Machinery Component Maintenance and Repair

Diunggah oleh

api-3723333100%(1)100% menganggap dokumen ini bermanfaat (1 suara)

900 tayangan2 halamanMaintenance organization and control for multi-plant corporations type of operation. Proper grout mixing is important. Recommendations for the installation, fabrication, testing, and cleaning of air, gas, or steam piping. Part ii: alignment and balancing 5 machinery alignment prealignment requirements.

Deskripsi Asli:

Hak Cipta

© Attribution Non-Commercial (BY-NC)

Format Tersedia

TXT, PDF, TXT atau baca online dari Scribd

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniMaintenance organization and control for multi-plant corporations type of operation. Proper grout mixing is important. Recommendations for the installation, fabrication, testing, and cleaning of air, gas, or steam piping. Part ii: alignment and balancing 5 machinery alignment prealignment requirements.

Hak Cipta:

Attribution Non-Commercial (BY-NC)

Format Tersedia

Unduh sebagai TXT, PDF, TXT atau baca online dari Scribd

100%(1)100% menganggap dokumen ini bermanfaat (1 suara)

900 tayangan2 halamanMachinery Component Maintenance and Repair

Diunggah oleh

api-3723333Maintenance organization and control for multi-plant corporations type of operation. Proper grout mixing is important. Recommendations for the installation, fabrication, testing, and cleaning of air, gas, or steam piping. Part ii: alignment and balancing 5 machinery alignment prealignment requirements.

Hak Cipta:

Attribution Non-Commercial (BY-NC)

Format Tersedia

Unduh sebagai TXT, PDF, TXT atau baca online dari Scribd

Anda di halaman 1dari 2

pdf, 614 pages, 9.

8 mb

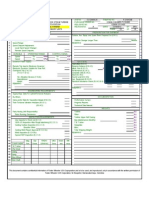

part i: background to process machinery maintenance

programming

1 machinery maintenance: an ovaview

2 maintenance organization and control for multi-plant corporations

type of operation. manager�s role. central control system. planning turbo-

machinery overhauls. assignment of qualified personnel. specific prepara-

tion and planning. inspection. cleaning. reassembly. documenting what

you�ve done.

3 machinery foundations and grouting

what�s an epoxy? epoxy grouts. proper grout mixing is important. job plan-

ning. conventional grouting. methods of installing machinery. pressure-in-

jection regrouting . foundation repairs. pump baseplate installation and ep-

oxy grouting. baseplate leveling procedures. baseplate preparation. new

concrete preparation. old concrete preparation. anchor bolts. grout forms.

epoxy grout placement. appendix 3-a-detailed checklist for rotating

equipment: horizontal pump baseplate checklist. appendix 3-b-specifica-

tion for portland cement grouting of rotating equipment. appendix 3-c-de-

tailed checklist for rotating equipment: baseplate grouting. appendix 3-d-

specifications for epoxy grouting of rotating equipment.

4 process machinery piming

fundamentals of piping design criteria. piping design procedure. flange

jointing practices. primary causes of flange leakage. proper gasket selec-

tion. controlled torque bolt-up of flanged connections. recommendations

for the installation, fabrication, testing, and cleaning of air, gas, or steam

piping. appendix 4-a-checklist for rotating equipment: machinery piping.

appendix 4-b-specifications for cleaning mechanical seal pots and piping

for centrifugal pumps. appendix 4-c-detailed checklist for rotating equip-

ment: pump piping.

part ii: alignment and balancing

5 machinery alignment

prealignment requirements. choosing an alignment measurement setup.

checking for bracket sag. face sag effect-examples. interpretation and data

recording. graphical techniques. reverse indicator method using crossover

brackets. horizontal movement by vertical adjustment. thermal growth-

eleven ways to correct for it. thermal growth estimation by rules of thumb.

