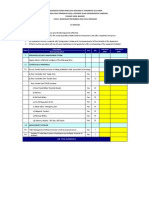

ADM Standard - Specifications (Traffic Control System Section XVII-4)

Diunggah oleh

Jose P. Bambalan Jr.Deskripsi Asli:

Judul Asli

Hak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

ADM Standard - Specifications (Traffic Control System Section XVII-4)

Diunggah oleh

Jose P. Bambalan Jr.Hak Cipta:

Format Tersedia

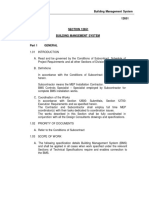

ABU DHABI MUNICIPALITY ROAD SECTION

STANDARD SPECIFICATIONS FOR ROAD AND BRIDGE CONSTRUCTION

DECEMEBER 1997

SECTION XVII-4 TRAFFIC CONTROL SYSTEM

1704.01 General. These Standard Specifications cover descriptions and requirements of the components and materials forming part of the Traffic Control System, all components, items, systems and sub-systems supplied and/or implemented under this Contract shall strictly comply with requirements and specifications stipulated in these documents. The system shall be compatible to the existing system and operate in harmony with the existing system. All non-civil works required under this section shall be executed by an appointed subcontractor (from herein referred to as Subcontractor). The subcontractor shall be a well established traffic control systems supplier and shall have carried out a number of works of similar nature and magnitude as this Contract. The subcontractor shall have previous experience in the hardware, software, principles and operational aspects of 1.5 generation computerized urban traffic control systems, and shall be technically capable of integrating the traffic signal controllers to be installed under this Contract with the existing Siemens Traffic Computer Control System such that full compatibility is ensured. The subcontractor shall have the necessary experience and resources to furnish, install, operate and maintain all components of the Traffic Control System such as signal poles and mast arms, vehicular and pedestrian signals, pedestrian pushbuttons and inductive loop detectors, automatic transfer dual power supply panels, local and master traffic signal controllers, audio and data communications system, cabling and wiring, and all other components as specified in these Particular Specifications. The unit rates entered in the Bill of Quantities must include for all work as specified plus all on costs for the main Contractor's work, attendance, overhead and profit. Any other items necessary for the satisfactory completion of the works but not specifically mentioned in the Contract documents will be considered as subsidiary obligations to this Contract. The main Contractor shall be responsible for the scheduling of the Traffic Signal works so that all works are completed by the Authorized Contract Completion Date. a. Scope of Works. The scope of work for the Traffic Control System Subcontractor shall cover the following works and services: 1. Supply and Installation of signalized intersections, arterial progression and computer control as shown on the relevant drawings and in these Particular Specifications. Maintenance of all installations as specified in these Particular Specifications.

2. b.

General Requirements. It is of great importance that all systems and sub-systems are standard products of the same manufacturer to ensure and guarantee proper interface and smooth operation of the complete system. The Contractor shall submit an undertaking to guarantee the availability of the spare parts for all systems and sub-systems covered by his offer for a period of 10 years from the date of final handingover of the system.

c.

Standards and Codes. The traffic control equipment furnished and installed shall meet the requirements of the internationally known standards and governing codes of the Emirates of Abu Dhabi or equivalent. Specific standards and codes used as a guide for the design are as follows: AASHTO ASTM BSS CEE IEC IMSA American Association of State Highway and Transportation Officials (USA) American Society for Testing Materials (USA) British Standard Specifications (UK) International Commission on Rules for the Approval of Electrical Equipment International Electrotechnical Commission International Municipal Signal Association

31.12.97/9059T

XVII14

IPCEA ITE NEMA UL d.

Insulated Power Cable Engineers Association (USA) Institute of Transportation Engineers National Electrical Manufacturers Association (USA) Underwriters Laboratories, Inc. (USA)

Definitions and Abbreviations 1. Wherever the words "selected", or "as directed", "as specified", "as required" or words of like effects are used in these Contract Documents, it is to be understood that the selection, direction, specification or requirements of the Engineer is intended. Similarly, the works "approved", "satisfactory", "equal", or words of like import shall mean "approved by", "satisfactory to" or "equal to" as considered by the Engineer. Wherever the words "necessary", "proper" or words of like import are used in the Contract Documents with respect to the extent, conduct or character of work described, it is to be understood that they shall mean that the said work shall be carried out to the extent, conducted in a manner, or to be of such character which is "necessary" or "proper" in the opinion of the Engineer. Words "Plan/Plans" and "Drawing/Drawings" used in these Contract Documents are to be considered synonymous and interchangeable. Wherever reference to specific designations or section numbers of Standards and Codes are made, this means that any latest revision of the specified standards and codes is implied and understood. Definition of terms used herein for the Traffic Control System: Actuation - shall mean the operation of a detector for placing a call or operation of an electrical circuit for transferring the right-of-way from one phase to another. Cabinet - an outdoor enclosure for housing the controller and its associated equipment. Coordinating Unit - a device used to relate the timing of one controller unit to another. Detectors - are electrical devices used for indicating the approach of traffic to an intersection. Types of detectors are loop detectors. Flasher Unit - a complete electrical mechanism for flashing traffic signals. Interval - the part of signal cycle during which signal indications do not change. Phase - the right-of-way and clearance interval in a cycle assigned to a movement or any combination of movements. Signal Face - a combination of signal sections each capable of displaying its indication in any one direction. Signal Head - an assembly containing one or more signal faces. Traffic Actuated Controller - a timing device used for the control of traffic signal lights in which the intervals or phases are varied in accordance with demands of traffic as registered by the vehicle actuation of detector. Master Controller - a coordinating unit or units that governs two (2) to ten (10) individual intersection controllers.

2.

3.

4.

5.

31.12.97/9059T

XVII15

Part A - General

1704.02 System Overview. The Traffic Control System provides effective and progressive traffic flow conditions in Abu Dhabi by utilizing the latest hardware and software, and up-to-date traffic engineering principles and procedures. The Traffic System Components provided under this sub-contract should complement the existing Traffic Control System in providing safe, effective and progressive traffic flow conditions in Abu Dhabi. The hardware and software to be used in this sub-contract should be operationally compatible with the existing Traffic Control System. The system to be provided under this sub-contract shall consist of the following features: a. Detection Equipment shall be provided including vehicle actuation detectors, pedestrian actuation detectors and vehicle system detectors. Actuation detectors shall be used to identify demands, to assign phases and to provide information to control timing interval lengths. System detectors shall provide vehicle volume and occupancy information to the artery Master Controllers and to the existing Central Computer in a format operationally recognizable by the existing hardware and software of the Central Computer. Poles, mastarms, vehicular and pedestrian signals shall be provided to give specific and clear indications to motorists and pedestrians of their rights-of-way. Local intersection microprocessor controllers with planning, timing, interconnection, coordination and emergency preemption equipment shall be provided to direct traffic flow at intersections. Each intersection shall be capable of stand-alone operation, subsystem interconnection and Computer Controlled Coordination from the existing Central Computer. Each controller shall be capable of pretimed, semi-actuated and fully actuated operation. The mode of operation shall be manually and remotely selectable at the controller without the use of special tools or equipment. Automatic Transfer Dual Power Supply Panels shall be provided to supply power for the traffic signalling related equipment at an intersection. Artery Master microprocessor controller shall be provided to supervise and maintain interconnection and progressive traffic flow among the designated intersections. The artery master controller shall accept information from system detectors and shall utilize such information to vary cycle lengths and offsets. The Artery Master microprocessor controller shall be interconnected to the local intersection traffic signal controllers by means of communication cables routed through concrete encased PVC conduits. Audio transmission equipment which will provide voice communications between the Central Computer Control Centre and the designated local intersection controller cabinets shall be provided. The format and protocol of this audio communication system should be fully compatible with the existing audio communication system. A data transmission system (communications system) shall be provided which shall carry commands from the Central Traffic Control Computer to the Arterial Master Controllers and the local intersection traffic signal controller. This system shall carry controller status and traffic surveillance data from the local intersection traffic signal controllers to Central Traffic Control Computer. The data transmission system shall be fully compatible with the existing Central Computer System and shall be connected to the Central Computer with cables. The cable shall be supplied and installed by the Contractor in concrete encased PVC conduits. The data transmission system shall also be designed such that no more than four, ten centimeter diameter ducts shall be used by the cable on any given cable run. Local intersection traffic signal controllers shall be placed under the Central Computer Control. All necessary software programming and additional hardware installation to the Central Computer Control System shall be done such that full compatibility and integration with the existing control programs of the Central Computer Control System is ensured.

b.

c.

d.

e.

f.

g.

