Safety: Linhas Aéreas Inteligentes

Diunggah oleh

Christian OliveiraDeskripsi Asli:

Judul Asli

Hak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

Safety: Linhas Aéreas Inteligentes

Diunggah oleh

Christian OliveiraHak Cipta:

Format Tersedia

Linhas areas Inteligentes

COMPOSITE SAFETY

SAFETY

Linhas areas Inteligentes

COMPOSITE SAFETY

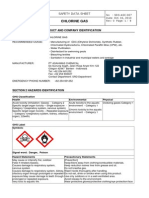

SAFETY PRECAUTIONS Throughout this manual the emphasis is upon the importance of safety at work. To many people this conception still conjures up images of hard helmets and other devices to protect against physical hazards, while the more insidious and sometimes more dangerous effects upon health of exposure to toxic chemicals are often overlooked. Chemicals may have acute or chronic effects. The more dangerous chemicals have threshold limit values (TLV) recommended by the American Conference of Governmental Industrial Hygienists (ACGIH). These limits are expressed in ppm (parts per million). Many countries adopt the ACGIH TLVs for their own use, but others, such as the UK, Germany or Netherlands are developing there own limit values recognized by different abbreviations (e.g. RL - recommended limits, CL - control limits in the UK; MAK or MAC values - maximum acceptable concentration. In future there will be a harmonized list of exposure standards for adoption by the EEC countries. All chemicals in the EEC must have on each container a label bearing the name of the material, its origin, the danger symbols, and the risk phrases. The inclusion of safety phrases on labels of small containers is still optional for low risk materials.

DANGER OR WARNING SYMBOLS Toxic substances are those offering a serious risk of acute or chronic poisoning by any route. Harmful substances are those which call attention to a risk. Corrosive substances are those which destroy tissues. Flammable substances are those with a flash point of between 21C and 55C; highly flammable have a flash point between 0C and 21C; extremely flammable have flash points below 0C. Irritant substances are those which can cause inflammation.

Linhas areas Inteligentes

COMPOSITE SAFETY

Linhas areas Inteligentes

COMPOSITE SAFETY

HANDLING PRECAUTION FOR EPOXY RESIN MATERIALS Epoxy materials are reactive chemicals which require correct handling to ensure that they are safely. The hazards raised in the handling of epoxy materials may be classified as: 1. Fire hazard associated with solvent containing products. Certain of these are highly flammable. SOME EPOXIES ARE INFLAMMABLE DONT TAKE A CHANCE ON IGNITION

Linhas areas Inteligentes

COMPOSITE SAFETY

Linhas areas Inteligentes

COMPOSITE SAFETY

HANDLING PRECAUTION FOR EPOXY RESIN MATERIALS Irritation due to contamination of the skin or eyes. The effect may be occur by contact with a liquid or solid uncured material - or by exposure to its vapor or dust.

DONT INHALE VAPOURS DONT BE UNTIDY DONTALLOW DIFFERENT JOBS IN THE RESIN WORK AREA

Linhas areas Inteligentes

COMPOSITE SAFETY

Linhas areas Inteligentes

COMPOSITE SAFETY

HANDLING PRECAUTION FOR EPOXY RESIN MATERIALS Toxic effects due to ingestion or to absorption through the skin. DON.EAT, DRINK OR SMOKE IN THE WORK AREA

Linhas areas Inteligentes

COMPOSITE SAFETY

Linhas areas Inteligentes

COMPOSITE SAFETY

HANDLING PRECAUTION FOR EPOXY RESIN MATERIALS Irritation to the eyes, nose, throat and lungs by dust from the machining or fully cured material.

DONT EXPOSE YOURSELF TO DUST DONT MACHINE WITHOUT WEARING CLOTHING AND DUST MASK OR RESPIRATOR PROTECTIVE

10

Linhas areas Inteligentes

COMPOSITE SAFETY

11

Linhas areas Inteligentes

COMPOSITE SAFETY

HANDLING PRECAUTION FOR EPOXY RESIN MATERIALS Provided that direct contact with resin materials is avoided and good ventilation is maintained, operators should be remain free of any skin, eye or respiratory irritation. PROVIDE SAFE AND CLEAN WORK AREA

12

Linhas areas Inteligentes

COMPOSITE SAFETY

13

Linhas areas Inteligentes

COMPOSITE SAFETY

HANDLING PRECAUTION FOR EPOXY RESIN MATERIALS TRANSPORT AND STORAGE When not in use, materials should be stored in sealed containers and away from food, food containers and clothing. DO KEEP CONTAINERS FIRMLY CLOSED AND NEATLY STACKED - IN THE DRY AND AWAY FROM HEAT SOURCES.

