CFD in Launch Vehicle Applications

Diunggah oleh

aeroalanDeskripsi Asli:

Hak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

CFD in Launch Vehicle Applications

Diunggah oleh

aeroalanHak Cipta:

Format Tersedia

PRACTICE NO.

PD-AP-1311 PAGE 1 OF 6

PREFERRED RELIABILITY PRACTICES

COMPUTATIONAL FLUID DYNAMICS (CFD) IN LAUNCH VEHICLE APPLICATIONS

Practice: Use high-speed, computer-based computational fluid dynamics analytical techniques, verified by test programs to establish propulsion and launch vehicle hardware designs for optimum performance and high reliability. These procedures will validate designs and provide an early assurance of operational viability. Benefits: The use of computer-based computational fluid dynamics methods will accelerate the design process, reduce preliminary development testing, and help create reliable, high-performance designs of space launch vehicles and their components. In addition to design verification and optimization, CFD can be used to simulate anomalies that occur in actual space vehicle tests or flights to more fully understand the anomalies and how to correct them. The result is a more reliable and trouble-free space vehicle and propulsion system. Programs That Certified Usage: Space Shuttle, Space Shuttle Solid Rocket Motor (SRM); Space Shuttle Main Engine (SSME). Center to Contact for More Information: Marshall Space Flight Center (MSFC) Implementation Method: Accurate definition of flow-induced pressure and temperature loads can be achieved long before actual hardware testing through the use of high-speed, computer-based computational fluid dynamics analytical techniques. Designs can be constructed in electronic three-dimensional computer-aided design format, and the flows of fluids and gases can be accurately simulated using CFD techniques. Computer-based simulations of this type can be accomplished so rapidly that designs can be changed in real time even before hardware is fabricated. CFD techniques are being successfully used as diagnostic tools to provide insight into problems with existing rocket engine components and to MARSHALL develop optimum designs of liquid rocket engine pump components such as SPACE FLIGHT impellers, diffuser vanes, and shrouds; turbine components such as turbine CENTER blades, turbine staging, volutes, and turbine wheels; launch vehicle base

PRACTICE NO. PD-AP-1311 PAGE 2 OF 6

COMPUTATIONAL FLUID DYNAMICS (CFD) IN LAUNCH VEHICLE APPLICATIONS

thermal protection configurations; transpiration and conductive cooling methods for rocket nozzles; flow paths within solid rocket motors at various stages of combustion; and launch and reentry pressure and thermal loads on vehicle configurations. The Team Approach to CFD Code and Data Base Development MSFC has found that a very effective way of developing and selecting CFD codes (the computer-based equations that control a CFD analysis) and CFD Data Bases (the empirically derived factors that fit the CFD codes to various specific applications) is to form multiorganizational teams in specialized areas related to propulsion and to other space flight applications. These teams, which are part of a CFD Consortium for Applications in Propulsion Technology (CAPT) are comprised of individuals from within MSFC, other NASA centers, prime and subcontractors, and the academic community, communicate frequently and meet periodically to exchange and disseminate information about the rapidly growing field of computational fluid dynamics as related to rocket propulsion and other related space flight applications. The teams take into account the best available theory on CFD, the most advanced computer computational and graphic capabilities, and the latest test techniques and results of component, subsystem, subscale and full scale rocket engine tests. This information is used to continuously develop and improve the computer-based representation of the temperatures, pressures, and flow patterns (velocities, accelerations, and directions) in space vehicles and their propulsion systems. Implementation of CFD Into the Design of Rocket Engine Pumps The implementation of CFD into the design process for rocket engine pumps has been aided by the activities of a Pump Stage Technology Team (PSTT) which is a part of the NASA/MSFC CFD Consortium for Applications in Propulsion Technology. The teams goals have included the assessment of the accuracy and efficiency of several CFD methodologies and application of the appropriate methodologies to understand and improve the flow inside fuel and oxidizer pumps for liquid propellant rocket engines. As an example of the type of CFD work that has been done under the cognizance of this team, subtle changes in the axial impeller length, blade count, and blade configurations of pump impellers resulted in efficiencies of up to 98 percent. This resulted in head coefficients (which are measures of pump power) increasing from 0.53 to 0.66 in experimental impeller designs. CFD Analysis of Base Flowfields in Clustered Nozzle Configurations As a launch vehicle proceeds up through the atmosphere into space from its near sea-level launch position, the rocket exhaust plumes expand to a point where a plume reverse flow is encountered. Where multiple nozzles are used, the closed impingement of the exhaust plumes

