Assessment of Existing Structures Using Cyclic Load Testing

Diunggah oleh

Professor Dr. Nabeel Al-Bayati-Consultant EngineerHak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

Assessment of Existing Structures Using Cyclic Load Testing

Diunggah oleh

Professor Dr. Nabeel Al-Bayati-Consultant EngineerHak Cipta:

Format Tersedia

Assessment of Existing Structures Using Cyclic Load Testing

Case studies illustrate procedures recommended in aCi Committee 437 report

By Tarek alkhrdaji, NesTore GalaTi, aNd aNToNio NaNNi

hen a building is renovated for a change of use, the load-carrying capacity of the structural system must be established. Load testing can be used to provide reliable verification that a given structure can safely support the calculated design loads. Per ACI 318,1,2 the test load magnitude (TLM) is required to be reached in at least four load increments. A set of response measurements (mainly deflection) is taken after the total test load has been applied and after at least 24 hours of sustained loading. A final set of response measurements is also required 24 hours after the test load has been removed, so the total duration of the load test can exceed 72 hours. When multiple load tests are required to verify the capacities of multiple elements or configurations, significant delays and expenses can be incurred. In the past 10 years, researchers and practitioners in the U.S. have been evaluating an alternative load test method.3 Known as the cyclic load test (CLT) method, this procedure requires the application of multiple cycles of loading and unloading (typically six). Structural adequacy is then verified by examining the linearity of the measured deflection response and magnitude of the permanent deformation after the load has been removed. CLT investigations are typically conducted using hydraulic rams that allow the test member to be quickly unloaded at any sign of distress, improving safety and

reducing the risk of overloading or damaging the structure. Using hydraulic rams may also be more economical than using weights. Although hydraulic rams require reaction systems that can be expensive and time consuming to implement, the labor required to apply gravity loads using dead weights can also be expensive. The CLT method is discussed in greater detail in ACI 437R4 and ACI 437.1R.5 In the following case studies, the CLT method was used to verify analyses and capacities of existing structural components. The method was also used to evaluate structural behavior after members were strengthened using externally bonded fiber-reinforced polymer (FRP) reinforcement alone or in conjunction with a reinforced concrete topping slab.

CASE STUdiES

For both of the structural investigations described herein, a building floor was evaluated for a change in use. Following industry recommendations, existing conditions were assessed by studying existing drawings, reports, and calculations; and the information was verified using on-site inspections.4,6,7 In each case, the assessments showed that strengthening would be required. Also, in each case, the CLT method was selected to minimize the duration of the testing program, as testing was required both before and after strengthening.

Concrete international

/ april 2010

39

Per ACI 437.1R-075 recommendations, loading and shoring systems were designed to ensure safety, prevent collapse of the test member, and avoid damaging adjacent structural elements. Also per ACI 437.1R-07,5 acceptance criteriaincluding deflection repeatability, permanency, and deviation from linearitywere used to examine the performance during and after the load test (Fig. 1).

National institutes of Health Library

Level B of Building 38 at the National Institutes of Health (NIH) in Bethesda, MD, houses the National Library of Medicine. This level was being renovated to accommodate a new high-density filing system and a new carousel

Index Repeatability, IR Permanency, IP

Calculation* I R=

2 max 1 max

Limit 0.95 IR 1.05 IP 0.10

2 r 1 r

r2 2 max tan i Deviation from Linearity, IDL = 1 IDL tan ref

IP=

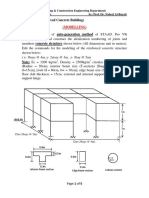

shelving system to store microforms collections. The elevated slab was originally designed for 100 psf (4.7 kN/m2) live load. The filing system required that the slab be upgraded to a live load demand of 200 psf (9.6 kN/m2). During the site investigation phase, flexural cracks were observed on the top of the slab. The discovery prompted NIH officials to request load tests to verify the capacity of the existing floor slab prior to strengthening. The load test was designed to induce loads mimicking the original design loads on certain areas of the slab. Level B comprises a 10.5 in. (265 mm) thick concrete flat plate slab reinforced with 40 ksi (275 MPa) deformed steel bars. A typical bay is supported by 24 x 34 in. (610 x 860 mm) reinforced concrete columns on a 21 x 21 ft (6.4 x 6.4 m) grid. The CLT was conducted on a 10.5 ft (3.2 m) wide column strip located along Grid Line 12 to evaluate the current bending capacity at midspan and at the support (Fig. 2). The TLM was determined using ACI 437.1R-075 TLM = Dw + 1.1 Ds + 1.6L Eq. (1)

IDL< 0.25

* Measured values used in calculations: 2max = maximum deflection in Cycle 2 under a load of Pmax = residual deflection after Cycle 2 under a load of Pmin 2r 1max = maximum deflection in Cycle 1 under a load of Pmax = residual deflection after Cycle 1 under a load of Pmin 1r = maximum load level achieved by Cycles 1 and 2 Pmax = minimum load level achieved at the end of Cycles 1 and 2 P

min

where Dw is the dead load due to slab self-weight (130 psf [6.2 kPa]), Ds is the sum of the superimposed dead loads (25 psf [1.2 kPa]), and L is the specified live load (125 psf [6.0 kPa]) per the original design. The test team also decided to perform two additional loading cycles using the load magnitude per ACI 318-05, Chapter 20.1 For this case, the TLM was TLM = 0.85 [1.4(Dw + Ds ) + 1.7L] Eq. (2)

