Frustrated Felines

Diunggah oleh

Syed Javeed HassanDeskripsi Asli:

Hak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

Frustrated Felines

Diunggah oleh

Syed Javeed HassanHak Cipta:

Format Tersedia

Frustated Felines

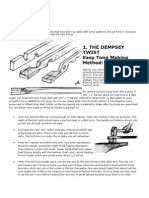

Action; Cat A jabs his fork at the sardine. Sardine swerves out of the path of fork but into the path of cat B's fork, thus lining himself up for another assault from cat A. An accurate representation of how the world should work. It was a product that we thought could be made pretty well entirely out of birch ply with no lathe or fancy fixings. Still, it seems rather challenging... Since staying with my dad and his cats, my dislike of them, which used to be pretended (to make myself seem interesting and opinionated) has become quite genuine. - Paul Spooner

You will need 6mm ply 1/4 dowel 1/2 x No.2 Round Head Black Japanned wood screws (If no black japanned youll have to paint the eye screws) 3/8 x No.2 Round Head any kind of wood screws (B.J. for uniformness) Little tension springs (Whistons) 18g - (3/64 dia) brass wire ( If different size get drill to match) Bits of tin plate from sardine tin, olive oil tin, pilchards etc preferably with gold inside. TOOLS Drills 1. 1/2 Flat bit or machine wood bit 2. 1/4 twist drill to make tight hole for dowel 3. 9/32 twist drill to make loose hole for dowel 4. 3/32 twist drill for screws 5. 3/64 twist drill for wire 6. 1/32 twist drill for tiny pilot holes. Get 2 youll break one. Sandpaper Bradawl Stanley Knife Tin Snips Round Nosed Pliers Drill in drill stand Soldering iron 25w Resin W wood glue

-1. Check t of base joint in frame. Take apart again. 1. Cut out sardine tin label. Reserve. 2. Sick down the rest of xerox onto 6mm ply. 3. When dry. Drill holes. 1/2 New sharp at bits for eyes Clearance hole for 1/4 dowel under cats chins (9/32) Tight t hole for 1/4 dowel (1/4) Check your dowel and drills to make sure that loose is loose and tight is tight. Other holes are screw holes /32 for clearance No.2 screws. Tiny holes are pilot holes drilled right through to transfer position to back of sheet 1/32. Drilling Holes. Its most necessary to be accurate. If you have difculty drill through all spots with tiny 1/32 drill to guide big drills and help see when marks drilled away. 3.5. Cut shapes out. 4. Sand back edges 5. Cut 5 pieces of dowel 4x20mm 1x 15mm 6. Knock 2 (20mm) dowels into the frame. Glue if necessary. The dowel Ive used is very tight without glue. Leave ush with front surface. 7. Put a dowel (20mm) into each front arm Use glue this time. 8. Put 2 black 1/2 screws No.2 into eye shutter. 9. Drill holes for forks along line shown on plan. Size of hole depends on size of wire. try not to get it too tight so you can t the forks later without mangling the whole thing. 10. Push rear arms (with eye shutters) onto dowel in front arm hrough hole in cat. This joint should move very easily. Put a blob of glue here when ouve got it right. 11. Fix cat body to frame with 1/2 screw. 12.Fix rocker to frame ditto. 13.Fix back leg between cat and rocker with 1/2 screws. ALL these joints easy to move. 14.Fix return pring between arm and body. Not too loose, not too tight, so it springs back every time. 15.Drill pilot hole fo 3/8 screw in this pillar. Make wire thing as near the same as example as poss. This is a better design than the one Ive made. The length of the loop is not important. Make jig when you got the size right. 16. Fix wire thing so that eyes are fully moved towards centre when hand is 1.5mm from surface of table. Grope around in this area for correct spot for screw. (Make a little wooden jig to t between hand + table) 17. Do the other cat. 18. Fish. Shape shs head both sides. sand. Undercoat + top coat humbrol silver. When dry try a hin wash of blue watercolour to make shy bluer. I havent tried that yet but will report. Draw eye + mouth with black humbrol on thin brush. 19.Put short dowel into sh tail. screw sh to back of frame with 1/2 screw. 20.Fix sh lever to rocker. With rocker in mid posiion lever and sh should be vertical. Use one screw only for now. (Glue piece of thin card (sample inc) behind for clearance) 21. Make forks. geddit? I didnt do mine like this yours will be good. 22.Fit forks. Check action forks should miss. If they hit a) move sh lever to best position b) Bend forks. Put second screw in sh lever. 23. Make sardine tin: Scribe round template onto sheet of tinplate. Preferably use a tin wih that goldish nish inside. Wrap tin round former. Solder. It doesnt matter if its not exactly the same... Make lid. Use end of former to get this shape. Wind up around round nosed pliers. Make key from brass wire. Push key into coil of lid. Solder if necessary. Solder lid to tin. 24. Find the best place for tin vis a vis sh + forks. Fasten with 10 min araldite. Try not to smear it all over as I did. You can make a gismo to help cramp it in place.