31.12.97/9059T

XVII16

Part B - Materials, General

1704.03 General Description. The materials of all parts used in the Traffic Control System shall be new and the best of their respective kind and the most suitable for working under the weather and site conditions set out in these specifications, thus withstanding the variations of temperatures and other prevailing conditions without distortion or deterioration of any part of the Traffic Control System. The equipment included in these specifications shall be so manufactured as to facilitate easy and proper erection and maintenance. The design of all equipment shall ensure satisfactory operation under the weather and site conditions mentioned. In general, dissimilar metals in contact shall be avoided. When, however, they have to be used, the contact points of dissimilar metals shall be adequately protected against galvanic corrosion. It is the intent of these specifications that the Subcontractor shall be the manufacturer of the main items of the Traffic Control System meeting the requirements of the specifications and drawings. The Subcontractor shall submit for review and approval a complete list of equipment and materials that is proposed for use. The list shall include descriptive literature, technical details and drawings sufficient to fully describe and explain the specified components of the traffic control system and its integration with the existing traffic system. Where specified herein or when directed by the Engineer, samples of any of the materials and equipment proposed for use shall be submitted for review and approval. It shall be the responsibility of the Contractor to ensure that all items supplied for use in this project comply with the specifications and approval of the Engineer. 1704.04 Materials for Traffic Control System. This specification governs the procedures for documentation and approval of all materials and equipment proposed for use in this Contract. The Subcontractor shall be responsible for the availability of the signal equipment and to ensure that all equipment shall be in strict adherence to the specification, drawings and approved shop drawings. All costs of work and materials required for satisfying these specifications shall be included in the Bill of Quantities under which the subject intersection or interchange type or material equipment shall be paid and no additional compensation will be allowed the Subcontractor for any incidental costs that may occur in fulfilling the requirements of the Contract Documents. The Subcontractor shall comply with the following requirements for the control of traffic signal materials. a. Within 30 days after the award of Contract and before work is performed, the Subcontractor shall submit the following for approval by the Engineer: 1. Complete descriptive literatures, wiring diagrams and instruction drawings and specifications of the traffic signal equipment that will be installed in accordance with the Contract. Complete shop drawings of the mast arm assemblies and poles, showing in detail the fabrication thereof and the description of any materials used in the fabrication, anchor bolts and reinforcing materials. Samples of all conduit and cable and sample of each type of cable splices that will be used in the work. All the above items shall be gathered by the Contractor and submitted to the Engineer at the same time.

2.

3.

4.

31.12.97/9059T

XVII17

b.

The Subcontractor shall provide samples and/or prototypes of all equipment, and components and parts thereof to the Engineer for his review and approval. The Subcontractor shall not start the procurement, manufacturing and/or assembly of any equipment, components and/or parts, until after the Engineer's approval of the samples and/or prototypes. The Engineer's approval of such samples and/or prototypes shall not relieve the Subcontractor from his responsibilities of equipment performance under this Contract. The Employer shall have the right to inspect by his representatives any or all equipment, components and/or parts of the Traffic Control System during its manufacture, preparation and/or assembly at the Subcontractor's home plant and/or at his Abu Dhabi facilities. For this purpose the Subcontractor shall notify the Employer in writing at least two weeks in advance of the commencement of such manufacture, preparation and/or assembly. If the Employer uses his right of inspection, no manufactured, prepared and/or assembled equipment, component, and/or part shall be shipped to the job site without bearing the inspection approval tag of the Employer's representative. Materials and signal equipment not complying with the above requirements that have been installed on the job will be done at the Subcontractor's own risk and may be subject to removal and disposal at the Subcontractor's expense. The Subcontractor shall be responsible for all commitments for the supply of materials and signal equipment so that he can complete the job within the specified time of the Contract. Delays in receipt of materials and signal equipment will not be considered as a valid reason for extension of time. The Subcontractor shall be responsible for the assembly and testing of the Traffic Controller System to make the system operational to the Satisfaction of the Engineer. All equipment, components and parts of the Traffic Control System shall continuously operate in satisfactory condition for one month on the job site before they will be conditionally accepted by the Engineer. The Engineer shall be the sole judge as to whether the equipment has operated in satisfactory condition. The Subcontractor shall be responsible for the maintenance and repair work on the signal controller and associated equipment until final handover.

c.

d.

e.

f.

g.

h.

1704.05 Conduit. All necessary conduits and pull boxes for the traffic system already exist or will be constructed by the prime contractor under this project. 1704.06 Electric, Communications and Audio Transmission (Telephone) Cable. The electric cable shall be rated 600 volts minimum and comply with the following requirements: a. Conductors. The conductors shall be of soft copper, solid or stranded. Solid conductors shall meet the requirements of ASTM Designation B-3 or B-189. Stranded conductors shall meet the requirements of ASTM Designation B-8 or B-33. Insulation and jacket. The electric cable shall be protected with either one of the following combinations of insulation and jacket. The average thickness of the jacket shall be as shown in Table 1704.06a, and the average thickness of the insulation shall be as shown in Table 1704.06b, with a minimum thickness 90 percent thereof in each case.

b.

31.12.97/9059T

XVII18

Table 1704.06a Jacket Thickness Multiple Conductor Cable Calculated Diameter of Cable Under Jacker (Inch) .425 or less .426 - .700 .427 - 1.050 Flat Twin Cable Conductor Size AWG 14 - 12 10 - 6 Jacket (Inch) .045 .060 Jacket (Inch) .045 .060 .080

Table 1704.06b Insulated Thickness Conductor Size, AWG Polyethylene Polyethylene Plus Nylon (Inch) Polyethylene Nylon (Inch) (Inch) .025 .025 .030 .030 .030 0.16 0.16 0.16 0.16 0.16 .004 .004 .004 .004 .004

19 14 12 10 8

1.

Polyethylene Insulation with Polyethylene or Polyvinylchloride Jacket. The polyethylene insulation compound shall conform to ASTM Designation D-1248, Type 1, Class B, Grade 4. The polyethylene jacket compound shall conform to ASTM Designation D-1248, Type 1, Class C, Grade 5. The polyvinylchloride jacket compound shall meet the following requirements when tested in accordance with ASTM Designation D-1047. i. Initial Properties: Tensile Strength - 1,500 P.S.I., minimum. Elongation at Rupture - 100 percent, minimum.

ii. After 5 days in air oven at 100 degree C: Tensile strength - 85 percent of original, minimum. Elongation at Rupture - 60 percent of original, minimum. 2. Polyethylene Insulation, extruded Nylon Covered with Neoprene Jacket. The polyethylene insulation compound shall conform to ASTM Designation D-1248, Type 1, Grade 4, Class A or B. A covering of clean nylon shall be extruded directly over the polyethylene insulation. The nylon shall meet the requirements of ASTM Designation D-372, Type I. The neoprene jacket compound shall conform to the requirements of Insulated Power Cables Engineer's Association (IPCEA) Specifications "Neoprene Heavy Duty Black", and, in addition, shall have a tear strength of 30 pounds per inch minimum.