Using Eq. (1) and (2), the TLM values were quite similar358 psf (17.1 kN/m2) and 365 psf (17.5 kN/m2), respectively. Table 1 summarizes the moment and punching shear capacities, fMn and fVn, and the factored bending and punching 11 11 12 12 13 13 shear demands, Mu and Vu, for the column strip under investigation based on the as-designed (original) J J conditions. To perform the load test, Load points concentrated loads P were applied 100 in in. using hydraulic rams to mimic the Load line 1 effect of the uniformly distributed 90 in. design loads on the test slab strip. H H Load points 100 in. Two loading configurations were 108 in. Critical cross section Load line 1 used to test the slab: Scheme 1 was Load line 2 72 in. 72 in Critical cross section used to reproduce the negative Load line 2 bending at Column H12; and Scheme 2 G G was used to reproduce the positive bending at midspan between (a) (b) Column G12 and H12, as shown in Fig. 2: Load point locations used for evaluation of Level B for the National Institutes of Fig. 2. Table 2 gives the magnitude Health project: (a) Scheme 1, positive moment test; (b) Scheme 2, negative moment of P for these load tests. test (1 in. = 25.4 mm)

Fig. 1: Acceptance criteria per ACI 437.1R-075

tan i = slope of secant line on load deflection envelope tan ref = slope of secant line for peak on first loading cycle

40

april 2010

/ Concrete international

As shown in Tables 1 and 2, the existing slab has higher shear capacity than that corresponding to the new demand. Accordingly, the test load layout was intended to produce the target bending moments without necessarily achieving the shear force demand simultaneously. Additionally, for the Scheme 2 load test, it was not possible to apply the load symmetrically with respect to Column H12 due to the presence of piping at those locations. A push-

down load test was selected (Fig. 3), using the deadweight of the floors above to resist reactions from the hydraulic rams. Once the load test components and instruments were installed, a preliminary load of 3000 lb (13.3 kN) was applied to eliminate slack in the load system. The slab was then tested using eight loading-unloading cycles for each test configuration, including four loading levels with two cycles for each load level. Each load

TABLe 1: CapaCities and demands for existing struCture

Test scheme 1 fMn, kip-ft (kN-m) 120.7 (163.7) Mu, kip-ft (kN-m) 98.8 (134.0) fVn, kip (kN) 105.6 (469.7) Vu, kip (kN) 67.7 (301.1) Objectives evaluate performance of column strip at positive moment region evaluate performance of column strip at negative moment region

212.5 (288.2)

211.6 (286.9)

105.6 (469.7)

67.7 (301.1)

TABLe 2: ConCentrated load values P used to mimiC moment and shear effeCts of uniform TLM

Test scheme 1 2 P, kip (kN) 14.1 (62.7) 28.4 (126.3) Mu(TLM), kip-ft (kN-m) 93.3 (126.5) 190.6 (258.5) Mu(P), kip-ft (kN-m) 93.5 (126.8) 191.4 (259.5) Vu(TLM), kip (kN) 64.2 (285.6) 64.2 (285.6) Vu(P), kip (kN) 46.2 (205.5) 46.2 (205.5)

cycle consisted of loading the slab in a minimum of four approximately equal loading steps, followed by at least two unloading steps. The maximum load reached in Cycles 5 and 6 corresponded to the load combination determined per Eq. (1), whereas the maximum load in Cycles 7 and 8 was per Eq. (2). Table 3 gives the load levels used in each cycle. Results of the Scheme 1 test indicate a fairly linear behavior for positive moments. Repeatability, permanency, and deviation from linearity were within the limits prescribed by ACI 437.1R-07.5 Additionally, no new cracks were observed while performing the cyclic load test. Although existing cracks did widen during loading, they returned to their original widths at the end of the tests. Figure 4 shows the applied load cycles for the Scheme 2 test. As indicated in Table 3, the limits on deviation from linearity were not met in the last two cycles. However, because no sign of failure, such as excessive deflection or cracking, was observed, the performance of the structure was deemed acceptable. The load test results and the preexisting top-side cracks were indications that the structure could have been subjected to loads that exceeded its original design live load of 100 psf (4.7 kN/m2). During further investigation of the buildings loading history, it was revealed that the floor was used to shore the floor above during a previous renovation. This might have overloaded the slab.

TABLe 3: aCCeptanCe evaluation for sCheme 2 results

Load cycles 1 and 2 3 and 4 4 and 6 7 and 8 Repeatability (95 to 105%), % 104.3 103.9 101.7 104.1 Permanency ( 10%), % 3.9 3.3 9.2 9.9 Deviation from linearity ( 25%), % 2.8 12.3 24.6 26.5

Concrete international

Load level D + Ds + L 0.75 (1.0Dw + 1.1Ds + 1.6L) (1.0Dw + 1.1Ds + 1.6L) 0.85 (1.4[Dw + Ds] + 1.7L)

Performance satisfactory satisfactory satisfactory acceptable

/ april 2010

41

14

13

12

11

Shoring

Steel plate Hydraulic ram Level B Steel post Shoring tower below each load point

Load cell

Timber block

Level A

Fig. 3: CLT setup for the National Institutes of Health project. Shoring was used to distribute the reaction forces to floors above the test floor

30 25 20 L o a d , kip 15 60 10 5 0 40 20 0 35000 140 120 100 D + Ds + L 80 L o a d , kN

0.85[1.4(D + Ds) + 1.7L 1.0D + 1.1Ds + 1.6L

Analytical predictions were based on a two-dimensional finite element model using commercial software (SAP 2000). The model consisted of one-dimensional beam elements representing existing columns and a fine mesh of plate elements to represent the floor slab. The concrete was assumed to be isotropic and linear elastic, and the modulus of elasticity was determined per ACI 318-08.2 Slab cracking during the test was introduced into the model by reducing the stiffness of the slab to the effective stiffness as defined in Section 9.5 of ACI 318-05.1 Figure 5 compares the analytical predictions with the experimental results for the Scheme 2 test. This figure shows that deflections measured in the first two cycles matched those predicted for an uncracked slab, whereas the measured deflections in the last two cycles are closer to deflections predicted based on a cracked slab condition. A transitional behavior can be observed on the third to sixth cycles, indicating that as the test load increased, cracks developed in the slab bringing the behavior close to that of a cracked slab at the higher load levels. To accommodate the new design load for the Level B floor, externally bonded carbon FRP was used to increase the bending capacity of the slab. FRP strips were installed in two directions on the top and bottom sides of the slab. Design and detailing of the FRP were performed according to ACI 440.2R8 guidelines.

