Kirloskar Brothers Limited, Kirloskarvadi

Diunggah oleh

Nilesh JadhavDeskripsi Asli:

Judul Asli

Hak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

Kirloskar Brothers Limited, Kirloskarvadi

Diunggah oleh

Nilesh JadhavHak Cipta:

Format Tersedia

KIRLOSKAR BROTHERS LIMITED

KIRLOSKARVADI 416 308, DIST. SANGLI (INDIA)

ENVIRONMENTAL APEX MANUAL MANUAL NO. EAM-0101

ENVIRONMENTAL MANAGEMENT SYSTEMS ENVIRONMENTAL APEX MANUAL

ENVIRONMENTAL MANAGEMENT SYSTEMS APEX MANUAL OF

KIRLOSKAR BROTHERS LIMITED, KIRLOSKARVADI

Note: Environmental Management System documentation may cross -refers some of the documents from Quality Management System defined in Quality Assurance Manual of Kirloskarvadi Operations. (Manual No. KOP-0103). Addresses Works: KIRLOSKAR BROTHERS LIMITED, Kirloskarvadi- 416 308, Dist-Sangli. (India) Telephones: (02346) 222301 to 222305, 222361 to 222365 Fax: (02346) 222311 E-mail: kblin@kbl.co.in.

Corporate Office: KIRLOSKAR BROTHERS LIMITED, Registered Office, Udyog Bhavan, Tilak Road, Pune-411 002. (India) Phones: (020) 24440770/ 24444444 Fax: (020) 2444-4198, 2444-0156 E-mail: kblin@kbl.co.in.

Reference: Index (Document Number. EAM-1) ISSUE NO. 2 REVISION NO. 0 DATE: - 15.12.2007 PAGE: 1 OF 1 PREPARED & VERIFIED BY: REVIEWED & APPROVED BY: ( K.D. Gandhi) (R.K.Srivastava)

KIRLOSKAR BROTHERS LIMITED

KIRLOSKARVADI 416 308, DIST. SANGLI (INDIA)

ENVIRONMENTAL APEX MANUAL DOCUMENT NO. EAM-1

ENVIRONMENTAL MANAGEMENT SYSTEMS INDEX Sr Procedure No 1 Revision Record Sheet 2 List of Controlled Copy Users 3 Abbreviations used in EMS 4 General and Scope 5 Environmental Policy 6 Environmental Aspects Review (Aspect-ImpactAnalysis) 7 Legal and Other Requirements 8 Objectives & Targets and Environmental Management Programme(s) 9 Resources, roles, responsibility and authority. 10 Competence, Training and Awareness 11 Communication 12 Documentation of EMS 13 Control of Documents 14 Operational Control 15 Emergency Preparedness and Response 16 Monitoring and Measurement 17 Evaluation of Legal Compliance 18 Non-conformity, Corrective and Preventive Actions 19 Control of Records 20 Internal Audit of EMS 21 Management Review Document Number EAM-2 EAM-3 EAM-4 EAM-410 EAM-420 EAM-431

Number of pages 01 02 02 03 01 08

ISO-14001 Clause 4.4.5 4.4.5 4.4.5 4.1 4.2 4.3.1

EAM-432 EAM-433

04 07

4.3.2 4.3.3

EAM-441 EAM-442 EAM-443 EAM-444 EAM-445 EAM-446 EAM-447 EAM-451 EAM-452 EAM-453 EAM-454 EAM-455 EAM-460

04 03 03 05 08 02 03 02 02 02 01 03 02

4.4.1 4.4.2 4.4.3 4.4.4 4.4.5 4.4.6 4.4.7 4.5.1 4.5.2 4.5.3 4.5.4 4.5.5 4.6

ISSUE NO. 2 REVISION NO. 0 DATE: - 15.12.2007 PAGE: 1 OF 1 PREPARED & VERIFIED BY: REVIEWED & APPROVED BY: ( K.D. Gandhi) (R.K.Srivastava)

KIRLOSKAR BROTHERS LIMITED

KIRLOSKARVADI 416 308, DIST. SANGLI (INDIA)

ENVIRONMENTAL APEX MANUAL DOCUMENT NO. EAM-2 Issue/ Revision Date

ENVIRONMENTAL MANAGEMENT SYSTEMS REVISION RECORD SHEET Sr. No

01

Document

Issue No and/or Rev. No.