31.12.97/9059T

XVII19

3.

Shielding. If shielded electric cable is specified, the conductors shall be stranded tinned-copper twisted approximately 15 turns per foot. The insulation shall be of the polyethylene, 0.037 inch nominal thickness for AWG No. 12 cable and 0.032 inch nominal thickness for AWG No. 14 cable. The shielding shall be of aluminized mylar or polyester. One AWG No. 16 stranded tinned-copper drain wire shall be provided. The shielding shall be 100 percent effective by providing a metal to metal contact between adjacent wraps. The jacket shall be of chrome vinyl, 0.037 inch nominal thickness for AWG No. 12 cable and 0.032 inch nominal thickness for AWG No. 14 cable. Another nylon sheath of 0.003 inch nominal thickness shall be applied over the vinyl jacket. The capacitance measured between conductors shall be 25 micro-microfarads or less per foot. The capacitance measured between the conductors with one conductor connected to the shield shall be 50 micro-microfarads or less per foot.

4.

Colour Coding. Each insulated conductor shall be colour coded in accordance with the following colour code, or as directed by the Engineer: Conductor Number 1 2 3 4 5 6 7 8 9 10 11 12 Base Colour Black White Red Green Orange Blue White Red Green Orange Blue Black Tracer Black Black Black Black Black White

All electrical cable colour code shall be consistent throughout the system. 5. 6. Fillers. Fillers, when used, shall be of a non-metallic moisture-resistant material. Tape. The conductor assembly shall be covered with a spiral wrapping of a moisture-resistant tape applied so as to lap at least 12-1/2 percent of its width. Construction. Cables shall be of the twisted type of construction, except that 2-conductor cable may have the conductors laid parallel to one another. The conductors shall be individually insulated. The twisted conductors shall be laid up concentrically, and fillers shall be used, where necessary, to form a firm and uniformly rounded core. Each layer shall have a spiral lay in the direction opposite to that of adjacent layers. The cross section of the cable shall have all layers of conductors in concentric circles. Each conductor in each layer shall maintain its position relative to every other conductor in the layer throughout the entire length of cable. The formed cable shall be firmly bound together by a helically applied layer of tape, except when rubber compound is used for filling the interstices, the tape over the core may be omitted. Electrical cables connecting the controller to each signal lamp shall have spare capacity of at least two conductors. Identification. Each shipping length of cable shall have a tape showing the name of the manufacturer and the year in which the cable is manufactured, placed over or under the tape covering the conductor assembly before application of outer coverings. As an alternate method of identification, the above information may be applied to the outer surface of the sheath. The sheath shall be marked at 10 meter increments in ascending numerical order for measurement and payment purposes. The electric cables furnished shall not be dated more than 5 years prior to the time of installation.

7.

8.

31.12.97/9059T

XVII20

The communications cable for interconnection, computer control, and audio transmission (telephone) shall be multipairs cable(s) with colour-coded twisted pairs and No. 19 AWG solid copper conductors. All colour coding for communications cable shall be consistent throughout the system. The communications cable used in this Contract shall be similar to the cable used in the existing system, i.e., conventional-type electric cable described above. 9. Installation. Cables shall be installed in number and sequence as approved by the Engineer.

31.12.97/9059T

XVII21

Part C - Poles and Mast Arms

1704.07 General Description. The vehicular signal poles and mast arms shall be designed to support the traffic signal loading as required by the Engineer, specified herein or shown on the Drawings. The design and fabrication shall conform to the requirements of the Standard Specifications for the Structural Supports for Highway Signs, Luminaires, and Traffic Signals, as published by the American Association of State Highway and Transportation Officials. The components of traffic signal poles and mast arms shall meet the requirements specified herein. The vehicular signal poles and mast arms shall be of durable, visually acceptable design and visually compatible with the existing signal poles. The poles shall be installed on concrete foundations all as approved by the Engineer. The poles shall not have "breakaway-on-impact" feature. The clearance between top of pavement and bottom of lowest vehicular signal head mounted on mast arms shall be no less than 6.20 meters taking vertical wind deflection into account. Generally, pedestrian signal heads shall be installed in pylons. However, in certain instances pedestrian signals may be installed on poles as shown on plans or as directed by the Engineer. In such instances the pedestrian signal poles used shall be of same material, construction and quality as the vehicular signal poles. 1704.08 Materials. The poles and mast arms shall be made of galvanized steel and as approved by the Engineer with a minimum outside diameter of 11.4 cm. The poles shall be welded to the baseplate as shown on Drawings. The baseplate of traffic signal poles shall be ASTM A36 structural steel. The shape and dimensions of the baseplate shall be as shown on the Drawings. Ground rods, if not supplied by others with the pole foundations, shall be 3/4 inch in nominal diameter and 8 feet long. A ground clamp capable of accommodating a No. 6 bare copper wire shall be furnished with the rod. All vehicular signal poles shall be equipped with a fuse of adequate capacity at the base. 1704.09 Pole and Mast Arm Assembly. The components of a mast arm assembly and pole shall conform to the requirements specified herein. Steel mast arm assembly and pole: a. The steel mast arm assembly and pole shall consist of a mast arm assembly, a pole and a base, and other appurtenances. The configuration of the mast arm assembly, pole and base shall be in accordance with the details shown on the plans. The steel mast arm assembly and pole shall be designed to support one 36.29-kilogram signal with a projected area of 1.366 square meters at the free end of the mast arm, one 22.68-kilogram signal with a projected area of 0.81 square meter mounted 3.66 meters inward on the mast arm, and one 56.7 kilogram signal with a projected area of 0.70 square meter mounted on the mast arm near the shaft, or the signal loading shown on the plans, whichever is greater, based on a 160 kilometer per hour wind velocity plus 30 percent gust factor. The design and fabrication of the mast arm assembly, pole, and base shall conform to the requirements of the Standard Specifications for Structural Supports for Highway Signs, Luminaires, and Traffic Signals, as published by the American Association of State Highway and Transportation Officials. No other design criteria are acceptable. The mast arm and pole shall be fabricated from steel of structural quality with specific ASTM designations, having minimum yield strength of 48,000 p.s.i., either of steel tubing or from welded sheets and plates. The base and flange plates, shall be of structural steel conforming to AASHTO M 183 or better or of cast steel conforming to ASTM A 27, Grade 70-36 or better.

b.

c.

31.12.97/9059T

XVII22

d.

The mast arm and pole must be of single length design i.e. not of sectional design. A handhole with reinforced frame shall be provided on each pole near the base. The handhole cover shall be fastened with stainless steel screws. All mast arm assemblies, poles, and bases, except those fabricated from material conforming to ASTM A 606, Type 4, shall be galvanized in accordance with AASHTO M 111. The mast arm assembly shall be attached to the pole in an angle from the horizontal of 5 degrees unless otherwise directed by the Engineer and shall provide the minimum clearances specified herein. The mast arm connection to the pole shall be as shown on the drawings and shall be designed to fail in rotation upon impact while being able to withstand the specified loadings. When fully loaded with signal heads as specified herein or as directed by the Engineer, maximum deflection at the free end of the mast arm shall not be more than 5 centimeters.

