Food Preservation

Diunggah oleh

Mohit sharmaDeskripsi Asli:

Hak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

Food Preservation

Diunggah oleh

Mohit sharmaHak Cipta:

Format Tersedia

Food preservation is the process of treating and handling food to stop or greatly slow down spoilage (loss of quality,

edibility or nutritive value) caused or accelerated by micro-organisms. Some methods, however, use benign bacteria, yeasts or fungi to add specific qualities and to preserve food (e.g., cheese, wine). While maintaining or creating nutritional value, texture and flavour is important in preserving its value as food. This is culturally dependent, as what qualifies as food fit for humans in one culture may not qualify in another culture. Preservation usually involves preventing the growth of bacteria, fungi, and other microorganisms, as well as retarding the oxidation of fats which cause rancidity. Some preservation methods require the food to be sealed after treatment to prevent recontamination with microbes; others, such as drying, allow food to be stored without any special containment for long periods. Common methods of applying these processes include drying, spray drying, freeze drying, freezing,vacuum-packing, canning, preserving in syrup, sugar crystallisation, food irradiation, and adding preservatives or inert gases such as carbon dioxide. Other methods that not only help to preserve food, but also add flavour, include pickling, salting, smoking, preserving in syrup or alcohol, sugar crystallisation and curing.

Preservation processes include:

Heating to kill or denature organisms (e.g. boiling) Oxidation (e.g. use of sulphur dioxide) Toxic inhibition (e.g. smoking, use of carbon dioxide, vinegar, alcohol etc) Dehydration (drying) Osmotic inhibition ( e.g. use of syrups) Low temperature inactivation (e.g. freezing) Ultra high water pressure (e.g. fresherized, a kind of cold pasteurization, the pressure kills naturally occurring pathogens, which cause food deterioration and affect food safety.)

Drying One of the oldest methods of food preservation is by drying, which reduces water activity sufficiently to prevent or delay bacterial growth.[citation needed] Drying also reduces weight, making food more portable. Most types of meat can be dried; a good example is beef. Drying is also the normal means of preservation for cereal grains such as wheat, maize, oats, barley, rice, millet and rye. Freezing Freezing is also one of the most commonly used processes commercially and domestically for preserving a very wide range of food including prepared food stuffs

which would not have required freezing in their unprepared state. For example, potato waffles are stored in the freezer Vacuum-packing Vacuum-packing stores food in a vacuum environment, usually in an air-tight bag or bottle. The vacuum environment strips bacteria of oxygen needed for survival, slowing spoiling. Vacuum-packing is commonly used for storing nuts to reduce loss of flavor from oxidation Salt Salting or curing draws moisture from the meat through a process of osmosis. Meat is cured with salt or sugar, or a combination of the two. heat heat dry the food without cooking it, and the addition of the aromatic hydrocarbons from the smoke preserves the food. lye Sodium hydroxide (lye) makes food too alkaline for bacterial growth. Lye will saponify fats in the food, which will change its flavor and texture.

jellying Food may be preserved by cooking in a material that solidifies to form a gel. Such materials include gelatine, flour and arrowroot flour. Fruit preserved by jellying is known as jelly, marmalade, or fruit preserves. In this case, the jellying agent is usually pectin, either added during cooking or arising naturally from the fruit. Potting A traditional British way of preserving meat is by setting it in a pot and sealing it with a layer of fat. Also common is potted chicken liver; compare jugging Meat can be preserved by jugging, the process of stewing the meat (commonly game or fish) in a covered earthenware jug or casserole. The animal to be jugged is usually cut into pieces, placed into a tightly-sealed jug with brine or gravy, and stewed.

