Article Outline

Diunggah oleh

ngochoa_1606Deskripsi Asli:

Hak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

Article Outline

Diunggah oleh

ngochoa_1606Hak Cipta:

Format Tersedia

Article Outline Title: Abstract: I.

Introduction - Ethanol production from renewable resources has been of interest in recent decades as an alternative fuel to the current fossil fuels. Lignocelluloses biomass like wood and agricultural crops residue, e.g., straw and sugarbeet pulp are potential raw materials for producing several high-value products like fuel ethanol and biodiesel. Rice straw is one of the abundant lignocellulosic waste materials in Vietnam, estimated about 30 40 mill.tons per year, that can be readily hydrolyzed into fermentable sugars and optain ethanol. It is the largest amount from a single biomass feedstock. - The Vietnamese Government has therefore asked for technical support from the Japanese Government to strongly develop the Mekong Delta, deal with agriculture waste and create renewable energy resources there. The project is planned for implementation from 2009 to 2014 under the technical collaboration between HCMUT and the Institute of Industrial Research of Tokyo University, as well as other research institutes and organizations. It will demonstrate a small-scale regional bio-refinery process based on the concept of local production of bio-fuels and bio-based materials for local consumption. During the projects period, a pilot plants will be established, namely Bio-refinery Experimental Process through which the study and key technologies for bio-refinery processes are expected to be developed. (Saigon time, 10/2009) - Typical bioethanol production processes using lignocellulosic feedstocks consist of four major steps: pretreatment, hydrolysis, fermentation, and separation. The goal of pretreatment is to make the cellulose accessible to hydrolysis for conversion to fuels. Various pretreatment techniques change the physical and chemical structure of the lignocellulosic biomass and improve hydrolysis rates. Dilute-alkaline hydrolysis has been successfully developed for pretreatment of lignocellulosic materials and caused swelling, leading to an increase in internal surface area, a decrease in the degree of polymerization, a decrease in crystallinity, separation of structural linkages between lignin and carbohydrates, and disruption of the lignin structure. The cellulose fraction of lignocelluloses can be converted to ethanol by either simultaneous saccharication

and fermentation (SSF) or separate enzymatic hydrolysis and fermentation (SHF) processes. SSF is more favored because of its low potential costs (Wyman CE, 1994). The hydrolysis is usually catalyzed by cellulase enzymes, and the fermentation is carried out by yeasts or bacteria to ethanol. In order for lignocellulosic bioethanol processes to be commercialized, each of these steps must be optimized for the particular feedstock. - Several researches have been completed on conversion of lignocellulosic materials to ethanol: Pretreatment of Lignocellulosic Wastes to Improve Ethanol(2008) by Mohammad J. Taherzadeh and Keikhosro Karimi research the effective parameters in pretreatment of lignocelluloses, such as crystallinity, accessible surface area, and protection by lignin and hemicelluloses. Then, several pretreatment methods are discussed and their effects on improvement in ethanol production are described in this article. In addition, Kerstin Hoyer has studied about the effect of enzyme feeding strategy on ethanol yield. Furthermore, there is article about Bioethanol Pilot plant of U.S Department of Energy. ( em c nh k m 3 b i b o) - The aim of this paper was: II. System and experiment methodology: 1. Materials and production system: Rice Straw

Rice straw used in the experiments was obtained from Thai My village ( Cu Chi, HCM city) ). The rice straw was chopped to achieve the size of less than 2cm, prior to pretreatment and contained about 11-13% water. Microorganism

The yeast S. cerevisae was used for fermentation. S. serevisiae was pre-cultivated from Ethanol RedTM ( Dry yeast, S. serevisiae, Eementics, France). Pre-cultivation of dry yeast was performed in media containing (g/l): sugar, 50; corn cereal lingquor (CSL), 10. 10lit this media was autoclaved at 121oC for 15 minutes. After the media was cool down to room temperature, 5g Ethanol RedTM was added. Pre-cultivation was taken 16-24 hours. The solution was diluted to 40 times and checked O.D. value at UV-Vis wavelength 600nm. The accepted O.D value was 0.3-0.5. Enzyme

A commercial cellulase enzyme (Acremomium Cellulase) supplied from Meiji Seika Co. (Japan) was used in all the experiments as sole enzymatic complex. The enzyme was originated by Acremonium Cellulolyticus.