6 balancing of machinery components

definition of terms. purpose of balancing. units of unbalance. types of un-

balance. motions of unbalanced rotors. balancing machines. centrifugal bal-

ancing machines. measurement of amount and angle of unbalance. classifi-

cation of centrifugal balancing machines. maintenance and production

balancing machines. supporting the rotor. balancing keyed end-drive

adapters. balancing arbors. testing balancing machines. test procedures.

balance tolerances. balance errors due to rotor support elements. com-

puter-aided balancing. field balancing overview. the vector diagram. ap-

pendix 6-a-balancing terminology. appendix 6-b-balancing machine no-

menclature. appendix 6-c-balancing and vibration standards. appendix

6-d-critical speeds of solid and hollow shafts.

part 111: maintenance and repair of machinery components

7 ball bearing maintenance and replacement

engineering and interchangeability data. cleanliness and working conditions

in assembly area. removal of shaft and bearings from housing. cleaning the

bearing. shaft and housing preparation. checking shaft and housing mea-

surements. basic mounting methods. hints on mounting duplex bearings.

preloading of duplex bearings. importance of the correct amount of preload.

assembly of bearings on shaft. cautions to observe during assembly of bear-

ings into units. mounting with heat. checking bearings and shaft after instal-

lation. testing of finished spindle. maintain service records on all spindles.

8 repair and maintenance of mechanical seals and rotating

equipment components

mechanical seal installation, repair, and maintenance. lapping and seal face

flatness. installation of stuffing box packing. welded repairs to pump shafts

and other rotating equipment components. how to decide if welded repairs

are feasible. case histories. high speed shaft repair. shaft straightening.

straightening carbon steel shafts. casting salvaging methods.

9 centrifugal compressor rotor repair

compressor rotor repairs. impeller manufacture. compressor impeller de-

sign problems. impeller balancing procedure. rotor bows in compressor and

steam turbines. clean up and inspection of rotor. disassembly of rotor for

shaft repair. shaft design. rotor assembly. shaft balancing. rotor thrust in

centrifugal compressors. managing rotor repairs at outside shops. mount-

ing of hydraulically fitted hubs. dismounting of hydraulically fitted hubs.

10 protecting machinery parts against loss of surface

basic wear mechanisms. hard surfacing techniques. special purpose materi-

als. the detonation gun process. selection and application of 0-rings. cas-

ing joint compounds. sealing compounds.

download :

http://rapidshare.de/files/21055043/bloch__h._p.__1990_._machinery_component_maint

enance_and_repair__2nd_ed._.rar 9.65 mb

Anda mungkin juga menyukai

- Stan Shiels on centrifugal pumps: Collected articles from 'World Pumps' magazineDari EverandStan Shiels on centrifugal pumps: Collected articles from 'World Pumps' magazinePenilaian: 5 dari 5 bintang5/5 (1)

- Impeller Repair Techniques For Centrifugal Compressors PDFDokumen8 halamanImpeller Repair Techniques For Centrifugal Compressors PDFFonCKm09Belum ada peringkat

- Turbogenerator Vibration Analysis and Maintenance ReportDokumen16 halamanTurbogenerator Vibration Analysis and Maintenance ReportNestor Lopez100% (1)

- Sample Pump Rebuild Report - 0Dokumen21 halamanSample Pump Rebuild Report - 0Trịnh Đức HạnhBelum ada peringkat

- Cook Compression PackingDokumen2 halamanCook Compression PackingMuhammad Imran100% (1)

- Failure Mode and Effects Analysis1Dokumen6 halamanFailure Mode and Effects Analysis1VLASTARBelum ada peringkat

- Ebara Submersible Pump PDFDokumen28 halamanEbara Submersible Pump PDFThinagaran N ManiamBelum ada peringkat

- Compressor Turbo-Air API a4-IRDokumen12 halamanCompressor Turbo-Air API a4-IRMachineryengBelum ada peringkat

- Hydraulics CurriculumDokumen8 halamanHydraulics CurriculumChris ChrisBelum ada peringkat

- ACHE Windmill DraftguardDokumen5 halamanACHE Windmill DraftguardTIKSHALABelum ada peringkat

- Ku Reprint Ps April2007Dokumen2 halamanKu Reprint Ps April2007keyur1109Belum ada peringkat

