Piping Specifications - Sn10 1 Pipe: Doc No: JKPM/DOC/M/001 Page 1 of 44 R0

Diunggah oleh

josphinvalarDeskripsi Asli:

Judul Asli

Hak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

Piping Specifications - Sn10 1 Pipe: Doc No: JKPM/DOC/M/001 Page 1 of 44 R0

Diunggah oleh

josphinvalarHak Cipta:

Format Tersedia

Doc No: JKPM/DOC/M/001

Page 1 of 44

R0

PIPING SPECIFICATIONS SN10 1

1.1 1.1.1

PIPE

Material Grade Specification : : Austenitic stainless steel pipes - Grade 304 ASTM A 312 TP 304/SS 2333 up to 200 NB ASTM A 358 Class II for 250 NB and above.

1.1.2 1.2 1.3

Process of manufacture : Dimensions Wall Thickness : :

ERW DIN 2448 / ANSI B 36.19 / ISO 4200 As Per Pressure Rating Standards Also refer Table

1.4 1.5 1.6

Tolerances End Preparation Type of weld

: : :

ASTM A 312/ ISO 1127 Bevelled end shall be square to axis Use Butt-weld joints for all sizes

1.7

General All pipes shall be supplied in random lengths of 6 m. All pipes shall be supplied with ends protected by plastic caps.

2 2.1 2.1.1 2.1.2 2.1.3 2.2 2.3

PIPE FITTINGS Type of Fittings Elbows : Reducers : Tee : Material Grade : Specification : Long radius (1.5 * Diameter) Concentric/Eccentric Equal/Unequal Wrought Austenitic stainless steel Grade 304/SS 2333 ASTM A 403 WPW 304/SS 2333

Doc No: JKPM/DOC/M/001

Page 2 of 44

R0

2.4 2.5

Dimensions & end preparation Fittings (butt) : As per ANSI B 16.9/MSS SP-43/ISO 5251 Fittings (screwed) : As per ANSI B 16.11/ISO 5251 Fittings (socket) : As per ANSI B16.11/ISO 5251

Wall Thickness : As Per Pressure Rating Standards Also refer Table

2.6 2.7

Tolerances

ASTM A 312/ ISO 1127

Wall Thickness Table.

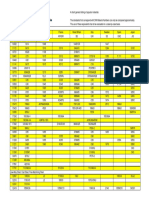

OD Pipe DIN EN10220 ( DIN 2448 ) ( ISO 4200 ) 1.6 1.6 1.6 1.6 1.6 1.6 1.6 1.6 1.6 2 2 2 2 2 2.6 2.6 3.2 4 5 5 6.3 8 8 10 Elbow DIN 2605 Cap DIN 2617 Reducer DIN 2616 Tee DIN 2615

Nominal Size

10 15 20 25 32 40 50 65 80 100 125 150 200 250 300 350 400 500 600 700 800 900 1000 1200

17.2 21.3 26.9 33.7 42.4 48.3 60.3 76.1 88.9 114.3 139.7 168.3 219.1 273 323.9 355.6 406.4 508 610 711 813 914 1016 1220

2 2 2 2 2 2 2 2.3 2.3 2.6 2.6 2.6 2.9 2.9 3.0 3.2 4 6.3 6.3 7.1 8 10 10 12.5

1.6 1.6 1.6 1.6 1.6 1.6 1.6 1.6 1.6 2 2 2 2 2 2.6 2.6 3.2 4 5 5 6.3 8 8 10

1.6 1.6 1.6 2 2 2 2 2.3 2.3 2.6 2.6 2.6 2.9 2.9 2.9 3.2 3.2 4 5 5 8 10 10 12.5

1.6 1.6 1.6 2 2 2 2 2.3 2.3 2.6 2.6 2.6 4.5 5 5.6 5.6 6.3 11 12.5 12.5 12.5 12.5 -

PIPING SPECIFICATIONS SN16 1

1.1 1.1.1

PIPE

Material Grade Specification : : Austenitic stainless steel pipes - Grade 304 ASTM A 312 TP 304/SS 2333 up to 200 NB

Doc No: JKPM/DOC/M/001

Page 3 of 44

R0

ASTM A 358 Class II for 250 NB and above. 1.1.2 1.2 1.3 Process of manufacture : Dimensions Wall Thickness : : ERW DIN 2448 / ANSI B 36.19 / ISO 4200 As Per Pressure Rating Standards Also refer Table 1.4 1.5 1.6 Tolerances End Preparation Type of weld : : : ASTM A 312/ ISO 1127 Bevelled end shall be square to axis Use Butt-weld joints for all sizes

1.7

General All pipes shall be supplied in random lengths of 6 m. All pipes shall be supplied with ends protected by plastic caps.

2 2.1 2.1.1 2.1.2 2.1.3 2.2 2.3

PIPE FITTINGS Type of Fittings Elbows : Reducers : Tee : Material Grade : Specification : Long radius (1.5 * Diameter) Concentric/Eccentric Equal/Unequal Wrought Austenitic stainless steel Grade 304/SS 2333 ASTM A 403 WPW 304/SS 2333

Doc No: JKPM/DOC/M/001

Page 4 of 44

R0

2.4 2.5

Dimensions & end preparation Fittings (butt) : As per ANSI B 16.9/MSS SP-43/ISO 5251 Fittings (screwed) : As per ANSI B 16.11/ISO 5251 Fittings (socket) : As per ANSI B16.11/ISO 5251

Wall Thickness : As Per Pressure Rating Standards Also refer Table 2.7

2.6 2.7

Tolerances

ASTM A 312/ ISO 1127

Wall Thickness Table.

OD Pipe DIN EN 10220 ( DIN 2448 ) ( ISO 4200 ) 1.6 1.6 1.6 1.6 1.6 1.6 1.6 1.6 1.6 2 2 2 2 3.2 4 4 5 6.3 8 8 10 10 12.5 Elbow DIN 2605 Cap DIN 2617 Reducer DIN 2616 Tee DIN 2615

Nominal Size

10 15 20 25 32 40 50 65 80 100 125 150 200 250 300 350 400 500 600 700 800 900 1000 1200

17.2 21.3 26.9 33.7 42.4 48.3 60.3 76.1 88.9 114.3 139.7 168.3 219.1 273 323.9 355.6 406.4 508 610 711 813 914 1016 1220

2 2 2 2 2 2 2 2.3 2.3 2.6 2.6 2.6 4.5 5 5.6 5.6 6.3 6 8 8 12.5 -

1.6 1.6 1.6 1.6 1.6 1.6 1.6 1.6 1.6 2 2 2 2 3.2 4 4 5 6.3 8 8 10 10 12.5 -

1.6 1.6 1.6 2 2 2 2 2.3 2.3 2.6 2.6 2.6 2.9 3.0 4.0 5.6 6.3 6.3 8.0 8.0 8.0 12.5 12.5 -

1.6 1.6 1.6 2 2 2 2 2.3 2.3 2.6 4 4 6.3 6.3 7.1 8 8.8 11 12.5 -

PIPING SPECIFICATIONS SN25 1

1.1 1.1.1

PIPE

Material Grade Specification : : Austenitic stainless steel pipes - Grade 304 ASTM A 312 TP 304/SS 2333 up to 200 NB

Doc No: JKPM/DOC/M/001

Page 5 of 44

R0

ASTM A 358 Class II for 250 NB and above. 1.1.2 1.2 1.3 Process of manufacture : Dimensions Wall Thickness : : ERW DIN 2448 / ANSI B 36.19 / ISO 4200 As Per Pressure Rating Standards Also refer Table 1.4 1.5 1.6 Tolerances End Preparation Type of weld : : : ASTM A 312/ ISO 1127 Bevelled end shall be square to axis Use Butt-weld joints for all sizes

1.7

General All pipes shall be supplied in random lengths of 6 m. All pipes shall be supplied with ends protected by plastic caps.

2 2.1 2.1.1 2.1.2 2.1.3 2.2 2.3

PIPE FITTINGS Type of Fittings Elbows : Reducers : Tee : Material Grade : Specification : Long radius (1.5 * Diameter) Concentric/Eccentric Equal/Unequal Wrought Austenitic stainless steel Grade 304/SS 2333 ASTM A 403 WPW 304/SS 2333

Doc No: JKPM/DOC/M/001

Page 6 of 44

R0

2.4 2.5

Dimensions & end preparation Fittings (butt) : As per ANSI B 16.9/MSS SP-43/ISO 5251 Fittings (screwed) : As per ANSI B 16.11/ISO 5251 Fittings (socket) : As per ANSI B16.11/ISO 5251

Wall Thickness : As Per Pressure Rating Standards Also refer Table 2.7

2.6 2.7

Tolerances

ASTM A 312/ ISO 1127

Wall Thickness Table.