24.5. Extra safe! Drill a weeny hole here + pin tin on with brass wire. 25. Glue label on tin 26. Glue stand on. Another sardine tin clamp. Patent spring clamp available halfords. Pressing tin to wood. Bridging piece between back legs.

Anda mungkin juga menyukai

- Crossbow 20 PDFDokumen8 halamanCrossbow 20 PDFGeoffrey Hamilton-adamsBelum ada peringkat

- $20 Combat Crossbow, TheDokumen8 halaman$20 Combat Crossbow, TheKaryllongBelum ada peringkat

- Homemade Ballista - The Oznog's Spruce Moose BallistaDokumen13 halamanHomemade Ballista - The Oznog's Spruce Moose BallistaIkkasama NaguenneBelum ada peringkat

- PinzasDokumen9 halamanPinzasjakjuBelum ada peringkat

- Wire Wrapping JewelryDokumen12 halamanWire Wrapping JewelryAlice M. Martelo100% (1)

- Cigar Box Guitar: Tools Used in This ProjectDokumen10 halamanCigar Box Guitar: Tools Used in This Projectbpearson02311132Belum ada peringkat

- Electronic Drum PadDokumen44 halamanElectronic Drum PadMarinko TikvickiBelum ada peringkat

- Serpentinesplendor: An Innovative Connection Technique Brings Form and Flexibility To This Metal-Clay BraceletDokumen4 halamanSerpentinesplendor: An Innovative Connection Technique Brings Form and Flexibility To This Metal-Clay BraceletDetalles Isabella100% (1)

- Easy To Build Stirling Engine FanDokumen14 halamanEasy To Build Stirling Engine Fanpatel_kalpesh1241100% (1)

- Woodsmith - 063Dokumen24 halamanWoodsmith - 063rsotoqp100% (2)

- Placa de Chladni CaseraDokumen11 halamanPlaca de Chladni CaseraVVANDERBelum ada peringkat

- Wooden Puzzle Vault GIZSIP 327278258Dokumen3 halamanWooden Puzzle Vault GIZSIP 327278258magoleija2010100% (1)

- Diy Travel UkuleleDokumen11 halamanDiy Travel Ukuleleblancofrank545Belum ada peringkat

- Art q1105Dokumen6 halamanArt q1105Bijouterie Du MondeBelum ada peringkat

- Easy Box Joints Adjustable Tooth WidthsDokumen15 halamanEasy Box Joints Adjustable Tooth WidthsRickBelum ada peringkat

- Rustic Hanging Shelves Display Small TreasuresDokumen2 halamanRustic Hanging Shelves Display Small TreasuresdjfwalkerBelum ada peringkat

- Getting Handle On CaneDokumen5 halamanGetting Handle On CaneStefan Van Cleemput100% (2)

- Boxes to Build: Sturdy & Stylish Projects to Organize Your Home & ShopDari EverandBoxes to Build: Sturdy & Stylish Projects to Organize Your Home & ShopBelum ada peringkat

- Horrocks - Trinity Wand Picture Tutorial (Orgonite Wand)Dokumen20 halamanHorrocks - Trinity Wand Picture Tutorial (Orgonite Wand)Rafita100% (5)

- Lisa Chain Mail BraceletDokumen4 halamanLisa Chain Mail Braceletgirasolete100% (2)

- American Woodworker - 10 Weekend ProjectsDokumen53 halamanAmerican Woodworker - 10 Weekend ProjectsEmilian Baluta100% (1)

- BNBSB1214BDokumen5 halamanBNBSB1214Bgraziana100% (5)

- Long Langstroth HiveDokumen7 halamanLong Langstroth HiveWolfgangBelum ada peringkat

- ChickShaw Plans DIY Mobile Chicken CoopDokumen24 halamanChickShaw Plans DIY Mobile Chicken CoopKen Taylor DCBelum ada peringkat