PRACTICE NO. PD-AP-1311 PAGE 3 OF 6

COMPUTATIONAL FLUID DYNAMICS (CFD) IN LAUNCH VEHICLE APPLICATIONS

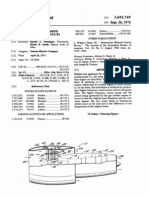

can cause a reverse jet. The reverse jet impinges on interior base surface areas, components, and base shields causing heating, contamination, and/or possible combustion in the launch vehicle base areas. Computational fluid dynamics has proven to be a useful tool in predicting the recirculating exhaust base flow patterns encountered in various launch vehicle configurations, and these patterns can be used as an input to the design and development of reliable vehicle configurations and thermal or pressure protection schemes. Figure 1 is a typical output from a CFD analysis which shows velocity vectors indicating the flow patterns that are generated at high altitude (approximately 92,000 feet above sea level) when a launch vehicle has four exhaust nozzles. With the knowledge of the pressure, temperature, and flow profiles in the base region provided by a CFD analysis, components and insulation systems can be designed to withstand environments in the base region or insulated to protect them against the potentially hostile environment that occurs due to exhaust recirculation at high altitude.

Figure 1. Velocity Vectors Indicating Flow Patterns for a Four-Nozzle Vehicle Base Configuration Turbine Improvements Using CFD Computational fluid dynamics techniques are being used in the advancement of turbine aerodynamic design techniques as well as the development of a understanding and characterization of the unsteady aerodynamic environments in existing rocket engine turbines. The CAPT Turbine Technology Team is addressing several areas of CFD application to existing and future liquid rocket engines. The techniques reduce developmental risk, decrease the amount of intermediate testing, improve performance and durability, and reduce cost. In one

PRACTICE NO. PD-AP-1311 PAGE 4 OF 6

COMPUTATIONAL FLUID DYNAMICS (CFD) IN LAUNCH VEHICLE APPLICATIONS

turbine improvement effort, gas turning angle in the turbine blades was increased from the traditional design limit of approximately 140 degrees to 160 degrees. The CFD analysis showed that this change, coupled with other minor improvements, would increase turbine efficiency by almost 10 percent and reduce the required number of turbine blades by approximately one half. Maximum blade mach number was decreased dramatically from the 1.32 of the original design to 0.87 for the new design. The new configuration employed a single stage turbine rather than an originally planned two stage configuration. CFD has also proven to be a useful tool in the evaluation of secondary losses and turbine blade tip loss control mechanisms such as endwall fences, blade fences, tip grooves, tip cavities, and mini-shrouds. This technique is also useful in the simulation and design of inlet and outlet turbine volutes. Cold flow testing of reduced scale and full scale turbines has verified many of the CFD simulations. Flow Fields, Flow Separation, Film Coolants, and Heat Transfer in Rocket Engine Combustors Computational fluid dynamics analyses have been successfully applied in areas related to the prediction and simulation of combustion flow behavior and heat transfer to the internal walls of rocket engine injectors, combustion chambers, and nozzles. These analyses have been used to optimize nozzle entrance geometries, evaluate new step nozzle exit configurations that adapt to altitude changes, determine pressure and temperature profiles in rocket engine chambers and nozzles, and to study the effects of coolant flows in liquid rocket engine chambers on internal wall temperatures. These analytical procedures have helped to evaluate anomalies discovered in actual engine firings and to design reliable combustion chamber, nozzle, and coolant arrangements that result in high thrust coefficients under various atmospheric and space conditions. The CAPT Combustion Devices Technology Team has been instrumental in many of these investigations. Computational fluid dynamics simulations have also been useful in determining pressure, heating, and insulation requirements for launch vehicles during liftoff, ascent, and reentry into the atmosphere. Technical Rationale: NASA/MSFC has sponsored the CFD Consortium for Applications in Propulsion Technology since the early 1980s. Symposia have been held for the past twelve years in which participants from MSFC, other centers, prime contractors, laboratories, other agencies, and the academic community have exchanged information in the development and application of CFD analytical techniques related to rocket engine propulsion systems. MSFC has also been involved in the other aerodynamic and fluid dynamics applications of CFD. Computational fluid dynamics is a