OD Pipe DIN EN 10220 ( DIN 2448 ) ( ISO 4200 ) 1.6 1.6 1.6 1.6 1.6 1.6 1.6 1.6 1.6 2 2 2.6 3.2 5 6.3 3.2 8 10 12.5 Elbow DIN 2605 Cap DIN 2617 Reducer DIN 2616 Tee DIN 2615

Nominal Size

10 15 20 25 32 40 50 65 80 100 125 150 200 250 300 350 400 500 600 700 800 900 1000 1200

17.2 21.3 26.9 33.7 42.4 48.3 60.3 76.1 88.9 114.3 139.7 168.3 219.1 273 323.9 355.6 406.4 508 610 711 813 914 1016 1220

2 2 2 2 2 2 2 2.3 2.3 2.6 4 4 4 5 6 8 8 -

1.6 1.6 1.6 1.6 1.6 1.6 1.6 1.6 1.6 2 2 2.6 3.2 5 6.3 3.2 8 10 12.5

1.6 1.6 1.6 2 2 2 2 2.3 2.3 2.6 2.6 4 4.5 5 7.1 8 8.8 11 12.5

1.6 1.6 1.6 2 2 2 2 2.9 3.2 3.6 4 5 6.3 8.8 10 11 12.5 -

Doc No: JKPM/DOC/M/001

Page 7 of 44

R0

PIPING SPECIFICATIONS SNL10 1 PIPE

1.1 1.1.1

Material Grade Specification

: :

Austenitic stainless steel pipes - Grade 304L ASTM A 312 TP 304L/SS 2352 up to 200NB ASTM A 358 Class II for 250 NB and above.

1.1.2 1.2 1.3

Process of manufacture : Dimensions Wall Thickness : :

ERW DIN 2448 / ANSI B 36.19 / ISO 4200 As Per Pressure Rating Standards Also refer Table

1.4 1.5 1.6

Tolerances End Preparation Type of weld

: : :

ASTM A 312/ ISO 1127 Bevelled end shall be square to axis Use Butt-weld joints for all sizes

1.7

General All pipes shall be supplied in random lengths of 6 m.

caps. All pipes shall be supplied with ends protected by plastic

2 2.1 2.1.1 2.1.2 2.1.3

2.2 2.3

PIPE FITTINGS Type of Fittings Elbows Reducers Tee

Material Grade Specification

: : :

: :

Long radius (1.5 * Diameter) Concentric/Eccentric Equal/Unequal

Wrought Austenitic stainless steel Grade 304L/SS 2352 ASTM A 403 WPW 304L/SS 2352

2.4

Dimensions & end preparation

Doc No: JKPM/DOC/M/001

Page 8 of 44

R0

2.5 2.6

Fittings (butt) Fittings (screwed) Fittings (socket)

Wall Thickness Tolerances

: : :

: :

As per ANSI B 16.9/MSS SP-43/ISO 5251 As per ANSI B 16.11/ISO 5251 As per ANSI B16.11/ISO 5251

As Per Pressure Rating Standards Also refer Table ASTM A 312/ ISO 1127

2.7 Wall Thickness Table

Nominal Size OD Pipe DIN EN10220 ( DIN 2448 ) ( ISO 4200 ) 1.6 1.6 1.6 1.6 1.6 1.6 1.6 1.6 1.6 2 2 2 2 2 2.6 2.6 3.2 4 5 5 6.3 8 8 10 Elbow DIN 2605 Cap DIN 2617 Reducer DIN 2616 Tee DIN 2615

10 15 20 25 32 40 50 65 80 100 125 150 200 250 300 350 400 500 600 700 800 900 1000 1200

17.2 21.3 26.9 33.7 42.4 48.3 60.3 76.1 88.9 114.3 139.7 168.3 219.1 273 323.9 355.6 406.4 508 610 711 813 914 1016 1220

2 2 2 2 2 2 2 2.3 2.3 2.6 2.6 2.6 2.9 2.9 3.0 3.2 4 6.3 6.3 7.1 8 10 10 12.5

1.6 1.6 1.6 1.6 1.6 1.6 1.6 1.6 1.6 2 2 2 2 2 2.6 2.6 3.2 4 5 5 6.3 8 8 10

1.6 1.6 1.6 2 2 2 2 2.3 2.3 2.6 2.6 2.6 2.9 2.9 2.9 3.2 3.2 4 5 5 8 10 10 12.5

1.6 1.6 1.6 2 2 2 2 2.3 2.3 2.6 2.6 2.6 4.5 5 5.6 5.6 6.3 11 12.5 12.5 12.5 12.5 -

Doc No: JKPM/DOC/M/001

Page 9 of 44

R0

PIPING SPECIFICATIONS SNL16 1 PIPE

1.1 1.1.1

Material Grade Specification

: :

Austenitic stainless steel pipes - Grade 304L ASTM A 312 TP 304L/SS 2352 up to 200NB ASTM A 358 Class II for 250 NB and above.

1.1.2 1.2 1.3

Process of manufacture : Dimensions Wall Thickness : :

ERW DIN 2448 / ANSI B 36.19 / ISO 4200 As Per Pressure Rating Standards Also refer Table

1.4 1.5 1.6

Tolerances End Preparation Type of weld

: : :

ASTM A 312/ ISO 1127 Bevelled end shall be square to axis Use Butt-weld joints for all sizes

1.7

General All pipes shall be supplied in random lengths of 6 m.

caps. All pipes shall be supplied with ends protected by plastic

2 2.1 2.1.1 2.1.2 2.1.3

2.2 2.3

PIPE FITTINGS Type of Fittings Elbows Reducers Tee

Material Grade Specification

: : :

: :

Long radius (1.5 * Diameter) Concentric/Eccentric Equal/Unequal

Wrought Austenitic stainless steel Grade 304L/SS 2352 ASTM A 403 WPW 304L/SS 2352

2.4

Dimensions & end preparation

Doc No: JKPM/DOC/M/001

Page 10 of 44

R0

2.5 2.6

Fittings (butt) Fittings (screwed) Fittings (socket)

Wall Thickness Tolerances

: : :

: :

As per ANSI B 16.9/MSS SP-43/ISO 5251 As per ANSI B 16.11/ISO 5251 As per ANSI B16.11/ISO 5251

As Per Pressure Rating Standards Also refer Table ASTM A 312/ ISO 1127

2.7 Wall Thickness Table

Nominal Size OD Pipe DIN EN 10220 ( DIN 2448 ) ( ISO 4200 ) 1.6 1.6 1.6 1.6 1.6 1.6 1.6 1.6 1.6 2 2 2 2 3.2 4 4 5 6.3 8 8 10 10 12.5 Elbow DIN 2605 Cap DIN 2617 Reducer DIN 2616 Tee DIN 2615

10 15 20 25 32 40 50 65 80 100 125 150 200 250 300 350 400 500 600 700 800 900 1000 1200

17.2 21.3 26.9 33.7 42.4 48.3 60.3 76.1 88.9 114.3 139.7 168.3 219.1 273 323.9 355.6 406.4 508 610 711 813 914 1016 1220

2 2 2 2 2 2 2 2.3 2.3 2.6 2.6 2.6 4.5 5 5.6 5.6 6.3 6 8 8 12.5 -

1.6 1.6 1.6 1.6 1.6 1.6 1.6 1.6 1.6 2 2 2 2 3.2 4 4 5 6.3 8 8 10 10 12.5 -

1.6 1.6 1.6 2 2 2 2 2.3 2.3 2.6 2.6 2.6 2.9 3.0 4.0 5.6 6.3 6.3 8.0 8.0 8.0 12.5 12.5 -

1.6 1.6 1.6 2 2 2 2 2.3 2.3 2.6 4 4 6.3 6.3 7.1 8 8.8 11 12.5 -

Doc No: JKPM/DOC/M/001

Page 11 of 44

R0

PIPING SPECIFICATIONS SNL25 1 PIPE

1.1 1.1.1

Material Grade Specification

: :

Austenitic stainless steel pipes - Grade 304L ASTM A 312 TP 304L/SS 2352 up to 200NB ASTM A 358 Class II for 250 NB and above.

1.1.2 1.2 1.3

Process of manufacture : Dimensions Wall Thickness : :

ERW DIN 2448 / ANSI B 36.19 / ISO 4200 As Per Pressure Rating Standards Also refer Table

1.4 1.5 1.6

Tolerances End Preparation Type of weld

: : :

ASTM A 312/ ISO 1127 Bevelled end shall be square to axis Use Butt-weld joints for all sizes

1.7

General All pipes shall be supplied in random lengths of 6 m.

caps. All pipes shall be supplied with ends protected by plastic

2 2.1 2.1.1 2.1.2 2.1.3

2.2 2.3

PIPE FITTINGS Type of Fittings Elbows Reducers Tee

Material Grade Specification

: : :

: :

Long radius (1.5 * Diameter) Concentric/Eccentric Equal/Unequal

Wrought Austenitic stainless steel Grade 304L/SS 2352 ASTM A 403 WPW 304L/SS 2352

2.4

Dimensions & end preparation

Doc No: JKPM/DOC/M/001

Page 12 of 44

R0

2.5 2.6

Fittings (butt) Fittings (screwed) Fittings (socket)

Wall Thickness Tolerances

: : :

: :

As per ANSI B 16.9/MSS SP-43/ISO 5251 As per ANSI B 16.11/ISO 5251 As per ANSI B16.11/ISO 5251

As Per Pressure Rating Standards Also refer Table ASTM A 312/ ISO 1127

2.7 Wall Thickness Table

Nominal Size OD Pipe DINEN10220 ( DIN 2448 ) ( ISO 4200 ) 1.6 1.6 1.6 1.6 1.6 1.6 1.6 1.6 1.6 2 2 2.6 3.2 5 6.3 3.2 8 10 12.5 Elbow DIN 2605 Cap DIN 2617 Reducer DIN 2616 Tee DIN 2615