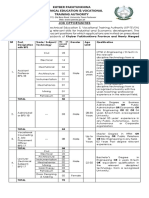

Rice Straw

Rice husk

Cutting

Carbonization and gasification

Charcoal

Water

Puffing Syngas

NaOH

Alkaline pretreatment Combustion Neutralize and Squezze Boiler Simultanous Saccharification and fermentation Distillation

HCl

Saccharomyces cerevisiae

Pri-cultivation Enz cellulase

Ethanol

2. Experiment methodology: Puffing: structures of straw fibers become more porous due to two effects: the friction and extrusion-compression. In which, the friction plays an important role. After puffing, the softness of rice straw was improved and water permeability was increasing. The rate

of puffing was about 200 450 kg( rice straw)/h, 15 17% of water. The humidity of rice straw was about 37% (w/w). The main purpose of this mechanical processing is create the porous inside the structure of rice straw therefore the hydrolysis took place easier. Puffing: cu trc rm tr nn xp hn nh 2 tc ng: s ch xt v nn n. Trong , vai tr ca s ch xt l ch yu. Cui qu trnh puffing, rm tr nn mm v tng kh nng thm nc. Tc puffing l 200 450 kg rm/h, 15 17% nc. m rm sau khi puffing l khong 37 % (w/w). Mc ch ca qu trnh x l c hc ny l to ra nhng l xp bn trong cu trc rm r qu trnh thy phn sau ny din ra thun li hn. Puffed straw was added to the plastic tub containing 1% NaOH solution with initial temperature as 50oC, then soaking overnight. The aim of this process is to reject lignin covering cellulose. It made the access of the enzyme cellulase to cellulose take place more favorable. Rm r sau khi puffing c cho vo cc bn nha cha dung dch NaOH 1%, nhit ban u 50oC v ngm qua m. Mc ch ca qu trnh ny l thy phn lignin bao bc cellulose, vic loi b lignin s gip qu trnh tip cn cellulose ca enzyme cellulase thun li hn. After overnight alkali treatment, rice straw was squeezed by piston compressor. The purpose of this step is to remove the solution containing lignin. Then it was adjusted to pH 5 6 with hydrochloric acid. This process was carried out in the plastic tank containing 7% HCl acid. The sewage effluent was neutralized with HCl acid to pH 6 7 and disposed. Rm sau khi ngm qua m trong dung dch kim c mang i lc p bng my p pittong. Mc ch ca qu trnh lc p l loi b phn dch nc cha lignin. Rm sau khi p c chnh pH n 5 6 bng acid HCl. Qu trnh ny c tin hnh trong bn nha cha dung dch acid HCl 7% (w/w). Phn nc thi s c trung ha bng acid HCl n pH 6 7 ri thi b vo h thng cng. After adjusting pH of rice straw, kept squeezing by piston compressor. The water of this squeeze was neutralized and disposed. The squeezed straw was stored in the fridge to prevent mold growth. Beside, it was needed to determine the humidity of squeezed straw

in order to calculate the weight of dry rice straw before adding to fermentation equipment. Moisture content should be lower than 70% Sau khi chnh pH ca rm t khong 5 6 tip tc lc p bng my p pittong. Phn nc p c cng c em trung ha ri thi b vo h thng cng nh trn. Phn b rn (rm) c thu hi v bo qun trong t lnh (khi cha s dng n) trnh s pht trin ca nm mc. Rm sau khi trung ha v lc p c em i xc nh m nhm tnh ton khi lng nguyn liu kh cho vo thit b ln men. Yu cu m sau khi lc p phi nh hn 70% Both saccharification and fermentation process were carried out simultaneously. Qu trnh thy phn v ln men ng thi (cn gi l qu trnh ng ha v ln men ng thi) tin hnh c thy phn v ln men trong cng mt bc. Vic b sung nguyn liu ln men (rm qua tin x l) c tin hnh tng t, 3 ln/ngy nhm kim sot tt iu kin khuy trn, gim tr lc cho cnh khuy. Ngay trc v sau mi ln b sung nguyn liu, tin hnh ly mu xc nh nng glucose v ethanol. Khi nng glucose gim dn tim cn v gi tr 0 v nng ethanol tng dn n lc coi nh cc i th ngng qu trnh. Thit b c s dng trong qu trnh ny l thit b truyn nhit v o, c cnh khuy. Cc bc tin hnh trong qu trnh ny nh sau: + Ban u, khong 200L nc c cho vo bn trong thit b cng vi lng nguyn liu t 1 v mi trng dinh dng cho nm men (360g corn steep powder pha trong 1L nc). Chnh pH v pH ti u cho nm men (pH 4.8 0.2) bng acid L-Lactic. + Tit trng. Dng hi nc bo ha p sut 2at lun chuyn trong lp v o nng nhit nguyn liu bn trong thit b ln khong 90oC v duy tr trong 30 pht. ngui hn hp xung 35oC, duy tr v kim sot nhit ny bng dng nc tun hon c nhit 35oC di chuyn trong lp v oCho 10L dch nhn ging chun b trn vo bn ln men. + Enzyme cellulase dng bt (khong 1.875% khi lng nguyn liu) c ha tan trong 2L nc ri cho vo bn ln men. Thi gian ln men bt u c tnh t thi im ny. + Sau nhng khong thi gian xc nh, mt lng rm ( qua tin x l) xc nh s c cho vo. C khong 9 t b sung nguyn liu vi khi lng khc nhau. Sau 6 t b sung nguyn