- CajonDokumen6 halamanCajonscribdtibiBelum ada peringkat

- Build A Toy BoxDokumen10 halamanBuild A Toy BoxkhunchaiyaiBelum ada peringkat

- Guide To Making Percussion Caps2Dokumen12 halamanGuide To Making Percussion Caps2Dave Markowitz100% (2)

- Woomera e AtlatsDokumen58 halamanWoomera e Atlatssoldatbr4183Belum ada peringkat

- Classic Pearls Chain NecklaceDokumen3 halamanClassic Pearls Chain Necklaceanomisolga100% (1)

- Wire JewelryDokumen13 halamanWire JewelryAlexa Miha90% (10)

- Flagcase ConstructionDokumen2 halamanFlagcase ConstructionajaxleonBelum ada peringkat

- Salero y PimenteroDokumen11 halamanSalero y PimenterokevineliBelum ada peringkat

- Basic Rod Wrapping JigDokumen8 halamanBasic Rod Wrapping JigRazib MokhtarBelum ada peringkat

- Secret Compartment Ring: How to Make a Ring with a Hidden Storage CompartmentDokumen32 halamanSecret Compartment Ring: How to Make a Ring with a Hidden Storage CompartmentHenrique Monteiro100% (1)

- How To Build Your Own KoraDokumen11 halamanHow To Build Your Own KoraJohnatan HubsBelum ada peringkat

- Simply Swirled EarringsDokumen21 halamanSimply Swirled EarringsAngelina Croft100% (1)

- DIY Air Dry Clay Projects Fun and Easy PR - Jose EscobarDokumen52 halamanDIY Air Dry Clay Projects Fun and Easy PR - Jose EscobarHady Soenarjo100% (4)

- Mint Box: RecycledDokumen5 halamanMint Box: Recycledgirasolete100% (3)

- GioielloB NDokumen6 halamanGioielloB Napi-3747418Belum ada peringkat

- A Reed Making Process For The Great Highland BagpipeDokumen11 halamanA Reed Making Process For The Great Highland BagpipekriktsemajBelum ada peringkat

- Whatnot Dish: The Ideal Gift BowlDokumen5 halamanWhatnot Dish: The Ideal Gift BowlMarcos R. Hernández M.Belum ada peringkat

- How To Make A Cigar Box FiddleDokumen8 halamanHow To Make A Cigar Box FiddleSadak00100% (1)

- Build A BowsawDokumen4 halamanBuild A Bowsawjon789100% (1)

- Jewelry BoxesDokumen14 halamanJewelry BoxesDan Goodpasture100% (4)

- Modern Planter Box Plans, Copyright Crafted Workshop 2018Dokumen11 halamanModern Planter Box Plans, Copyright Crafted Workshop 2018robins115350100% (2)

- Car Case ConstructionDokumen7 halamanCar Case ConstructionAnonymous QJ5j94luLmBelum ada peringkat

- Eric Meyer Peg TurningDokumen36 halamanEric Meyer Peg TurningponbohacopBelum ada peringkat

- How To Make A Coin RingsDokumen4 halamanHow To Make A Coin RingsPeter Snyder100% (1)

- Wire StyleDokumen8 halamanWire StyleInterweave65% (23)

- 5KÖPEK'İNG'HUGLESDokumen29 halaman5KÖPEK'İNG'HUGLESrgcastilloe0% (1)

- Best of Beadwork 8 Projects by Designer of The Year Jean Campbell PDFDokumen24 halamanBest of Beadwork 8 Projects by Designer of The Year Jean Campbell PDFbeading100% (10)

- Easel Plans de 1Dokumen9 halamanEasel Plans de 1JuanRodriguezBelum ada peringkat

- Creating Wooden Boxes on the Scroll Saw: Patterns and Instructions for Jewelry, Music, and Other Keepsake BoxesDari EverandCreating Wooden Boxes on the Scroll Saw: Patterns and Instructions for Jewelry, Music, and Other Keepsake BoxesBelum ada peringkat

- MoodboardDokumen24 halamanMoodboardmarcellino919100% (1)

- Taschen - Graphic Design - Logo CatalogDokumen221 halamanTaschen - Graphic Design - Logo Catalogmarcellino919100% (3)

- Walking Rhino Patterns PDFDokumen1 halamanWalking Rhino Patterns PDFmarcellino919Belum ada peringkat