Issue No.-0 Rev. No.-0

Nature of change

EAM-0101 EMS Apex Manual EAM-0101 EMS Apex Manual EAM-0101 EMS Apex Manual

02

Issue No.-1 Rev. No.-0

03

Issue No.-2 Rev. No.-0

EMS Apex Manual of KBL-Kirloskarvadi 14.01.2001 issued as per index EAM-1 in line with applicable ISO -14001 -1996 standard requirements. Entire EMS Apex manual is reviewed 15.09.2005 updated to establish, document, implement and maintain EMS as per ISO: 14001 -2004 standard requirements. Entire EMS Apex manual is reviewed 15.12.2007 updated as per current changes in structure and status.

ISSUE NO. 2 REVISION NO. 0 DATE: - 15.12.2007 PAGE: 1 OF 1 PREPARED & VERIFIED BY: REVIEWED & APPROVED BY: ( K.D. Gandhi) (R.K.Srivastava)

KIRLOSKAR BROTHERS LIMITED

KIRLOSKARVADI 416 308, DIST. SANGLI (INDIA)

ENVIRONMENTAL APEX MANUAL DOCUMENT NO. EAM-3

ENVIRONMEN TAL MANAGEMENT SYSTEMS LIST OF CONTROLLED COPY HOLDERS/USERS

1) List of Controlled Copy Holders/Users is as follows: No Controlled Copy User (Designation) Copy Type and Location

01 02 03 04 05 06 07 08 09 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24 25 26 27 28 29 30 31 32 33 34 Directors Management Representative HOD-Quality Systems Department HOD-Manufacturing-IPS HOD-Product Engineering Division HOD-Pump Testing Laboratory HOD-End Suction Pumps Division HOD-Split Case Pumps Division HOD-Multi-stage Pumps Division HOD-Composite Section (IPS). HOD-Quality Control Division HOD-Pattern Shop HOD-Cast Iron Foundry HOD-Non-Ferrous Foundry HOD-Fabrication Department HOD-General Stores (IPS) HOD-Materials/Purchase (IPS) Head-Operations (PEP) HOD-Product Design & Development Dept. and HRE HOD-HRE-Pump Testing Department HOD-Engineered Pumps Division HOD-Quality Assurance Department In charge -NDT (QAD) HOD-Heavy Foundry Division HOD-Steel Foundry Division and Heat Treatment HOD-Special Pumps & Turbine HOD-Composite Section(PEP) HOD-General Stores & Scrap Yard (PEP) HOD-Mate rials/Purchase(PEP) HOD-HRM&C. HOD-HRD (HRMC) HOD-Dispensary (HRMC) Safety Officer (HRMC) HOD-Building Department Soft copy on Intranet on own Laptop/PC Hard Copy (Master Copy) Soft Copy On Intranet Soft copy on Intranet Soft Copy On Intranet Soft Copy On Intranet Soft Copy On Intranet Soft Copy On Intranet Soft Copy On Intranet Soft Copy On Intranet Soft Copy On Intranet Soft Copy On Intranet Soft Copy On Intranet Soft Copy On Intranet Soft Copy On Intranet Soft Copy On Intranet Soft Copy On Intranet Soft Copy On Intranet Soft Copy On Intranet Soft Copy On Intranet Soft Copy On Intranet Soft Copy On Intranet Soft Copy On Intranet Soft Copy On Intranet Soft Copy On Intranet Soft Copy On Intranet Soft Copy On Intranet Soft Copy On Intranet Soft Copy On Intranet Soft Copy On Intranet Soft Copy On Intranet Soft Copy On Intranet Soft Copy On Intranet Soft Copy On Intranet