liu th enzyme cellulase s c cho thm vo (280g enzyme cellulase dng bt pha trong 1L nc). Sau mi t b sung nguyn liu cn tin hnh o v chnh pH v gi tr ti u cho hot ng ca nm men. + Nng ethanol t c cui qu trnh khong 5%. + Qu trnh thy phn v ln men ng thi vi s tham gia ca enzyme cellulase v nm men Saccharomyces cerevisiae. Trong , enzyme cellulase c vai tr chuyn ha cellulose thnh glucose, ng c to ra t qu trnh ng ha s c ln men ng thi thnh ethanol nh nm men. Nh vy lm gim ng k s c ch do sn phm ca qu trnh ng phn ln enzyme. Nhit ti u ca SSF khong 35oC l nhit trung bnh gia nhit ti u ca s thy phn bi enzyme (45 50oC) v s ln men bi nm men (30oC). Sn phm sau qu trnh ln men c a qua lu tr trong bn cha (tank cha). Dch sau ln men c em i chng ct thu hi ethanol tinh khit. Qu trnh chng ct c tin hnh thng qua 2 thp chng: chng ct th v chng ct tinh. Khi lng np liu mi ln chng l 80kg, nhp liu y, thu sn phm nh, c hon lu. Nng ethanol sau chng ct tinh c xc nh bng ph k (sai s dao ng trong khong rng) v phng php o HPLC ( chnh xc cao). Ngoi ra, trong qu trnh SSF, xc nh thnh phn ca dch ln men th sau nhng khong thi gian xc nh ngi ta s tin hnh ly mu o HPLC. Fiber Analysis:

Anda mungkin juga menyukai

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDari EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifePenilaian: 4 dari 5 bintang4/5 (5794)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDari EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You ArePenilaian: 4 dari 5 bintang4/5 (1090)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDari EverandNever Split the Difference: Negotiating As If Your Life Depended On ItPenilaian: 4.5 dari 5 bintang4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDari EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RacePenilaian: 4 dari 5 bintang4/5 (895)

- Grit: The Power of Passion and PerseveranceDari EverandGrit: The Power of Passion and PerseverancePenilaian: 4 dari 5 bintang4/5 (588)

- Shoe Dog: A Memoir by the Creator of NikeDari EverandShoe Dog: A Memoir by the Creator of NikePenilaian: 4.5 dari 5 bintang4.5/5 (537)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDari EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersPenilaian: 4.5 dari 5 bintang4.5/5 (345)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDari EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FuturePenilaian: 4.5 dari 5 bintang4.5/5 (474)

- Her Body and Other Parties: StoriesDari EverandHer Body and Other Parties: StoriesPenilaian: 4 dari 5 bintang4/5 (821)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Dari EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Penilaian: 4.5 dari 5 bintang4.5/5 (121)

- The Emperor of All Maladies: A Biography of CancerDari EverandThe Emperor of All Maladies: A Biography of CancerPenilaian: 4.5 dari 5 bintang4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingDari EverandThe Little Book of Hygge: Danish Secrets to Happy LivingPenilaian: 3.5 dari 5 bintang3.5/5 (400)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDari EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyPenilaian: 3.5 dari 5 bintang3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)Dari EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Penilaian: 4 dari 5 bintang4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDari EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaPenilaian: 4.5 dari 5 bintang4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDari EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryPenilaian: 3.5 dari 5 bintang3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnDari EverandTeam of Rivals: The Political Genius of Abraham LincolnPenilaian: 4.5 dari 5 bintang4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealDari EverandOn Fire: The (Burning) Case for a Green New DealPenilaian: 4 dari 5 bintang4/5 (74)

- The Unwinding: An Inner History of the New AmericaDari EverandThe Unwinding: An Inner History of the New AmericaPenilaian: 4 dari 5 bintang4/5 (45)

- Rise of ISIS: A Threat We Can't IgnoreDari EverandRise of ISIS: A Threat We Can't IgnorePenilaian: 3.5 dari 5 bintang3.5/5 (137)

- RTDM Admin Guide PDFDokumen498 halamanRTDM Admin Guide PDFtemp100% (2)

- Comparitive Study ICICI & HDFCDokumen22 halamanComparitive Study ICICI & HDFCshah faisal100% (1)

- Deal Report Feb 14 - Apr 14Dokumen26 halamanDeal Report Feb 14 - Apr 14BonviBelum ada peringkat