31.12.97/9059T

XVII23

Part D - Vehicular Signal Heads

1704.10 General Description. Vehicular signal heads shall be mounted on mast arms to increase visibility. Pedestal or span wire mounting shall not be used. Vehicular signal heads shall be comprised of up to four signal faces together with necessary mounting devices capable of holding signal heads rigidly in place against wind and other external effects. Vehicular signal faces shall be comprised of three sections as shown on the plans, specified herein or as directed by the Engineer. Vehicular signal sections shall be placed vertically one on top of the other with Green indication at the bottom, Amber indication at the middle, and Red indication at the top. Arrow indications, if any, shall be placed immediately below the signal indication of the same colour. All elements of the vehicular signal heads shall be properly grounded as specified herein and as directed by the Engineer. 1704.11 Materials. The signal faces shall be modular and comprised of individual signal sections. The components of each signal section shall comply with the following requirements. a. Housing and door shall be one of the following: 1. The cast aluminum housing and door shall meet the alloy and tensile requirements conforming to ASTM Designation B-85 or B-108. The door shall be attached to the housing with two stainless steel hinge pins, and shall be held closed with a stainless steel latching device. All access openings shall be provided with neoprene or rubber gaskets to make the housings waterproof and dustproof. The polycarbonate housing shall be molded in one piece and shall be capable of withstanding 31.75 kilograms of impact without fracture or permanent deformation. The polycarbonate resin shall be minimum 2.28 mm thick. The door shall be attached to the housing with two stainless steel hinge pins, and shall be held closed with a stainless steel latching device. All access openings shall be provided with neoprene or rubber gaskets to make the housing waterproof and dustproof. The ends of each signal face adjacent to the mounting hardware shall be reinforced with metal plates of adequate thickness to keep the signal face from vibrating in the wind. b. Optical Unit. The conventional signal section shall have an optical unit conforming to the following requirements: 1. Signal Lamp. The signal lamp shall be a nominal 100 watts luminaire suitable for use in traffic signal heads, capable of operating at 240 volts, and shall have an average rated life of not less than 6,000 hours. The lamp socket shall be heat-resistant, rotatable and have a lamp grip to prevent the lamp from working loose by vibration. Reflector. The reflector shall be of parabolic silvered glass, metalized plastic or Alzak aluminum and shall conform to the Institute of Transportation Engineers Standards (ITE Publication No. ST017). Signal Lens. All vehicular signal lenses shall be antiphantom and 30 cm (12 inch) in diameter unless otherwise directed by the Engineer and shall conform to the Institute of Transportation Engineers Standards (ITE Publication No. ST-017).

2.

2.

3.

31.12.97/9059T

XVII24

4.

Signal Dimmers. When specified by the Engineer, signal dimmers shall be provided for the amber signal sections. The dimmer shall allow the signal lamp to operate at full intensity under daylight conditions and to reduce proportionally to 25 5 percent to full intensity at night. A dimmer shall not control more than one amber section for each direction.

c. d.

Terminal Block. Each signal face shall contain a terminal block with at least 12 terminals. Visor. The conventional signal section shall be furnished with a cut-away type visor over each aspect. The visor shall not be less than 1.27 mm in thickness. The visor for a 30.48 cm signal section shall be a minimum of 22.86 cm in length. Mounting Bracket. The mounting bracket shall be made of aluminum. Signal heads with more than one signal face shall be furnished with terminal compartments. Each terminal compartment shall contain a terminal block with at least 16 terminals. Colour. The aluminum housing and bracket shall be painted with one coat of primer and finished with two coats of Federal Yellow (as specified by U.S. Federal Highway Administration) enamel, dark olive green enamel or as specified by the Engineer in consultation with the Employer. The aluminum signal door and visor shall be shop painted with one coat of primer and finished with two coats of dull black paint. For polycarbonate signal heads, the above specified colours shall be an integral part of the material composition.

e.

f.

1704.12 Traffic Signal Backplate. The traffic signal backplate, if and when specified, shall be made of sheet aluminum or sheet ABS plastic. The sheet aluminum shall have a nominal thickness of 1.587 mm and shall conform to ASTM B 209 Alloy 3003 H 14 or better. The sheet ABS plastic shall have a nominal thickness of 3.968 mm and shall have a minimum tensile strength of 4,300 p.s.i. The backplate shall be designed to be attached to a signal face without interfering with the opening and closing of the traffic signal door. It shall be rectangular in shape with ground corners and shall be of such dimensions as to give an exposed margin of 12.7 cm on each side. The backplate shall not be composed of more than four pieces, and a minimum of three evenly spaced stainless steel bolts meeting the applicable requirements of ASTM A 193, Class 1, Grade 8, shall be used to connect any two pieces. 1704.13 Traffic Signal Backplate Finishing. The aluminum backplates shall be painted with one coat of primer and finished with one coat of dull black paint. For plastic backplates, the black colour shall be an integral part of the material composition.

31.12.97/9059T

XVII25

Part E - Pedestrian Signal Heads

1704.14 General Description. Pedestrian signal head and faces shall be mounted as specified herein. Pedestrian signal heads shall have no more than two faces and shall be mounted in a vertical position. The use of span wire mounting will not be permitted. Pedestrian signal heads and faces shall be mounted in one of the following ways as shown on plans and as directed by the Engineer: a. b. c. On the vertical portion of the traffic signal poles. On the top of poles as specified. Installed within the sidewalk pylons to be furnished and installed separately under this Contract.

Pedestrian signals shall allow pedestrians to cross the roadway within the pedestrian crosswalks during the same phases with through and right turning vehicles in the same direction, as shown on the Drawings. The pedestrian signals shall disallow pedestrian movements during the left turn phase unless otherwise shown on the Drawings or directed by the Engineer. Pedestrian signals shall be mounted on the signal poles and top of post in an approved manner and so that the bottom of the signal head is no less than 2.40 meters and no more than 3.00 meters above the top of the curb. The pedestrian signals shall not be mounted out over the traffic lanes. In general, the pedestrian signals shall be no closer than 1 meter from the edge of pavement unless otherwise shown on the Drawings or approved by the Engineer. 1704.15 Materials. The pedestrian signal faces shall be of a sectional design, completely compatible with signal head hardware and when mounted in any standard arrangement (i.e. other than with pylon) the appearance of the pedestrian signal head will be compatible with the balance of the traffic signals. All pedestrian signal poles shall be equipped with a fuse of adequate capacity at the base. a. The poles for the top-mounted pedestrian signal heads shall conform to the following: 1. The pedestrian signal pole shall consist of a nominal 10 cm (4") diameter steel pole and a base, together with anchor bolts and other appurtenances. The configuration of the pole and base shall be in accordance with the details shown on the Drawings and shall be subject to approval by the Engineer. Foundations for the poles shall be included and constructed under the respective civil works contract. The steel pole shall be designed to support two pedestrian signal heads and withstand steady wind velocity of 160 km/hr. with a gust factor of 30 percent plus taking into account the requirement imposed by the exposed surface area and total weight of signal heads and brackets. The design and fabrication of the pole and base shall conform to the requirements of the Standard Specifications for Structural Supports for Highway Signs, Luminaires, and Traffic Signals, as published by the American Association of State Highway and Transportation Officials (AASHTO). The pole shall be fabricated from steel of structural quality with specified ASTM designations, having a minimum yield strength of 48,000 p.s.i., either of steel tubing or from welded sheets and plates. The base and flange plates shall be of structural steel conforming to AASHTO M 183 or better or of cast steel conforming to ASTM A 27, Grade 70-36 or better. The pole must be of single length design i.e. not of sectional design. A handhold with reinforced frame shall be provided on each pole near the base. The handhole cover shall be fastened with hexagonal head stainless steel screws. All poles and bases, except those fabricated from material conforming to ASTM A 606, shall be galvanized in accordance with AASHTO M 111.

2.

3.

4.