Commercial retail building

5000

10000

15000

20000

25000

30000

T im e, seconds

Fig. 4: Load cycles for Scheme 2 test on the National Institutes of Health project. Load includes weight of loading apparatus

0.05 E xperim ental R e su lts 0.04 D eflections, in. F E M U ncra cked F E M C racked

1.4 1.2 1 0.8 0.6 0.4 D e fle ctio n s, m m

0.03

0.02

0.01

0.2 0

4 5 Load C ycles

Fig. 5: Comparison of results for Scheme 2 test on the National Institutes of Health project

To address the needs of a potential tenant, the owner of a commercial building in Cleveland, OH, evaluated options for upgrading the second level floor to house telecommunications equipment. The live load required for this equipment ranged from 125 to 150 psf (6.0 to 7.2 kN/m2). The nine-story building was constructed in 1917 with a masonry skin on a concrete-encased steel frame and reinforced concrete (RC) floor system. The existing drawings provided only floor plans and geometry of the members, but no details were available for the structural steel members or steel reinforcement. The typical floor system consists of 6 in. (150 mm) wide reinforced concrete joists supporting a 3.5 in. (90 mm) concrete slab reinforced with No. 3 (No. 10) bars spaced at 18 in. (460 mm) on center. A typical joist has a total depth of 15.5 in. (40 mm) and a span of 27.6 ft (8.4 m), and the joists are 26 in. (660 mm) on center. Dimensions of the existing joists were field verified. Condition assessment and site investigation revealed that the joists were typically reinforced with two 1 in. (25 mm) square bottom bars at midspan. About 5.5 ft (1.7 m) from each support, one bar is bent up and extends as a top bar over each support and into the adjacent span. An additional 1 in. (25 mm) straight top bar was located over the support at each end of a joist. No transverse reinforcement was

42

april 2010

/ Concrete international

Full span saw cuts to isolate test joists

Load Beam

Test Joist 1

Load app lication points

Test 1 and Test 2

Test Joist 2 Test 3

Timber Pads

Spreader Beam

Test Joist 3

Fig. 6: Plan of the load test area for commercial building retrofit project

Load C e ll H yd ra u lic Ram

H ig h S tre n g th S te e l B a r

Reaction Beam

R C M icro Pile

Fig. 7: Loading points for two joists test for commercial building retrofit project

Fig. 8: CLT setup for Tests 1 and 2 of the commercial building retrofit project

located in the joists. Based on available historical data and observed conditions, a nominal concrete strength of 4000 psi (27.6 MPa) and steel yield strength of 33 ksi (240 MPa) were used for preliminary analysis of the joists. The proposed new loads included a superimposed dead load of 25 psf (1.2 kN/m2) for a new concrete overlay to level the slab surface and a service live load of 150 psf (7.2 kN/m2). Analyses indicated that the joists were deficient in both flexure and shear for the proposed loads, with an existing live load capacity of approximately 96 psf (4.6 kN/m2) governed by the shear strength of the existing joists. The existing shear capacity of a typical joist was estimated at 9 kips (40 kN), whereas the shear demand for the new load was approximately 11.4 kips (50.7 kN). To eliminate the possibility of brittle shear failure, all test joists were strengthened for shear using externally bonded CFRP prior to testing. Three load tests were performed to verify the existing load-carrying capacity, controlling failure mode, and strength improvement after the strengthening systems were installed. In Tests 1 and 2, two joists were simultaneously load testedonce

before and once after they were strengthened (Tests 1 and 2, respectively). A third joist was tested after it was strengthened to examine the performance with no pre-induced damage (Test 3). The test joists were isolated by saw cutting the concrete slab to eliminate load sharing with adjacent members (Fig. 6). Analytical modeling indicated that the maximum moment and shear forces due to the design uniform loads could be replicated using two point loads, each located 3 ft (0.9 m) from the joist midspan (Fig. 6 and 7). A pull-down-type load was used in these load tests. The load was applied using hydraulic rams that were connected to (and pulled against) a reinforced concrete micropile installed at the ground floor (one level below) to provide necessary reactions (Fig. 8). In each test, the load was applied in six cycles comprising two cycles at each of three loading levels. Test 1 was performed on two joists isolated by saw cutting the concrete slab at mid-distance to the first adjacent joist on each side of the test joists. The two joists were then strengthened for shear with an externally bonded CFRP system. Corners on the joist stems were

Concrete international

/ april 2010

43

-0.4

-10

-0.6

Test 1 Test 2 Test 3

-15

-0.8

0.125L

0.25L

0.375L 0.5L 0.625L 0.75L Distance From Support

0.875L

-20 1.0L

Fig. 9: CFRP shear strengthening of test joists of the commercial building retrofit project