14

Linhas areas Inteligentes

COMPOSITE SAFETY

15

Linhas areas Inteligentes

COMPOSITE SAFETY

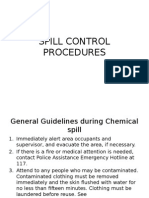

HANDLING PRECAUTION FOR EPOXY RESIN MATERIALS REMOVAL OF SPILLAGES Materials should be kept in securely closed containers, and particular care should be taken to avoid leakage or spillage. In the event of any such escape of liquid materials, the spillage should at once be taken up with sand, cotton waste, sawdust, paper towels or other absorbent material, and the contaminated material taken to a safe place until disposal. Spillages of powder or granular materials should be covered with damp sand and transferred carefully into containers for removal, the area then cleaned by vacuum, with the spillage cleared away, the contaminated area should be washed clean with detergent solution, preferable hot. In the event of a serious spillage which enters public drains or waterways, the local Water Authority must be informed immediately, and the police should be notified. Particular care is necessary to avoid any possible risk of contact with foodstuffs and food utensils. DONT ALLOW TO SPILL DONT BE CARELESS. SOAK UP ACCIDENTAL SPILLAGES IMMEDIATELY WITH SAND, SAWDUST, PAPER TOWELS, ETC. AND WASH THE AREA CLEAN.

16

Linhas areas Inteligentes

COMPOSITE SAFETY

17

Linhas areas Inteligentes

COMPOSITE SAFETY

HANDLING PRECAUTION FOR EPOXY RESIN MATERIALS ROAD TRANSPORTATION EMERGENCY LABELS Outer containers of hazardous resin materials have to carry a Road Transport Emergency Label stating in concise terms the hazards inherent in the particular material and the immediate and follow-up actions to be taken in the event of an emergency. The label also lists personal protective equipment to be carried in the vehicle when conveying the material. Low- hazard resin materials in single containers 200 liters or above likewise carry Road Transport Emergency Labels setting out the actions to be taken in the event of an emergency. Rating the hazards as minor, the label for these materials also serve as a reassurance to local authorities. STORAGE OF DANGEROUS MATERIALS Certain solvent-containing materials are highly flammable and the containers are marked with a torch symbol on an orange background, signifying a flashpoint below 21C. Care must be taken to ensure the observance of the relevant regulations. Likewise, certain polyamine hardeners are corrosive and their containers are marked with a pictogram showing, on an orange background, the effects of corrosion.

18

Linhas areas Inteligentes

COMPOSITE SAFETY

19

Linhas areas Inteligentes

COMPOSITE SAFETY

HANDLING PRECAUTION FOR EPOXY RESIN MATERIALS PLACE OF WORK Good general ventilation, cleanliness and tidiness in workshops are essential. Effective local ventilation is necessary to avoid contact or inhalation of vapor, fumes or dust. Handling of resin materials should take place only in areas designated for this work. VENTILATION Whenever undertaken indoors, the mixing of resin materials should be carried out in workshops equipped with a good general ventilation system. In addition, fume cupboards or efficiently ventilated bench-type hoods should be provided for the actual mixing. Use of the prepared mixtures should likewise be confined to areas provided with efficient mechanical exhaust ventilation. Exhaust ventilation of curing ovens must be maintained in good condition so that operators, when opening ovens, do not expose the sensitive skin areas of face and neck to the hot fumes. Certain resin materials give off highly flammable vapors. Ventilation systems used to extract these vapors must not provide a means of ignition. The motors and associated wiring must be flame proof, or located in a safe place, or pressurized to prevent the ingress of flammable vapor. WHERE HOT CURING - DO USE AIR CIRCULATING OVENS WITH EXHAUST SYSTEMS TO PREVENT EXPOSURE OF FACE AND NECK TO HOT GASES. DONT CURE IN LASH-UP OVENS.

