Everything You Need to Know About CMM Probes

Diunggah oleh

iazeem240Deskripsi Asli:

Judul Asli

Hak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

Everything You Need to Know About CMM Probes

Diunggah oleh

iazeem240Hak Cipta:

Format Tersedia

CMM Probes Information

Coordinate measuring machines (CMM) probes are transducers that convert physical measurements into electrical signals by using numerous measuring systems within the probe structure. CMM probes are a broad category of instruments that use diverse technologies for direct and comparative measurements. CMM probes are available in three main designs: touch-trigger or discrete point, displacement measuring or scanning probes, and proximity or non-contact probes. Touch-trigger probes or discrete point probes are the most common type of CMM probe. As their name suggests, they literally touch the surface of the workpiece. Upon contact, these CMM probes send a signal with the points coordinates to the CMM. The probe is then moved to the next location, where the process is repeated. Displacement measuring probes or scanning probes are another basic type of CMM probe. As these CMM probes pass over a targets surface, they transmit a continuous flow of information to the measurement system. Scanning contact probes may use linear variable differential transformer (LVDT) or optoelectronic position sensing. Proximity probes or non-contact probes function similarly to displacement-measuring CMM probes. The difference is that proximity probes use laser, capacitive, or video measurement technology instead of LVDTs. CMM probes use many different sensor technologies to attain their measurements. Each technology offers its own strengths that may be specifically desired for a given application. The most common technologies include kinematic or switching, strain sensing, piezoelectric, LVDT, optoelectronic, laser triangulation, capacitive, and video imaging. Kinematic or switch technologies are available in a wide range of CMM probes. In terms of size, they are the smallest of the CMM probe types. They offer low over-travel force, simple interfacing, and robust and universal filament. Strain-sensing CMM probes offer fewer lobing errors, long operating life, wide operating speed range, and long stylus carrying. They are ideal for peck, or stitch scanning. Piezoelectric, LVDT, and optoelectronic CMM probes are commonly available. Features for piezoelectric devices include very few lobing errors, large stylus-carrying capability, multi-mode sensor operating, extended versatility, and restricted operating-speed range. LVDT sensor types provide a high degree of accuracy and large stylus carrying capacity. Optoelectronic devices offer a higher degree of accuracy than kinematic sensor types and high data rates. CMM probes can use laser triangulation, capacitive, and video imagine sensor types. Laser triangulation sensor types are equipped with single axis profile measurements. The laser may be reflected by surface reflectivity. Capacitive CMM probes provide another form of non-contact technology. Material types may affect profile, form, surface flaw measurements, or surface chemistry; therefore, they use a fixed stylus. Video imaging sensor types are suitable for 2-D, flexible parts, and automatic edge detection; however, they may be affected by surface reflectivity and ambient light.

Anda mungkin juga menyukai

- Main Parts of CMMDokumen9 halamanMain Parts of CMMRamprakashSundaram100% (1)

- CMM (Coordinate Measuring Machine) GuideDokumen18 halamanCMM (Coordinate Measuring Machine) GuideDeepak ChoudharyBelum ada peringkat

- ME8501 - Metrology and Measurements - Unit - IIIDokumen69 halamanME8501 - Metrology and Measurements - Unit - IIIarunpdcBelum ada peringkat

- 04 Data Acquisition Contact 2019 09 12Dokumen53 halaman04 Data Acquisition Contact 2019 09 12TimBelum ada peringkat

- How CMM Probes Work to Measure Machine PartsDokumen3 halamanHow CMM Probes Work to Measure Machine PartsDeepak MisraBelum ada peringkat

- Measuring Characteristics of Coordinate Measuring MachineDokumen4 halamanMeasuring Characteristics of Coordinate Measuring MachineMuhammad JahanzaibBelum ada peringkat

- CMMDokumen37 halamanCMMSachin AggarwalBelum ada peringkat

- CMM Machine Measures Geometric PartsDokumen34 halamanCMM Machine Measures Geometric PartsShanti Lal MeenaBelum ada peringkat

- Assignment No.1Dokumen13 halamanAssignment No.1Muhammad WaleedBelum ada peringkat

- Co-Ordinate Measuring Machines & It's Applications: Introduction ToDokumen65 halamanCo-Ordinate Measuring Machines & It's Applications: Introduction Toshiva dBelum ada peringkat