PRACTICE NO. PD-AP-1311 PAGE 5 OF 6

COMPUTATIONAL FLUID DYNAMICS (CFD) IN LAUNCH VEHICLE APPLICATIONS

discipline that has come of age in the concurrent engineering process that results in the design, development, and flight of highly reliable and cost effective launch vehicle systems. Impact of Nonpractice: Failure to thoroughly analyze the pressures, temperatures, and flow rates of gases and fluids in propulsion systems using CFD techniques prior to design and manufacture could result in inadequate strength, thermal protection, and operational control of liquid rocket propulsion systems and related launch vehicles and components. The ultimate result of inadequate designs could be excessive redesign and testing, increased costs, and the potential for launch vehicle, engine, system, or component failure. Other Related Practices: PT-TE-1427, Rocket Engine Technology Test Bed Practice. References: 1. Proceedings of Workshop for Computational Fluid Dynamic (CFD) Applications in Rocket Propulsion, April 19-21, 1994, Marshall Space Flight Center, NASA. Overview of the NASA/MSFC CFD Consortium for Applications in Propulsion Technology, McConnaughey, P.K. and L.A. Schutzenhofer, AIAA, 92-3219, AIAA/SAE/ASME/ASEE 28th Joint Propulsion Conference, July 6-8, 1992, Nashville, TN. Computational Fluid Dynamics Analysis for the Reduction of Impeller Discharge Flow Distortion, R. Garcia, et al, 32nd AIAA Aerospace Sciences Meeting, January 10-13, 1994, Reno, NV. Numerical Analysis of Base Flowfield at High Altitude for a Four-Engine Clustered Nozzle Configuration, T.S. Wang, 29th AIAA Joint Propulsion Conference, June 28-30, 1993, Monterey, CA. Analytical Investigation of the Unsteady Aerodynamic Environments in Space Shuttle Main Engine (SSME) Turbines, Lisa W. Griffin, et al, May 24-27, 1993, ASME, New York, NY. Advancement of Turbine Aerodynamic Design Techniques, Lisa W. Griffin, et al, May 24-27, 1993, ASME, New York, NY.

2.

3.

4.

5.

6.

PRACTICE NO. PD-AP-1311 PAGE 6 OF 6

COMPUTATIONAL FLUID DYNAMICS (CFD) IN LAUNCH VEHICLE APPLICATIONS

7. Advanced Technology Low Cost Engine (ATLCE) 50K Testbed Combustion Chamber Film Coolant Parametrics, Joe Ruf, November 5, 1993, MSFC, AL. Unified Navier-Stokes Flowfield and Performance Analysis of Liquid Rocket Engines, T.S. Wang, et al, Journal of Propulsion and Power, September 1993, AIAA, New York, NY. Numerical Analysis of the Hot-Gas-Side and Coolant-Side Heat Transfer for Liquid Rocket Engine Combustors, T.S. Wang, et al, 28th AIAA Joint Propulsion Conference, July 6-8, 1992, Nashville, TN. Numerical Study of the Transient Nozzle Flow Separation of Liquid Rocket Engines, T.S. Wang, CFD Journal, October 1992, MSFC, AL.

8.

9.

10.