10 15 20 25 32 40 50 65 80 100 125 150 200 250 300 350 400 500 600 700 800 900 1000 1200

17.2 21.3 26.9 33.7 42.4 48.3 60.3 76.1 88.9 114.3 139.7 168.3 219.1 273 323.9 355.6 406.4 508 610 711 813 914 1016 1220

2 2 2 2 2 2 2 2.3 2.3 2.6 4 4 4 5 6 8 8 -

1.6 1.6 1.6 1.6 1.6 1.6 1.6 1.6 1.6 2 2 2.6 3.2 5 6.3 3.2 8 10 12.5

1.6 1.6 1.6 2 2 2 2 2.3 2.3 2.6 2.6 4 4.5 5 7.1 8 8.8 11 12.5

1.6 1.6 1.6 2 2 2 2 2.9 3.2 3.6 4 5 6.3 8.8 10 11 12.5 -

Doc No: JKPM/DOC/M/001

Page 13 of 44

R0

PIPING SPECIFICATIONS SS10 1

1.1 1.1.1 1.1.2 1.2 1.3

PIPE

Material Grade Specification : : Austenitic stainless steel pipes - Grade 316 ASTM A 312 TP 316/SS 2343 up to 200 NB ASTM A 358 Class II for 250 NB and above. ERW DIN 2448 / ANSI B 36.19 / ISO 5252 As Per Pressure Rating Standards Also refer Table

Process of manufacture : Dimensions Wall Thickness : :

1.4 1.5 1.6

Tolerances End Preparation Type of weld

: : :

ASTM A 312/ ISO 1127 Bevelled end shall be square to axis Use Butt-weld joints for all sizes

1.7

General All pipes shall be supplied in random lengths of 6 m.

All pipes shall be supplied with ends protected by

plastic caps.

2 2.1 2.1.1 2.1.2 2.1.3 2.2 2.3 2.4 -

PIPE FITTINGS Type of Fittings Elbows Reducers Tee Material Grade Specification : : : : : Long radius (1.5 * Diameter) Concentric/Eccentric Equal/Unequal Wrought Austenitic stainless steel Grade 316/SS 2343 ASTM A 403 WPW 316/SS 2343

Dimensions & end preparation Fittings (butt) : As per ANSI B 16.9/MSS SP-43/ISO 5251 Fittings (screwed) : As per ANSI B 16.11/ISO 5251 Fittings (socket) : As per ANSI B16.11/ISO 5251

Doc No: JKPM/DOC/M/001

Page 14 of 44

R0

2.5

Wall Thickness

As Per Pressure Rating Standards Also refer Table

2.6

Tolerances

ASTM A 312/ ISO 1127

2.7 Wall Thickness Table

Nominal Size OD Pipe DINEN10220 ( DIN 2448 ) ( ISO 4200 ) 1.6 1.6 1.6 1.6 1.6 1.6 1.6 1.6 1.6 2 2 2.6 3.2 5 6.3 3.2 8 10 12.5 Elbow DIN 2605 Cap DIN 2617 Reducer DIN 2616 Tee DIN 2615

10 15 20 25 32 40 50 65 80 100 125 150 200 250 300 350 400 500 600 700 800 900 1000 1200

17.2 21.3 26.9 33.7 42.4 48.3 60.3 76.1 88.9 114.3 139.7 168.3 219.1 273 323.9 355.6 406.4 508 610 711 813 914 1016 1220

2 2 2 2 2 2 2 2.3 2.3 2.6 4 4 4 5 6 8 8 -

1.6 1.6 1.6 1.6 1.6 1.6 1.6 1.6 1.6 2 2 2.6 3.2 5 6.3 3.2 8 10 12.5

1.6 1.6 1.6 2 2 2 2 2.3 2.3 2.6 2.6 4 4.5 5 7.1 8 8.8 11 12.5

1.6 1.6 1.6 2 2 2 2 2.9 3.2 3.6 4 5 6.3 8.8 10 11 12.5 -

Doc No: JKPM/DOC/M/001

Page 15 of 44

R0

PIPING SPECIFICATIONS SS16 1

1.1 1.1.1 1.1.2 1.2 1.3

PIPE

Material Grade Specification : : Austenitic stainless steel pipes - Grade 316 ASTM A 312 TP 316/SS 2343 up to 200 NB ASTM A 358 Class II for 250 NB and above. ERW DIN 2448 / ANSI B 36.19 / ISO 5252 As Per Pressure Rating Standards Also refer Table

Process of manufacture : Dimensions Wall Thickness : :

1.4 1.5 1.6

Tolerances End Preparation Type of weld

: : :

ASTM A 312/ ISO 1127 Bevelled end shall be square to axis Use Butt-weld joints for all sizes

1.7

General All pipes shall be supplied in random lengths of 6 m.

All pipes shall be supplied with ends protected by

plastic caps.

2 2.1 2.1.1 2.1.2 2.1.3 2.2 2.3 2.4 -

PIPE FITTINGS Type of Fittings Elbows Reducers Tee Material Grade Specification : : : : : Long radius (1.5 * Diameter) Concentric/Eccentric Equal/Unequal Wrought Austenitic stainless steel Grade 316/SS 2343 ASTM A 403 WPW 316/SS 2343

Dimensions & end preparation Fittings (butt) : As per ANSI B 16.9/MSS SP-43/ISO 5251 Fittings (screwed) : As per ANSI B 16.11/ISO 5251 Fittings (socket) : As per ANSI B16.11/ISO 5251

Doc No: JKPM/DOC/M/001

Page 16 of 44

R0

2.5

Wall Thickness

As Per Pressure Rating Standards Also refer Table

2.6

Tolerances

ASTM A 312/ ISO 1127

2.7 Wall Thickness Table

Nominal Size OD Pipe DIN EN 10220 ( DIN 2448 ) ( ISO 4200 ) 1.6 1.6 1.6 1.6 1.6 1.6 1.6 1.6 1.6 2 2 2 2 3.2 4 4 5 6.3 8 8 10 10 12.5 Elbow DIN 2605 Cap DIN 2617 Reducer DIN 2616 Tee DIN 2615

10 15 20 25 32 40 50 65 80 100 125 150 200 250 300 350 400 500 600 700 800 900 1000 1200

17.2 21.3 26.9 33.7 42.4 48.3 60.3 76.1 88.9 114.3 139.7 168.3 219.1 273 323.9 355.6 406.4 508 610 711 813 914 1016 1220

2 2 2 2 2 2 2 2.3 2.3 2.6 2.6 2.6 4.5 5 5.6 5.6 6.3 6 8 8 12.5 -

1.6 1.6 1.6 1.6 1.6 1.6 1.6 1.6 1.6 2 2 2 2 3.2 4 4 5 6.3 8 8 10 10 12.5 -

1.6 1.6 1.6 2 2 2 2 2.3 2.3 2.6 2.6 2.6 2.9 3.0 4.0 5.6 6.3 6.3 8.0 8.0 8.0 12.5 12.5 -

1.6 1.6 1.6 2 2 2 2 2.3 2.3 2.6 4 4 6.3 6.3 7.1 8 8.8 11 12.5 -

Doc No: JKPM/DOC/M/001

Page 17 of 44

R0

PIPING SPECIFICATIONS SS25 1

1.1 1.1.1 1.1.2 1.2 1.3

PIPE

Material Grade Specification : : Austenitic stainless steel pipes - Grade 316 ASTM A 312 TP 316/SS 2343 up to 200 NB ASTM A 358 Class II for 250 NB and above. ERW DIN 2448 / ANSI B 36.19 / ISO 5252 As Per Pressure Rating Standards Also refer Table

Process of manufacture : Dimensions Wall Thickness : :

1.4 1.5 1.6

Tolerances End Preparation Type of weld

: : :

ASTM A 312/ ISO 1127 Bevelled end shall be square to axis Use Butt-weld joints for all sizes

1.7

General All pipes shall be supplied in random lengths of 6 m.

All pipes shall be supplied with ends protected by

plastic caps.