- UNIT-5 Advances in MetrologyDokumen45 halamanUNIT-5 Advances in MetrologySURESH KUMAR APBelum ada peringkat

- CMM MQCDokumen36 halamanCMM MQCThanigaivel ABelum ada peringkat

- Coordinate Measuring Machine (CMM)Dokumen18 halamanCoordinate Measuring Machine (CMM)Smw SmsBelum ada peringkat

- Presentation On CMMDokumen17 halamanPresentation On CMMSonu Sharma100% (1)

- CMM LazerDokumen6 halamanCMM LazermechanicemreBelum ada peringkat

- 2nd educational article_part 3Dokumen22 halaman2nd educational article_part 3Francisco AugustoBelum ada peringkat

- WhitePaper - Laser Tracker TechnologyDokumen4 halamanWhitePaper - Laser Tracker Technologyviorelu99Belum ada peringkat

- Machining Processes And Metrology GuideDokumen93 halamanMachining Processes And Metrology GuideAayush KBelum ada peringkat

- MULTIUSER DETECTION AND INTERFACE TECHNIQUESDokumen40 halamanMULTIUSER DETECTION AND INTERFACE TECHNIQUESDishant KhoslaBelum ada peringkat

- Multiuser Detection and Interface DetectionDokumen29 halamanMultiuser Detection and Interface DetectionDishant KhoslaBelum ada peringkat

- Literature Review MCTDokumen6 halamanLiterature Review MCTRohan SolavatBelum ada peringkat

- OIE 751 ROBOTICS Unit 3 Class 8 (30-10-2020)Dokumen14 halamanOIE 751 ROBOTICS Unit 3 Class 8 (30-10-2020)MICHEL RAJBelum ada peringkat

- CMM Inspection ModuleDokumen93 halamanCMM Inspection Modulejaskaran singhBelum ada peringkat

- Unit-Iv Laser MetrologyDokumen48 halamanUnit-Iv Laser MetrologySaravanan ShriBelum ada peringkat

- Module 4 PDFDokumen33 halamanModule 4 PDFRachnaBelum ada peringkat

- Tilt Sensors: Tilt Sensor Working PrincipleDokumen6 halamanTilt Sensors: Tilt Sensor Working PrincipleGnanam RBelum ada peringkat

- Nota MetroDokumen1 halamanNota Metrolienna77-1Belum ada peringkat

- Types of Sensors and Their ApplicationsDokumen5 halamanTypes of Sensors and Their ApplicationsSaurabh RajputBelum ada peringkat

- High Speed Sensor: Pratyush ParimalDokumen5 halamanHigh Speed Sensor: Pratyush ParimalAnonymous mlYYLRe7HBelum ada peringkat

- SEO-Optimized title for document on sensors used in roboticsDokumen4 halamanSEO-Optimized title for document on sensors used in roboticsMegha OmshreeBelum ada peringkat

- Vibration sensor types and applicationsDokumen18 halamanVibration sensor types and applicationsDRathikaBelum ada peringkat

- What S An CMMDokumen6 halamanWhat S An CMMHector JEBelum ada peringkat

- CMM PresentationDokumen22 halamanCMM PresentationVipin PachouriBelum ada peringkat

- Effect of Input Shaping on CMM Measurement RepeatabilityDokumen5 halamanEffect of Input Shaping on CMM Measurement RepeatabilitytuongnvBelum ada peringkat

- Coordinate MeasuringDokumen9 halamanCoordinate MeasuringRadin HazimahBelum ada peringkat

- Sensor PDFDokumen8 halamanSensor PDFConstanzaBelum ada peringkat

- Evolution of CMMs and the Future of Multi-Sensor MetrologyDokumen13 halamanEvolution of CMMs and the Future of Multi-Sensor MetrologySun TzunamiBelum ada peringkat

- Measure Complex Shapes With Co-ordinate Measuring MachinesDokumen4 halamanMeasure Complex Shapes With Co-ordinate Measuring MachinessathiaBelum ada peringkat

- 3D Scanning Technologies - An OverviewDokumen7 halaman3D Scanning Technologies - An Overviewuzair awanBelum ada peringkat

