficiency

112

8. Energy Performance Assessment of Compressors

Atmospheric pressure P0 Compressor output m3/minute

: : :

1.026 kg/cm2,a (P2 P1 ) Total Volume Atm. Pressure Pumpup time

= 13.17 m3/minute 1.026 4.021 Capacity shortfall with respect to 14.75 m3/minute rating is 1.577 m3/minute i.e., 10.69 %, which indicates compressor performance needs to be investigated further.

(7.03 0.5) 8.322

Bureau of Energy Efficiency

113

8. Energy Performance Assessment of Compressors

QUESTIONS

1) 2) 3) 4) 5) 6)

What is meant by Free Air Delivery? Describe the method of estimating flow by nozzle method. Describe the method of estimating flow by pump up method. Define the term isothermal efficiency and explain its significance. Define the term volumetric efficiency and explain its significance. How is specific power requirement calculated?

REFERENCES

1.

IS 10431:1994: Measurement of airflow of compressors and exhausters by nozzles.

2.

IS 5456:1985 code of practice for testing of positive displacement type air compressors and exhausters

3.

Compressor performance Aerodynamics for the user by M Theodore GreshButterworth Heinemann.

Bureau of Energy Efficiency

114

Anda mungkin juga menyukai

- Assessment of CompresorsDokumen14 halamanAssessment of CompresorsranveerBelum ada peringkat

- Pressure Ake Int Absolute Stage Last of Pressure e Arg Disch AbsoluteDokumen8 halamanPressure Ake Int Absolute Stage Last of Pressure e Arg Disch Absolutemasih tadayonBelum ada peringkat

- Compressor-Performance Evaluation PDFDokumen4 halamanCompressor-Performance Evaluation PDFAlvin Smith100% (1)

- Air Receiver Sizing Metric UnitsDokumen4 halamanAir Receiver Sizing Metric UnitsAnonymous Od7nYs8Belum ada peringkat

- BlowersDokumen58 halamanBlowersmahmad61100% (1)

- Process Equipment Design-1Dokumen15 halamanProcess Equipment Design-1Nikunj Thummar100% (1)

- Compressor Air Intake Quality ImportanceDokumen12 halamanCompressor Air Intake Quality Importanceanup_nairBelum ada peringkat

- Stepless Variable Capacity ControlDokumen7 halamanStepless Variable Capacity Controlswapneel_kulkarniBelum ada peringkat

- Design Conditions CriteriaDokumen4 halamanDesign Conditions CriteriaJaldhi PatelBelum ada peringkat

- IA Compressor & SystemDokumen51 halamanIA Compressor & SystemKazi Irfan100% (1)

- Sizing Forced Draft Fans For Fired HeatersDokumen5 halamanSizing Forced Draft Fans For Fired Heatersdlalameen4471Belum ada peringkat

- Compressed Air Supply: Training NotesDokumen22 halamanCompressed Air Supply: Training NotesardianalimBelum ada peringkat

- Essential Guide to Air CompressorsDokumen59 halamanEssential Guide to Air Compressorsommech2020Belum ada peringkat

- Protecting A Centrifugal Compressor From SurgeDokumen2 halamanProtecting A Centrifugal Compressor From SurgeDylanAdams100% (1)

- Adiabtaic Vs Polytropic Head Compressor - ComparisonDokumen1 halamanAdiabtaic Vs Polytropic Head Compressor - Comparisonvijay_jvBelum ada peringkat

- 02 Chapter 2Dokumen0 halaman02 Chapter 2Imtinan MohsinBelum ada peringkat

- Valvulas STEPLESSDokumen10 halamanValvulas STEPLESSHerlin MorenoBelum ada peringkat

- Acfm vs. SCFM vs. Icfm: Series of Technical White Papers From Squire-CogswellDokumen9 halamanAcfm vs. SCFM vs. Icfm: Series of Technical White Papers From Squire-Cogswellegsg50100% (1)

- Pressure Safety Valves: Selection, Sizing & Design in 40 CharactersDokumen19 halamanPressure Safety Valves: Selection, Sizing & Design in 40 CharactersAbdulAbdulBelum ada peringkat

- Cooling Towers: Codes and Standards Enhancement ReportDokumen19 halamanCooling Towers: Codes and Standards Enhancement ReportAIYODOT DOTBelum ada peringkat

- C Module-5 Reciprocating Air Compressors. Reciprocating Compressors - Construction - WorkingDokumen48 halamanC Module-5 Reciprocating Air Compressors. Reciprocating Compressors - Construction - WorkingJasraj Gill100% (1)

- Air Receiver SizingDokumen3 halamanAir Receiver Sizinglutfi awnBelum ada peringkat

- Pump selection and head calculation exampleDokumen37 halamanPump selection and head calculation exampleIhsan Wiratama100% (1)