Fig. 10: Comparison of test results commercial building retrofit project. Values were measured at P = 14,500 lb (64.5 kN)

rounded to a 0.5 in. (13 mm) radius to prevent stress concentrations, and 12 in. (305 mm) wide strips of U-wrap CFRP were installed at 16 in. (406 mm) spacing along the full span of each joist (Fig. 9). The calculated shear strength of the joists with this CFRP configuration was 13 kips (58 kN). Deflections and crack widths were monitored in real-time during the load test. Test 1 was terminated when the midspan deflection indicated inelastic behavior. Failure of the joists was governed by yielding of reinforcement at the support, as evidenced by a large crack that developed on the top side of the slab. The width of this crack increased until the load test was terminated. There was no indication of failure at midspan, as midspan crack widths were stable at maximum load. Based on the results of Test 1, it was concluded that the CFRP-strengthened joists were able to support a superimposed dead load of 25 psf (1.2 kN/m2) plus a live load of 135 psf (6.5 kN/m2). The shear performance was adequate with no shear cracks observed on the joist after the test was completed. To resolve the observed negative bending deficiency, a bonded concrete overlay, approximately 3 in. (76.2 mm) thick and reinforced with a steel wire mesh, was installed on the same two joists after roughening the slab surface to approximately 0.25 in. (6 mm) amplitude. Test 2 was performed after the concrete overlay cured. The joists were loaded cyclically, following the same protocol as Test 1 but using a maximum test load of 85% of the factored design loads, as specified by Chapter 20 of ACI 318-05.1 This load level would not cause excessive damage to the upgraded joists, thus eliminating the need for additional repairs after the test. As the load approached the maximum test load, a number of flexural cracks developed on the top side of the overlay at both ends of the joists (negative moment

regions). The number and distribution of the cracks indicated that sufficient bond existed between the existing slab and new overlay to transfer horizontal shear forces and produce monolithic behavior. The reinforced concrete overlay enhanced the strength and stiffness of the test joists and reduced deflection (Fig. 10). Based on the test results, the strengthened joists were rated as adequate to support their self-weight, a 36 psf (1.7 kN/m2) superimposed dead load (reinforced concrete overlay), and 150 psf (7.2 kN/m2) live load. Test 3 was performed on a single joist that was isolated by saw cutting the slab on each side (Fig. 6). Prior to testing, the joist was strengthened for flexure using a bonded RC overlay and for shear using CFRP strips. To expedite the construction schedule and minimize construction cost, the CFRP layout for Test 3 comprised vertical strips applied only to the sides of the joist stem, thus avoiding the need to round the corners of the joists. In addition, the system provided full coverage of the side faces of the joists, as the fibers in one ply of the CFRP strip had fibers oriented in the vertical direction. The calculated shear capacity of the strengthened joist was 14 kips (62.3 kN). The purpose of Test 3 was to verify that this optimal CFRP layout would provide adequate shear performance and to examine the performance of a strengthened joist that was not previously damaged by load testing (as was the case for Test 2 joists). In Test 3, the joist was loaded cyclically to 85% of the design factored loads. The strengthened joist had improved stiffness relative to the damaged and strengthened joists evaluated in Test 2. The strengthened joist also had almost twice the stiffness of the unstrengthened joist evaluated in Test 1. Based on the acceptance criteria parameters, the performance of the joist was considered satisfactory. As with the previous tests, no shear cracks

44

april 2010

/ Concrete international

Deflection, mm

-0.2 Deflection, in.

-5

were observed in Test 3, confirming the adequacy of the alternate CFRP layout.

CHANgE iN USE

In both of the described cases, the CLT method efficiently verified the capacities of the existing structures. For the first case, load testing was used to determine the load-carrying capacity of the existing slab, verify the cause of existing cracks, and confirm the reliability of the analytical models that were later used to determine the required level of strengthening at various locations. For the second case, the load tests provided information on the load-carrying capacity of the existing joists and their governing failure mode, confirmed the performance and composite behavior of the bonded reinforced concrete overlay upgrade solution, and allowed for optimizing the shear strengthening solution using an externally bonded CFRP system. It should be emphasized that externally bonded CFRP reinforcement provided a cost-effective strengthening solution in both cases. Also, because load testing verified that the existing structural components had adequate capacity to carry the design service loads without the contribution of the FRP, no additional fire protection was needed for the CFRP. Only an intumescent top coat was used to provide the smoke-density and flame-spread ratings required per the governing building codes.

4. ACI Committee 437, Strength Evaluation of Existing Concrete Buildings (ACI 437R-03), American Concrete Institute, Farmington Hills, MI, 2003, 28 pp. 5. ACI Committee 437, Test Load Magnitude, Protocol and Acceptance Criteria (ACI 437.1R-07), American Concrete Institute, Farmington Hills, MI, 2007, 38 pp. 6. ACI Committee 364, Guide for Evaluation of Concrete Structures before Rehabilitation (ACI 364.1R-07), American Concrete Institute, Farmington Hills, MI, 2007, 22 pp. 7. SEI-ASCE Committee 11, Guideline for Structural Condition Assessment of Existing Buildings, (SEI-ASCE 11-99), American Society of Civil Engineers, Reston, VA, 2000, 147 pp. 8. ACI Committee 440, Guide for the Design and Construction of Externally Bonded FRP Systems for Strengthening Concrete Structures (ACI 440.2R-02), American Concrete Institute, Farmington Hills, MI, 2002, 45 pp. Received and reviewed under Institute publication policies.