- Sensor List For Indoor Navigation DroneDokumen8 halamanSensor List For Indoor Navigation DronechandrakanthatsBelum ada peringkat

- Types of Sensor and Their ApplicationDokumen6 halamanTypes of Sensor and Their Applicationpogisimpatiko0% (1)

- Assignment 1Dokumen9 halamanAssignment 1Alimin AnniBelum ada peringkat

- Cat OptoNCDT en UsDokumen40 halamanCat OptoNCDT en UsDaniel FredianiBelum ada peringkat

- Coordinate Measuring Machine (CMM) : Salient CharacteristicsDokumen12 halamanCoordinate Measuring Machine (CMM) : Salient CharacteristicsAnuj SaidBelum ada peringkat

- 3d Machine Vision SystemsDokumen12 halaman3d Machine Vision SystemskandukurivivekBelum ada peringkat

- Coordinate Measuring MachineDokumen13 halamanCoordinate Measuring MachineAjay G RBelum ada peringkat

- Coordianate MeasurmentDokumen6 halamanCoordianate MeasurmentMilos RadovicBelum ada peringkat

- 3D machine vision shop metrologyDokumen7 halaman3D machine vision shop metrologysharmikbkBelum ada peringkat

- Advancement in Large Scale Dimensional MetrologyDokumen8 halamanAdvancement in Large Scale Dimensional MetrologyAnantama karisBelum ada peringkat

- Laser Interferometers & CMM Machine VisionDokumen153 halamanLaser Interferometers & CMM Machine Visionjaikrishna100% (1)

- 论文三Multi-Parameter Sensing in a MultimodeDokumen16 halaman论文三Multi-Parameter Sensing in a Multimoderen hongliangBelum ada peringkat

- Sensor: Microsensor Reaches A Significantly Higher Speed and Sensitivity Compared WithDokumen7 halamanSensor: Microsensor Reaches A Significantly Higher Speed and Sensitivity Compared WithMaratur RoifahBelum ada peringkat

- Visvesvaraya National Institute of Technology Nagpur: Vlsi Design MTECH 2021-23 Mems LabDokumen16 halamanVisvesvaraya National Institute of Technology Nagpur: Vlsi Design MTECH 2021-23 Mems LabRutvik PatelBelum ada peringkat

- Unit III NotesDokumen14 halamanUnit III NotesVijay JaiBelum ada peringkat

- CMM Inspection & Operating PrinciplesDokumen15 halamanCMM Inspection & Operating PrinciplesMeena RameshBelum ada peringkat

- Final Module 2Dokumen32 halamanFinal Module 2RachnaBelum ada peringkat

- Sensors and Control ConsiderationsDokumen3 halamanSensors and Control ConsiderationsPrashanth BnBelum ada peringkat

- Textbook of Urgent Care Management: Chapter 35, Urgent Care Imaging and InterpretationDari EverandTextbook of Urgent Care Management: Chapter 35, Urgent Care Imaging and InterpretationBelum ada peringkat

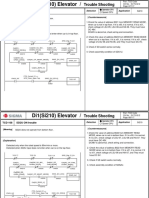

- Automotive Electronic Diagnostics (Course 2)Dari EverandAutomotive Electronic Diagnostics (Course 2)Penilaian: 4 dari 5 bintang4/5 (2)

- Test Taker GRE Verbal Reasoning SamplesDokumen11 halamanTest Taker GRE Verbal Reasoning SamplesShreyas GoṏnayBelum ada peringkat

- Presentation 1Dokumen1 halamanPresentation 1iazeem240Belum ada peringkat

- CMM m8 Magnetic Kit BPDF 20090825 101547 49 Q+Dokumen1 halamanCMM m8 Magnetic Kit BPDF 20090825 101547 49 Q+iazeem240Belum ada peringkat

- Presentation 1Dokumen1 halamanPresentation 1iazeem240Belum ada peringkat

- Presentation 1Dokumen1 halamanPresentation 1iazeem240Belum ada peringkat

- Presentation 1Dokumen1 halamanPresentation 1iazeem240Belum ada peringkat

- 7I76/7I76D Step/Dir Plus I/O DaughtercardDokumen58 halaman7I76/7I76D Step/Dir Plus I/O DaughtercardElenilton MelchiorsBelum ada peringkat