20

Linhas areas Inteligentes

COMPOSITE SAFETY

21

Linhas areas Inteligentes

COMPOSITE SAFETY

HANDLING PRECAUTION FOR EPOXY RESIN MATERIALS MACHINING OF CURED MATERIALS Whenever the fully cured or hardened material is to be machined (sawn, filed, etc. ), the equipment should be provided with an effective local extraction system. Operators should wear eye protection and a dust mask protection to nose and mouth. DO USE EFFECTIVE LOCAL EXTRACTION, SET UP SO THAT THE AIRFLOW IS AWAY FROM YOU.

22

Linhas areas Inteligentes

COMPOSITE SAFETY

23

Linhas areas Inteligentes

COMPOSITE SAFETY

HANDLING Resin materials in an uncured stage are reactive by their nature. General Handling techniques must ensure that no uncured material resin material comes in contact with the eyes or skin. Operators should wear gloves, overall, eye protection and, when there is a risk of forming dust cloud, protection for the nose and mouth. Any skin abrasions must be covered to eliminate the possibility of accidental contact with the materials. Adequate facilities for washing are essential. They should be provided at or very near the place of work so that accidental contamination can at once be removed from the skin. Washing accommodation should be kept clean and be provided with a plentiful supply of clean running warm water, soap, skin cream and disposable towels. Benches should have impervious surfaces and, whenever practical, be protected by a disposable cover - e.g.. paper, aluminum foil or plastics- for replacement when contaminated. Waste bins should be equipped with lids and with replaceable liners. All the waste material should be deposited directly into the bins.

DO DISCARD HEAVILY CONTAMINATED ARTICLES IN A PROPER RUBBISH BINS. DO USE VENTILATION PROVIDED. DO DISPOSE OF EMPTY CONTAINERS AND WASTE MA TERIAL DIRECTLY INTO WASTE BINS.

IF CONTACT OCCURS: DO WASH IMMEDIATELY WITH SOAP AND WARM WATER. KEEP CLEAN! DO CHANGE CLOTHES THATGET CONTAMINATED. DONT DELAY! KEEP CLEAN! DO WASH HANDS,ARMS WITH SOAP AND WARM WATER BEFORE RELIEF PERIODS - BEFORE EATING.

24

Linhas areas Inteligentes

COMPOSITE SAFETY

25

Linhas areas Inteligentes

COMPOSITE SAFETY

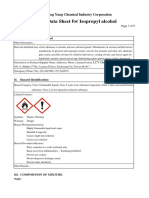

CLEANING OF TOOLS Mixing and application equipment must be cleaned before the resin material have hardened. Acetone, Isopropanol and MEK are suitable cleaning solvents. PROTECTIVE CLOTHING Operators should be provided with protective clothing and equipment to minimize personal contact with the uncured materials. Operators should wear: Gloves The following types of gloves are in standard use with resin materials: nitrile rubber, natural rubber, surgical rubber or polyethylene disposable. The nature of work will determine the choice of gloves. The inside of the gloves must be kept clean. Damaged gloves must be replaced. For operators commencing a long word period: It is advisable to wear cotton gloves under the protective gloves. The inner cotton gloves will reduce the risk of skin irritation due the sweating. The cotton gloves should be changed regularly at the end of each work period before removal, the protective gloves should be cleaned with soap and warm water. Eye protection Safety spectacles are the minimum standard of eye protection. In work areas where dust clouds, fumes, vapors, mists or splashes are not removed by a local extraction system, operators should wear goggles or a visor.

Overalls and heavy-duty aprons Overalls are essential for all operators engaged in continuous processes. In some instances, heavy-duty plastics or rubber aprons may be required for added protection. When powder resin materials, fillers or glass fibres are in use, operators should take measures to prevent any risk of these materials lodging between clothing and the skin. Overalls should be changed frequently and regularly. Protection against dust inhalation The handling of powder resin materials, fillers, glass or carbon fibres makes it necessary to take precautions against the inhalation of dust. When there is a risk of dust of a hazardous resin material, operators should wear protective respiratory equipment, i.e. high-efficiency dust masks which either remove contaminates with filters or provide clean air from an uncontaminated source. Barrier creams A barrier cream, applied to the skin before work, offers a useful addition to protective clothing. The use of barrier creams must not be considered as an alternative to the wearing of protective gloves. Cleansing of the skin The skin should be thoroughly cleansed as a standard routine: after work before eating and drinking before smoking before using the lavatory 26