ISSUE NO. 2 REVISION NO. 0 DATE: - 15.12.2007 PAGE: 1 OF 1 PREPARED & VERIFIED BY: REVIEWED & APPROVED BY: ( K.D. Gandhi) (R.K.Srivastava)

KIRLOSKAR BROTHERS LIMITED

KIRLOSKARVADI 416 308, DIST. SANGLI (INDIA)

ENVIRONMENTAL APEX MANUAL

ENVIRONMENTAL MANAGEMENT SYSTEMS LIST OF CONTROLLED COPY HOLDERS/USERS No

35 36 37 38 39 40 41 42 43 44 45 46 47

DOCUMENT NO. EAM-3

Controlled Copy Holder/User Designation

HOD-Manufacturing Services ( IPS ) HOD-Manufacturing Services (PEP) HOD-Plant Engg. Division ( IPS ) HOD-Manufacturing Engineering Division ( IPS ) HOD-Manufacturing Engineering Division(PEP) HOD-Industrial Engineering Division( IPS ) HOD-Industrial Engineering Division( IPS ) HOD-Accounts, Kirloskarvadi HOD-IC-Kov SBU Head, IPS SBU Head, PEP Principal-Kirloskar High School and Junior College HOD _Secretariat Deptt, CO, Pune

Copy Type and Location

Soft copy On Intranet Soft copy On Intranet Soft Copy On Intranet Soft Copy On Intranet Soft Copy On Intranet Soft Copy On Intranet Soft Copy On Intranet Soft Copy On Intranet Soft Copy On Intranet. Soft copy on Intranet Soft copy on Intranet Hard Copy At High School Soft Copy on intranet

2) Following are the authorities and responsibilities for control of this manual. Authority for reviewing and approving Director. Responsibility for preparing, verifying, Management Representative issuing and maintaining Master Copy Issuing department shall communicate changes/amendments in the manual done on soft copy on intranet to all users so as to take effect of the changes. 3) Controlled copy holder/user is responsible for, 3.1) Referring controlled copies (including available on intranet) for use. 3.2) Informing availability & location of controlled copy of manual (including available on intranet) to persons working in their area and to the person taking charge in case of transfers / Resignation . 3.3) Ensuring understanding and implementation of the procedures laid down in this manual by concerned persons working in their areas. 3.4) Preventing usage of uncontrolled/duplicate copies of documents in this manual in any media (Hard copy or Soft copy).

ISSUE NO. 2 REVISION NO. 0 DATE: - 15.12.2007 PAGE: 2 OF 2 PREPARED & VERIFIED BY: REVIEWED & APPROVED BY: ( K.D. Gandhi) (R.K.Srivastava)

KIRLOSKAR BROTHERS LIMITED

KIRLOSKARVADI 416 308, DIST. SANGLI (INDIA)

ENVIRONMENTAL APEX MANUAL DOCUMENT NO. EAM-4

: : : : : : : : : : : : : : : Associate Vice President Annual Operating Plan Assistant Anti Corrosion Product Division Building Department Chairman and Managing Director Clause Carbon Monoxide Customer Support Cell Composite Section (PEP) Cast Iron Foundry Cubic Cross-Functional Team Document Division Decibel Unit for Sound/Noise Level Sound/Noise level Low/Medium/High Environmental Review -Aspect Impact Analysis Environmental Policy Engineered Pump Division. Effluent Treatment Plant Electronic Media.