Anda mungkin juga menyukai

- Parametric Analysis of Aerodynamic Characteristics of Launch Vehicles With Strap-On BoostersDokumen12 halamanParametric Analysis of Aerodynamic Characteristics of Launch Vehicles With Strap-On Boostersali68fat64Belum ada peringkat

- Research ProposalDokumen9 halamanResearch ProposalSrinivasan Viswanathan100% (1)

- Eects of Aircraft Integration On Compact Nacelle AerodynamicsDokumen35 halamanEects of Aircraft Integration On Compact Nacelle AerodynamicsHao LiuBelum ada peringkat

- GT2018 76880Dokumen13 halamanGT2018 76880DeckrunBelum ada peringkat

- New Report 11Dokumen45 halamanNew Report 11sangeethaBelum ada peringkat

- AHS2011 HECC Design Final PDFDokumen15 halamanAHS2011 HECC Design Final PDFKarl GlorstadBelum ada peringkat

- A Practical Design Approach To Improve TheDokumen16 halamanA Practical Design Approach To Improve Thesalty soldier mainBelum ada peringkat

- Von Karman Institute For Fluid Dynamics: Arts@vki - Ac.beDokumen4 halamanVon Karman Institute For Fluid Dynamics: Arts@vki - Ac.beMarcos A SantosBelum ada peringkat

- Application of Roms To Aeroengines Health Monitoring: April 2019Dokumen20 halamanApplication of Roms To Aeroengines Health Monitoring: April 2019tadele10Belum ada peringkat

- Optimized Location of Air-Conditioning Unit Inside Office Room To Obtain Good Thermal ComfortDokumen6 halamanOptimized Location of Air-Conditioning Unit Inside Office Room To Obtain Good Thermal ComfortKVSRIT Dept. of MEBelum ada peringkat

- Welcome To International Journal of Engineering Research and Development (IJERD)Dokumen5 halamanWelcome To International Journal of Engineering Research and Development (IJERD)IJERDBelum ada peringkat

- Literature Review On CFD Application For Helical Coil Heat Exchanger DesignDokumen5 halamanLiterature Review On CFD Application For Helical Coil Heat Exchanger DesignSantosh SanchetiBelum ada peringkat

- C.R. Siqueira - 3d Transient Simulation of An Intake Manifold CFD - SAE 2006-01-2633Dokumen7 halamanC.R. Siqueira - 3d Transient Simulation of An Intake Manifold CFD - SAE 2006-01-2633Thomas MouraBelum ada peringkat

- Aero ElasticityDokumen19 halamanAero ElasticityswaroopkumarnagnooriBelum ada peringkat

- Openfoam Thesis CombustionDokumen5 halamanOpenfoam Thesis Combustioncatherineaguirresaltlakecity100% (2)

- Research Papers CFDDokumen6 halamanResearch Papers CFDh03318kj100% (1)

- Current Hypersonic Research in The USA: Dr. Robert BakosDokumen26 halamanCurrent Hypersonic Research in The USA: Dr. Robert BakosChema GomezBelum ada peringkat

- CFD Simulation of Solar Loading in Car: Ravi. DDokumen6 halamanCFD Simulation of Solar Loading in Car: Ravi. DTJPRC PublicationsBelum ada peringkat

- CAD-Based Parametric Cross-Section Designer For Gas Turbine Engine MDO ApplicationsDokumen10 halamanCAD-Based Parametric Cross-Section Designer For Gas Turbine Engine MDO ApplicationsValiyakattel NilsBelum ada peringkat

- Turbomachinery CFD On Parallel ComputersDokumen20 halamanTurbomachinery CFD On Parallel ComputersYoseth Jose Vasquez ParraBelum ada peringkat

- Design and Performance Validation of A Fuel Cell Unmanned Aerial VehicleDokumen20 halamanDesign and Performance Validation of A Fuel Cell Unmanned Aerial VehiclepatrickNX9420Belum ada peringkat

- Transonic Axial-Flow Blade Shape Optimization Using Evolutionary Algorithm and Three-Dimensional Navier-Stokes SolverDokumen11 halamanTransonic Axial-Flow Blade Shape Optimization Using Evolutionary Algorithm and Three-Dimensional Navier-Stokes SolverEslam NagyBelum ada peringkat

- Axial Compressor Optimization Method: IOP Conference Series: Materials Science and EngineeringDokumen10 halamanAxial Compressor Optimization Method: IOP Conference Series: Materials Science and EngineeringSami AhmadBelum ada peringkat