Increased use of load testing can be anticipated as more owners opt to update rather than replace existing buildings. The CLT method offers significant time and costs savings relative to the current ACI 3182 procedure, but there is a need to understand the effects of short-term creep on both old and new structures when loaded to near their capacities. It would appear that this can be achieved by using the two test methods to evaluate similar structural members and comparing the resulting deflection behaviors and residual deformations. Buildings that are to be replaced can also be used for comparative tests to failure.

FUTUrE CoNSidErATioNS

aCi member Tarek Alkhrdaji is an engineering Manager with the strengthening division of structural Group, inc., hanover, Md. he is a member of aCi Committees 437, strength evaluation of existing Concrete structures; 440, Fiber reinforced polymer reinforcement; and 562, evaluation, repair, and rehabilitation of Concrete Buildings. he is also a member of the international Concrete repair institute. Nestore Galati is a design engineer with the strengthening division of structural Group, inc., hanover, Md. he is a member of aCi Committees 437, strength evaluation of existing Concrete structures, and 440, Fiber reinforced polymer reinforcement.

references

1. ACI Committee 318, Building Code Requirements for Structural Concrete (ACI 318-05) and Commentary (318R-05), American Concrete Institute, Farmington Hills, MI, 2005, 430 pp. 2. ACI Committee 318, Building Code Requirements for Structural Concrete (ACI 318-08) and Commentary, American Concrete Institute, Farmington Hills, MI, 2008, 473 pp. 3. RILEM Technical Committee 20-TBS, General Recommendation for Statistical Loading Test of Load-Bearing Concrete Structures In Situ, RILEM Technical Recommendations for the Testing and Use of Construction Materials, E&FN Spon, London, England, 1994, pp. 379-385.

Antonio Nanni, FaCi, holds professorships at the University of Miami and University of NaplesFederico ii. he is an active member of several aCi technical committees.

Concrete international

/ april 2010

45

Anda mungkin juga menyukai

- 20 Repair of Fire Damaged Structures PDFDokumen1 halaman20 Repair of Fire Damaged Structures PDFtaz_taz3Belum ada peringkat

- Optimum Fly Ash and Fiber Content For M20 Grade ConcreteDokumen5 halamanOptimum Fly Ash and Fiber Content For M20 Grade ConcreteIJMER0% (1)

- CracksDokumen10 halamanCracksSyed Mohd MehdiBelum ada peringkat

- Effect of Piles on Seismic Response of Mosque MinaretsDokumen12 halamanEffect of Piles on Seismic Response of Mosque MinaretsMuhammadFaysal100% (1)

- Retrofitting Bridges Effectively in 40 CharactersDokumen30 halamanRetrofitting Bridges Effectively in 40 Charactersmanu_696Belum ada peringkat

- AGGREGATE ABRASION TEST VALUESDokumen6 halamanAGGREGATE ABRASION TEST VALUESAbdur RazzakBelum ada peringkat

- Concrete Mix Design ProcessDokumen54 halamanConcrete Mix Design Processgman444Belum ada peringkat

- Steel Section Table ConciseDokumen36 halamanSteel Section Table ConciseVance KangBelum ada peringkat

- Shotcrete Boiled Water AbsorptionDokumen6 halamanShotcrete Boiled Water AbsorptiondjajadjajaBelum ada peringkat

- Standard Test Method For Splitting Tensile Strength of Cylindrical Concrete Specimens1Dokumen5 halamanStandard Test Method For Splitting Tensile Strength of Cylindrical Concrete Specimens1Lupita RamirezBelum ada peringkat

- 05 Hollow Core Ferrocement ProjectDokumen19 halaman05 Hollow Core Ferrocement ProjectDeo NievesBelum ada peringkat

- Gravity LoadDokumen24 halamanGravity Loadapi-19884175100% (2)

- Bs 1881 - 112 (1983) PDFDokumen11 halamanBs 1881 - 112 (1983) PDFAdesina AlabiBelum ada peringkat

- Setting Time - Vicat Needle ASTM C 191Dokumen10 halamanSetting Time - Vicat Needle ASTM C 191alex_g00dy100% (1)

- Fire Damaged Concrete StructuresDokumen11 halamanFire Damaged Concrete StructuresbarouniamineBelum ada peringkat

- Retaining WallDokumen20 halamanRetaining WallCharlesBelum ada peringkat

- Piling GuideDokumen3 halamanPiling GuidesandycastleBelum ada peringkat

- Compressive Strength TestDokumen6 halamanCompressive Strength TestjejojuBelum ada peringkat

- 4 Precast Concrete: Automatic Rebar Fabrication MachineDokumen14 halaman4 Precast Concrete: Automatic Rebar Fabrication MachineAnonymous AJ99xEBelum ada peringkat

- Compressive Strength Test On Concrete CoreDokumen4 halamanCompressive Strength Test On Concrete CoreSyed Mohd MehdiBelum ada peringkat

- ACI Mix Design CalculationsDokumen5 halamanACI Mix Design CalculationsHaris AlamBelum ada peringkat

- Mass Concrete Temperature Monitoring ExampleDokumen12 halamanMass Concrete Temperature Monitoring ExampleAndy RogersBelum ada peringkat

- BS - SlumpDokumen10 halamanBS - SlumpAna FarBelum ada peringkat

- Control Thermal Cracking Concrete StructuresDokumen5 halamanControl Thermal Cracking Concrete StructuresAnuraBelum ada peringkat

- Bearing CapacityDokumen54 halamanBearing CapacityMasood AhmedBelum ada peringkat

- CAISSONDokumen14 halamanCAISSONnagitaigaBelum ada peringkat

- Design For 11early Thermal CrackingDokumen9 halamanDesign For 11early Thermal CrackingdhruvgokuBelum ada peringkat