- M PM 170Dokumen34 halamanM PM 170mahesh_eilBelum ada peringkat

- Ms Hda A1826 8e 1 PDFDokumen35 halamanMs Hda A1826 8e 1 PDFradanpetricaBelum ada peringkat

- Increasing Pump CapacityDokumen3 halamanIncreasing Pump Capacitydk4monjureBelum ada peringkat

- Centrifugal CompressorDokumen21 halamanCentrifugal CompressorChiviya Fariku100% (1)

- SEALDokumen6 halamanSEALkishorsinghBelum ada peringkat

- PumpsDokumen45 halamanPumpsMehmood Ul Hassan100% (1)

- Top 10 Rotating Equipment Engineer Interview Questions and AnswersDokumen17 halamanTop 10 Rotating Equipment Engineer Interview Questions and AnswersSathishkumar VeluBelum ada peringkat

- Bibby CouplingsDokumen25 halamanBibby CouplingsKemoy JohnsonBelum ada peringkat

- Centrifugal Pumps Chapter OverviewDokumen21 halamanCentrifugal Pumps Chapter Overviewmonjardin68Belum ada peringkat

- AgitatorsDokumen9 halamanAgitatorsB Santosh Kumar DoddalaBelum ada peringkat

- Limited End Float Couplings: CautionDokumen2 halamanLimited End Float Couplings: CautionsanthoshBelum ada peringkat

- P178Dokumen9 halamanP178keepmoshingBelum ada peringkat

- How to Calculate Polytropic EfficiencyDokumen2 halamanHow to Calculate Polytropic Efficiencysevero97Belum ada peringkat

- Syn Gas Compressor Oil Tank ExplosionDokumen6 halamanSyn Gas Compressor Oil Tank Explosionarunanshu palBelum ada peringkat

- Week 2 Water PumpingDokumen76 halamanWeek 2 Water PumpingAbdullahi Dirie AbdiBelum ada peringkat

- 2012 Paper Screw CompressorsDokumen25 halaman2012 Paper Screw CompressorsravisankarBelum ada peringkat

- 2016 Vol-2 3 OCTDokumen12 halaman2016 Vol-2 3 OCTsppramBelum ada peringkat

- Case Study Tuning Out Difficult Torsional Vibration ProblemDokumen15 halamanCase Study Tuning Out Difficult Torsional Vibration Problempathakshashank100% (1)

- Hydraulic Resevoir Design Criteria PDFDokumen10 halamanHydraulic Resevoir Design Criteria PDF2345421Belum ada peringkat

- Centrifugal Pump Set Failure ModesDokumen70 halamanCentrifugal Pump Set Failure ModesArif WidyatamaBelum ada peringkat

- Api 611 5Th Edition General " Purpose Steam Turbine Existing TurbineDokumen1 halamanApi 611 5Th Edition General " Purpose Steam Turbine Existing TurbineAlejandro GilBelum ada peringkat

- Dynamic Reaction Inside Co-Rotating Twin Screw Extruder. II. Waste Ground Rubber Tire Powder - Polypropylene BlendsDokumen11 halamanDynamic Reaction Inside Co-Rotating Twin Screw Extruder. II. Waste Ground Rubber Tire Powder - Polypropylene Blendspickpocket27Belum ada peringkat

- Piston RingDokumen8 halamanPiston RingashokkumarBelum ada peringkat

- المستندDokumen5 halamanالمستندMahdi HassanBelum ada peringkat

- 03 Product OverviewDokumen44 halaman03 Product OverviewMamdouh ElhanafyBelum ada peringkat

- Guidelines For Preventing Torsional Vibration Problems in Reciprocating MachineryDokumen48 halamanGuidelines For Preventing Torsional Vibration Problems in Reciprocating MachineryFabbrox100% (2)

- Experience With Torsional Vibration at Reciprocating CompressorsDokumen14 halamanExperience With Torsional Vibration at Reciprocating CompressorsÏmŗäņPŗïņċëBelum ada peringkat

- Effect of Oil Flow on Gearbox Pinion Critical Speed During TestingDokumen10 halamanEffect of Oil Flow on Gearbox Pinion Critical Speed During TestingFarzadBelum ada peringkat