Method Refrigeration Freezing Drying, curing and conserving Vacuum and oxygen free modified atmosphere packaging Carbon dioxide enriched modified atmosphere packaging Addition of weak acids; e.g. sodium lactate

Effect on microbial growth or survival Low temperature to retard growth Low temperature and reduction of water activity to prevent microbial growth, slowing of oxidation reactions Reduction in water activity sufficient to delay or prevent microbial growth Low oxygen tension inhibits strict aerobes and delays growth of facultative anaerobes Specific inhibition of some microorganisms Reduction of the intracellular pH of micro-organisms

Reduction of pH value in situ by microbial action and sometimes additional inhibition by the lactic and Lactic fermentation acetic acids formed and by other microbial products. (e.g. ethanol, bacteriocins) Cooking in high sucrose concentration creating too high Sugar preservation osmotic pressure for most microbial survival. Steeping or cooking in Ethanol produces toxic inhibition of microbes. Ethanol preservation Can be combined with sugar preservation Compartmentalisation and nutrient Emulsification limitation within the aqueous droplets in water-in-oil emulsion foods Addition of Inhibition of specific groups of preservatives such as micro-organisms nitrite or sulphite ions Delivery of heat sufficient to Pasteurization and inactivate target micro-organisms to appertization the desired extent Food irradiation (Radurization, Delivery of ionising radiation to radicidation and disrupt cellular RNA radappertization) Application of high Pressure-inactivation of vegetative hydrostatic pressure bacteria, yeasts and moulds (Pascalization) Pulsed electric field Short bursts of electricity for processing (PEF microbial inactivation treatment)

Anda mungkin juga menyukai

- HistoryDokumen1 halamanHistoryJason Bueta100% (1)

- Rehabilitation of Criminals and Juveniles in Society andDokumen43 halamanRehabilitation of Criminals and Juveniles in Society andHarshil ShahBelum ada peringkat

- Geo-Strategic Importance of PakistanDokumen6 halamanGeo-Strategic Importance of Pakistanwajid malikBelum ada peringkat

- Principles of Islamic Economics in The Light of The Holy Quran and SunnahDokumen7 halamanPrinciples of Islamic Economics in The Light of The Holy Quran and SunnahinventionjournalsBelum ada peringkat

- USA As A British Colony (1606-1783) : Subject: US History 4 CSS By: Imran ZahoorDokumen59 halamanUSA As A British Colony (1606-1783) : Subject: US History 4 CSS By: Imran ZahoorAmara FarooqBelum ada peringkat

- The Historical Development of CriminologyDokumen18 halamanThe Historical Development of CriminologyĀżiżBelum ada peringkat

- SociologyDokumen14 halamanSociologyGhulam muhammad100% (1)

- Status of Women in PakistanDokumen2 halamanStatus of Women in Pakistanaati89Belum ada peringkat

- Gsa Notes PDFDokumen35 halamanGsa Notes PDFhasanBelum ada peringkat

- Is Colonial Mentality Impeding PakistanDokumen4 halamanIs Colonial Mentality Impeding PakistanAnas MughalBelum ada peringkat

- IntroductionDokumen9 halamanIntroductionadarshBelum ada peringkat

- What Is The Importance of Coral Reefs PDFDokumen11 halamanWhat Is The Importance of Coral Reefs PDFAtulJhaKumar100% (1)

- Cultural Diversity in Pakistan 27042023 100257pmDokumen5 halamanCultural Diversity in Pakistan 27042023 100257pmKasho KhanBelum ada peringkat

- CR 1 PDFDokumen65 halamanCR 1 PDFAmmara JahangirBelum ada peringkat

- Status of Women in PakistanDokumen18 halamanStatus of Women in PakistanFawad ShahBelum ada peringkat

- All About PolioDokumen6 halamanAll About PolioNandini Saxena100% (1)

- Strain TheoryDokumen16 halamanStrain Theoryapi-291832916Belum ada peringkat

- The Quaid’s Critical Role in Creating PakistanDokumen8 halamanThe Quaid’s Critical Role in Creating PakistanWardah SiddiquiBelum ada peringkat

- Advances in Aquaculture Fisheries Villay 1976Dokumen681 halamanAdvances in Aquaculture Fisheries Villay 1976Cíntia LeikaBelum ada peringkat