31.12.97/9059T

XVII26

All pedestrian signal heads shall conform to the requirements for materials as specified under Part D - Vehicular Signal Heads in these Particular Specifications and as follows: Pedestrian signal heads to be mounted on poles shall have one or two signal faces. In the case of two signal faces, they shall be placed either back to back or at an angle, as shown on the Drawings. Pedestrian signal heads to be mounted in pylons shall have one signal face, or two signal faces placed at a right angle or back to back. The pedestrian signal head shall be of sectional design completely compatible with vehicular signal head mounting assemblies and other hardware. When mounted on a pole or on the vertical shaft of a signal pole with mast arm, the appearance of the pedestrian signal head shall be compatible with the balance of the traffic signals furnished as part of the system. b. Signal face and signal section shall conform to the following: 1. Each pedestrian signal face shall have two signal sections each 36 cm x 36 cm in size and square in shape with the two signal sections placed vertically. One section shall have a WALK symbol in the shape of a walking person and the other section shall have a DON'T WALK symbol in the shape of a vertically placed human hand. The symbols shall be at least 23 cms high. The section with the WALK symbol shall be placed at the bottom directly below the DON'T WALK section and shall be illuminated in green. The WALK symbol shall start flashing at the end of the pedestrian green interval. The section with the DON'T WALK symbol shall be placed directly above the WALK section and shall be illuminated in red. The optical unit of the pedestrian signals shall be same as the vehicular signals except the lens which shall be square in shape and a nominal 30 cm (12") in size. All elements of the pedestrian signal heads shall be properly grounded as specified herein, and as directed by the Engineer. 1704.16 Complete Pedestrian Pushbutton. The complete pedestrian pushbutton shall consist of the installation of a pedestrian pushbutton, a sign displaying instructions for usage, an arrow signs pointing to the crosswalk it controls, all necessary cabling and wiring, and the necessary programming of the intersection traffic signal controllers. The pedestrian movements shall be serviced only when called and shall be either a separate phase or concurrent with the respective vehicular phase as directed by the Engineer. The instructions sign shall be in both English and Arabic languages and shall be on 3mm aluminum plate with engineering grade reflective sheeting or similar material as directed by the Engineer. The signs shall be suitably mounted above the pushbutton unit on the pole or pylon using tamper-resistant clamps or industrial adhesive as approved by the Engineer. The housing of the pedestrian pushbutton shall be fabricated out of diecast aluminum or suitable cast metal. The pushbutton unit shall be extremely sturdy, tamper-resistant, and weatherproof. It shall be securely attached to the pole or pylon. The unit shall be completely sealed and all wiring connections shall be from the back of the unit through a compression type cable entry gland. The pushbutton unit shall have an illuminated indicator panel to show the state of operation i.e.- wait/walk of the respective pedestrian signal. The programming of the signal operations to accommodate pedestrian pushbuttons shall not disallow the coordinated operation of the local traffic signal controller, whether it is under arterial progression control or under the central computer control. 1704.17 Installation. Under this Contract the Subcontractor shall furnish and install all pedestrian signal heads, control mechanisms and cables within sidewalk pylons as provided and installed under separate contracts for the respective intersection, interchange or roadway construction.

2.

31.12.97/9059T

XVII27

To ensure correct positioning of the equipment installed under this Contract, the Subcontractor shall be responsible for coordination with the work executed under separate contracts in accordance with the requirements of respective Clauses under Conditions of Contract in the Standard Specifications.

31.12.97/9059T

XVII28

Part F - Vehicle Actuation and System Detectors

1704.18 General Description. The Subcontractor shall supply and install vehicle actuation detectors (shown on the Construction Drawings) for intersection controls, and system detectors (not shown on the Construction Drawings) for the Arterial Master Control (Progression) and/or the Central Computer Control Systems. The location of the system detectors shall be determined by the Engineer. Basic hardware for both vehicle actuation detectors and system detectors shall be the same and they shall be interchangeable. The Subcontractor shall install detectors in roadway pavement by neat saw cutting of the pavement. The Subcontractor shall restore the pavement after detector installation to the satisfaction of the Engineer. Curbstones, sidewalks, etc. disturbed for detector installation shall be similarly restored. The Contractor shall submit to the Employer for field test and evaluation 2 detectors of the same type and manufacture to be installed under this Contract. The Contractor shall also submit a certificate verifying that the detectors conform to the requirements defined herein and that these same detectors have been thoroughly field-proven and time-tested as to their reliability and maintenance characteristics. Each detector shall consist of three elements: the detector amplifier unit, the roadway loop and the lead-in to the amplifier unit. All units shall be interchangeable without any wiring or component changes. Field tuning shall not require a meter, circuit changes, substitutions, modifications, or additions to the sensing unit. The unit shall not drift with time or environmental changes after initial tuning. The unit shall be housed in a nonferrous, plug-in case. All component parts shall be readily accessible with the case removed. The detector amplifier unit shall be mounted in the local controller cabinet. 1704.19 Technical Requirements. The detector amplifier unit shall be a complete, functional unit and planned so as to operate on 240-volt, 50-hertz, single-phase alternating current. Variations in voltage of 20 percent or ambient temperature changes between -5C and 90C shall not affect the normal operation of the unit nor shall false calls be issued when input voltage fluctuates between the above limits. The power supply shall be made an integral part of the unit. Incorporated in the design of the unit shall be a fail-safe feature which, in the absence of power, places a continuous call on the sensing circuit. Following power failure the unit shall restore to operation within one second. A manual switch shall be provided on the front of the unit for the selection of either motion or presence sensing. In the "presence" position, the unit shall sense the presence of a vehicle within the loop up to a minimum of 15 minutes after which it cancels the call. A minimum of three operating frequencies shall be provided to avoid crosstalk between adjacent detectors, and a minimum of three sensitivity ranges shall be provided. Each detector loop shall be comprised of at least three turns of loop wire. The sensor circuits shall be of the microprocessor based type. The unit shall operate when connected to an inductance of 50 - 1000 micro-henries and shall render reliable detection when a conductive mass effects a 0.02 percent change in inductance and shall be neither position nor attitude sensitive. The unit shall be capable of operating properly when connected to field loop feeder length up to 152.4 meters and total loop area up to 37.16 square meters. An indicator lamp shall be permanently mounted to the front of the unit and shall indicate each actuation. Necessary connectors shall be supplied with each unit for connection to the external circuitry. The manufacturer shall furnish certification that the detector conforms to the requirements of these specifications. 1704.20 Surge Protection. All loop detector connections to the detector terminal shall be protected from lightning by using 20-volt Zener diodes back-to-back across the loop leads or by a device that has been field proven and approved by the Engineer. 1704.21 Roadway Loop Wire. The loop wire shall be 600-volt single conductor and shall conform to the requirements of specifications 51-3, 1984 of the Specifications for Signal Cable of the IMSA (International Municipal Signal Association, U.S.A.) and to the requirements of IPCEA. The manufacturer's name and the identification of the type of wire shall be plainly marked on the outside jacket and certification shall be furnished that the wire conforms to the requirements of the designated specifications.