Linhas areas Inteligentes

COMPOSITE SAFETY

Cleansing of the skin (cont) Routine cleansing necessitates washing with soap and warm water. Following this, a resin-removing cream should be used, followed by further washing to remove remnants of the cream from the skin. Solvents should be avoided. Disposable paper towels, not cloth towels, should be used to dry the skin. As repeated hand washing and use of cleansing cream tend to cause skin dryness, it is advisable to use a skin reconditioning cream after work. DO KNOW WHERE THE NEAREST EYE BATH, SINK WITH RUNNING WATER, AND FIRE EXTINGUISHER ARE LOCATED. DO COVER WORKBENCH WITH DISPOSABLE METAL FOIL OR PAPER SHEET. DO PUT ON PROTECTIVE CLOTHING AND GLOVES AND EYE PROTECTION. DO BE CLEAN AND STAY CLEAN

27

Linhas areas Inteligentes

COMPOSITE SAFETY

28

Linhas areas Inteligentes

COMPOSITE SAFETY

EMERGENCY ACTION FIRST-AID PROCEDURES Skin contact Immediately remove liquids from the skin by wiping with disposable paper towels (remove powders by brushing), then cleanse the affected skin area with resin removing cream, followed by washing with warm soapy water. DO NOT USE SOLVENTS. DONT ... WASH WITH POWERFUL SOLVENTS. Eye contamination or irritation Immediately flush the affected eye with eyewash bottle or fountain, or with low pressure running water, for at least 15 minutes. Seek medical attention promptly. Inhalation Operators affected by the inhalation of powders or fumes, vapors, mists, droplets, etc., should be taken immediately into fresh air and made to rest while medical attention is called. Clothing Remove and isolate contaminated overalls and clothing. DO REMOVE WORK CLOTHING. PUT A SIDE CONTAMINATED CLOTHES FOR WORKS ORGENISED LAUNDERING. DONT TAKE CONTAMINATED CLOTHING HOME FOR LAUNDERING. Ingestion (entry by mouth and swallowing) Immediately rinse the mouth with water. If swallowing has occurred, drink plenty of water. Seek medical attention promptly. Fires If any resin material catches fire, use either a carbon dioxide, dry powder, foam or vaporizing liquid extinguisher, or apply water spray. Do not use water jets. Avoid the products of combustion while putting out the fire. In a serious fire it may be necessary to wear a self-contained breathing apparatus.

29

Linhas areas Inteligentes

COMPOSITE SAFETY

30

Anda mungkin juga menyukai

- Dunlop Vinyl Adhesive MSDSDokumen8 halamanDunlop Vinyl Adhesive MSDSSN NazihahBelum ada peringkat

- DULUX Diamond Matt Safety SheetDokumen8 halamanDULUX Diamond Matt Safety SheetjustinBelum ada peringkat

- MSDS - Monopropylene Glycol - Industrial - EngDokumen11 halamanMSDS - Monopropylene Glycol - Industrial - Engamiller1987Belum ada peringkat

- Chemical Spill Response PlanDokumen8 halamanChemical Spill Response Planathul subashBelum ada peringkat

- MSDS EverstickDokumen7 halamanMSDS EverstickDil VasconcelosBelum ada peringkat

- Dulux Water BasedDokumen7 halamanDulux Water BasedDya PratamaBelum ada peringkat

- Safe Use Pyrophoric ReagentsDokumen9 halamanSafe Use Pyrophoric ReagentsDarius DsouzaBelum ada peringkat

- Chemical SpillResponse PlanDokumen7 halamanChemical SpillResponse PlanJobstarr TechnoserveBelum ada peringkat

- Lab SafetyDokumen5 halamanLab SafetyHafeez AliBelum ada peringkat

- Standard Operating Procedure: AmmoniaDokumen6 halamanStandard Operating Procedure: AmmoniaRASHEED YUSUFBelum ada peringkat

- Safe Use Pyrophoric ReagentsDokumen8 halamanSafe Use Pyrophoric ReagentsGeorgeBelum ada peringkat