2 2.1 2.1.1 2.1.2 2.1.3 2.2 2.3 2.4 -

PIPE FITTINGS Type of Fittings Elbows Reducers Tee Material Grade Specification : : : : : Long radius (1.5 * Diameter) Concentric/Eccentric Equal/Unequal Wrought Austenitic stainless steel Grade 316/SS 2343 ASTM A 403 WPW 316/SS 2343

Dimensions & end preparation Fittings (butt) : As per ANSI B 16.9/MSS SP-43/ISO 5251 Fittings (screwed) : As per ANSI B 16.11/ISO 5251 Fittings (socket) : As per ANSI B16.11/ISO 5251

Doc No: JKPM/DOC/M/001

Page 18 of 44

R0

2.5

Wall Thickness

As Per Pressure Rating Standards Also refer Table

2.6

Tolerances

ASTM A 312/ ISO 1127

2.7 Wall Thickness Table

Nominal Size OD Pipe DIN EN 10220 ( DIN 2448 ) ( ISO 4200 ) 1.6 1.6 1.6 1.6 1.6 1.6 1.6 1.6 1.6 2 2 2.6 3.2 5 6.3 3.2 8 10 12.5 Elbow DIN 2605 Cap DIN 2617 Reducer DIN 2616 Tee DIN 2615

10 15 20 25 32 40 50 65 80 100 125 150 200 250 300 350 400 500 600 700 800 900 1000 1200

17.2 21.3 26.9 33.7 42.4 48.3 60.3 76.1 88.9 114.3 139.7 168.3 219.1 273 323.9 355.6 406.4 508 610 711 813 914 1016 1220

2 2 2 2 2 2 2 2.3 2.3 2.6 4 4 4 5 6 8 8 -

1.6 1.6 1.6 1.6 1.6 1.6 1.6 1.6 1.6 2 2 2.6 3.2 5 6.3 3.2 8 10 12.5

1.6 1.6 1.6 2 2 2 2 2.3 2.3 2.6 2.6 4 4.5 5 7.1 8 8.8 11 12.5

1.6 1.6 1.6 2 2 2 2 2.9 3.2 3.6 4 5 6.3 8.8 10 11 12.5 -

PIPING SPECIFICATIONS SSL10

1

1.1 1.1.1 1.1.2 1.2

PIPE

Material Grade Specification : : Austenitic stainless steel pipes - Grade 316L ASTM A 312 TP 316L/SS 2348 up to 200NB ASTM A 358 Class II for 250 NB and above. ERW DIN 2448 / ANSI B 36.19 / ISO 5252

Process of manufacture : Dimensions :

Doc No: JKPM/DOC/M/001

Page 19 of 44

R0

1.3 1.4 1.5 1.6

Wall Thickness Tolerances End Preparation Type of weld

: : : :

As Per Pressure Rating Standards Also refer Table ASTM A 312/ ISO 1127 Bevelled end shall be square to axis Use Butt-weld joints for all sizes

1.7

General All pipes shall be supplied in random lengths of 6 m.

All pipes shall be supplied with ends protected by

plastic caps.

2 2.1 2.1.1 2.1.2

2.1.3

PIPE FITTINGS Type of Fittings Elbows : Reducers :

Tee :

Long radius (1.5 * Diameter) Concentric/Eccentric

Equal/Unequal

2.2 2.3

Material Grade Specification

: :

Wrought Austenitic stainless steel Grade 316/SS 2348 ASTM A 403 WPW 316L/SS 2348

2.4 2.5

Dimensions & end preparation Fittings (butt) : As per ANSI B 16.9/MSS SP-43/ISO 5251 Fittings (screwed) : As per ANSI B 16.11/ISO 5251 Fittings (socket) : As per ANSI B16.11/ISO 5251

Wall Thickness : As Per Pressure Rating Standards Also refer Table

2.6

Tolerances

ASTM A 312/ ISO 1127

2.7 Wall Thickness Table

Nominal Size OD Pipe DIN EN10220 ( DIN 2448 ) Elbow DIN 2605 Cap DIN 2617 Reducer DIN 2616 Tee DIN 2615

Doc No: JKPM/DOC/M/001

Page 20 of 44

R0

10 15 20 25 32 40 50 65 80 100 125 150 200 250 300 350 400 500 600 700 800 900 1000 1200

17.2 21.3 26.9 33.7 42.4 48.3 60.3 76.1 88.9 114.3 139.7 168.3 219.1 273 323.9 355.6 406.4 508 610 711 813 914 1016 1220

( ISO 4200 ) 1.6 1.6 1.6 1.6 1.6 1.6 1.6 1.6 1.6 2 2 2 2 2 2.6 2.6 3.2 4 5 5 6.3 8 8 10

2 2 2 2 2 2 2 2.3 2.3 2.6 2.6 2.6 2.9 2.9 3.0 3.2 4 6.3 6.3 7.1 8 10 10 12.5

1.6 1.6 1.6 1.6 1.6 1.6 1.6 1.6 1.6 2 2 2 2 2 2.6 2.6 3.2 4 5 5 6.3 8 8 10

1.6 1.6 1.6 2 2 2 2 2.3 2.3 2.6 2.6 2.6 2.9 2.9 2.9 3.2 3.2 4 5 5 8 10 10 12.5

1.6 1.6 1.6 2 2 2 2 2.3 2.3 2.6 2.6 2.6 4.5 5 5.6 5.6 6.3 11 12.5 12.5 12.5 12.5 -

PIPING SPECIFICATIONS SSL16

1

1.1 1.1.1 1.1.2 1.2 1.3 1.4 1.5 1.6

PIPE

Material Grade Specification : : Austenitic stainless steel pipes - Grade 316L ASTM A 312 TP 316L/SS 2348 up to 200NB ASTM A 358 Class II for 250 NB and above. ERW DIN 2448 / ANSI B 36.19 / ISO 5252 As Per Pressure Rating Standards Also refer Table Tolerances End Preparation Type of weld : : : ASTM A 312/ ISO 1127 Bevelled end shall be square to axis Use Butt-weld joints for all sizes

Process of manufacture : Dimensions Wall Thickness : :

1.7

General

Doc No: JKPM/DOC/M/001

Page 21 of 44

R0

All pipes shall be supplied in random lengths of 6 m.

All pipes shall be supplied with ends protected by

plastic caps.

2 2.1 2.1.1 2.1.2

2.1.3

PIPE FITTINGS Type of Fittings Elbows : Reducers :

Tee :

Long radius (1.5 * Diameter) Concentric/Eccentric

Equal/Unequal

2.2 2.3

Material Grade Specification

: :

Wrought Austenitic stainless steel Grade 316/SS 2348 ASTM A 403 WPW 316L/SS 2348

2.4 2.5

Dimensions & end preparation Fittings (butt) : As per ANSI B 16.9/MSS SP-43/ISO 5251 Fittings (screwed) : As per ANSI B 16.11/ISO 5251 Fittings (socket) : As per ANSI B16.11/ISO 5251

Wall Thickness : As Per Pressure Rating Standards Also refer Table

2.6

Tolerances

ASTM A 312/ ISO 1127

2.7 Wall Thickness Table

Nominal Size OD Pipe DIN EN 10220 ( DIN 2448 ) ( ISO 4200 ) 1.6 1.6 1.6 1.6 1.6 1.6 1.6 Elbow DIN 2605 Cap DIN 2617 Reducer DIN 2616 Tee DIN 2615

10 15 20 25 32 40 50

17.2 21.3 26.9 33.7 42.4 48.3 60.3

2 2 2 2 2 2 2

1.6 1.6 1.6 1.6 1.6 1.6 1.6

1.6 1.6 1.6 2 2 2 2

1.6 1.6 1.6 2 2 2 2

Doc No: JKPM/DOC/M/001

Page 22 of 44

R0

65 80 100 125 150 200 250 300 350 400 500 600 700 800 900 1000 1200

76.1 88.9 114.3 139.7 168.3 219.1 273 323.9 355.6 406.4 508 610 711 813 914 1016 1220

1.6 1.6 2 2 2 2 3.2 4 4 5 6.3 8 8 10 10 12.5 -

2.3 1.6 2.3 2.3 1.6 2.3 2.6 2 2.6 2.6 2 2.6 2.6 2 2.6 4.5 2 2.9 5 3.2 3.0 5.6 4 4.0 5.6 4 5.6 6.3 5 6.3 6 6.3 6.3 8 8 8.0 8 8 8.0 12.5 10 8.0 10 12.5 12.5 12.5 PIPING SPECIFICATIONS SSL25

2.3 2.3 2.6 4 4 6.3 6.3 7.1 8 8.8 11 12.5 -

1

1.1 1.1.1 1.1.2 1.2 1.3 1.4 1.5 1.6

PIPE

Material Grade Specification : : Austenitic stainless steel pipes - Grade 316L ASTM A 312 TP 316L/SS 2348 up to 200NB ASTM A 358 Class II for 250 NB and above. ERW DIN 2448 / ANSI B 36.19 / ISO 5252 As Per Pressure Rating Standards Also refer Table Tolerances End Preparation Type of weld : : : ASTM A 312/ ISO 1127 Bevelled end shall be square to axis Use Butt-weld joints for all sizes

Process of manufacture : Dimensions Wall Thickness : :

1.7

General All pipes shall be supplied in random lengths of 6 m.

All pipes shall be supplied with ends protected by

plastic caps.