- Advanced Turbo MachineryDokumen2 halamanAdvanced Turbo Machineryjvinod2025Belum ada peringkat

- Compressor piston rings and rider rings guideDokumen22 halamanCompressor piston rings and rider rings guidemauricioBelum ada peringkat

- Selecting The Best Slurry Pump For Specific Operating ConditionsDokumen9 halamanSelecting The Best Slurry Pump For Specific Operating ConditionssmendozaBelum ada peringkat

- Reduce Oil Leakage with OT Oil Wiper Packing DesignDokumen4 halamanReduce Oil Leakage with OT Oil Wiper Packing DesignsaravananknpcBelum ada peringkat

- Guide To Measure Rotating EquipmentDokumen18 halamanGuide To Measure Rotating EquipmentMDRBelum ada peringkat

- 2020 Style 688 Split SealtekDokumen8 halaman2020 Style 688 Split SealtekdiamsamBelum ada peringkat

- 2 How To Make A Pump Selection - Intro To PumpsDokumen7 halaman2 How To Make A Pump Selection - Intro To PumpsMohammed MustafaBelum ada peringkat

- Compressors Course-Chapter 8Dokumen3 halamanCompressors Course-Chapter 8vela vanBelum ada peringkat

- LN Uk Magtecta 01Dokumen8 halamanLN Uk Magtecta 01denizarazBelum ada peringkat

- 7 Tips On Compressor DesignDokumen18 halaman7 Tips On Compressor DesignkrazylionBelum ada peringkat

- Shaft and Bearing Calculations in PumpsDokumen21 halamanShaft and Bearing Calculations in Pumpsnarendradounde143Belum ada peringkat

- Microproject Report HPCDokumen7 halamanMicroproject Report HPCkadamnavadeep5863Belum ada peringkat

- Use of Cold Air Velocity Test (CAVT) To Locate Erosion Prone Zones in Pulverized Coal Fired Utility BoilerDokumen5 halamanUse of Cold Air Velocity Test (CAVT) To Locate Erosion Prone Zones in Pulverized Coal Fired Utility BoilerVinoth KumarBelum ada peringkat

- Vertical Turbine Pumps Engineering Data: Effective April 1, 2003Dokumen11 halamanVertical Turbine Pumps Engineering Data: Effective April 1, 2003Israel CastilloBelum ada peringkat

- 06 - Lube Oil SystemDokumen13 halaman06 - Lube Oil SystemNaveedullah AwanBelum ada peringkat

- AgitatorDokumen8 halamanAgitatorMugesh KannaBelum ada peringkat

- Research and Innovations For Continuous Miner's Cutting Head, For Efficient Cutting Process of Rock/CoalDokumen12 halamanResearch and Innovations For Continuous Miner's Cutting Head, For Efficient Cutting Process of Rock/CoalKarthii Aju100% (1)

- Structural Health MonitoringDari EverandStructural Health MonitoringDaniel BalageasBelum ada peringkat

- Major Process Equipment Maintenance and RepairDari EverandMajor Process Equipment Maintenance and RepairPenilaian: 4 dari 5 bintang4/5 (4)

- Moorings DesignDokumen3 halamanMoorings Designapi-37233330% (1)

- Fractography of Ceramics and GlassesDokumen4 halamanFractography of Ceramics and Glassesapi-3723333Belum ada peringkat

- Passive Solar HandbookDokumen2 halamanPassive Solar Handbookapi-3723333Belum ada peringkat

- Landscape Design and Planting CriteriaDokumen1 halamanLandscape Design and Planting Criteriaapi-3723333Belum ada peringkat

- Biodiesel Handling and Use GuidelinesDokumen1 halamanBiodiesel Handling and Use Guidelinesapi-3723333Belum ada peringkat

- Interior and Exterior Lighting SystemDokumen2 halamanInterior and Exterior Lighting Systemapi-3723333Belum ada peringkat

- Calibration of Timer and StopwatchDokumen1 halamanCalibration of Timer and Stopwatchapi-3723333Belum ada peringkat