- Judicial Activism Is The Natural Corollary of Poor Governance in PakistanDokumen3 halamanJudicial Activism Is The Natural Corollary of Poor Governance in PakistanSohail NasirBelum ada peringkat

- Syllabus of CSS PapersDokumen15 halamanSyllabus of CSS PapersNida GondalBelum ada peringkat

- PDF Complete Criminology Notes For Css by SSP Asmatullah Junejo CompressDokumen10 halamanPDF Complete Criminology Notes For Css by SSP Asmatullah Junejo CompressAhsan AliBelum ada peringkat

- CSS Essay - South China Sea and Strategic CompetitionDokumen6 halamanCSS Essay - South China Sea and Strategic CompetitionAnaya RanaBelum ada peringkat

- A Nation in Chains by G. M. SayedDokumen176 halamanA Nation in Chains by G. M. SayedSani PanhwarBelum ada peringkat

- Concept of Human RightsDokumen3 halamanConcept of Human RightsSebin JamesBelum ada peringkat

- Indian History Notes by Sir Ah Tisha Mali ButtDokumen110 halamanIndian History Notes by Sir Ah Tisha Mali ButtSheRazTarar100% (3)

- Materialism Destroys SpiritualismDokumen2 halamanMaterialism Destroys SpiritualismMuhammad Zia SheikhBelum ada peringkat

- Juvenile Delinquency in PakDokumen17 halamanJuvenile Delinquency in Pakwdhgwhjbdje100% (1)

- Indian Ocean Politics PDFDokumen21 halamanIndian Ocean Politics PDFAsma RaisBelum ada peringkat

- In The Fight Against Terrorism and CorruptionDokumen10 halamanIn The Fight Against Terrorism and CorruptionSafa KhanBelum ada peringkat

- Psychological Theories of Crime ManuscriptDokumen3 halamanPsychological Theories of Crime ManuscriptEduardo FriasBelum ada peringkat

- 1 TauheedDokumen3 halaman1 TauheedZohaib PervaizBelum ada peringkat

- International & Regional Organizations: Sarfraz Hussain Ansari (CSP)Dokumen47 halamanInternational & Regional Organizations: Sarfraz Hussain Ansari (CSP)Sami ullah khan BabarBelum ada peringkat

- Similarities and Diversities Between Plant and Animal KingdomDokumen8 halamanSimilarities and Diversities Between Plant and Animal Kingdomfr.faisal8265100% (1)

- Sociology Sample NotesDokumen46 halamanSociology Sample NotesARIF HUSSAIN AN ENGLISH LECTURER FOR ALL CLASSESBelum ada peringkat

- CPEC Projects Transforming PakistanDokumen68 halamanCPEC Projects Transforming Pakistanch_nasir834481Belum ada peringkat

- Dr. Israr Ahmed Scholar, Teacher and Founder of Tanzeem-e-Islami'Dokumen8 halamanDr. Israr Ahmed Scholar, Teacher and Founder of Tanzeem-e-Islami'Shahid KhanBelum ada peringkat

- Costs and Benefits of CPECDokumen14 halamanCosts and Benefits of CPECALI RAZA100% (1)

- Juvenile Justice System of PakistanDokumen15 halamanJuvenile Justice System of PakistanMuhammad Naveed IqbalBelum ada peringkat

- Non Traditional Security Threats To PakistanDokumen10 halamanNon Traditional Security Threats To PakistanAwan Nadia100% (1)

- Classification of Animals Based on Fundamental FeaturesDokumen89 halamanClassification of Animals Based on Fundamental Features333366998Belum ada peringkat

- Boys Will Be Boys - Complete OutlineDokumen2 halamanBoys Will Be Boys - Complete OutlineWaqar Ahmad100% (1)

- Quaid-e-Azam As MagistrateDokumen21 halamanQuaid-e-Azam As Magistrate02-111142-036 AREESHA SHAIKHBelum ada peringkat

- Islamic Concept of Jihad - Shaykh Ul Islam Dr. Tahir Ul QadriDokumen2 halamanIslamic Concept of Jihad - Shaykh Ul Islam Dr. Tahir Ul Qadriskquadri7Belum ada peringkat