- Crown WF-3000 1.2Dokumen5 halamanCrown WF-3000 1.2Qirat KhanBelum ada peringkat

- Pivot TableDokumen19 halamanPivot TablePrince AroraBelum ada peringkat

- LetrasDokumen9 halamanLetrasMaricielo Angeline Vilca QuispeBelum ada peringkat

- 04 - Fetch Decode Execute Cycle PDFDokumen3 halaman04 - Fetch Decode Execute Cycle PDFShaun HaxaelBelum ada peringkat

- Jesus Prayer-JoinerDokumen13 halamanJesus Prayer-Joinersleepknot_maggotBelum ada peringkat

- An Exploration of The Ethno-Medicinal Practices Among Traditional Healers in Southwest Cebu, PhilippinesDokumen7 halamanAn Exploration of The Ethno-Medicinal Practices Among Traditional Healers in Southwest Cebu, PhilippinesleecubongBelum ada peringkat

- Lec 33 - Householder MethodDokumen11 halamanLec 33 - Householder MethodMudit SinhaBelum ada peringkat

- Time-Sensitive Networking - An IntroductionDokumen5 halamanTime-Sensitive Networking - An Introductionsmyethdrath24Belum ada peringkat

- All You Need To Know About Egg YolkDokumen7 halamanAll You Need To Know About Egg YolkGolden Era BookwormBelum ada peringkat

- KP Tevta Advertisement 16-09-2019Dokumen4 halamanKP Tevta Advertisement 16-09-2019Ishaq AminBelum ada peringkat

- PSG College of Technology, Coimbatore - 641 004 Semester Examinations, SemesterDokumen3 halamanPSG College of Technology, Coimbatore - 641 004 Semester Examinations, SemesterBabitha DhanaBelum ada peringkat

- Chapter 3 - Organization Structure & CultureDokumen63 halamanChapter 3 - Organization Structure & CultureDr. Shuva GhoshBelum ada peringkat

- PED003Dokumen1 halamanPED003ely mae dag-umanBelum ada peringkat

- Damodaram Sanjivayya National Law University Visakhapatnam, A.P., IndiaDokumen25 halamanDamodaram Sanjivayya National Law University Visakhapatnam, A.P., IndiaSumanth RoxtaBelum ada peringkat

- Washing Machine: Service ManualDokumen66 halamanWashing Machine: Service ManualFernando AlmeidaBelum ada peringkat

- Ron Kangas - IoanDokumen11 halamanRon Kangas - IoanBogdan SoptereanBelum ada peringkat

- Strucure Design and Multi - Objective Optimization of A Novel NPR Bumber SystemDokumen19 halamanStrucure Design and Multi - Objective Optimization of A Novel NPR Bumber System施元Belum ada peringkat

- 74HC00D 74HC00D 74HC00D 74HC00D: CMOS Digital Integrated Circuits Silicon MonolithicDokumen8 halaman74HC00D 74HC00D 74HC00D 74HC00D: CMOS Digital Integrated Circuits Silicon MonolithicAssistec TecBelum ada peringkat

- Talking Art As The Spirit Moves UsDokumen7 halamanTalking Art As The Spirit Moves UsUCLA_SPARCBelum ada peringkat

- C C C C: "P P P P PDokumen25 halamanC C C C: "P P P P PShalu Dua KatyalBelum ada peringkat

- Solved Simplex Problems PDFDokumen5 halamanSolved Simplex Problems PDFTejasa MishraBelum ada peringkat

- Negotiating Skills Negotiating Skills: To Provide You With The Skills To Plan & Implement Successful NegotiationDokumen32 halamanNegotiating Skills Negotiating Skills: To Provide You With The Skills To Plan & Implement Successful NegotiationKanimozhi.SBelum ada peringkat

- B122 - Tma03Dokumen7 halamanB122 - Tma03Martin SantambrogioBelum ada peringkat

- 15.053/8 February 7, 2013: More Linear and Non-Linear Programming ModelsDokumen42 halaman15.053/8 February 7, 2013: More Linear and Non-Linear Programming ModelsShashank SinglaBelum ada peringkat

- Science7 - q1 - Mod3 - Distinguishing Mixtures From Substances - v5Dokumen25 halamanScience7 - q1 - Mod3 - Distinguishing Mixtures From Substances - v5Bella BalendresBelum ada peringkat

- Leigh Shawntel J. Nitro Bsmt-1A Biostatistics Quiz No. 3Dokumen6 halamanLeigh Shawntel J. Nitro Bsmt-1A Biostatistics Quiz No. 3Lue SolesBelum ada peringkat

- Prelim Examination MaternalDokumen23 halamanPrelim Examination MaternalAaron ConstantinoBelum ada peringkat