ENVIRONMENTAL MANAGEMENT SYSTEMS ABBREVIATIONS USED IN EMS 1) LIST OF ABBREVIATIONS USED FOR EMS: AMR ASP A/C ADM BVQI BOD CAM CG COD CPCB CMP CFN CA CII Dy Dept. DISP EAM EMS EMP ESP EPR EPP FAB FDY FC FAD GST GM GOI GET HO HOD HFE/HF HRD HAZ ISO IPS IPC INC ITI : : : : : : : : : : : : : : : : : Associate Management Representative Aspect Accounts Administration Bureau Veritas Quality International Bio-Chemical Oxygen Demand Corporate Apex Manual (CAM-0101) Capital Goods Chemical Oxygen Demand Central Pollution Control Board Composite Section SBU1 Corporate Function Corrective Action Confederation Of Indian Industry Deputy Department Dispensary AVP AOP Asst ACPD BLD CMD CL CO CSC CME CIF cu CFT DOC DIV dB ER EP EPE/EPD ETP E-Media

dBA/B/C

:

: : : : :

: Environmental Apex Manual of Kirloskar Brothers Limited- Kirloskarvadi : Environmental Management System : Environmental Management Programme : End Suction Pump Division : Environmental Performance : Emergency Preparedness and Response Plan : Fabrication Department : Foundries : Finish Component. : Finance, Accounts & Public Affairs- Kov : General Stores (IPS) : General Manager. : Government of India : Graduate E xecutive Trainees in Staff : Head Office : Head of Departments : Heavy Foundry Division : Human Resource Development-Training : Hazardous : International Organization For Standardization. : Industrial Pumps SBG : Interested Party Concern : Incineration : Industrial Training Institute

FIR FF FTR GSE GL GOM HRE HT/HTE HSD HRM/ HRMC IMTE IED / IEE IMP ICK/IC

: : : : : : : : : :

Fire Fire Fighting Fire Tender-Vehicle General Stores & Scrap Yard (PEP) Group Leader Government of Maharashtra HRC -Pump Testing Department Heat Treatment Department High Speed Diesel Human Resource Management & Communication- Legal, Administration, Safety, Security and Dispensary Inspection Measuring and Test Equipment Industrial Engineering Division (IPS , PEP ) Impact Information Center-Kirloskarvadi

: : : :

ISSUE NO. 2 REVISION NO. 0 DATE: - 15.12.2007 PAGE: 1 OF 2 PREPARED & VERIFIED BY: REVIEWED & APPROVED BY: ( K.D. Gandhi) (R.K.Srivastava)

KIRLOSKAR BROTHERS LIMITED

KIRLOSKARVADI 416 308, DIST. SANGLI (INDIA)

ENVIRONMENTAL APEX MANUAL DOCUMENT NO. EAM-4

: Kirloskarvadi : Quality Assurance Manuals of Kirloskarvadi Operations (KOP-0103) : Liquefied Petroleum Gas

ENVIRONMENTAL MANAGEMENT SYSTEMS ABBREVIATIONS USED IN EMS

KBL KHS LDO LGL MD MFG MS MGR MSD MKTG MRM NFF NGO NOx OCP OP O&G PAT PED PDE PLD / PLE PPD PA QCD/QC QSD ROR : Kirloskar Brothers Limited KOV : Kirloskar High School & Jr. College KOP : Light Diesel Oil : Legal Requirements/Legislations : Managing Director : Manufacturing : Manufacturing Services : : : : : : : : : : Manager Multi- Stage Pumps Division Marketing Management Review Meeting Non-Ferrous Foundry Non-Government Organizations Oxides of Nitrogen Operation Control Procedure Operations Oil and Grease LPG

MoEF : Ministry of Environment and Forests MPCB : Maharashtra Pollution Control Board MED / : Manufacturing Engineering Division ( IPS, MEE PEP ) MATL : Material MR : Management Representative MSDS : Material Safety Data Sheets MAT/MTE : Materials-IPS(Purchase) /Materials-PEP No./ No : Number NC : Non- conformity or Non-Compliance NS : Not Significant O&T : Objectives and Targets O/A,A/O : O rder Acceptance PUR PO PEP PTL PRD CPE Q AE QMS R&D RSPM REV RSO SPCB SOP SPM Sp SPE SFT S, SN, SIG STP/SWTP TUR TSS TM WMC Y RD ZP : Purchase : Purchase Order : Projects and Engineered Pumps SBG : Pump Testing Laboratory : Production Divisions Machine Shop/Assy : Central Planning (PEP) : : : : : : : : : : : : : : : : : : : : Quality Assurance Department Quality Management System Research & Development, Kirloskarvadi.