- The History of Culinary ArtsDokumen13 halamanThe History of Culinary ArtsMaruBelum ada peringkat

- Islamic Perspective On CrimeDokumen3 halamanIslamic Perspective On CrimeSyed Ali GilaniBelum ada peringkat

- China-Pakistan Economic Corridor - A Road To Development and Its ChallengesDokumen18 halamanChina-Pakistan Economic Corridor - A Road To Development and Its ChallengesMuhammad AteeqBelum ada peringkat

- National Accountability BureauDokumen21 halamanNational Accountability BureauAhmad JuttBelum ada peringkat

- Pakistan Beyond the Crisis State Book ReviewDokumen8 halamanPakistan Beyond the Crisis State Book ReviewAdeel IftikharBelum ada peringkat

- Post-Colonialism in South Asia: British Rule and Independence StrugglesDokumen5 halamanPost-Colonialism in South Asia: British Rule and Independence StrugglesAyesha Butt50% (2)

- Status of Women in Pakistan - The Hudood OrdinanceDokumen9 halamanStatus of Women in Pakistan - The Hudood OrdinanceloststoneBelum ada peringkat

- 2 Schools of ThoughtsDokumen4 halaman2 Schools of ThoughtsbotiodBelum ada peringkat

- Two Nation TheoryDokumen3 halamanTwo Nation TheoryMutahir Shafique AwanBelum ada peringkat

- ENGLISH (Précis & Composition) : Mock TestDokumen3 halamanENGLISH (Précis & Composition) : Mock Testshahid mehmoodBelum ada peringkat

- Food Preservation & PhysicsDokumen12 halamanFood Preservation & Physicsamber_lynn_28Belum ada peringkat

- Food PreservationDokumen12 halamanFood Preservationjaved_tech5583Belum ada peringkat

- Wiki Food PreservationDokumen10 halamanWiki Food PreservationRisa aprianiBelum ada peringkat

- Hurdle TechDokumen13 halamanHurdle TechVikas Singh PariharBelum ada peringkat

- Food Preservation Epp ReviewerDokumen6 halamanFood Preservation Epp ReviewerElaine FajanilanBelum ada peringkat

- Food Preservation Is The Process of Treating and Handling Food To Stop or Greatly SlowDokumen8 halamanFood Preservation Is The Process of Treating and Handling Food To Stop or Greatly SlowEmily Torrace DunbarBelum ada peringkat

- Golf TourismDokumen11 halamanGolf TourismMohit sharmaBelum ada peringkat

- Fatty AcidsDokumen14 halamanFatty AcidsMohit sharmaBelum ada peringkat

- Continental Kitchen EquipmentsDokumen14 halamanContinental Kitchen EquipmentsMohit sharmaBelum ada peringkat

- Haryana TourismDokumen5 halamanHaryana TourismMohit sharmaBelum ada peringkat

- F&B Cost ControlDokumen22 halamanF&B Cost ControlMohit sharma100% (1)

- Golf TourismDokumen11 halamanGolf TourismMohit sharmaBelum ada peringkat

- F&B Cost ControlDokumen22 halamanF&B Cost ControlMohit sharma100% (1)

- Continental Kitchen EquipmentsDokumen14 halamanContinental Kitchen EquipmentsMohit sharmaBelum ada peringkat

- Causes of Damage The Raw MaterialDokumen7 halamanCauses of Damage The Raw MaterialMohit SharmaBelum ada peringkat

- Baker's ImportanceDokumen18 halamanBaker's ImportanceMohit sharmaBelum ada peringkat

- Army Catering ManualDokumen533 halamanArmy Catering ManualTheHairyOne100% (7)

- Bread Roll Product 2Dokumen7 halamanBread Roll Product 2Cristy Javinar100% (1)

- Homemade Mayo - Minute-Made Delicious - DaysDokumen11 halamanHomemade Mayo - Minute-Made Delicious - DayschristianbaierBelum ada peringkat