- Fleet Mooring Underwater Inspection GuidelinesDokumen1 halamanFleet Mooring Underwater Inspection Guidelinesapi-3723333Belum ada peringkat

- Underwater Cutting and Welding ManualDokumen2 halamanUnderwater Cutting and Welding Manualapi-3723333Belum ada peringkat

- Settlement AnalysisDokumen2 halamanSettlement Analysisapi-3723333Belum ada peringkat

- Design of Sheet Pile WallsDokumen2 halamanDesign of Sheet Pile Wallsapi-3723333Belum ada peringkat

- Statistical Concepts in MetrologyDokumen1 halamanStatistical Concepts in Metrologyapi-3723333Belum ada peringkat

- Test Procedures For Developing Solder DataDokumen1 halamanTest Procedures For Developing Solder Dataapi-3723333Belum ada peringkat

- Cooling Buildings by Natural VentilationsDokumen2 halamanCooling Buildings by Natural Ventilationsapi-3723333Belum ada peringkat

- Maintenance of Petroleum SystemsDokumen1 halamanMaintenance of Petroleum Systemsapi-3723333Belum ada peringkat

- Fuel Cell-Micro Turbine Combine CycleDokumen1 halamanFuel Cell-Micro Turbine Combine Cycleapi-3723333Belum ada peringkat

- Heating System Operation and MaintenanceDokumen3 halamanHeating System Operation and Maintenanceapi-3723333Belum ada peringkat

- Guide To Fuel CellsDokumen1 halamanGuide To Fuel Cellsapi-3723333Belum ada peringkat

- The Fundamentals of Neutron Powder DiffractionDokumen1 halamanThe Fundamentals of Neutron Powder Diffractionapi-3723333Belum ada peringkat

- Engineering Use of GeotextilesDokumen2 halamanEngineering Use of Geotextilesapi-3723333Belum ada peringkat

- Active Solar Preheat SystemsDokumen2 halamanActive Solar Preheat Systemsapi-3723333Belum ada peringkat

- Standard Practice For ShotcreteDokumen2 halamanStandard Practice For Shotcreteapi-3723333Belum ada peringkat

- A Finite Element Scheme For Shock CapturingDokumen1 halamanA Finite Element Scheme For Shock Capturingapi-3723333Belum ada peringkat

- Soil MechanicsDokumen2 halamanSoil Mechanicsapi-3723333Belum ada peringkat

- Reservoir Water Quality AnalysisDokumen2 halamanReservoir Water Quality Analysisapi-3723333Belum ada peringkat

- DTAandHeat-flux DSC Measurements of Alloy Melting and FreezingDokumen2 halamanDTAandHeat-flux DSC Measurements of Alloy Melting and Freezingapi-3723333Belum ada peringkat

- Underwater Geotechnical FoundationsDokumen2 halamanUnderwater Geotechnical Foundationsapi-3723333Belum ada peringkat

- Hvac and Dehumidifying SystemsDokumen3 halamanHvac and Dehumidifying Systemsapi-3723333Belum ada peringkat

- Measurement EvaluationDokumen1 halamanMeasurement Evaluationapi-3723333Belum ada peringkat

- Industrial and Oily Wastewater ControlsDokumen2 halamanIndustrial and Oily Wastewater Controlsapi-3723333Belum ada peringkat

- YORK Eager Series Brochure ANBIDokumen2 halamanYORK Eager Series Brochure ANBIJibran AlamBelum ada peringkat

- Sayers OCRDokumen164 halamanSayers OCRWellington Paro Tuito50% (2)

- Unit Viib Fans and BlowersDokumen8 halamanUnit Viib Fans and BlowersRaffy Calamonte CanoyBelum ada peringkat

- CSD - CSDX 45 90 KWDokumen11 halamanCSD - CSDX 45 90 KWShrikantBelum ada peringkat

- Types of CompressorsDokumen44 halamanTypes of Compressorsjezreeleda.limBelum ada peringkat

- Energies 08 08497 PDFDokumen19 halamanEnergies 08 08497 PDFAbuubakr Abdelwhab HassanBelum ada peringkat