- Gas Compression IIDokumen13 halamanGas Compression IIAnuraag MulpuriBelum ada peringkat

- Compressor Data SheetDokumen3 halamanCompressor Data Sheetkumsan leeBelum ada peringkat

- Sizing Air Receiver TankDokumen3 halamanSizing Air Receiver TankDennis DanielBelum ada peringkat

- Air CompressorDokumen51 halamanAir CompressorInaam Ur RehmanBelum ada peringkat

- A Guideline For Design Pressure - Part 2Dokumen4 halamanA Guideline For Design Pressure - Part 2Said Ahmed SalemBelum ada peringkat

- Air CompressorDokumen37 halamanAir Compressorsamal_biswaBelum ada peringkat

- Compressors & Compressed Air System: Presented by Naushad Ahmad Department: Mechanical MaintDokumen48 halamanCompressors & Compressed Air System: Presented by Naushad Ahmad Department: Mechanical Maintnaushadmnnit100% (1)

- Rightsizing Compressed Air SystemDokumen6 halamanRightsizing Compressed Air SystemRahul ChandrawarBelum ada peringkat

- 31-SAMSS-006 - 2 July 2019 ERDokumen15 halaman31-SAMSS-006 - 2 July 2019 ERjulius100% (1)

- Centrifugal Compressors For CPI Plants PDFDokumen4 halamanCentrifugal Compressors For CPI Plants PDFAmanda Aracely Herreria SalazarBelum ada peringkat

- Design Features and Operation of Jet EjectorsDokumen2 halamanDesign Features and Operation of Jet EjectorsSamiYousifBelum ada peringkat

- Compressed Air Velocity CalculatorDokumen1 halamanCompressed Air Velocity CalculatorLucky Karunia Setyawan PratamaBelum ada peringkat

- Centrifugal Compressor Calculations: Suction Discharge Input ParametersDokumen1 halamanCentrifugal Compressor Calculations: Suction Discharge Input Parametersankur20610% (1)

- TGI Sabana Gas Transport: Operating Conditions Normal D E F A B CDokumen3 halamanTGI Sabana Gas Transport: Operating Conditions Normal D E F A B Chernan plazasBelum ada peringkat

- Compressor Head Calculations Design GuideDokumen24 halamanCompressor Head Calculations Design Guidec_nghiaBelum ada peringkat

- Pacol Stripper Optimization Saves $74K AnnuallyDokumen16 halamanPacol Stripper Optimization Saves $74K AnnuallyMohamad IbrahimBelum ada peringkat

- Reciprocating Compressor Cooloing ConsoleDokumen22 halamanReciprocating Compressor Cooloing ConsolerutujaBelum ada peringkat

- Typical P&ID for Centrifugal Compressor SystemsDokumen7 halamanTypical P&ID for Centrifugal Compressor SystemsmsaroladanBelum ada peringkat

- Air Receivers Volume CalculationDokumen123 halamanAir Receivers Volume CalculationsdgthdtrtretBelum ada peringkat

- Cag I Air Compressor HPDokumen24 halamanCag I Air Compressor HPcamenitaBelum ada peringkat

- Trial On CompresorDokumen3 halamanTrial On CompresorA JBelum ada peringkat

- Three-Stage Compressor Power CalculationDokumen6 halamanThree-Stage Compressor Power CalculationRifka Aisyah0% (1)

- Air DryerDokumen4 halamanAir Dryerrashm006ranjanBelum ada peringkat

- Compressed Air Distribution SystemsDokumen33 halamanCompressed Air Distribution SystemsSamik MukherjeeBelum ada peringkat

- The Energy Costs Associated With Nitrogen Specifications: Sustainable Manufacturing FeaturesDokumen8 halamanThe Energy Costs Associated With Nitrogen Specifications: Sustainable Manufacturing FeaturesJaime Andres Pardo QuinteroBelum ada peringkat

- Dynamic Depressuring PDFDokumen16 halamanDynamic Depressuring PDFAsimBelum ada peringkat

- Fire Relief Dynamic StudyDokumen2 halamanFire Relief Dynamic StudylguardiaBelum ada peringkat

- Heat ChemCADDokumen25 halamanHeat ChemCADthawdarBelum ada peringkat

- UtilityDokumen8 halamanUtilityAmit JainBelum ada peringkat

- 8.assessment of CompresorsDokumen14 halaman8.assessment of CompresorsPrudhvi RajBelum ada peringkat

- γ γ × ∆ × × × × P 81 - 9 2 Cp A: Selected questionsDokumen6 halamanγ γ × ∆ × × × × P 81 - 9 2 Cp A: Selected questionsHhaabbde SybaritzBelum ada peringkat

- Heat Transfer Lab - 1Dokumen31 halamanHeat Transfer Lab - 1Nikhil JayanthBelum ada peringkat