Respirable Suspended Particulate Matter

: Pattern Shop. : Product Engineering Division. : Product Design & Development Dept. : Plant Engineering Division ( IPS, PEP) : Process Pumps Division : Preventive Action

: Quality Control Division : Quality Systems Department. : Register of Regulations or Legal Register REF : Reference. RSP : Resource Saving Potential SBG/SBU : Strategic Business Unit/Group SCP : Split Casing Pumps Division. Sr : Senior SER : Servicing SFE/ACS : Steel Foundry Division SEB : State Electricity Boards SEC : Security SO2 : Sulphur Dioxide SOx : Oxides of Sulphur TLK : Technical Library, KOV TDS : Total Dissolved Solids TL : Team Leader VP : Vice President WP : Work Permit ZON : Zone

Revision Regional Sales Offices. State Pollution Control Board Standard Operating Procedure Suspended Particulate Matter Spares Special Pumps Division Safety Significant Sewage Treatment Plant Turbine Division Total Suspended Solids Team Member Waste Management and Control Yard Zilah Parishad

ISSUE NO. 2 REVISION NO. 0 DATE: - 15.12.2007 PAGE: 2 OF 2 PREPARED & VERIFIED BY: REVIEWED & APPROVED BY: ( K.D. Gandhi) (R.K.Srivastava)

KIRLOSKAR BROTHERS LIMITED

KIRLOSKARVADI 416 308, DIST. SANGLI (INDIA)

ENVIRONMENTAL APEX MANUAL DOCUMENT NO. EAM-410

ENVIRONMENTAL MANAGEMENT SYSTEMS GENERAL AND SCOPE

GENERAL Kirloskar Brothers Limited (KBL) in real sense is the mother industry of other Kirloskar Group Companies. KBL was started in 1888 and was incorporated in 1920. The new era of industrial revolution was dawning in India, when KBL initiated its activities with the manufacture of Iron Ploughs and Chaff Cutters. KBL soon became the nursery of India's industrialization. The Chaff Cutter and Iron Ploughs made by KBL revolutionized the agricultural methods and implements of those days. KBL foresaw the changing demands of agriculture and shifted its manufacturing focus to providing water for farming. KBL branched into the field of fluid handling and fluid control and soon became a leader in manufacturing of Pumps and Valves for irrigation, water supply and industrial use. Today KBL is a renowned manufacturer of a variety of Pumps & Pumping System, Valves & Turbines. KBL has its manufacturing plants at Kirloskarvadi (Sangli), Shirval and Kondhapuri (Pune) in Maharashtra and at Dewas in Madhya Pradesh. The Corporate Office of KBL is located in Pune with Regional Sales offices in metro cities and most of the state capitals. KBL Pumps and Valves are ren owned in overseas markets for their quality. KBL exports its products to more than 70 countries including developed countries like U.S.A., U.K., Hong Kong and Singapore. Kirloskarvadi, which is spread over the area of about 100 acres, has plant area of 40 acres and colony area of 60 acres. Kirloskarvadi is 40 kms towards north-west of Sangli and 40 kms towards south-east of Karad. Geographically Kirloskarvadi is located at Latitude of 170, 6' North and Longitude of 74 0,26' East. Kirloskarvadi is under Kundal Grampanchayat and surrounded by Ramanandnagar, Savantpur-Vasahat, Palus, Burli and Dudhondi. SCOPE OF EMS Scope of EMS implementation covers scope of supply Design, Development, Manufacture and Supply of Centrifugal Pumps, Pump Sets and Pumping Systems, Valves and Hydel Turbines. Manufacture of Ferrous, Non-ferrous and Alloy Steel Castings. Administration, Housekeeping and Maintenance of Kirloskarvadi Township. All related activities, all products and services that KBL Kirloskarvadi Plant have control and can influence. PURPOSE OF GOING IN FOR INITIATIVE OF EMS IMPLEMENTATION KBL, as a responsible corporate citizen, is committed to protect environment by preventing pollution and conserving natural resources as evidenced by Corporate Environmental Po licy stated by our Chairman and Managing Director and Environmental Policy by Director & Occupier for Kov Plant. KBL, Kirloskarvadi has decided to implement Environmental Management System for realization of this commitment at Kirloskarvadi Plant and Kirloskarvadi Colony. KBL, Kirloskarvadi would also like to meet the environment related expectations of stake holders like Government, Financial Institutions/Banks, Share -holders, Employees, Residents of colony and Surrounding Areas, Customers and Society. Implementation of EMS will reinforce confidence of stake holders in investing their time, money and trust in KBL. ISSUE NO. 2 REVISION NO. 0 DATE: - 15.12.2007 PAGE: 1 OF 3 PREPARED & VERIFIED BY: REVIEWED & APPROVED BY: ( K.D. Gandhi) (R.K.Srivastava)