- DGLP660 MSDSDokumen7 halamanDGLP660 MSDSAbadBelum ada peringkat

- I. Standard Operating ProcedureDokumen7 halamanI. Standard Operating Procedureibnu wicaksonoBelum ada peringkat

- Adhesives and Sealants PDFDokumen3 halamanAdhesives and Sealants PDFNerinel CoronadoBelum ada peringkat

- Ah-400l MSDSDokumen7 halamanAh-400l MSDSAbadBelum ada peringkat

- Safety Policy (Administrative)Dokumen89 halamanSafety Policy (Administrative)salamon2tBelum ada peringkat

- LabActivity Task#2 - Lab Safety and Apparatuses - RAMOSDokumen6 halamanLabActivity Task#2 - Lab Safety and Apparatuses - RAMOSMichael Josh RamosBelum ada peringkat

- Ah-179n MSDSDokumen7 halamanAh-179n MSDSAbadBelum ada peringkat

- MSDS Dulux Brilliant WhiteDokumen9 halamanMSDS Dulux Brilliant WhiteDya PratamaBelum ada peringkat

- Safety Data Sheet: 1. Identification of The Substance/preparation and of The Company/undertakingDokumen4 halamanSafety Data Sheet: 1. Identification of The Substance/preparation and of The Company/undertakingBalasubramanian AnanthBelum ada peringkat

- Mirr Alma Super Api SL Sae 15W40 SDSDokumen8 halamanMirr Alma Super Api SL Sae 15W40 SDSAbdul GhafoorBelum ada peringkat

- A0200 Acetic Acid Glacial EngDokumen5 halamanA0200 Acetic Acid Glacial EngWaqas RamayBelum ada peringkat

- Nalco Eliminox: Material Safety Data SheetDokumen9 halamanNalco Eliminox: Material Safety Data SheetSrikar Reddy GummadiBelum ada peringkat

- Standard Operating Procedure: Hydrochloric AcidDokumen6 halamanStandard Operating Procedure: Hydrochloric AcidJulio100% (1)

- Vinyl Acetate Monomer PresenationDokumen12 halamanVinyl Acetate Monomer Presenationtatarey79Belum ada peringkat

- 07 SDS Cl2Dokumen8 halaman07 SDS Cl2Fadlul Akbar HerfiantoBelum ada peringkat

- Current Practices Being Used in Their Manufacturing ProcessDokumen5 halamanCurrent Practices Being Used in Their Manufacturing ProcessjaredjoeBelum ada peringkat

- It Xylene MsdsDokumen8 halamanIt Xylene MsdsHendriyana StBelum ada peringkat

- Material Safety Data Sheet: Version No.01 - Revision Date 12/07/2010Dokumen10 halamanMaterial Safety Data Sheet: Version No.01 - Revision Date 12/07/2010shulhan nstBelum ada peringkat

- ERC Clean Room Standard Operating Procedure Chemical SpillDokumen6 halamanERC Clean Room Standard Operating Procedure Chemical SpillMv PatelBelum ada peringkat

- Tandex 245Dokumen10 halamanTandex 245Harnani NanikBelum ada peringkat

- RulesandpracticesDokumen9 halamanRulesandpracticesRodolfo CorpuzBelum ada peringkat

- Msds - m153 Base - Sds10828Dokumen7 halamanMsds - m153 Base - Sds10828cmkohBelum ada peringkat

- Spill Control ProceduresDokumen7 halamanSpill Control ProceduresCherryRoseSaguinsin0% (1)

- 5.3 Working With Substances Hazardous To Your HealthDokumen3 halaman5.3 Working With Substances Hazardous To Your HealthPrécieux BabiBelum ada peringkat

- Health and Safety Data Sheet For Common Cements and Cement ProductsDokumen6 halamanHealth and Safety Data Sheet For Common Cements and Cement Productsjack21abBelum ada peringkat

- Asphalt and Bitumen Patching PDFDokumen1 halamanAsphalt and Bitumen Patching PDFcityofdarwingisBelum ada peringkat

- Poly Ultra Nails Construction Adhesive-Aus SdsDokumen7 halamanPoly Ultra Nails Construction Adhesive-Aus SdsGavin PintoBelum ada peringkat