- Datasheet SerialCamera en 1Dokumen9 halamanDatasheet SerialCamera en 1RicardoAlvarezBelum ada peringkat

- Analogue Report Common Emitter AmplifierDokumen5 halamanAnalogue Report Common Emitter Amplifierfedley sikoliaBelum ada peringkat

- Lab Report Process (Repaired)Dokumen16 halamanLab Report Process (Repaired)amirulBelum ada peringkat

- Xilinx Device Drivers ApiDokumen1.213 halamanXilinx Device Drivers ApihypernuclideBelum ada peringkat

- TCD 114 RPD ON trouble detection and countermeasuresDokumen7 halamanTCD 114 RPD ON trouble detection and countermeasuresFERNSBelum ada peringkat

- Troubleshoot EV100 LX SCR Control IssuesDokumen33 halamanTroubleshoot EV100 LX SCR Control IssuesMigue Angel Rodríguez CastroBelum ada peringkat

- Ericsson Rbs 2216 PDFDokumen2 halamanEricsson Rbs 2216 PDFMonique100% (1)

- Fujitsu - ASIC/COT - 40nm CMOS Technology CS302 SeriesDokumen2 halamanFujitsu - ASIC/COT - 40nm CMOS Technology CS302 SeriesFujitsu Semiconductor EuropeBelum ada peringkat

- Naveen Resume 12Dokumen3 halamanNaveen Resume 12Sri SathyarajBelum ada peringkat

- Mmel DHC6Dokumen65 halamanMmel DHC6Celin Concha AranedaBelum ada peringkat

- Chemistry Paper 2 End-of-Year Test Cemerlang Studi Secondary School MalaysiaDokumen20 halamanChemistry Paper 2 End-of-Year Test Cemerlang Studi Secondary School MalaysiaCemerlang StudiBelum ada peringkat

- Quick setup guide for D-Link ShareCenter DNS-320L cloud storageDokumen5 halamanQuick setup guide for D-Link ShareCenter DNS-320L cloud storageMauricio GlezBelum ada peringkat

- APG-83 Vs APG-80Dokumen8 halamanAPG-83 Vs APG-80David Vương100% (2)

- Codigos Autodesk 2015Dokumen3 halamanCodigos Autodesk 2015RubenCH59Belum ada peringkat

- Epson TM t82Dokumen2 halamanEpson TM t82lalukurniawanBelum ada peringkat

- PSS20 Cost ReportDokumen385 halamanPSS20 Cost Reportjaciel leonBelum ada peringkat

- Eti Fuses PDFDokumen2 halamanEti Fuses PDFCaseyBelum ada peringkat

- Xlamp Xhp50.3 Leds: Product Description FeaturesDokumen46 halamanXlamp Xhp50.3 Leds: Product Description FeaturesDom HandBelum ada peringkat

- PADS Standard Plus Evaluation GuideDokumen204 halamanPADS Standard Plus Evaluation GuideDavid MittmannBelum ada peringkat

- CSF 110Dokumen46 halamanCSF 110damanchurw210Belum ada peringkat

- LR-02 Manual EnglishDokumen24 halamanLR-02 Manual EnglishCharliie RooseveltBelum ada peringkat

- Nota Padat Fizik F5 ElectronicDokumen21 halamanNota Padat Fizik F5 Electronicslokkro100% (24)

- Powermax125: Plasma Arc Cutting SystemDokumen134 halamanPowermax125: Plasma Arc Cutting SystemMohammed AhmedBelum ada peringkat

- A Low-Voltage MOS Cascode Current Mirror For All Current LevelsDokumen23 halamanA Low-Voltage MOS Cascode Current Mirror For All Current LevelsSureshnaidu LekkalaBelum ada peringkat

- Sony - HCD rg110, MHC rg110Dokumen21 halamanSony - HCD rg110, MHC rg110Marin VlahovićBelum ada peringkat

- Sure Step Manuals PDokumen70 halamanSure Step Manuals PjondeividBelum ada peringkat

- Mobile DRAM Standard FormulationDokumen5 halamanMobile DRAM Standard FormulationGajanand RajaputBelum ada peringkat

- Electrical Machines Lab ManualDokumen133 halamanElectrical Machines Lab ManualDagnachewBelum ada peringkat