KIRLOSKAR BROTHERS LIMITED

KIRLOSKARVADI 416 308, DIST. SANGLI (INDIA)

ENVIRONMENTAL APEX MANUAL DOCUMENT NO. EAM-410

ENVIRONMENTAL MANAGEMENT SYSTEMS GENERAL AND SCOPE

CORPORATE ENVIRONMENTAL POLICY Our corporate environmen tal guidelines communicated through policy are as below. CORPORATE ENVIRONMENTAL POLICY We are committed to continually improve our environmental performance by? ? ? ? ? ? ? Striving to go beyond legal compliance wherever applicable. Conserving resources such as energy, metals, minerals, water, wood and conditioned air. Minimising generation and ensuring proper disposal of wastes. Enhancing work environment through better housekeeping practices. Adopting safer work methods. Creating awareness in all employees on environmental issues. Striving to enhance the environmental performance of our products.

This policy shall be communicated to all employees and shall be made available to the public on request. 5th June, 1999 World Environment Day KIRLOSKARVADI PLANT The Kirloskarvadi plant is spread over about 40 acres and is engaged in the manufacture of Centrifugal Pumps, Pumping System & Turbines and Anti Corrosion Coating Materials. The plant also provides services like application of anti corrosion coatings on components of pump & Turbines as per customer's requirements. The facilities at Kirloskarvadi include Research and Development, Design, Pattern Shop, Foundries, Machine Shops, Assembly and Materials & Product Testing Laboratories under one roof. The company has a wide marketing network in India and abroad. The Cast Iron Foundry, Heavy Foundry, Alloy Steel Foundry and Non -Ferrous Foundries are capable of producing various grades of Cast Iron, Carbon Steels, Alloy Steels and wide range of Non-Ferrous Metals. Cast iron castings weighing upto 9 MT and alloy steel castings weighting upto 1.5 MT can be poured in a single piece. The foundry laboratory provides facilities for analysis foundry raw materials, mechanical testing of materials and has a spectrometer for instant chemical analysis of metals. KBL has recently modernized its Cast Iron Foundry to enhance its capacity from 500 tons/month to 1000 tons/month. KBL Research and Development Center has a test bed for pumps with flow measuring capacity of 12,000 Liters per second and power ratings upto 4000 kW. Pump and sump model studies can also be conducted in this facility. There are four more test beds, for testing the pumps of various sizes and types. ISSUE NO. 2 REVISION NO. 0 DATE: - 15.12.2007 PAGE: 2 OF 3 PREPARED & VERIFIED BY: REVIEWED & APPROVED BY: ( K.D. Gandhi) (R.K.Srivastava) Sd/Sanjay C. Kirloskar Chairman and Managing Director