31.12.97/9059T

XVII29

The conductor shall be insulated, uncoated copper, stranded wire and shall retain its critical properties with no adverse effects to its functional capabilities while conforming to the following requirements: Maximum Diameter (AWG Number) Maximum Diameter (AWG Number) Maximum Resistance at 20C (ohms/304.8 meters) Maximum Breaking Strength (kilograms) Minimum Tensile Strength (kgs/sq. cm) 12 14 2.650

56.25

2706.55

The loop wire shall be insulated with a chemically cross-lined polyethylene insulation conforming to the following requirements: Maximum Thickness (mm) Maximum Operating Temperature (degrees C) Minimum Emergency Overload Temperature (degrees C) Minimum Installation Temperature (degrees C) Minimum Elongation (megohms/ 304.8 meters) Minimum Insulation Resistance (megohm/304.8 meters) Maximum Dielectric Constant Minimum Tensile Strength (percent of original) Minimum elongation (percent of original) after 7 days in an air oven at 120 degrees C. Maximum Mechanical Moisture Absorption (mg/sq.cm) Change in Specific Inductive Capacity (percent of maximum) after 1 to 14 days in water at 74 degrees C. Retention of Critical Properties (percentage of minimum) after 80 days at 120 degrees C. Minimum Breakdown Voltage 0.76 88

127

-23

350

5,000

3 75

75

80

15,000

31.12.97/9059T

XVII30

1704.22 Lead-In-Cable and Sealer. The lead-in-cable shall consist of a twisted pair of Number 12 or 14 AWG stranded conductors, insulated for 600 volts and shielded in conformance with the requirements of IMSA Specification 50-2, 1984. The insulated conductors making up the cable shall be colour-coded. The manufacturer's name and the identification of the type of cable shall be plainly marked on the outside jacket and the manufacturer shall furnish a certification that the cable conforms to the requirements of these specifications. The sealer shall be a suitable epoxy and capable of curing in a maximum time of 4 hours at 10C. Curing is defined as capability of withstanding normal traffic loads without degradation. 1704.23 Field Tests. Prior to applying the loop sealant, the Contractor shall perform the following tests. Tests shall be recorded for each of the detectors. a. b. c. d. Megger Test - Resistance to ground not less than 1 megohm. Inductance Test - Inductance between 50 - 1000 micro-henries at 50 KHz. Continuity Test - Closed electrical loop. Circuit Resistance - Resistance shall not exceed 2 ohms.

Each test shall be repeated at the local controller cabinet to include the loop lead-in. No test shall be considered acceptable unless performed in the presence of and to the satisfaction of the Engineer. 1704.24 Additional Loops for Traffic Violation Recording Equipment. At certain locations it is desired that provision be made for installing Traffic Violation Recording Equipment in the future. At such locations, it is necessary to install the detection equipment in the form of inductive loop detectors embedded in the pavement, and with the lead-in cable installed up to the foundation of the Traffic Violation Recording Equipment. The `Additional loops for Traffic Violation Recording Equipment' item covers the supply and installation of the detection equipment as described above for one approach covering two lanes of traffic. The loop wire and lead-in cable shall fully comply with the specifications in Clauses 1704.21 through 1704.23 described above.

31.12.97/9059T

XVII31

Part G - Local Controllers and Associated Equipment

1704.25 General Description. The local intersection control equipment shall perform all functions necessary for the control of traffic signals such as to safely assign rights-of-way to vehicular and pedestrian traffic. Intersection control equipment shall be uniform throughout the Contract unless otherwise approved by the Engineer. The local control equipment shall include but not by way of limitation the following major components: a. b. c. d. e. f. Local Intersection Controller Local Intersection Controller Cabinet Solid State Load Switches Security Unit (Conflict Monitor) External Flash Device Communications Interface Unit as required to interface with the Artery Master Controller and the Central Computer Control. Detector Amplifier Units

g.

Descriptions for each of the major components above are provided herein except for detector amplifiers which are described earlier in Part F. The Subcontractor shall provide any additional equipment necessary to make the system perform in accordance with the Object of the Contract, in full compatibility with the existing system, with good traffic engineering practices, and to the satisfaction of the Engineer. 1704.26 Local Controllers. All local controllers shall be microprocessor based devices and shall be the complete equivalent of Siemens MP(16) Traffic Signal Controller. The Subcontractor shall supply all devices necessary to fully program the microprocessors for the traffic control programs. All microprocessor memory shall be non-volatile. The timing shall be digital in nature and based on a 50 hertz supply frequency. All controllers shall be capable of fully traffic actuated operation, semi-actuated operation or pre-timed operation. The mode of operation shall be selectable at the controller without rewiring or without the need for special tools. The number and sequence of phases at each intersection shall be as shown on functional drawings to be supplied by the Engineer, as required by the traffic patterns and traffic volumes, and as directed by the Engineer. Controllers shall include all circuitry necessary to provide the specified phases and phase sequences. The number of phases and phase sequencing shall be selectable at the controller without the need for special tools. Where necessary to insure safe operation of the controller, a hardware watchdog timer shall be provided. In the event the watchdog timer is not reset within a pre-set time period, the controller shall be deactivated and the external flash device shall be activated. It shall be possible to change controller timing parameters manually from the front of the controller cabinet. These changes shall be made either by inputs via the front panel of the controller or through use of a portable readout device. In the event a portable readout device is used it shall be connected to the controller via a plugin on the front panel. In the event the portable readout device is used, a minimum of two shall be provided. All controllers shall provide the following features: a. Signal Indication Sequence. The vehicular signal indication sequence shall be Green-Amber-RedGreen. No Amber indication shall appear between Red and Green indications. Capability shall be included to provide all-red clearance intervals for each phase. The pedestrian signal indication sequence shall be Green-Flashing Green-Red-Green.

31.12.97/9059T

XVII32

b.

Cycle Length. Signals shall have a cycle length range of 45 to 240 seconds, adjustable at 5 second steps. Number of Phases. Capability to accommodate eight separate phases with skip-phase capability shall be provided (see figures on attached two pages).

c.

31.12.97/9059T

XVII33

(this page (Page 34) to be replaced by diagram)

31.12.97/9059T

XVII34

(this page (Page 35) to be replaced by diagram)

31.12.97/9059T

XVII35

d.

Volume - Density Operations. The microprocessor controllers shall provide for Volume-Density Operation. In this mode of operation, the green interval in each phase shall consist of a minimum green and a Vehicle Extension (Passage). The minimum green time shall be guaranteed irrespective of whether vehicle demand exists or not.

e.

Vehicle Extension (Passage). The Vehicle Extension (Passage) shall be reset by vehicle actuations on this phase when the signal is green (after minimum green has expired) and shall commence timing when the actuation is removed. This period shall change by reducing the Allowed Gap between successive vehicle actuations from the Maximum Gap to the Minimum Gap parameters which shall also be capable of being loaded into the controller through the front panel. The Gap Reduction increment and frequency shall be as prescribed by the parameters Reduce Gap By and Reduce Gap Every which shall also be capable of being loaded into the controller through the front panel. The Gap Reduction shall begin with arrival of the first vehicle actuation on an opposing phase after minimum green has expired. Upon expiration of the Allowed Gap (gap timer) the green interval shall be terminated. The Vehicle Extension portion of the green shall also be terminated if the Maximum Extension has been exceeded. The amount of the Maximum Extension shall be capable of being loaded into the controller through the front panel. Pedestrian Intervals and Termination of Green. Pedestrian timing shall be concurrent with the above vehicle intervals. The pedestrian intervals shall consist of a walk indication, a flashing walk indication, and a solid don't walk indication. The vehicle green interval shall normally terminate if the minimum green has expired, the pedestrian cycle has completed, an opposing call is present and one of the following events has occurred: 1. 2. 3. Extension time has expired Gap timer has expired Maximum extension has expired

f.

g.

Clearance Intervals. Following the green interval, there shall be a yellow (amber) change interval which is timed in accordance with the setting for that phase. There shall be provision for an all red interval following the yellow interval. Ranges and Increments. The ranges and increments of the volume-Density timing intervals for each phase shall be as follows: Interval Minimum green Extension (Passage) Maximum Extension Added per actuation Maximum Gap Minimum Gap Reduce Gap Every Reduce Gap By Range 0-199 Sec 0-19.9 Sec 0-199 Sec 0-19.9 Sec 0-19.9 Sec 0-19.9 Sec 0-19.9 Sec 0-19.9 Sec Increment 1 Sec 0.1 Sec 1 Sec 0.1 Sec 0.1 Sec .1 Sec .1 Sec .1 Sec

h.

i.