- Aerodynamic and Mechanical Design of An 8 - 1 Pressure Ratio Centrifugal CompressorDokumen147 halamanAerodynamic and Mechanical Design of An 8 - 1 Pressure Ratio Centrifugal CompressorvincemugnaioBelum ada peringkat

- Power Test Code-Centrifugals PTC10Dokumen3 halamanPower Test Code-Centrifugals PTC10Ashitava SenBelum ada peringkat

- API 617 - Centrifugal CompressorDokumen46 halamanAPI 617 - Centrifugal CompressorAnas Mohammed92% (13)

- Turbo Machines Lab: Centrifugal and Reciprocating CompressorsDokumen38 halamanTurbo Machines Lab: Centrifugal and Reciprocating CompressorsUpendra SravanBelum ada peringkat

- Flow Through Centrifugal & Axial Flow Compressors: A ComparisonDokumen56 halamanFlow Through Centrifugal & Axial Flow Compressors: A ComparisonAzra H.Belum ada peringkat

- Applied Thermal Engineering - II (MEC 316) Unit - 2 Gas Turbines Tutorial SheetDokumen4 halamanApplied Thermal Engineering - II (MEC 316) Unit - 2 Gas Turbines Tutorial SheetShashi Kant KhalkhoBelum ada peringkat

- Spray Humidifier Design PED II FinalDokumen39 halamanSpray Humidifier Design PED II FinalPritam SharmaBelum ada peringkat

- Stress Analysis Training - (Analysis) BY Nedunchezhiyan AnbazhaganDokumen50 halamanStress Analysis Training - (Analysis) BY Nedunchezhiyan Anbazhaganchandra shekhar mishra100% (1)

- 2010 Gas Pipeline Toolbox ModulesDokumen4 halaman2010 Gas Pipeline Toolbox ModulesPENYU_1855100% (1)

- Axc Catalogue PDFDokumen4 halamanAxc Catalogue PDFSanket SinghBelum ada peringkat

- FM Global Property Loss Prevention Data Sheets: List of FiguresDokumen20 halamanFM Global Property Loss Prevention Data Sheets: List of FiguresSANJAY KUMAR M ABelum ada peringkat

- BS en Iso TR 11688-2-2001Dokumen56 halamanBS en Iso TR 11688-2-2001Rinu RavikumarBelum ada peringkat

- Centrifugal Fan DesignDokumen6 halamanCentrifugal Fan Designoureducation0% (1)

- ASME Code Section 8Dokumen14 halamanASME Code Section 8ShieeplBelum ada peringkat

- CompressorDokumen118 halamanCompressorsjois_hs100% (1)

- Air Conditioning Compressor Types - AC CompressorsDokumen3 halamanAir Conditioning Compressor Types - AC CompressorsdasmechBelum ada peringkat

- John M. Campbell & Company - Best Tips of The MonthDokumen152 halamanJohn M. Campbell & Company - Best Tips of The Monthcamanjarresv100% (3)

- Rotating Machinery EngineerDokumen15 halamanRotating Machinery EngineerJose Luis RattiaBelum ada peringkat

- STEAM METHANE REFORMING PLANT DESIGN PROPOSALDokumen251 halamanSTEAM METHANE REFORMING PLANT DESIGN PROPOSALArman Jade LazarteBelum ada peringkat

- 200905094-Ppt On Classification of Air CompressorsDokumen32 halaman200905094-Ppt On Classification of Air CompressorsPrasanna Kumar100% (4)

- 300 KW Ceramic TurbineDokumen6 halaman300 KW Ceramic Turbinejr110livecomBelum ada peringkat

- Mechanical Power Department 4 Year Turbo-Machinery II Centrifugal CompressorDokumen5 halamanMechanical Power Department 4 Year Turbo-Machinery II Centrifugal Compressorاحمد تاشهاويBelum ada peringkat

- Petroleum Gas Compression 3Dokumen55 halamanPetroleum Gas Compression 3Медетбек ҒайноллаBelum ada peringkat

- Practical Rotordynamics For Centrifugal PumpsDokumen52 halamanPractical Rotordynamics For Centrifugal PumpsEric21Belum ada peringkat