- Safety Data Sheet: 1. Identification of The Substance/preparation and of The Company/undertakingDokumen4 halamanSafety Data Sheet: 1. Identification of The Substance/preparation and of The Company/undertakingBalasubramanian AnanthBelum ada peringkat

- Safety Data Sheet: 1. Identification of The Substance/preparation and of The Company/undertakingDokumen3 halamanSafety Data Sheet: 1. Identification of The Substance/preparation and of The Company/undertakingBalasubramanian AnanthBelum ada peringkat

- General Safety Instruction - AmmoniaDokumen5 halamanGeneral Safety Instruction - AmmoniaVăn Phú PhạmBelum ada peringkat

- RS Potting Compound Safety Data Sheets PDFDokumen25 halamanRS Potting Compound Safety Data Sheets PDFAchira Chanaka PeirisBelum ada peringkat

- Golden Power 5000 API SL Sae 20w-50 SdsDokumen8 halamanGolden Power 5000 API SL Sae 20w-50 SdsAbdul GhafoorBelum ada peringkat

- Safety in Pathology LaboratoryDokumen15 halamanSafety in Pathology LaboratoryMohammed Yousif mzoriBelum ada peringkat

- Wattyl Colourthane Thinner Standard 6100-99 MSDS May13Dokumen12 halamanWattyl Colourthane Thinner Standard 6100-99 MSDS May13Dil VasconcelosBelum ada peringkat

- Alcohol MSDSDokumen8 halamanAlcohol MSDSAjay KastureBelum ada peringkat

- Safety GuidelinesDokumen12 halamanSafety GuidelinesMai TuấnBelum ada peringkat

- SDS - Crosstrans 206 - 0Dokumen6 halamanSDS - Crosstrans 206 - 0omidBelum ada peringkat

- Marlins Test Kita - READINGDokumen22 halamanMarlins Test Kita - READINGзавир мансуровBelum ada peringkat

- Industrial Safety 2024Dokumen8 halamanIndustrial Safety 2024harunaheer02Belum ada peringkat

- Original MSDS SolidifierDokumen6 halamanOriginal MSDS SolidifierSaad IqbalBelum ada peringkat

- Kerosene PDFDokumen9 halamanKerosene PDFishnafathonahBelum ada peringkat

- Safety Guidelines in Chemical Laboratories DISATDokumen55 halamanSafety Guidelines in Chemical Laboratories DISATFloare de PrimavaraBelum ada peringkat

- Bio Security Guidelines Final 030113Dokumen5 halamanBio Security Guidelines Final 030113freak009Belum ada peringkat

- CC Internship Day1Dokumen6 halamanCC Internship Day1Angelica Joy GonzalesBelum ada peringkat

- Tandex 285Dokumen10 halamanTandex 285Harnani NanikBelum ada peringkat

- Safety Data Sheet: 1. Identification of The Substance/preparation and of The Company/undertakingDokumen4 halamanSafety Data Sheet: 1. Identification of The Substance/preparation and of The Company/undertakingBalasubramanian AnanthBelum ada peringkat

- Workplace Vocabulary for Esl Students: With Exercises and TestsDari EverandWorkplace Vocabulary for Esl Students: With Exercises and TestsBelum ada peringkat

- Inside the Pill Bottle: A Comprehensive Guide to the Pharmaceutical IndustryDari EverandInside the Pill Bottle: A Comprehensive Guide to the Pharmaceutical IndustryBelum ada peringkat

- 7 SRMDokumen22 halaman7 SRMChristian Oliveira100% (3)

- 4 ToolsDokumen24 halaman4 ToolsChristian OliveiraBelum ada peringkat

- Damage Evaluation and NDT: Linhas Aéreas InteligentesDokumen38 halamanDamage Evaluation and NDT: Linhas Aéreas InteligentesChristian OliveiraBelum ada peringkat

- Repair Basic-2: Linhas Aéreas InteligentesDokumen58 halamanRepair Basic-2: Linhas Aéreas InteligentesChristian OliveiraBelum ada peringkat

- Glossary: Linhas Aéreas InteligentesDokumen9 halamanGlossary: Linhas Aéreas InteligentesChristian OliveiraBelum ada peringkat