Signal Indication Ranges and Steps. Signal indications shall have controls for each phase in the following time ranges and steps:

31.12.97/9059T

XVII36

Vehicular Green: Minimum Green: Extension: Maximum:

Range 0-199 Seconds 0-19.9 Seconds 0-199 Seconds

Increment 1 Second 0.1 Second 1 Second 0.1 Second

Vehicular Amber Clearance: 0-19.9 Seconds Vehicular Red Clearance (All Red): Pedestrian Green (Walk): Pedestrian Clearance (Flashing Walk) j.

0-19.9 Seconds 0-199 Seconds

0.1 Second 1 Second

0-199 Seconds

1 Second

Manual Control. Manual controls shall be provided to permit vehicular and pedestrian signals to switch to any related phase, or to display red indication in all directions, or to switch from one time plan to another. Vehicle Actuation. Full vehicle actuation shall be provided as specified herein. However, signals shall also be capable of operating in a semi-actuated mode with a selected phase given priority whereby signals shall rest in that phase until vehicular demand is recorded for another phase. It shall be possible to place any or all phases on recall at the local controller without the use of special tools. Signals shall also be capable of operating in a pre-timed mode with phasing and sequencing shown on the Construction Drawings. Pedestrian Signal Control. Pedestrian signals shall be controlled by the local intersection controllers. Pedestrian signal intervals shall be capable of being timed concurrently with vehicular phases as well as being timed as independent phases. When pedestrian signals are timed concurrently with vehicular phases, the pedestrian green and flashing green shall coincide with the vehicular green indication. The appropriate pedestrian Red Clearance shall coincide with the later part of vehicular Green indication and vehicular Amber indication. Pedestrian actuation of signals will be required. Capability for full pedestrian actuation shall be provided in each controller.

k.

l.

m. Stand-Alone Operation. The stand-alone operation shall consist of two modes as follows: 1. Free Running Mode: In this mode the controller shall not be coordinated and shall operate as a fully-actuated controller. Time-base Coordination Mode. In this mode signals shall operate on a stand-alone basis in accordance with a minimum of seven different timing plans.

2.

Change from one mode to the other and among different timing plans in Mode (b) shall be automatic and pre-programmable on a time-of-day and day-of-week basis. However, capability to switch manually from one mode to the other or from one timing plan to another shall also be provided. n. Coordination Operation. The controller shall be capable of following the commands of the artery master controller and/or the existing central computer control. In this mode, each controller's timing parameters shall be as dictated by the artery master controller or the central computer control. All clearance intervals shall be preset at the local controller. The duration of clearance intervals shall not be overridden by the artery master controller or the central computer control.

31.12.97/9059T

XVII37

o.

Flashing Mode. Signal shall have the capability of operating in a flashing mode whereby vehicular signals controlling the main road shall show flashing yellow and vehicular signals controlling the turning movements and cross roads shall show flashing red indication, and pedestrian signals in all directions shall be turned off. Capability shall be provided for an alternative flash mode whereby vehicular signals controlling the main road shall show no indication, vehicular signals controlling the turning movements and cross roads shall flash showing amber indication, and all pedestrian signals shall be turned off. Voice Communications. Audio communications equipment shall be included in each controller cabinet to provide voice communications between the intersection controller, the artery master controller, and the Computer Control Center. The Subcontractor shall bring electric power to the Automatic Transfer Dual Power Supply Panels and on to the local controllers in accordance with the Water and Electricity Department requirements. A fuse shall be provided to protect the controller circuity against surges in the electric power.

p.

1704.27 Controller Cabinets. All local control equipment at a given intersection shall be mounted in a single waterproof cabinet made of fibre-glass reinforced polyster housing or similar approved materials. All cabinets shall be sized to yield 20 percent unused shelf space when all equipment necessary for proper operation including communication equipment is installed and operating. The cabinet shall provide a door, complete with all hardware, of sufficient size to permit easy access for maintenance of the enclosed equipment. The hardware shall include but not by way of limitation a latch type handle, mortise lock (master-keyed), stainless steel or other durable hinges and appurtenant materials. The inside of the controller door shall be equipped with a built-in documentation pocket to house a complete set of operating and maintenance documents. It shall be possible to operate the controller in a manual mode without opening the large door (e.g., via a "police panel" or a remote panel attached to the cabinet). All equipment necessary to properly mount the cabinets (including mounting poles if required) and to install the local control equipment in the cabinet shall be provided by the Contractor. The lightning arrester (thyrector) shall be installed in each cabinet adjacent to the terminal strip used for grounding. The arrester shall be installed between the live wire and the ground on the supply side of the circuit breaker or fuse. The live wire shall be connected directly to the lightning arrester. The connection between the arrester and the grounding terminal strip shall be made by a Number 8 AWG insulated copper wire and shall be as straight and short as possible. The lightning arrester shall be of the self-restoring type and shall be designed to operate when a potential from the live wire to ground exceeds 300 volts. An electric power outlet shall be provided in each controller cabinet. Adequate screening facilities shall be provided to protect all sensitive devices in the controller, so as to be immune to the electrical noise and spikes generated by the switching operation and/or induced on the power side from any source whatsoever. Each cabinet shall be provided with a fan rated at a minimum of 2.83 cubic meters per minute. The fan or cooling system shall be capable of operating continuously for a minimum of 6000 hours in a 50 degree celsius (C) environment, without the need for after-installation maintenance. Each cabinet shall be provided with a thermostat to control the operation of the fan or cooling system. The thermostat turn-on point shall be manually adjustable from 33C and 45C, with a differential of not more than 6C between automatic turn-on and turn-off. The cabinets shall be factory wired to include all equipment harnesses and terminal facilities for field wiring including computer communication cables, arterial communication cables, audio communication cables, Traffic Violation Recording Equipment Cables, lead-in loop wires from all system and local detectors and signaling cables. All terminals shall be labelled and leads wired to the terminal strips shall be identified with marked aluminum or plastic sleeves. The cabinet shall include a radio interference suppressor which shall meet Underwriters Laboratories Inc. standards. The minimum attenuation shall be 50 decibels over a frequency range of 200 kilohertz to 75 Megahertz when used in connection with normal installations.

31.12.97/9059T

XVII38

The interference suppressor shall be hermetically sealed in a substantial metal case filled with a suitable insulating compound. The terminals shall be nickel-plated with brass studs of sufficient external length to provide for a suitable connection. 1704.28 Solid State Load Switches. Signal light circuits shall be controlled by solid state load switches. Each circuit shall have a minimum rating of 600 watts for tungsten lamp or gas tubing transformer load at 240 volts, AC. Solid state load switches shall be functionally unaffected by transient voltages. Fail-safe operation for all signal lamp circuits shall be provided. The external load switches shall be wired so that all opposing and conflicting traffic movements shall have red indication prior to the display of the green indication on the phase which is to receive the right-of-way. Each load switch shall be mounted in the controller cabinet on a plug-in base by means of a plug-in mounting and shall be designed for continuous duty. The outputs of the load switches shall provide a Red, an Amber, and a Green indication for the vehicle and overlap use; and a WALK and a DON'T WALK for pedestrian use. Flashing Red and flashing Amber indications for vehicles, and flashing WALK indications for pedestrians shall also be provided as specified herein. 1704.29 Security Unit (Conflict Monitor). A security unit (conflict monitor) shall be provided which shall monitor the output of the Green, Amber, Red and Walk load switches. In the event a conflict condition exists, the security unit shall cause the intersection to go to the emergency flash condition by performing the following functions: a. b. Energize the external flash unit. Disconnect or otherwise interrupt any coordination commands, whether they are from an Artery Master or from the central computer. Disconnect the local controller output from the load switches. Hold and display the conflict conditions until reset. The designation of conflicting phases shall be programmable without the use of special tools. The intersection shall also go to the emergency flash condition under any of the following occurrences: 1. 2. 3. Absence of required Red or Amber signal. Absence of security program. Signals "hanging" indefinitely in one state (except the semi-actuation mode when there is no vehicular demand in the cross road). Processor fault condition.

c. d.