- Heat and Mass TransferDokumen28 halamanHeat and Mass TransfersureshkumarBelum ada peringkat

- LAB 3 Air Compressor System AuditDokumen7 halamanLAB 3 Air Compressor System AuditAmirulAminBelum ada peringkat

- Heat Transfer Lab - NGS (1) (2) - YathinDokumen48 halamanHeat Transfer Lab - NGS (1) (2) - Yathinswaroopdash.201me256Belum ada peringkat

- Performance Test On Two-Stage Reciprocating Air CompressorDokumen6 halamanPerformance Test On Two-Stage Reciprocating Air CompressorAji V s100% (2)

- PNEUMATICS AND AIR CIRCUITS UNDERSTANDING THE CASCADE VALVE AND PLC UNDERSTANDINGDari EverandPNEUMATICS AND AIR CIRCUITS UNDERSTANDING THE CASCADE VALVE AND PLC UNDERSTANDINGBelum ada peringkat

- Q3e RW4 VideoTranscriptsDokumen17 halamanQ3e RW4 VideoTranscriptshunBelum ada peringkat

- SP 1Dokumen204 halamanSP 1montecarlo22000Belum ada peringkat

- Env Questions PDFDokumen33 halamanEnv Questions PDFDeepti KulkarniBelum ada peringkat

- Oer BoosterDokumen8 halamanOer Boosteredison58100% (1)

- Climatology VernacularDokumen38 halamanClimatology VernacularShivam ThukralBelum ada peringkat

- Loss On Ignition TruthDokumen3 halamanLoss On Ignition TruthL PRASANT RAOBelum ada peringkat

- Project Environmental Appraisal GuideDokumen27 halamanProject Environmental Appraisal GuideKartik BhartiaBelum ada peringkat

- ASTER User Guide v2.0Dokumen80 halamanASTER User Guide v2.0Bebe WeBelum ada peringkat

- Chaapter 4 PEMDDokumen13 halamanChaapter 4 PEMDPradhunya KambleBelum ada peringkat

- TRIZ 40 Principles - SummaryDokumen4 halamanTRIZ 40 Principles - SummarydaniellskBelum ada peringkat

- Earth Different SystemsDokumen6 halamanEarth Different SystemsJohn Alexis CabolisBelum ada peringkat

- Physics Solutions UNITS 1-4 PDFDokumen337 halamanPhysics Solutions UNITS 1-4 PDFAmogh Narvekar80% (5)

- Avalanche HandbookDokumen156 halamanAvalanche HandbookSorin CraciunBelum ada peringkat

- Applied Respiratory Physiology 2010 NUNNSDokumen516 halamanApplied Respiratory Physiology 2010 NUNNSJaime Alberto Rodriguez100% (1)

- By Yasir Sharif & Waheeb AhmedDokumen21 halamanBy Yasir Sharif & Waheeb Ahmedwaheebahmed100% (3)

- Thermal Energy Transfer: ConductionDokumen2 halamanThermal Energy Transfer: ConductionJaniah Aaliyah M. DrakesBelum ada peringkat

- What Is A HurricaneDokumen7 halamanWhat Is A HurricanepitufitoBelum ada peringkat

- Grade 7 Concept TestDokumen4 halamanGrade 7 Concept Testapi-334295481Belum ada peringkat

- Shipborne Meteorological InstrumentsDokumen10 halamanShipborne Meteorological InstrumentsGiz Miciano79% (24)

- Assignment On Air PollutionDokumen31 halamanAssignment On Air PollutionHassan_BIBMBelum ada peringkat

- HvacDokumen249 halamanHvacengrjayasis20Belum ada peringkat

- Position Paper Rough DraftDokumen5 halamanPosition Paper Rough Draftapi-29161788867% (3)

- Industrial Oven: Operation & Maintenance Manual Ultra - Temp SeriesDokumen48 halamanIndustrial Oven: Operation & Maintenance Manual Ultra - Temp SerieszernnBelum ada peringkat

- Study GuideDokumen398 halamanStudy GuideVo HaianhBelum ada peringkat

- Questionaire 2Dokumen9 halamanQuestionaire 2Dain AliceBelum ada peringkat

- Duo 3 EnglishDokumen19 halamanDuo 3 Englishkungfugrid100% (2)

- Little Ice AgeDokumen7 halamanLittle Ice Ageb_42_jimBelum ada peringkat

- Global Warming and Climate Change ExplainedDokumen27 halamanGlobal Warming and Climate Change ExplainedAishwarya MadduruBelum ada peringkat

- The Rise of Oxygen in The Earth's AtmosphereDokumen8 halamanThe Rise of Oxygen in The Earth's AtmosphereGabriel Hernandez GallardoBelum ada peringkat