- Early Cracking of Concrete PavementDokumen25 halamanEarly Cracking of Concrete PavementRajesh KhadkaBelum ada peringkat

- Span DeflectionDokumen12 halamanSpan Deflectionnirmala_siva_1100% (1)

- Model For Indirect Determination of The Tensile Stree-Strain Curve Carmona2012Dokumen13 halamanModel For Indirect Determination of The Tensile Stree-Strain Curve Carmona2012MICHAEL MWONGABelum ada peringkat

- AS 1012.20-1992 Methods of Testing Concrete - Concrete and C PDFDokumen6 halamanAS 1012.20-1992 Methods of Testing Concrete - Concrete and C PDFmm100% (1)

- Qcs 2010 Part 14 Protective Treatments For ConcreteDokumen19 halamanQcs 2010 Part 14 Protective Treatments For ConcreteRotsapNayrb100% (1)

- TD For ManholeDokumen9 halamanTD For ManholeRachel FloresBelum ada peringkat

- ASTM C1552 - 16 Standard Practice For Capping Concrete Masonry Units, Related Units and Masonry Prisms For Compression TestingDokumen3 halamanASTM C1552 - 16 Standard Practice For Capping Concrete Masonry Units, Related Units and Masonry Prisms For Compression TestingShaneBelum ada peringkat

- Tolerances and BackfillingDokumen4 halamanTolerances and BackfillingAjitesh YelisettyBelum ada peringkat

- Initial and Final SettingDokumen5 halamanInitial and Final SettingHaris AlamBelum ada peringkat

- Schmidt Hammer TestDokumen7 halamanSchmidt Hammer TestJas DhillonBelum ada peringkat

- 6 Defects in Brickwork Due To Poor WorkmanshipDokumen7 halaman6 Defects in Brickwork Due To Poor WorkmanshipMichael Matshona100% (1)

- Thermal Control in ConcreteDokumen14 halamanThermal Control in ConcreteDeshapriyaBelum ada peringkat

- Post Cast Strip PDFDokumen2 halamanPost Cast Strip PDFKwoshaba PidsonBelum ada peringkat

- Etc - BD 28-87Dokumen1 halamanEtc - BD 28-87arun_angshuBelum ada peringkat

- How To Calculate The Total Load On The FootingDokumen7 halamanHow To Calculate The Total Load On The Footingram_babu_59100% (3)

- Testing Concrete: 108. Method Test Cubes From Fresh ConcreteDokumen5 halamanTesting Concrete: 108. Method Test Cubes From Fresh ConcreteYajBelum ada peringkat

- Bs12 PDFDokumen15 halamanBs12 PDFraed waheebBelum ada peringkat

- Quantity SurveyingDokumen6 halamanQuantity SurveyingEmmanuel Sto TomasBelum ada peringkat

- Lab Report: Design of Concrete Structures (ENG466)Dokumen11 halamanLab Report: Design of Concrete Structures (ENG466)Amrit AcharyaBelum ada peringkat

- KDS 41 17 00 건축물 내진설계기준Dokumen131 halamanKDS 41 17 00 건축물 내진설계기준colt0Belum ada peringkat

- Development of Seismic Fragility Curves in The Assessment of Vitas Bridge Using Capacity Spectrum MethodDokumen68 halamanDevelopment of Seismic Fragility Curves in The Assessment of Vitas Bridge Using Capacity Spectrum MethodBuoyancy100% (1)

- Time of Setting of Hydraulic Cement by Vicat Needle: Standard Test Method ForDokumen6 halamanTime of Setting of Hydraulic Cement by Vicat Needle: Standard Test Method ForAhmed AbidBelum ada peringkat

- Core Tests:: Easy To Perform, Not Easy To InterpretDokumen10 halamanCore Tests:: Easy To Perform, Not Easy To InterpretEngr Shofiul AlamBelum ada peringkat

- Pile Foundation DesignDokumen36 halamanPile Foundation DesignAfendi AriffBelum ada peringkat

- Pile Foundation Spacing and Skin Fraction in Pile GroupDokumen4 halamanPile Foundation Spacing and Skin Fraction in Pile GroupJustin MusopoleBelum ada peringkat

- Design Guidelines For Timber Ceiling Structures With Asbestos Cement Sheets or Light Timber Planks by Prof. S.R. de S. Chandrakeerthy 2005Dokumen8 halamanDesign Guidelines For Timber Ceiling Structures With Asbestos Cement Sheets or Light Timber Planks by Prof. S.R. de S. Chandrakeerthy 2005ishanBelum ada peringkat

- Estimating Two-Way Slab Deflections: Spreadsheet Includes Construction Load EffectsDokumen6 halamanEstimating Two-Way Slab Deflections: Spreadsheet Includes Construction Load EffectsKojo AsareBelum ada peringkat

- AXIAL LOAD TEST PROCEDURESDokumen6 halamanAXIAL LOAD TEST PROCEDURESNay Win SheinBelum ada peringkat

- Testing Bored Cast In Situ Piles at Project Management BuildingDokumen4 halamanTesting Bored Cast In Situ Piles at Project Management BuildingRitesh Dahiya100% (1)

- Testing Deep FoundationsDokumen9 halamanTesting Deep FoundationsDRocha1Belum ada peringkat

- Steel Frame Structure Modeling by Staad-Pro (Example - 2) by Prof. Dr. Nabeel Al-BayatiDokumen6 halamanSteel Frame Structure Modeling by Staad-Pro (Example - 2) by Prof. Dr. Nabeel Al-BayatiProfessor Dr. Nabeel Al-Bayati-Consultant Engineer100% (1)