Doc No: JKPM/DOC/M/001

Page 23 of 44

R0

2 2.1 2.1.1 2.1.2

2.1.3

PIPE FITTINGS Type of Fittings Elbows : Reducers :

Tee :

Long radius (1.5 * Diameter) Concentric/Eccentric

Equal/Unequal

2.2 2.3

Material Grade Specification

: :

Wrought Austenitic stainless steel Grade 316/SS 2348 ASTM A 403 WPW 316L/SS 2348

2.4 2.5

Dimensions & end preparation Fittings (butt) : As per ANSI B 16.9/MSS SP-43/ISO 5251 Fittings (screwed) : As per ANSI B 16.11/ISO 5251 Fittings (socket) : As per ANSI B16.11/ISO 5251

Wall Thickness : As Per Pressure Rating Standards Also refer Table

2.6

Tolerances

ASTM A 312/ ISO 1127

2.7 Wall Thickness Table

Nominal Size OD Pipe DIN EN 10220 ( DIN 2448 ) ( ISO 4200 ) 1.6 1.6 1.6 1.6 1.6 1.6 1.6 1.6 1.6 2 2 2.6 3.2 5 6.3 3.2 Elbow DIN 2605 Cap DIN 2617 Reducer DIN 2616 Tee DIN 2615

10 15 20 25 32 40 50 65 80 100 125 150 200 250 300 350

17.2 21.3 26.9 33.7 42.4 48.3 60.3 76.1 88.9 114.3 139.7 168.3 219.1 273 323.9 355.6

2 2 2 2 2 2 2 2.3 2.3 2.6 4 4 4 5 6 8

1.6 1.6 1.6 1.6 1.6 1.6 1.6 1.6 1.6 2 2 2.6 3.2 5 6.3 3.2

1.6 1.6 1.6 2 2 2 2 2.3 2.3 2.6 2.6 4 4.5 5 7.1 8

1.6 1.6 1.6 2 2 2 2 2.9 3.2 3.6 4 5 6.3 8.8 10 11

Doc No: JKPM/DOC/M/001

Page 24 of 44

R0

400 500 600 700 800 900 1000 1200

406.4 508 610 711 813 914 1016 1220

8 10 12.5

8 -

8 10 12.5

8.8 11 12.5

12.5 -

PIPING SPECIFICATIONS PL 1.0 1.1 1.1.1 1.1.2 1.1.3 1.1.4 1.2 1.3 PIPE Material Grade Specification Manufacturing standards Process of manufacture Additional Requirement : : : : : Carbon Steel (PTFE/ PFA / FEP Lined) ASTM A 106 Gr B ASTM F 1545 95 Seamless Pre-fabricated pipe inner surface to be PTFE lined to 3 thk minimum. ANSI B 36.10

Dimensions : Wall Thickness NPS 150 & Below : STD weight/Sch. 40 NPS 200 to NPS 300 : Sch. 20 NPS 350 & Above : Sch. 10 Note : Alternatively, NPS 350 & above pipes may be fabricated out of plates conforming to ASTM A515 Gr. 60 or equivalent material to suit Sch 10 pipe thickness. End Preparation General

All pipes shall be supplied in random lengths of 6 m. Pipes shall not be joined / welded to make up the required length. Make up length shall not be less than 2.5 m. caps. All pipes shall be supplied with ends protected by plastic

1.4

: Bevelled end shall be square to axis

1.5

All pipes shall be supplied with fixed flange at one end and loose flange in the other end All fittings shall be with fixed flanges

Doc No: JKPM/DOC/M/001

Page 25 of 44

R0

2.0 2.1

2.1.1

PIPE FITTINGS (PTFE / PFA / FEP LINED) Type of Fittings

Elbows : Long radius (1.5 * Diameter)

2.1.2 2.1.3 2.2 2.3 2.4

Reducers Tee Material Grade Specification Designation

: : : : :

Concentric/Eccentric Equal/Unequal Wrought Carbon Steel ASTM A 234 ASTM A 234 WPB

2.5 Dimensions & end preparation Fittings (butt) : As per ANSI B 16.9/MSS SP-79 Fittings (screwed) : As per ANSI B 16.11 Fittings (socket) : As per ANSI B16.11 2.6 Wall Thickness : Same as pipe wall thickness 3.0 3.1 3.2 3.3 3.4 COUPLINGS AND HALF COUPLINGS (PTFE LINED) Manufacturing standard Material grade Rating Dimension : : : : ASTM A105/A181 ASTM A105/A181 Gr. 70 3000 # As per ANSI B16.11

Doc No: JKPM/DOC/M/001

Page 26 of 44

R0

PIPING SPECIFICATIONS PL25 (PN 25) 1.0 1.1 1.1.1 1.1.2 1.1.3 1.1.4 1.2 1.3 PIPE Material Grade Specification Manufacturing standards Process of manufacture Additional Requirement Dimensions Wall Thickness NPS 150 & Below NPS 200 to NPS 300 NPS 350 & Above Note : : : : : : : : : : Carbon Steel (PTFE/ PFA / FEP Lined) ASTM A 106 Gr B ASTM F 1545 95 Seamless Pre-fabricated pipe inner surface to be PTFE lined to 3 thk minimum. ANSI B 36.10 STD weight/Sch. 40 Sch. 20 Sch. 10

Alternatively, NPS 350 & above pipes may be fabricated out of plates conforming to ASTM A515 Gr. 60 or equivalent material to suit Sch 10 pipe thickness. : Bevelled end shall be square to axis

All pipes shall be supplied in random lengths of 6 m.

1.4 1.5

End Preparation General

Pipes shall not be joined / welded to make up the required length. Make up length shall not be less than 2.5 m. caps. All pipes shall be supplied with ends protected by plastic

All pipes shall be supplied with fixed flange at one end and loose flange in the other end All fittings shall be with fixed flanges

Doc No: JKPM/DOC/M/001

Page 27 of 44

R0

2.0 2.1

2.1.1

PIPE FITTINGS (PTFE / PFA / FEP LINED)

: Long radius (1.5 * Diameter)

Type of Fittings

Elbows

2.1.2 2.1.3 2.2 2.3 2.4 2.5 2.6

Reducers Tee Material Grade Specification Designation

: : : : :

Concentric/Eccentric Equal/Unequal Wrought Carbon Steel ASTM A 234 ASTM A 234 WPB As per ANSI B 16.9/MSS SP-79 As per ANSI B 16.11 As per ANSI B16.11 Same as pipe wall thickness

Dimensions & end preparation Fittings (butt) : Fittings (screwed) : Fittings (socket) : Wall Thickness : 3.0

COUPLINGS AND HALF COUPLINGS (PTFE LINED) : : : : ASTM A105/A181 ASTM A105/A181 Gr. 70 3000 # As per ANSI B16.11

3.1 3.2 3.3 3.4

Manufacturing standard Material grade Rating Dimension

Doc No: JKPM/DOC/M/001

Page 28 of 44

R0

PIPING SPECIFICATIONS CSL53 1.0 1.1 1.1.1 1.1.3 1.2 1.3 PIPE Material Grade Specification Process of manufacture Dimensions Wall Thickness From DN 10 to 15 DN 20 From DN 25 to 40 From DN 50 to 65 DN 80 DN 100 DN 125 DN 150 From DN 200 to 250 DN 300 DN 350 DN 400 DN 450 DN 500 DN 600 DN 700 : : : : : : : : : : : : : : : : 2 2.3 2.6 2.9 3.2 3.6 4 4.5 6.3 7.1 8 8.8 10 11 12.5 14.2 : : : : Carbon Steel A 53 Gr. B, St 37.0, S 360 ERW ANSI B 36.10, ISO 4200, BS 3600 DN 2448, DN 2458

Note: Alternatively, NPS 350 & above pipes may be fabricated out of plates conforming to IS: 2062 Gr. 410 W in 6 mm Thk up to 500 mm and 8 mm Thk for 550 mm above and ends as per IS: 3589.

1.4

End Preparation General

caps.

Bevelled end shall be square to axis

All pipes shall be supplied in random lengths of 6 m. All pipes shall be supplied with ends protected by plastic

1.5

Doc No: JKPM/DOC/M/001

Page 29 of 44

R0

2.0 2.1 2.1.1 2.1.2 2.1.3 2.2 2.3 -

PIPE FITTINGS Type of Fittings Elbows : Long radius (1.5 * Diameter) Reducers : Concentric/Eccentric Tee : Equal/Unequal Material Standard : ASTM A 234 WPB / BS 3601 Dimensions & end preparation Fittings (butt) : As per ANSI B 16.9/MSS SP-79, BS 1965 Fittings (screwed) : As per ANSI B 16.11 Fittings (socket) : As per ANSI B16.11

3.0 3.1 3.2 3.3 3.4 4.0

COUPLINGS AND HALF COUPLINGS Manufacturing standard Material grade Rating Dimension : : : : ASTM A105/A181 ASTM A105/A181 Gr. 70 3000 # As per ANSI B16.11

CERTIFICATES FOR PIPES AND FITTINGS

The vender shall furnish material certificates to ensure conformity to specifications.

Doc No: JKPM/DOC/M/001

Page 30 of 44

R0

PIPING SPECIFICATIONS CSL106 1.0 1.1 1.1.1 1.1.2 1.1.3 1.2 1.3 PIPE Material Grade Specification Designation Process of Manufacture Dimensions Wall Thickness : : : : : : Carbon Steel ASTM A 106 Gr. B/ DN 17155/ BS 3602 360 to 460 A 106 Gr B Seamless ANSI B 36.10, ISO 4200, BS 3600, DN 2448 DN 2458

- NPS 50 & Below : Sch 80 - NPS 65 to NPS 200 : Sch 40 - NPS 250 & Above : Sch 20 Note: Alternatively, NPS 350 & above pipes may be fabricated out of plates conforming to ASTM A 515 Gr 60 to suit Sch 20 pipe thickness. 1.4 1.5 End Preparation General

caps. All pipes shall be supplied in random lengths of 6 m. All pipes shall be supplied with ends protected by plastic

Bevelled end shall be square to axis

2.0 2.1 2.1.1 2.1.2 2.1.3 2.2 2.3 3.0 3.1 3.2 3.3

PIPE FITTINGS Type of Fittings Elbows Reducers Tee Material Standard : : : : Long radius (1.5 * Diameter) Concentric/Eccentric Equal/Unequal ASTM A 234 WPB / BS 3602

Dimensions & end preparation Fittings (butt) : As per ANSI B 16.9/MSS SP-79, BS 1965 Fittings (screwed) : As per ANSI B 16.11 Fittings (socket) : As per ANSI B16.11 COUPLINGS AND HALF COUPLINGS Manufacturing standard Material grade Rating : : : ASTM A105/A181 ASTM A105/A181 Gr. 70 3000 #

Doc No: JKPM/DOC/M/001

Page 31 of 44

R0

3.4 4.0

Dimension

As per ANSI B16.11

CERTIFICATES FOR PIPES AND FITTINGS

The vender shall furnish material certificates to ensure conformity to specifications.