- Taste 10Dokumen21 halamanTaste 10bangsadapBelum ada peringkat

- LPG OVEN FOR BAMBOO LEMANG COOKINGDokumen2 halamanLPG OVEN FOR BAMBOO LEMANG COOKINGHeru PramudiaBelum ada peringkat

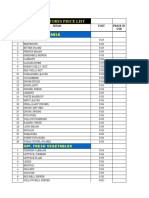

- Provision Stores Price List: Fresh VegetableDokumen18 halamanProvision Stores Price List: Fresh VegetableBatuhan SürerBelum ada peringkat

- DocxDokumen26 halamanDocxMikey MadRat29% (7)

- Prepare Display Petit Fours FN 030214Dokumen31 halamanPrepare Display Petit Fours FN 030214neilaldrichgequinto91% (11)

- Charcuterie: The Craft of Salting, Smoking, and Curing (Revised and Updated) - Michael RuhlmanDokumen5 halamanCharcuterie: The Craft of Salting, Smoking, and Curing (Revised and Updated) - Michael RuhlmancilenugyBelum ada peringkat

- Exam TLE Q3Dokumen7 halamanExam TLE Q3Nick TejadaBelum ada peringkat

- RasamDokumen3 halamanRasamrajece1982Belum ada peringkat

- Panasonic SD-YR2550 Manual enDokumen24 halamanPanasonic SD-YR2550 Manual enGustavs KrievkalnsBelum ada peringkat

- Fish Smoking Project Proposal for Libertad FisherfolksDokumen4 halamanFish Smoking Project Proposal for Libertad FisherfolksRiza D. Sioco100% (4)

- He BPP Gr11 q1 Module-2editedDokumen17 halamanHe BPP Gr11 q1 Module-2editedSharon DannugBelum ada peringkat

- Augusta Brewing Company 1888 Augusta, Georgia 1888 The Rise and FallDokumen5 halamanAugusta Brewing Company 1888 Augusta, Georgia 1888 The Rise and Falldoug_herman_srBelum ada peringkat

- Salty Chocolate Chunk CookiesDokumen1 halamanSalty Chocolate Chunk Cookiesbooter0504Belum ada peringkat

- CochinDokumen2 halamanCochinAmanda RoweBelum ada peringkat

- 22312-Article Text-105613-1-10-20200626Dokumen12 halaman22312-Article Text-105613-1-10-20200626Azwa SafrinaBelum ada peringkat

- Function Package Only MenuDokumen3 halamanFunction Package Only MenuAndrew ReadBelum ada peringkat

- Saffron Menu 2018Dokumen2 halamanSaffron Menu 2018dinedhBelum ada peringkat

- The Nuts Creative: Recipes GuideDokumen20 halamanThe Nuts Creative: Recipes GuideChristopher González80% (5)

- How To Make Neapolitan PizzaDokumen2 halamanHow To Make Neapolitan Pizzamuhammadsmith123456Belum ada peringkat

- Thesis Chap 1 FinaleDokumen11 halamanThesis Chap 1 FinaleYoung Dagger Diick100% (1)

- Shorty's BBQ MenuDokumen2 halamanShorty's BBQ MenuTammy Taillac HawkesBelum ada peringkat

- Marco Pierre White's Vegetable LasagneDokumen2 halamanMarco Pierre White's Vegetable LasagnecoolshavaBelum ada peringkat

- Futura Cookware Catalog 2022Dokumen48 halamanFutura Cookware Catalog 2022Amelia GunawanBelum ada peringkat

- Beef Wellington - Chef Jean PierreDokumen2 halamanBeef Wellington - Chef Jean Pierrevasilescu2Belum ada peringkat

- Recipes From Vegetronic by Alexis GauthierDokumen16 halamanRecipes From Vegetronic by Alexis GauthierThe Recipe Club0% (1)

- T5u6h PDFDokumen10 halamanT5u6h PDFMissmt LópezBelum ada peringkat

- Taste of Home 05 2009Dokumen76 halamanTaste of Home 05 2009Ariana Pazzini100% (3)