- Reinforced Concrete Building, Modelling, Analysis and Design by Staad-Pro (Example 3) by Prof. Dr. Nabeel Al-BayatiDokumen5 halamanReinforced Concrete Building, Modelling, Analysis and Design by Staad-Pro (Example 3) by Prof. Dr. Nabeel Al-BayatiProfessor Dr. Nabeel Al-Bayati-Consultant Engineer50% (2)

- Steel Frame Structure Analysis and Design by Staad-Pro (Example - 4) by Prof. Dr. Nabeel Al-BayatiDokumen3 halamanSteel Frame Structure Analysis and Design by Staad-Pro (Example - 4) by Prof. Dr. Nabeel Al-BayatiProfessor Dr. Nabeel Al-Bayati-Consultant Engineer100% (2)

- Experimental Behavior of Composite Deep Beams, AUB Conference, 2015 PDFDokumen8 halamanExperimental Behavior of Composite Deep Beams, AUB Conference, 2015 PDFProfessor Dr. Nabeel Al-Bayati-Consultant EngineerBelum ada peringkat

- New Approach Prediction of Compression Strength of Normal and Porcelanite Aggregate Lightweight Concrete by Non-Destructive TestDokumen8 halamanNew Approach Prediction of Compression Strength of Normal and Porcelanite Aggregate Lightweight Concrete by Non-Destructive TestProfessor Dr. Nabeel Al-Bayati-Consultant EngineerBelum ada peringkat

- Structural Concrete Details by AutoCAD-Example 2-Prof. Dr. Nabeel Al-Bayati PDFDokumen7 halamanStructural Concrete Details by AutoCAD-Example 2-Prof. Dr. Nabeel Al-Bayati PDFProfessor Dr. Nabeel Al-Bayati-Consultant Engineer100% (1)

- Reinforced Concrete Building Modeling by Staad-Pro (Example-1) by Prof. Dr. Nabeel Al-BayatiDokumen6 halamanReinforced Concrete Building Modeling by Staad-Pro (Example-1) by Prof. Dr. Nabeel Al-BayatiProfessor Dr. Nabeel Al-Bayati-Consultant Engineer100% (1)

- Experimental Behavior of Composite Deep Beams, AUB Conference, 2015 PDFDokumen8 halamanExperimental Behavior of Composite Deep Beams, AUB Conference, 2015 PDFProfessor Dr. Nabeel Al-Bayati-Consultant EngineerBelum ada peringkat

- Strength Assessment of Concrete Structures PDFDokumen58 halamanStrength Assessment of Concrete Structures PDFProfessor Dr. Nabeel Al-Bayati-Consultant Engineer100% (1)

- Shear StrengtheningDokumen8 halamanShear StrengtheningMohamed MoatazBelum ada peringkat

- Strength and Behavior in Shear of Reinforced Concrete Deep Beams Under Dynamic Loading Conditions PDFDokumen15 halamanStrength and Behavior in Shear of Reinforced Concrete Deep Beams Under Dynamic Loading Conditions PDFProfessor Dr. Nabeel Al-Bayati-Consultant EngineerBelum ada peringkat

- Bending Stiffness and Neutral Axis Depth Variation of High Strength Concrete Beams in Seismic Hazardous Areas Experimental InvestigationDokumen13 halamanBending Stiffness and Neutral Axis Depth Variation of High Strength Concrete Beams in Seismic Hazardous Areas Experimental InvestigationArjun MulluBelum ada peringkat

- Repair of Reinforced Concrete Deep Beams Using Post-Tensioned CFRP Rods PDFDokumen39 halamanRepair of Reinforced Concrete Deep Beams Using Post-Tensioned CFRP Rods PDFProfessor Dr. Nabeel Al-Bayati-Consultant EngineerBelum ada peringkat

- New Approach Prediction of Compression Strength of Normal and Porcelanite Aggregate Lightweight Concrete by Non-Destructive TestDokumen8 halamanNew Approach Prediction of Compression Strength of Normal and Porcelanite Aggregate Lightweight Concrete by Non-Destructive TestProfessor Dr. Nabeel Al-Bayati-Consultant EngineerBelum ada peringkat

- Astm C-42Dokumen6 halamanAstm C-42Víctor M Fernández JiménezBelum ada peringkat

- Shear Design Summary for Reinforced Concrete BeamsDokumen8 halamanShear Design Summary for Reinforced Concrete BeamsShashikant Gaur0% (1)

- Aci Structural Journal Jan.-Feb. 2015 v. 112 No. 01Dokumen122 halamanAci Structural Journal Jan.-Feb. 2015 v. 112 No. 01Professor Dr. Nabeel Al-Bayati-Consultant Engineer100% (3)

- IBM SPSS Statistics PDFDokumen8 halamanIBM SPSS Statistics PDFProfessor Dr. Nabeel Al-Bayati-Consultant EngineerBelum ada peringkat

- Computer Application in Water Works EngineeringDokumen12 halamanComputer Application in Water Works EngineeringProfessor Dr. Nabeel Al-Bayati-Consultant EngineerBelum ada peringkat

- StaircaseDokumen14 halamanStaircaserameshbabu_1979Belum ada peringkat

- Bulk Density ("Unit Weight") and Voids in Aggregate: Standard Test Method ForDokumen4 halamanBulk Density ("Unit Weight") and Voids in Aggregate: Standard Test Method ForIbeth S OTBelum ada peringkat

- EIA Practice in India and Its EvaluationDokumen19 halamanEIA Practice in India and Its EvaluationDharmesh100% (1)

- A Design For Circular Concrete Tank Pca Design MethodDokumen15 halamanA Design For Circular Concrete Tank Pca Design MethodajebBelum ada peringkat