Doc No: JKPM/DOC/M/001

Page 32 of 44

R0

PIPING SPECIFICATIONS CSLERW 1.0 1.1 1.1.1 1.1.2 1.1.3 1.2 1.3 PIPE Material Grade Specification Designation Process of manufacture Dimensions Wall Thickness From DN 10 to 15 DN 20 From DN 25 to 40 From DN 50 to 65 DN 80 DN 100 DN 125 DN 150 From DN 200 to 250 DN 300 DN 350 DN 400 DN 450 DN 500 DN 600 DN 700 1.4 1.5 End Preparation General

: : : : : : : : : : : : : : : : : : : : : :

Carbon Steel IS 1239 IS 1239 Part 1 ERW IS 1239 Part 1 2 2.3 2.6 2.9 3.2 3.6 4 4.5 6.3 7.1 8 8.8 10 11 12.5 14.2 Bevelled end shall be square to axis

All pipes shall be supplied in random lengths of 6 m.

Pipes shall not be joined/welded to make up the required length. Make up length shall not be less than 2.5 m. caps. All pipes shall be supplied with ends protected by plastic

2.0 2.1 2.1.1 2.1.2 2.1.3 2.2 2.3 2.4

PIPE FITTINGS Type of Fittings Elbows Reducers Tee Material Grade Specification Designation : : : : : : Long radius (1.5 * Diameter) Concentric/Eccentric Equal/Unequal Wrought Carbon Steel IS 1239 IS 1239 Part 2

Doc No: JKPM/DOC/M/001

Page 33 of 44

R0

2.5 2.6 3.0 3.1 3.2 3.3 3.4

Dimensions & end preparation Fittings (butt) : IS 1239 Part 2 Fittings (screwed) : IS 1239 Part 2 Fittings (socket) : IS 1239 Part 2 Wall Thickness NPS 150 & Below : Heavy Grade COUPLINGS AND HALF COUPLINGS Manufacturing standard Material grade Rating Dimension : : : : ASTM A105/A181 ASTM A105/A181 Gr. 70 3000 # As per ANSI B16.11

Doc No: JKPM/DOC/M/001

Page 34 of 44

R0

PIPING SPECIFICATIONS TI 1.0 1.1 1.1.1 1.1.2 1.1.3 1.2 1.3 337 Note: However, the wall thickness of titanium pipes may be determined accorDNg to the pressure and temperature rating 1.4 1.6 End Preparation General

PIPE Material Grade Specification Designation Process of manufacture Dimensions Wall Thickness NPS 15 to 100 NPS 150 to 200 NPS 250 and above : : : : : : : : Titanium ASTM B 337 ASTM B 337 Gr. 2 ERW ANSI B 36.19 Sch. 10S Sch. 10S 3.18 mm, Fabricated out of sheet ASTM B 265 Gr2 to ANSI B 36.19 and ASTM B

Bevelled end shall be square to axis

All pipes shall be supplied in random lengths of 6 m.

Pipes shall not be joined/welded to make up the required length. Make up length shall not be less than 2.5 m. caps. All pipes shall be supplied with ends protected by plastic

2.0 2.1 2.1.1

PIPE FITTINGS Type of Fittings Flange - For PN 10 rating : LOOSE FLANGE PN10 HOT DIP GALV ASTM A105, EN1092-1 TYPE 02 - For PN 16 rating : LOOSE FLANGE PN16 HOT DIP GALV ASTM A105, EN1092-1 TYPE 02 - For PN 25 rating : LOOSE FLANGE PN25 HOT DIP GALV ASTM A105, EN1092-1 TYPE 02 Elbows : Long Radius (1.5 * Diameter) Reducers : Concentric/Eccentric Tee : Equal/Unequal Stub end - For PN 10 Rating TYPE 35 : STUB END, TITANIUM GR. 2 PN10, EN1092-1

2.1.4 2.1.5 2.1.6 2.1.7

Doc No: JKPM/DOC/M/001

Page 35 of 44

R0

2.2 2.3 2.4 2.5 3.0 3.1 3.2 3.3 3.4

- For PN 16 Rating : STUB END, TITANIUM GR. 2 PN16, EN1092-1 TYPE 35 - For PN 25 Rating : STUB END, TITANIUM GR. 2 PN25, EN1092-1 TYPE 35 Material Grade : Titanium Grade 2 Specification : ASTM B 363 Dimensions & end preparation Fittings (butt) : As per ANSI B 16.9/MSS SP-43 Type A Fittings (screwed) : As per ANSI B 16.11 Fittings (socket) : As per ANSI B16.11 Wall Thickness : Same as pipe wall thickness COUPLINGS AND HALF COUPLINGS Manufacturing standard Material grade Rating Dimension : : : : ASTM B 381 Gr.F Titanium ASTM B 381 Gr.F Titanium 3000 # As per ANSI B16.11

PIPING SPECIFICATIONS DUST

Duplex 2205 STAINLESS STEEL EN NO. 1.4462

Doc No: JKPM/DOC/M/001

Page 36 of 44

R0

P63/1/1.0

SERVICE

Chlorine dioxide, pulp, D stage washers

P63/1/2.0

RATING

8 kg/cm2 and 85o to 90oC

P63/1/3.0

SIZE

Above 25 mm dia or Chutes fabricated out of plates

P63/1/4.0

MATERIAL

Duplex 2205 STAINLESS STEEL EN NO. 1.4462

P63/1/5.0

PIPE Wall Thickness : 10Sch

P63/2/1.0

FITTINGS Flange - For PN 10 rating : LOOSE FLANGE PN10 HOT DIP GALV ASTM A105, EN1092-1 TYPE 02 - For PN 16 rating : LOOSE FLANGE PN16 HOT DIP GALV ASTM A105, EN1092-1 TYPE 02 - For PN 25 rating : LOOSE FLANGE PN25 HOT DIP GALV ASTM A105, EN1092-1 TYPE 02

Mfg standard 31254/Werksloff No : 1.4462 Mfg standard 31254/Werksloff No : 1.4462 As As per per UNS UNS S S

Doc No: JKPM/DOC/M/001

Page 37 of 44

R0

Stub end : STUB END, DUPLEX 2205-EN1.4462 PN10, and EN1092-1TYPE 35 - For PN 16 Rating : STUB END, DUPLEX 2205-EN1.4462 PN16, and EN1092-1 TYPE 35 - For PN 25 Rating : STUB END, DUPLEX 2205-EN1.4462 PN25, and EN1092-1 TYPE 35 For PN 10 Rating

Doc No: JKPM/DOC/M/001

Page 38 of 44

R0

PIPING SPECIFICATIONS FRP150

1.0 1.1 1.1.1 1.1.2 1.1.3 PIPE Material Grade Specification Designation Process of manufacture : : : : Glass-fibre reinforced plastic pipes (FRP) Glass-fibre reinforced plastic pipes (FRP) FRP pipes As per National Bureau of standards, voluntary product standard PS 15-69 of United States

1.2

Requirements : The general requirements such as the materials, surface finish of inner and outer layers, cut edges, wall thickness, fittings, mechanical properties and dimensions are accorDNg to the above standard General

All pipes shall be supplied in random lengths of 4 to 5 m. All pipes shall not be joined to make up the required length. Make up length shall not be less than 2.5 m.

1.3

1.4

Dimension:

Minimum Pipe Wall Thickness Pipe Size 50 80 100 150 200 250 300 350 400 450 500 150 psi 5 6.5 6.5 10 12 13 16 20 22 22 24

Doc No: JKPM/DOC/M/001

Page 39 of 44

R0

600

24

Note: Pipes sizes mean inside diameter of pipes and wall thickness is the minimum required

Doc No: JKPM/DOC/M/001

Page 40 of 44

R0

1.5

Fittings

All fitting dimensions shall be in accordance with ASME/ANSI B 31.3, US specification PS 1569 or Cdn. Specification SPI-FRP-002-92 (latest edition) All flanges shall be drilled accorDNg to DN Standard PN10 The use of stub flanges is restricted to straight lengths of pipe.

1.6 Resin

Derakane411-45 up to a temperature of 80C and Derakane 470-30 up to temperature of 100C - Source-Derakane Catalogue 1.7 Glass wool mats (special reference) Acid resistant glass mat should be used in the corrosion resistant barrier and in structural walls. Double surface mat (Veil) and a 5mm/200 mil corrosion resistant barrier should be used - Source-Derakane Catalogue In case of corrosive chemicals at ambient and elevated temperatures:

Doc No: JKPM/DOC/M/001

Page 41 of 44

R0

PIPING SPECIFICATIONS FRP300 1.0 1.1 1.1.1 1.1.2 1.2 PIPE Material Grade Specification Designation : : : Glass-fibre reinforced plastic pipes (FRP) Glass-fibre reinforced plastic pipes (FRP) FRP pipes

Requirements : The general requirements such as the materials, surface finish of inner and outer layers, cut edges, wall thickness, fittings, mechanical properties and dimensions are accorDNg to the above standard General

All pipes shall be supplied in random lengths of 4 to 5 m.