- LiberDokumen55 halamanLibermarcellino919Belum ada peringkat

- Liber OptDokumen55 halamanLiber Optmarcellino919Belum ada peringkat

- Because The NightDokumen1 halamanBecause The Nightmarcellino919Belum ada peringkat

- Bamboo JointsDokumen4 halamanBamboo Jointskunal chaudhariBelum ada peringkat

- Manual de Instrucciones Yamaha Grizzly 700ccDokumen93 halamanManual de Instrucciones Yamaha Grizzly 700ccMaria Nencheva NenchevaBelum ada peringkat

- Dowel GuidelinesDokumen4 halamanDowel GuidelinesFrank SandorBelum ada peringkat

- 1O Dayton Tech-BalllockDokumen12 halaman1O Dayton Tech-BalllockSIMONEBelum ada peringkat

- Installing Coverings Technical GuideDokumen40 halamanInstalling Coverings Technical GuideSamBelum ada peringkat

- Meter PD Series m16-s1 s3 s5 s6 Po01024Dokumen8 halamanMeter PD Series m16-s1 s3 s5 s6 Po01024gabo mangoBelum ada peringkat

- Build a Greenland Kayak Part 4Dokumen10 halamanBuild a Greenland Kayak Part 4manoel souzaBelum ada peringkat

- SN09924 - Precision Crosscut SledDokumen12 halamanSN09924 - Precision Crosscut SledamelieBelum ada peringkat

- Chess Board Construction: by Trent KellyDokumen7 halamanChess Board Construction: by Trent KellySalvador LuqueBelum ada peringkat

- Yamaha XT 550 J MicroficheDokumen54 halamanYamaha XT 550 J Microfichemp100% (1)

- Utter Chaos InstructionsDokumen9 halamanUtter Chaos InstructionsDavid JannkeBelum ada peringkat

- DME Metric ComponentsDokumen60 halamanDME Metric ComponentsSyuhadah RashidBelum ada peringkat

- Assembly Manual: The Desk You DeserveDokumen4 halamanAssembly Manual: The Desk You DeserveantonioBelum ada peringkat

- Kubota PumpsDokumen19 halamanKubota PumpsВенцислав Венев50% (2)

- Sew and Stow (Sample Pages)Dokumen16 halamanSew and Stow (Sample Pages)Storey Publishing33% (3)

- Wood JointsDokumen10 halamanWood JointsLeslie Joy Anastacio VizcarraBelum ada peringkat

- Handmade Christmas 2015Dokumen180 halamanHandmade Christmas 2015Mara100% (28)

- 00-01 Honda CBR929RR Parts BookDokumen118 halaman00-01 Honda CBR929RR Parts BookelderhomeBelum ada peringkat

- Eco Application GuideDokumen8 halamanEco Application GuidemsbaupartnerBelum ada peringkat

- 5JJ8 2001Dokumen80 halaman5JJ8 2001carru palaBelum ada peringkat

- ATI Robot Tool Changer - 9610-20-1265Dokumen63 halamanATI Robot Tool Changer - 9610-20-1265XIEXUEWUBelum ada peringkat

- ShopNotes No. 122 Full PDFDokumen52 halamanShopNotes No. 122 Full PDFKen Lock100% (3)

- Procedimiento de Cambio de Manto y Concavo - C1540Dokumen28 halamanProcedimiento de Cambio de Manto y Concavo - C1540Cristhian AlcedoBelum ada peringkat

- BS 1804 - Part 2 - 1968 - Parallel Steel Dowel PinsDokumen11 halamanBS 1804 - Part 2 - 1968 - Parallel Steel Dowel PinsPhyu Mar Thein KyawBelum ada peringkat

- Design For Assembly Lecture NotesDokumen56 halamanDesign For Assembly Lecture NotesPethurajBelum ada peringkat

- Cat Transmission 950F PDF - PDFDokumen43 halamanCat Transmission 950F PDF - PDFMehdi ChakrouneBelum ada peringkat

- 9mm BSP Machine Gun: Legal NoteDokumen29 halaman9mm BSP Machine Gun: Legal NoteLeonBackupsBelum ada peringkat

- Carpentry TermsDokumen12 halamanCarpentry TermsReniel Ortega100% (1)

- The Floating Arm TrebuchetDokumen9 halamanThe Floating Arm Trebuchetmarandan85Belum ada peringkat

- Connections in Cross Laminated TimberDokumen59 halamanConnections in Cross Laminated TimberFlip EeyeoreBelum ada peringkat