- Encit 2018Dokumen11 halamanEncit 2018Cesar CelisBelum ada peringkat

- Design and Analysis of Annular Combustion Chamber For A Low Bypass Turbofan Engine in A Jet Trainer AircraftDokumen12 halamanDesign and Analysis of Annular Combustion Chamber For A Low Bypass Turbofan Engine in A Jet Trainer AircraftviniciustasilBelum ada peringkat

- Compressor Map Prediction Tool: IOP Conference Series: Materials Science and EngineeringDokumen11 halamanCompressor Map Prediction Tool: IOP Conference Series: Materials Science and Engineeringthlim19078656Belum ada peringkat

- Aerodynamics Overview of The Ground Transportation Systems (GTS) Project For Heavy Vehicle Drag Reduction PDFDokumen18 halamanAerodynamics Overview of The Ground Transportation Systems (GTS) Project For Heavy Vehicle Drag Reduction PDFMarcusHuynh88Belum ada peringkat

- Engine CalibrationDokumen8 halamanEngine CalibrationbiopoweredBelum ada peringkat

- Design of An Advanced Marine WaterjetDokumen9 halamanDesign of An Advanced Marine Waterjetgnd100Belum ada peringkat

- Flow and Thermal Analysis On The FUMEX: 2) Fumex & Domex Exhaust FansDokumen5 halamanFlow and Thermal Analysis On The FUMEX: 2) Fumex & Domex Exhaust FanslukhmanBelum ada peringkat

- 2005-Guo, Zenglin-App of CFD For Rotating machinery-HD, HS Bearings - SFDDokumen7 halaman2005-Guo, Zenglin-App of CFD For Rotating machinery-HD, HS Bearings - SFDAlex CooperBelum ada peringkat

- Recent Examples On Design Aerodynamics For Transport AircraftDokumen8 halamanRecent Examples On Design Aerodynamics For Transport AircraftewiontkoBelum ada peringkat

- Prototype Race CarDokumen9 halamanPrototype Race CarznamBelum ada peringkat

- Twinkle Sharma Resume PDFDokumen2 halamanTwinkle Sharma Resume PDFarchit gargBelum ada peringkat

- 1 s2.0 S2212540X16300025 MainDokumen12 halaman1 s2.0 S2212540X16300025 MainDƯƠNG CẨM TOÀNBelum ada peringkat

- Aermacchi Landing GearDokumen10 halamanAermacchi Landing GearRahman Ehvan100% (1)

- Airfoil Shape OptimizationDokumen1 halamanAirfoil Shape OptimizationCris RoppaBelum ada peringkat

- 3-D P D A U C CFDDokumen31 halaman3-D P D A U C CFDFlorin NiteBelum ada peringkat

- CFD JD SampleDokumen5 halamanCFD JD SampleSariya VBelum ada peringkat

- Vectis Undeunderrhood AirflowDokumen14 halamanVectis Undeunderrhood AirflowdineshBelum ada peringkat

- Tb2-2-Bi - Performance Investigation of Ducted Aerodynamic PropulsorsDokumen11 halamanTb2-2-Bi - Performance Investigation of Ducted Aerodynamic PropulsorsklopakBelum ada peringkat

- Numerical Simulation of Turbulent Flow Over The Fuselage of A Small-Sized High-Speed AircraftDokumen13 halamanNumerical Simulation of Turbulent Flow Over The Fuselage of A Small-Sized High-Speed AircraftAditya R BharadwajBelum ada peringkat

- Modern Solutions For Ground Vibration Testing of Large AircraftDokumen8 halamanModern Solutions For Ground Vibration Testing of Large Aircraftuamiranda3518Belum ada peringkat

- Scramjet Combustor DevelopmentDokumen20 halamanScramjet Combustor DevelopmentKanimozhivendhan VendhanBelum ada peringkat

- 30 14 00805 JinHyukKIM - Jan 2015 PDFDokumen14 halaman30 14 00805 JinHyukKIM - Jan 2015 PDFMohamed Amine AchouriBelum ada peringkat

- A Numerical Analysis For The Cooling Module Related To Automobile Air Conditioning SystemDokumen10 halamanA Numerical Analysis For The Cooling Module Related To Automobile Air Conditioning SystematosayBelum ada peringkat