- Encyclopedia How Things Are Made Volume FiveDokumen370 halamanEncyclopedia How Things Are Made Volume Fivei_b_2hot4u185Belum ada peringkat

- Co 123Dokumen1 halamanCo 123MIN GUIBelum ada peringkat

- Catalogo de CocinaDokumen44 halamanCatalogo de CocinaPeter RodriguezBelum ada peringkat

- Tony Robbins - 10 Day ChallengeDokumen2 halamanTony Robbins - 10 Day Challengeaberto75100% (5)

- Test Paper: I. Match The Definitions To These School Subjects. (10p)Dokumen2 halamanTest Paper: I. Match The Definitions To These School Subjects. (10p)ddavidBelum ada peringkat

- Learning Activity 3 Evidence: The Story of Bottled Water: Fuente: SENADokumen4 halamanLearning Activity 3 Evidence: The Story of Bottled Water: Fuente: SENANorelis PadillaBelum ada peringkat

- Industrial Visit To Higland Factory Digana 3Dokumen9 halamanIndustrial Visit To Higland Factory Digana 3kolita kamal100% (2)

- 2016-2017 WFISD Elementary MenuDokumen1 halaman2016-2017 WFISD Elementary MenuAnonymous XetrNzBelum ada peringkat

- Ec RedbullDokumen3 halamanEc RedbullZakky Azhari100% (1)

- Mi Rind ADokumen20 halamanMi Rind ARosmin WilsonBelum ada peringkat

- Should and Shouldn'tDokumen1 halamanShould and Shouldn'tJanina DoradoBelum ada peringkat

- Critical and Creative Thinking (CCT) Practice-VI 2020: Unit 1: Pen DriveDokumen18 halamanCritical and Creative Thinking (CCT) Practice-VI 2020: Unit 1: Pen DrivePieus Chandra PalBelum ada peringkat

- 【清真认证2020】MORAs Decree No. 464 - 2020Dokumen60 halaman【清真认证2020】MORAs Decree No. 464 - 2020周永樂Belum ada peringkat

- Parent Handbook 19-20Dokumen26 halamanParent Handbook 19-20api-374785125100% (1)

- Chinese Fried RiceDokumen16 halamanChinese Fried RiceDrew Nicholas SantiagoBelum ada peringkat

- TariffDokumen254 halamanTariffrehmannazirBelum ada peringkat

- Past Simple: Yeny Viviana Ruiz CardonaDokumen16 halamanPast Simple: Yeny Viviana Ruiz CardonaDaNii CarmonaBelum ada peringkat

- High-Density Polyethylene - WikipediaDokumen3 halamanHigh-Density Polyethylene - Wikipediakirthi83Belum ada peringkat

- Dish City S1E2 - Ethiopian CuisineDokumen12 halamanDish City S1E2 - Ethiopian Cuisinewamu885100% (1)

- SWOTDokumen7 halamanSWOTSamson A. OluwoleBelum ada peringkat

- Starbucks Corp in Consumer Foodservice World-1Dokumen69 halamanStarbucks Corp in Consumer Foodservice World-1Angelin Baban0% (1)

- 29 Pounds in 29 Days Report FINALDokumen16 halaman29 Pounds in 29 Days Report FINALMile Strugar100% (1)

- Exercises For Grammar 1 ReviewDokumen3 halamanExercises For Grammar 1 Reviewduy tân nguyễnBelum ada peringkat

- Blue Menu 2023 NEWDokumen14 halamanBlue Menu 2023 NEWDerie GamalsyahBelum ada peringkat

- Case StudyDokumen15 halamanCase StudyGaurav Kumar0% (1)

- 5 Interesting Facts About Businesses Around The WorldDokumen7 halaman5 Interesting Facts About Businesses Around The WorldMuhammad AriffBelum ada peringkat

- At Coffee Shop: Vocabulary Tellin The Time ReadingDokumen1 halamanAt Coffee Shop: Vocabulary Tellin The Time ReadingChristian M Laura100% (1)

- Relative 4Dokumen1 halamanRelative 4mariacarlosmariaBelum ada peringkat

- Magimix4100 ManualDokumen24 halamanMagimix4100 ManualSorin Hodosan100% (1)

- Sound in HumansDokumen121 halamanSound in HumansVasu KodagantiBelum ada peringkat