4.

1704.30 External Flash Units. Each local controller cabinet shall contain a solid state flasher unit to drive the signal lights during periods of controller maintenance or controller malfunction. When operating, the flasher shall flash the red and amber indications in designated directions at a rate of 60 flashes per minute. The ratio of the illuminated period to the dark period shall be as much as 60-40 but not less than 50-50. It shall be possible to remove control of the signal lights from the local controller and give control of the flasher unit in the following manner: a. b. c. Manually changing position of a single switch. Through automatic programming. Action of a conflict monitor.

31.12.97/9059T

XVII39

d. e.

Action of a watchdog timer, as applicable. By command from the Central Computer.

All switches, solid state components and other ancillary equipment required to provide the operation just described shall be provided and installed by the Subcontractor. 1704.31 Watchdog Timer. A watchdog timer shall be provided and installed, and shall be used with microprocessor based controllers. The purpose of this timer is to prohibit faulty controller operation from causing the signal light indication to "hang" indefinitely in one state (except the semi-actuation mode when there is no vehicular demand in the cross road). When used, the controller shall reset the timer periodically. If allowed to time out, the watchdog timer shall cause the signal lights to be put in the flash mode by performing, or causing to be performed, the following actions. a. b. Energize the external flash unit Disconnect or otherwise interrupt any coordination commands, whether they are from the Artery Master Controller or a Central Computer Control. Disconnect the local controller output from the load switches. Hold and display the conditions until reset.

c. d.

The watchdog timer may be either part of the hardware of the local controller or an external device. All switches, solid state components and other ancillary equipment necessary to provide the operation just described shall be provided and installed by the Subcontractor. 1704.32 Communications Interface. It shall be possible to interface all controllers with an Artery Master Controller and the Central Computer Control System. All equipment necessary to interface a controller with the Artery Mater Controller and the existing Central Computer Control shall be provided and installed as part of this Contract. All local controller interface equipment required for the interface with artery master controllers and the Central Computer Control System shall be mounted in the local controller cabinet.

31.12.97/9059T

XVII40

Part H - Artery Master Controller

1704.33 General Description. The artery master control equipment shall perform all functions necessary to provide interconnection among individual intersections along a designated artery. The artery master control equipment shall include but not by way of limitation the following major components: a. b. c. d. Master Controller Master Controller Cabinet Interconnection (System) Detectors Communications Interface Equipment

Descriptions for each of the above-mentioned components are provided herein. The Contractor shall provide any additional equipment necessary to make the system perform in accordance with the Object of the Contract, with good traffic engineering practices, in full compatibility with the existing traffic control system, and to the satisfaction of the Engineer. 1704.34 Master Controller. The master controller shall be a microprocessor based device. The Master controller shall be capable of coordinating up to ten (10) fully-actuated local intersection controllers. Master controller timing shall be digital in nature and based on a 50 hertz supply frequency. Master controller design shall be fully compatible with the design of local intersection controllers and shall include all necessary features to operate the local intersection controllers in the progressive mode as well as the independent (free) mode. Interconnection of local intersection controllers to a master controller for progressive traffic flow shall not negate the full actuation feature of local intersection controllers. It shall be possible to change master controller timing parameters manually from the front of the master controller cabinet or remotely from the Central Computer. Those changes shall be made either by inputs via the front panel of the master controller or through use of a portable readout device. In the event a portable readout device is used it shall be connected to the master controller via a plug-in on the from panel. In the event the portable readout device is used, a minimum of two shall be provided. The master controller shall provide the following features: a. In the event that more than one model of local intersection controller exists in a designated artery, the master controller shall be capable of coordinating any such combination of local controller models. The master controller shall be capable of providing a minimum of eight pre-programmable coordination time plans to accommodate changing traffic conditions. The master controller shall be capable of coordinating local intersection controllers based upon automatically obtained volume-occupancy data. Below a pre-selected level of volume and occupancy, the master controller shall switch to independent (free) operation mode. The master controller shall be capable of providing a minimum of three background cycle lengths with each cycle length adjustable between 45 to 240 seconds at 5 second steps. The master controller shall be capable of providing a minimum of three offsets per cycle. Each offset shall be adjustable from 0 to 99 percent of cycle length in steps of one second. The master controller shall have a built-in fail-safe system to assure proper functioning of local controllers in cases of interruption in the communication system or any other system failure.

b.

c.

d.

e.

f.

31.12.97/9059T

XVII41

g.

Audio communications equipment shall be included in the master controller cabinet to provide voice communications between the master controller, the computer control center and intersection controllers. The Subcontractor shall, as part of this Contract, bring electric power to the artery master controller in accordance with the Water and Electricity Department requirements. A fuse shall be provided to protect the master controller circuity against surges in the electric power.

1704.35 Master Controller Cabinet. All master controller equipment shall be mounted in a single waterproof climate resistant cabinet made of approved materials. The cabinets shall be sized to yield 20 percent unused shelf space when all equipment necessary for proper operation is installed and operating. Equipment required to interface with the Central Computer Control System shall be considered as necessary for proper operation (i.e., the Central Computer Control interface equipment shall not require any of the 20 percent spare shelf space). An electric power outlet shall be provided in the master controller cabinet. All materials, fixtures and appurtenances of the Master Controller Cabinet shall be similar to that of the local controller cabinets as described in Clause 1704.27 of these specifications. 1704.36 Interconnection (System) Detectors. If the Artery master Control System to be installed under this Contract requires interconnection (system) detectors at locations other than those shown on the Drawings, the Contractor shall provide and install the necessary detector amplifiers, loops, lead-in wires and conduit. Such equipment shall conform to the specifications and requirements set forth in Part F: Vehicle Actuation and System Detectors. Any other ancillary equipment required for the Artery Master Control System to operate according to the object of this specification and to good traffic engineering practices shall be provided and installed by the Contractor. 1704.37 Communications Interface. All equipment necessary to interface a master controller with the Central Computer Control shall be provided and installed as part of this Contract. The interface should be capable of transmitting and receiving all necessary data in a format which is fully compatible with the existing Central Computer Control System. All master controller interface equipment required for the interface with the Central Computer Control System shall be mounted in the master controller cabinet.

31.12.97/9059T

XVII42

Part I - Communications, and Intersections Placed Under Central Computer Control

1704.38 General Description. The Contractor shall provide all necessary communications means and equipment required for the proper and satisfactory operation of the Traffic Control System and its parts and components. The communications equipment and protocol shall be fully compatible with the existing Traffic Control Computer System. The communication system shall connect specified arterial master controllers and specified local intersection traffic signal controllers to the Central Traffic Control Computer. The information carried by the communications system shall consist of commands issued to local controllers by the Central Control Computer. In addition, the communications system shall carry local traffic signal controller status information and traffic flow information from system detectors through each signal controller to the Central Computer. Commands from the Central Computer to each local controller shall accomplish the following functions: a. b. c. d. e. f. g. h. i. j. k. l. Place controller under computer control Release controller from computer control and place controller in free running mode. Release controller from computer control and place controller in Time Based Coordination mode. Release controller from computer control and place controller under arterial master control. Stop and start controller timing. Step controller to next phase. Issue yield command to local controller. Issue force-off phase command to local controller. Alter phase sequence of local controller. Alter timing interval durations. Synchronize controller clock. Respond to request to return controller status and surveillance data.

The data to be carried by the communications system emanating from each local controller shall provide for displaying the following information at the central control room: a. b. Current controller phase Traffic flow surveillance data sensed by the system detectors and consisting of volume, speed, occupancy, stops and delay. Indication that vehicle violation recorder sensed a vehicle crossing the violation detector during the red interval. Any messages regarding malfunctioning of controller.

c.

d.

31.12.97/9059T

XVII43