- IC CFD AnalysisDokumen6 halamanIC CFD Analysispuyang48Belum ada peringkat

- HP Steam Turbine StageDokumen8 halamanHP Steam Turbine StageTarun ChoudharyBelum ada peringkat

- Conceptual Design Optimization of Francis TurbinesDokumen11 halamanConceptual Design Optimization of Francis TurbinesJun GWan ParkBelum ada peringkat

- ECOS 2011 Pariotis Kosmadakis RakopoulosDokumen18 halamanECOS 2011 Pariotis Kosmadakis RakopoulosPariotis EfthimiosBelum ada peringkat

- Chapter Two 2.0 Literature ReviewDokumen5 halamanChapter Two 2.0 Literature ReviewbayorBelum ada peringkat

- Axial Flow Turbine Aerodynamic Shape DesignoptimizationDokumen11 halamanAxial Flow Turbine Aerodynamic Shape Designoptimizationntik 23Belum ada peringkat

- CFD in IndiaDokumen14 halamanCFD in IndianileshraneBelum ada peringkat

- Aerospace 05 00102Dokumen19 halamanAerospace 05 00102PatriceBelum ada peringkat

- 035 TT015Dokumen4 halaman035 TT015Behailu FelekeBelum ada peringkat

- Resumen Tren MotrizDokumen8 halamanResumen Tren MotrizHéctor Reydavid GallardoBelum ada peringkat

- FulltextDokumen22 halamanFulltextChristina Christina ChristinaBelum ada peringkat

- Commercial Airplane Design PrinciplesDari EverandCommercial Airplane Design PrinciplesPenilaian: 3 dari 5 bintang3/5 (2)

- Marine Rudders and Control Surfaces: Principles, Data, Design and ApplicationsDari EverandMarine Rudders and Control Surfaces: Principles, Data, Design and ApplicationsPenilaian: 4.5 dari 5 bintang4.5/5 (3)

- ASIASAT 3S - Channel InformationDokumen10 halamanASIASAT 3S - Channel InformationaeroalanBelum ada peringkat

- FAA Contract Tower Closure ListDokumen4 halamanFAA Contract Tower Closure ListHonolulu Star-AdvertiserBelum ada peringkat

- A320 Family Performance Retention An Fuel SavingsDokumen59 halamanA320 Family Performance Retention An Fuel SavingsHeni Guedri100% (4)

- FAA Contract Tower Closure ListDokumen4 halamanFAA Contract Tower Closure ListHonolulu Star-AdvertiserBelum ada peringkat

- Pressure Vessel Design in ANSYSDokumen5 halamanPressure Vessel Design in ANSYSRohan KarandeBelum ada peringkat

- CPWG12 IP10 En-Route Diversion AirportsDokumen4 halamanCPWG12 IP10 En-Route Diversion AirportsaeroalanBelum ada peringkat

- CFRPDokumen4 halamanCFRPaeroalanBelum ada peringkat

- RFP 737-400Dokumen11 halamanRFP 737-400aeroalanBelum ada peringkat

- ANSYS CFX Solver TheoryDokumen312 halamanANSYS CFX Solver Theoryiklln6Belum ada peringkat

- Design of Concrete Airport PavementDokumen64 halamanDesign of Concrete Airport Pavementaeroalan100% (4)

- G150 SpecificationsDokumen2 halamanG150 SpecificationsaeroalanBelum ada peringkat

- US3693749Dokumen6 halamanUS3693749aeroalanBelum ada peringkat

- RFP 737-400Dokumen11 halamanRFP 737-400aeroalanBelum ada peringkat

- RFP 737-400Dokumen11 halamanRFP 737-400aeroalanBelum ada peringkat

- PART 5 AirworthinessDokumen58 halamanPART 5 AirworthinessOrlando BelandresBelum ada peringkat

- 10) Diseño Pavimentos en AeroportuariosDokumen104 halaman10) Diseño Pavimentos en AeroportuariosMaxJanampaValleBelum ada peringkat

- vEZY A320 Family Operations ManualDokumen219 halamanvEZY A320 Family Operations ManualhuxoP3DBelum ada peringkat