1.3

Pipes shall not be joined to make up the required length. Make up length shall not be less than 2.5 m.

1.4 Pipe Corrosion liner Structural Joining 1.5 Pipe Dimensions Size (NPS) 10 15 20 25 32 40 50 65 80 100 125 150 200 250 300 350 400 500 600

: : :

Hand-lay-up only Hand-lay-up or filament winDNg Tapered but & strap

Tolerance +1, 1/-1,1 +1, 1/-1,1 +1, 1/-1,1 +1, 2/-1,2 +1, 2/-1,2 +1, 2/-1,2 +1, 3/-1,3 +1, 3/-1,3 +1, 3/-1,3 +1, 5/-1,5 +1, 7/-1,7 +1, 8/-1,8 +2,0/-2,0 +2,3/-2,3 +2,5/-2,5 +2,8/-2,8 +3,0/-3,0 +3,5/-3,5 +4,0/-4,0

Class 300# 5 5 5 5 5 5 5 5 7 7 8 10 12 13 16 20 24 24 26

Doc No: JKPM/DOC/M/001

Page 42 of 44

R0

Size (NPS) 700 800 900

Tolerance +4,5/-4,0 +5,0/-4,0 +5,5/-4,0

Class 300# 30 34 38

FITTINGS

All fitting dimensions shall be in accordance with ASME/ANSI B31.3, US specification PS 1569 or Cdn. Specification SPI-FRP-002-92 (latest edition) All flanges shall be drilled accorDNg to DN Standard The use of stub flanges is restricted to straight lengths of pipe, 90o elbows <50mm dia and 45o elbows < 150 mm dia.

PIPING SPECIFICATIONS PVC-FRP

Doc No: JKPM/DOC/M/001

Page 43 of 44

R0

PVC/FRP Armoured

Temp. oC Press kPa(g) Pipe PVC 15 Size nomi nal dia 20 25 32 32 103 4 40 38 979 50 80 43 793 49 634 54 476 60 345 54 FV Test Temp. oC Test Press kPa(g) Ambient 1.5xDPxCorr.

100 150 200 250 300

Wall 3.73 3.91 4.55 4.85 5.08 5.54 7.62 8.56 10.9 12.7 15.0 17.4 Thik. 7 6 5

Schedule

ASTM D1785, Schedule 80

Over 3.3 3.3 3.3 3.3 3.3 4.3 4.3 4.3 4.3 4.3 4.3 4.3 lay Thk. Mm

Material Pipe

ASTM D1784 Class 12454-B, ASTM D1785-PVC 1120

Note: 1. 2.

Pressure/Temperature limits are based on GF sloane PVC. The reinforcement shall be an overly of reinforced vinyl/ester resin, Resin shall be Derakane 411-45 or equal, Derakane 510N (fine retardant) or equal with 5% antimony trioxide shall be used in the last two layers of mat. The reinforcement shall be commercial grade, E type, glass fiber with silane finish compatible with the resin

Doc No: JKPM/DOC/M/001

Page 44 of 44

R0

system. The outside exposed surface of all reinforcement shall be pigmented and contain UV inhibitors. 3. The outer surface of al substrate (PVC) piping shall be treated prior to overlaying to ensure adhesion between the FRP reinforcement and the PVC pipe. Treatment shall be Faboo # 820 bonDNg agent or approved equal. BonDNg agent shall be applied in accordance with the manufacturers instructions. Reinforcement shall be applied to lengths of piping to a thickness given by the table above (see OVERLAY). The reinforcement may be applied by filament winDNg (FW) or hand lay up (HLU). A double layer of chopped strand may (CSM) and resin shall be applied over all pipe fittings; the hubs only of all flanges; and the adjacent potions of pipe reinforcements to length equal to the O.D. of the reinforced pipe (minimum 25 mm).

4.

Anda mungkin juga menyukai

- Metal Valves & Pipe Fittings World Summary: Market Values & Financials by CountryDari EverandMetal Valves & Pipe Fittings World Summary: Market Values & Financials by CountryBelum ada peringkat

- Statisitics Project 3Dokumen22 halamanStatisitics Project 3AMAN PRAKASHBelum ada peringkat

- Steam Table Si UnitsDokumen19 halamanSteam Table Si UnitsPrashant SharmaBelum ada peringkat

- Mat CodesDokumen64 halamanMat CodesgopaltryBelum ada peringkat

- Isometric PipingDokumen31 halamanIsometric PipingneelandanBelum ada peringkat

- Safety Valve Reaction ForceDokumen16 halamanSafety Valve Reaction ForceSharun Suresh0% (1)

- Why use Pipe Supports: Types of Pipe Hangers and SupportsDokumen25 halamanWhy use Pipe Supports: Types of Pipe Hangers and SupportsmurugesanBelum ada peringkat

- Why Insulate Pipes: 3 Key Benefits of InsulationDokumen13 halamanWhy Insulate Pipes: 3 Key Benefits of InsulationnguyenBelum ada peringkat

- CAESAR II 5.00 Sneak Preview - New Interface, Technology and ReportingDokumen61 halamanCAESAR II 5.00 Sneak Preview - New Interface, Technology and ReportingRokan PipelineBelum ada peringkat

- Pipe Hangers, Pipe Supports, Variable and Constant Spring HangersDokumen2 halamanPipe Hangers, Pipe Supports, Variable and Constant Spring Hangerskaiju85Belum ada peringkat

- Steam System of Power PlantDokumen34 halamanSteam System of Power PlantEjaz AhmedBelum ada peringkat

- Tube Bundle DrawingDokumen1 halamanTube Bundle DrawingVeera ManiBelum ada peringkat

- Pipe Schedules Chart Imperial and Metric HFT50-WEB-PDokumen7 halamanPipe Schedules Chart Imperial and Metric HFT50-WEB-PAmjad ShahBelum ada peringkat

- Pipe Fittings and Piping AuxiliariesDokumen38 halamanPipe Fittings and Piping Auxiliariesmsaad2Belum ada peringkat

- Material Selection and SpecificationDokumen50 halamanMaterial Selection and SpecificationbashirBelum ada peringkat

- Disclosure To Promote The Right To InformationDokumen9 halamanDisclosure To Promote The Right To InformationtpchoBelum ada peringkat

- Tube Expander-Tools PDFDokumen120 halamanTube Expander-Tools PDFmarceilinus devaluantoBelum ada peringkat

- KL UHP Catalog 2011-02 PDFDokumen30 halamanKL UHP Catalog 2011-02 PDFaconibet9040Belum ada peringkat

- Flow Tek C4700 Series Cryo Ball ValveDokumen8 halamanFlow Tek C4700 Series Cryo Ball ValveDanielle JohnsonBelum ada peringkat

- Typical Definition Drawing for DN65 & Smaller Pipe SupportsDokumen1 halamanTypical Definition Drawing for DN65 & Smaller Pipe Supportskamal arabBelum ada peringkat

- Kontur Pipeflow BaruDokumen33 halamanKontur Pipeflow BaruAngga Lionix ManullangBelum ada peringkat

- ANSI FlangeDokumen10 halamanANSI FlangemechftpBelum ada peringkat

- Wall Thickness CalcDokumen2 halamanWall Thickness Calcpbao_12Belum ada peringkat

- Most Reliable and Easiest to Maintain Heat Exchangers in IndiaDokumen23 halamanMost Reliable and Easiest to Maintain Heat Exchangers in IndiaKarthik AnandanBelum ada peringkat

- Valve DetailDokumen5 halamanValve DetailRakesh RanjanBelum ada peringkat

- Boq For AS BoilerDokumen1 halamanBoq For AS BoilerGayan ChathurangaBelum ada peringkat

- KIL3012 - WEEK 3 - 24.9.19 (Student Copy)Dokumen84 halamanKIL3012 - WEEK 3 - 24.9.19 (Student Copy)EdBelum ada peringkat

- Blowdown ValvesDokumen13 halamanBlowdown ValvesShameer MajeedBelum ada peringkat

- Pipe FittingsDokumen40 halamanPipe FittingsLucky Jaswal100% (1)

- En 1092-1 PN-40 Steel Pipe FlangeDokumen5 halamanEn 1092-1 PN-40 Steel Pipe FlangeHoria ZecheruBelum ada peringkat

- Bolt Tightening Procedure GuideDokumen6 halamanBolt Tightening Procedure Guideal arabiBelum ada peringkat

- HTTP WWW - Wermac.org Fittings Buttweld Fittings Part5Dokumen4 halamanHTTP WWW - Wermac.org Fittings Buttweld Fittings Part5prabu prasad100% (1)

- ElbowDokumen5 halamanElbowMehman NasibovBelum ada peringkat

- ASME B31.3 Piping Design - Part BDokumen21 halamanASME B31.3 Piping Design - Part BA_UossefBelum ada peringkat

- Dimensions of Weld Neck Flanges and Stud Bolts ASME B16.5 NPS 3Dokumen1 halamanDimensions of Weld Neck Flanges and Stud Bolts ASME B16.5 NPS 3Hanafi MansorBelum ada peringkat