- APSEC 2006 Proceedings on Design of RC BeamsDokumen17 halamanAPSEC 2006 Proceedings on Design of RC BeamsvinthfBelum ada peringkat

- Ansi - Eia 748 BDokumen34 halamanAnsi - Eia 748 BProfessor Dr. Nabeel Al-Bayati-Consultant EngineerBelum ada peringkat

- Aci Structural Journal Mar.-Apr. 2015 v. 112 No. 02Dokumen146 halamanAci Structural Journal Mar.-Apr. 2015 v. 112 No. 02Professor Dr. Nabeel Al-Bayati-Consultant Engineer100% (5)

- Beam Design Formulas With Shear and MomentDokumen20 halamanBeam Design Formulas With Shear and MomentMuhammad Saqib Abrar100% (8)

- IBM SPSS Statistics PDFDokumen8 halamanIBM SPSS Statistics PDFProfessor Dr. Nabeel Al-Bayati-Consultant EngineerBelum ada peringkat

- Oil StorFage Tank Foundations BobergDokumen3 halamanOil StorFage Tank Foundations BobergNabil Al-KhirdajiBelum ada peringkat

- MS Project 2002 Getting Started PDFDokumen20 halamanMS Project 2002 Getting Started PDFProfessor Dr. Nabeel Al-Bayati-Consultant EngineerBelum ada peringkat

- Albert Bandura'S Social Learning TheoryDokumen13 halamanAlbert Bandura'S Social Learning Theorysofia lynel paladaBelum ada peringkat

- A Learning Theory Approach To Attachment Theory: Exploring Clinical ApplicationsDokumen22 halamanA Learning Theory Approach To Attachment Theory: Exploring Clinical ApplicationsCláudioToméBelum ada peringkat

- Drive Reduction Theory by Hull C.Dokumen9 halamanDrive Reduction Theory by Hull C.Adeleye 'Wale RichardBelum ada peringkat

- Chapter 5 & 6 Sample QuestionsDokumen6 halamanChapter 5 & 6 Sample Questionsdipak2401100% (1)

- A Survival Cheat Sheet' For ParentsDokumen6 halamanA Survival Cheat Sheet' For ParentsdancingstarsBelum ada peringkat

- Behavior Management (Notes)Dokumen3 halamanBehavior Management (Notes)alvinlinlBelum ada peringkat

- What Is Operant Conditioning - Definition and ExamplesDokumen10 halamanWhat Is Operant Conditioning - Definition and ExamplesAlekhya DhageBelum ada peringkat

- Why managers need people skillsDokumen34 halamanWhy managers need people skillsmelyantitheresiaBelum ada peringkat

- Educational Implications of Classical Condi NGDokumen2 halamanEducational Implications of Classical Condi NGChikyBelum ada peringkat

- 1935 - Two Types of Conditioned Reflex and A Pseudo TypeDokumen9 halaman1935 - Two Types of Conditioned Reflex and A Pseudo TypemchlspBelum ada peringkat

- Field Study 1 Full EpisodesDokumen45 halamanField Study 1 Full EpisodesHannahclaire Delacruz100% (3)

- Are Theories of Learning Necessary? B.F. Skinner's Classic AnalysisDokumen28 halamanAre Theories of Learning Necessary? B.F. Skinner's Classic AnalysisMariza CabralBelum ada peringkat

- Chapter 2Dokumen26 halamanChapter 2MeaadBelum ada peringkat

- Consumer Perception: How Can Business Create Value?Dokumen15 halamanConsumer Perception: How Can Business Create Value?Dũng Mạnh TrầnBelum ada peringkat

- T.O.P Finals Reviewer IncompleteDokumen11 halamanT.O.P Finals Reviewer IncompleteSARAH MARGARETTE PAGLINAWANBelum ada peringkat

- Behavioural Approach To AddictionDokumen2 halamanBehavioural Approach To AddictionjukazadeBelum ada peringkat

- Canter & Canter - Assertive DisciplineDokumen13 halamanCanter & Canter - Assertive DisciplineJessica ArchieBelum ada peringkat

- Robbins Mgmt15 PPT 15Dokumen51 halamanRobbins Mgmt15 PPT 15Hala JabrBelum ada peringkat

- Learning and MemoryDokumen24 halamanLearning and MemoryNadapoyBelum ada peringkat

- Apa ch21 PDFDokumen21 halamanApa ch21 PDFNBBelum ada peringkat

- Dont Shoot The Dog Karen Pryor 0Dokumen95 halamanDont Shoot The Dog Karen Pryor 0sambrefo100% (1)

- BABCP Ed WatkinsDokumen84 halamanBABCP Ed WatkinsMonica MohnblattBelum ada peringkat

- QP Psychology 23-24 Class XIIDokumen5 halamanQP Psychology 23-24 Class XIISanthanalakshmi ThyagarajanBelum ada peringkat

- Chapter 4Dokumen20 halamanChapter 4Nasyitah RusliBelum ada peringkat

- Coach CarterDokumen16 halamanCoach CarterRachit WadhwaBelum ada peringkat

- Business in Action 7e Bovée/ThillDokumen34 halamanBusiness in Action 7e Bovée/ThillQuỳnh Nga LêBelum ada peringkat

- Chapter 3 Lesson 2Dokumen6 halamanChapter 3 Lesson 2Tim Ang100% (1)

- Psychological Theories of DepressionDokumen7 halamanPsychological Theories of Depressionwe sagara dewiBelum ada peringkat

- Post Lesson ReflectionDokumen8 halamanPost Lesson Reflectionapi-430394514Belum ada peringkat