- 1E5 APL1 Glass Structures VUDokumen10 halaman1E5 APL1 Glass Structures VUAnonymous AV90SAXa5VBelum ada peringkat

- CNX VTCCDokumen40 halamanCNX VTCCaoonjaiBelum ada peringkat

- Direct Operating Cost AircraftDokumen44 halamanDirect Operating Cost AircraftusakalambaBelum ada peringkat

- Mr. KLM (A) : Jacob Veldhuyzen: ESMT Case StudyDokumen4 halamanMr. KLM (A) : Jacob Veldhuyzen: ESMT Case StudyShri VeemaBelum ada peringkat

- Work Sheets in Science 9 Q4 WEEK 1 and 2Dokumen7 halamanWork Sheets in Science 9 Q4 WEEK 1 and 2Je-an CautibarBelum ada peringkat

- Appraisal Bell UH 1H SN 73 21783Dokumen46 halamanAppraisal Bell UH 1H SN 73 21783Carl Radle100% (1)

- Temperature Effect On The Mechanical Behavior of Acrylic Polymers Under Quasi-Static and Dynamic LoadingDokumen6 halamanTemperature Effect On The Mechanical Behavior of Acrylic Polymers Under Quasi-Static and Dynamic LoadingXimena RuizBelum ada peringkat

- Cheyenne Iiia Spec - PerfDokumen2 halamanCheyenne Iiia Spec - PerfJuniorSousaBelum ada peringkat

- Motivation Letter: Dear Sir/MadamDokumen3 halamanMotivation Letter: Dear Sir/MadamFahad Amin100% (1)

- IOSA Audit Handbook Edition 5 Révision 0Dokumen32 halamanIOSA Audit Handbook Edition 5 Révision 0Amadou OuorouBelum ada peringkat

- Axial Flow Compressor Design: S J GallimoreDokumen13 halamanAxial Flow Compressor Design: S J GallimoreshaowyBelum ada peringkat

- Insat 3d BrochureDokumen6 halamanInsat 3d BrochureNambi HarishBelum ada peringkat

- Manual de Servicio MK4-5 (Parte 2) PDFDokumen117 halamanManual de Servicio MK4-5 (Parte 2) PDFJosé SchumanBelum ada peringkat

- Boundary LayerDokumen29 halamanBoundary LayerMdnor RahimBelum ada peringkat

- Radio NavvDokumen18 halamanRadio NavvSwapnil KarkiBelum ada peringkat

- Roughness Body Reynolds-Number: The Effect of Surface of The High FlowDokumen11 halamanRoughness Body Reynolds-Number: The Effect of Surface of The High FlowLuizBelum ada peringkat

- PHNLDokumen18 halamanPHNLakash0% (1)

- MMG ModelDokumen6 halamanMMG ModelAji Brahma NugrohoBelum ada peringkat

- Drilling MachineDokumen13 halamanDrilling MachineArabinda ParidaBelum ada peringkat

- Aircraft Structural IntegrityDokumen3 halamanAircraft Structural IntegrityCarlos BustamanteBelum ada peringkat

- Untitled Document 8Dokumen1 halamanUntitled Document 8api-541044613Belum ada peringkat

- Ultimate 707 Guide, by David HingtgenDokumen19 halamanUltimate 707 Guide, by David HingtgencaptainpetermBelum ada peringkat

- Calspan Transonic Wind Tunnel LinecardDokumen2 halamanCalspan Transonic Wind Tunnel LinecardfuccioniBelum ada peringkat

- Refresh GuideDokumen42 halamanRefresh Guideamiltonmorillas100% (3)

- MC GILL UNIVERSITY - 2014-2015 Undergraduate Ecalendar Fall EditionDokumen14 halamanMC GILL UNIVERSITY - 2014-2015 Undergraduate Ecalendar Fall EditionxevniBelum ada peringkat

- CSD Drone Databook WebDokumen353 halamanCSD Drone Databook Webkojener163100% (6)

- Sailplane and Gliding - Vo 51 No.1 - Feb-March 2000 WebDokumen68 halamanSailplane and Gliding - Vo 51 No.1 - Feb-March 2000 Weblaerciofilho100% (1)