- Steel Pipes - Pipe Schedule ChartDokumen1 halamanSteel Pipes - Pipe Schedule ChartAlzaki AbdullahBelum ada peringkat

- Is 4310 Spec Weldeable Steel Pipe Fittings For Marine PurposesDokumen12 halamanIs 4310 Spec Weldeable Steel Pipe Fittings For Marine Purposesnarasimhareddy415Belum ada peringkat

- Butt Weld Stainless Steel FittingsDokumen16 halamanButt Weld Stainless Steel Fittingsbayu susiloBelum ada peringkat

- Carbon Steel s45cDokumen4 halamanCarbon Steel s45ctam200Belum ada peringkat

- Pipe Dimensions and Friction FactorDokumen22 halamanPipe Dimensions and Friction FactorSARAVANANBelum ada peringkat

- 60+ Frequently Asking Piping Engineering Interview QuestionsDokumen8 halaman60+ Frequently Asking Piping Engineering Interview QuestionsDENYSBelum ada peringkat

- BM Europe Expansion Joints Technical CalculationDokumen9 halamanBM Europe Expansion Joints Technical CalculationsahirprojectsBelum ada peringkat

- BS 4504 Slip On Flanges PDFDokumen7 halamanBS 4504 Slip On Flanges PDFMaclean ArthurBelum ada peringkat

- Valve Spec.Dokumen15 halamanValve Spec.koner_debasishBelum ada peringkat

- ValveDokumen9 halamanValveAdhie_ginthinkBelum ada peringkat

- What Is Lined and Clad Pipe - Difference Between Line and Clad Pipes PDFDokumen5 halamanWhat Is Lined and Clad Pipe - Difference Between Line and Clad Pipes PDFbobyBelum ada peringkat

- ASME CLASS 150 lbs NPS 25 (1Dokumen15 halamanASME CLASS 150 lbs NPS 25 (1심판자Belum ada peringkat

- (VESBO) Catalog en 100317Dokumen55 halaman(VESBO) Catalog en 100317AnhNguyen100% (1)

- ENG2068 SampleofcontentsDokumen10 halamanENG2068 SampleofcontentsKlich77Belum ada peringkat

- Dimensions of Bolts and Nuts BS3692Dokumen6 halamanDimensions of Bolts and Nuts BS3692azam RazzaqBelum ada peringkat

- Pipingpresentationmaster 170219125347Dokumen61 halamanPipingpresentationmaster 170219125347Vignesh Nadimuthu100% (1)

- Technical Data Handbook of Carbon Steel FittingsDokumen244 halamanTechnical Data Handbook of Carbon Steel FittingsKrishna KumarBelum ada peringkat

- Elwood Parts and Service ManualDokumen75 halamanElwood Parts and Service Manualdindin6666Belum ada peringkat

- Material GradesDokumen2 halamanMaterial GradesDvs RameshBelum ada peringkat

- Att 2 - EdsDokumen30 halamanAtt 2 - Eds정동현Belum ada peringkat

- Catalog Valve KSBDokumen58 halamanCatalog Valve KSByoboo100% (1)

- S-LOK Tube FittingsDokumen58 halamanS-LOK Tube FittingsCesar YalanBelum ada peringkat

- High-Tech Block & Bleed ValvesDokumen20 halamanHigh-Tech Block & Bleed ValvesMayur PatelBelum ada peringkat

- Kala Sarp A YogaDokumen2 halamanKala Sarp A YogaKsmurthy MurthyBelum ada peringkat

- Tricks On How To Hack Crack Wifi PasswordDokumen5 halamanTricks On How To Hack Crack Wifi PasswordjosphinvalarBelum ada peringkat

- Lalitha Sahasra NamamDokumen61 halamanLalitha Sahasra NamamjosphinvalarBelum ada peringkat

- Lalitha Sahasra NamamDokumen61 halamanLalitha Sahasra NamamjosphinvalarBelum ada peringkat

- Cheiro About HimDokumen5 halamanCheiro About Himjosphinvalar100% (1)

- Personality TestDokumen24 halamanPersonality Testapi-3827604100% (4)

- Lalitha Sahasra NamamDokumen61 halamanLalitha Sahasra NamamjosphinvalarBelum ada peringkat

- Steam HeaderDokumen1 halamanSteam HeaderjosphinvalarBelum ada peringkat

- Head LinesDokumen3 halamanHead LinesjosphinvalarBelum ada peringkat

- Boiler CodesDokumen8 halamanBoiler CodesJaykumarBelum ada peringkat

- Nokia C6-00 User Guide: Issue 2.1Dokumen130 halamanNokia C6-00 User Guide: Issue 2.1asgarmBelum ada peringkat

- Engineer Manual - Engineer and Design Liquid Process Piping - ReviewDokumen245 halamanEngineer Manual - Engineer and Design Liquid Process Piping - ReviewSyedFAkharAbbas100% (5)

- Tightening Systems Technical Catalog 2015Dokumen142 halamanTightening Systems Technical Catalog 2015BalajiBelum ada peringkat

- IONE-AA00-MS-MS-0003 WMS For Rotating Equipment InstallationDokumen17 halamanIONE-AA00-MS-MS-0003 WMS For Rotating Equipment InstallationYusuf50% (2)

- PDS3 5Dokumen2 halamanPDS3 5Catur Budi KusumoBelum ada peringkat

- Towa Seiden Industrial Co., LTD.: Instruction Manual Paddle Type Level Switch PRLDokumen16 halamanTowa Seiden Industrial Co., LTD.: Instruction Manual Paddle Type Level Switch PRLMuh ImronBelum ada peringkat

- Commissioning Valve Product BrochureDokumen14 halamanCommissioning Valve Product BrochureblindjaxxBelum ada peringkat

- Static Web Moment ConnectionsDokumen43 halamanStatic Web Moment ConnectionsAlejandro SantiagoBelum ada peringkat

- PQ DI DocumentDokumen47 halamanPQ DI DocumentJanith Saumya BandaraBelum ada peringkat

- SAES-E-004 02-18-2018 FinalDokumen35 halamanSAES-E-004 02-18-2018 Finalsaleem naheedBelum ada peringkat

- National Oil Corporation Packaged Reciprocating Compressor SpecificationDokumen26 halamanNational Oil Corporation Packaged Reciprocating Compressor SpecificationYousab JacobBelum ada peringkat

- L&T Pipeline Ball ValvesDokumen24 halamanL&T Pipeline Ball Valvesjamil vora100% (1)

- MPD Dhs 1400 RCDDokumen2 halamanMPD Dhs 1400 RCDali_yy2003Belum ada peringkat

- Tabung Filter Air PentairDokumen4 halamanTabung Filter Air PentairPT Purione MegatamaBelum ada peringkat

- Compact Disc Check Valve for Industrial ApplicationsDokumen2 halamanCompact Disc Check Valve for Industrial ApplicationsDinesh ChouguleBelum ada peringkat

- MCT Cable Transit System: Fire Rated, Environmental Cable Sealing SystemsDokumen7 halamanMCT Cable Transit System: Fire Rated, Environmental Cable Sealing SystemsRaju ThamkeBelum ada peringkat

- KPC Piping SpecDokumen111 halamanKPC Piping Specinfo_shakib100% (1)

- Sec XDokumen290 halamanSec XK.s. Raghavendra Kumar100% (1)

- Extracto Norma Asme B16.5 PDFDokumen2 halamanExtracto Norma Asme B16.5 PDFklevra21Belum ada peringkat

- ASME Standards Technology, LLC: New PublicationsDokumen5 halamanASME Standards Technology, LLC: New PublicationsTrushar ParmarBelum ada peringkat

- Ep31492 PDFDokumen11 halamanEp31492 PDFJilJilBelum ada peringkat

- Water Distribution Pumps SpecificationDokumen6 halamanWater Distribution Pumps Specificationadel rihanaBelum ada peringkat

- Specification For Small Bore Tubing and Fittings: MarchDokumen25 halamanSpecification For Small Bore Tubing and Fittings: Marchsajid aslamBelum ada peringkat

- VEDV1003Dokumen13 halamanVEDV1003BHAVEESH100% (1)

- GB150 1-2011enDokumen46 halamanGB150 1-2011enIrfan AhmedBelum ada peringkat

- Butterfly Valve B7GDokumen3 halamanButterfly Valve B7GJorgeCabreraCoronelBelum ada peringkat

- Parker - Ppl-Cat-P6m (A) 5S-001Dokumen4 halamanParker - Ppl-Cat-P6m (A) 5S-001Santiago PeñuelaBelum ada peringkat

- Vikings-Halar Coated Deluge ValveDokumen12 halamanVikings-Halar Coated Deluge ValveHenry WuBelum ada peringkat

- ATFD QUOTEr1Dokumen12 halamanATFD QUOTEr1Hariharan M EBelum ada peringkat

- Woodward Gs6 Gas ValveDokumen4 halamanWoodward Gs6 Gas ValveIsaias Fernandez Calderon100% (1)

- Catalog Suruburi KrinnerDokumen49 halamanCatalog Suruburi KrinnergabisolomonBelum ada peringkat

- 21 12 00 Fire Protection SystDokumen16 halaman21 12 00 Fire Protection SystMichel CorrêaBelum ada peringkat