KIRLOSKAR BROTHERS LIMITED

KIRLOSKARVADI 416 308, DIST. SANGLI (INDIA)

ENVIRONMENTAL APEX MANUAL DOCUMENT NO. EAM-410

ENVIRONMENTAL MANAGEMENT SYSTEMS GENERAL AND SCOPE KIRLOSKARVADI COLONY

The Kirloskarvadi Colony has around 250 residential quarters and has all the modern amenities like Schools, Shops, Swimming Tank , Golf Course, Tennis Courts and Dish Antennas for National and International Television Programs. RECOGNITIONS Relentless pursuit of excellence has been a notable feature of KBL's corporate philosophy, Total Quality Management has enabled Kirloskarvadi to achieve customer satisfaction and high growth rate. This has consequently brought us the following recognition's: 1. National Quality Award for 1991 from Institute of Directors, New Delhi, for outstanding achievement in the pursuit of Total Quality. 2. Ravi Kirloskar Quality Award (Second Prize) for 1990-91 among Kirloskar group of companies for Total Quality. 3. MKRC Energy Conservation Award1991, 1993 and 1997 Instituted by the Institute of Indian Foundrymen for being the best energy efficient foundry. 4. Received awards for excellence in exports on All India basis for a record 12 times in a row from Engineering Export Promotion Council-New Delhi-for highest exports of mechanical pumps/pump-sets. 5. Certificate of Recognition as an "Export House" by the "Ministry of Commerce Govt. of India", New Delhi. 6. `H N Thadani Award' Instituted by "Indian Institution of Industrial Engineering, Bombay", for outstanding contribution in the field of Industrial Engineering and Total Quality Management. 7. `Vanashree Puraskar 1991' by the Government of Maharashtra, for afforestation in KBL colony and surrounding areas. 8. Quality Management Systems Certification to ISO-9001 in August 1991. 9. `National Award for R&D efforts in Industry 1992' by Department of Scientific and Industrial Research (DSIR), New Delhi, in the "Capital Goods Development" category for development of CNC Machines. 10. Best Productivity Performance Award for 1993-94 : Given at the hand of President of India. 11. FICCI Award for year 1996-97 for R&D efforts. 12. National Award for Best HRD Practices (1996-97) from ISTD-New Delhi. 13. FICCI Award for year 1998-99 for outstanding achievement in family welfare. 14. National Green Tech Silver Award for Safety in 2003 15. State Level Award for Excellence in ENCON management from MEDA for Year 2004. 16. CII-EXIM BANK Award-2007- SBG-IP received certificate commendation for strong commitment to excel 17. Certificate of merit in the General Category for the National Energy Conservation Award-2007 by Ministry of Power, Govt. of India. ISSUE NO. 2 REVISION NO. 0 DATE: - 15.12.2007 PAGE: 3 OF 3 PREPARED & VERIFIED BY: REVIEWED & APPROVED BY: ( K.D. Gandhi) (R.K.Srivastava)

KIRLOSKAR BROTHERS LIMITED

KIRLOSKARVADI 416 308, DIST. SANGLI (INDIA)

ENVIRONMENTAL APEX MANUAL

ENVIRONMENTAL MANAGEMENT SYSTEMS ENVIRONMENTAL POLICY

DOCUMENT NO. EAM-420

Enriching Lives

KIRLOSKAR BROTHERS LIMITED ENVIRONMENTAL POLICY

We, at Kirloskar Brothers Limited, Kirloskarvadi, involved in manufacturing of Pumps, Pumping Systems and Turbines are committed to protect environment by prevention of pollution. We will continually improve our environmental performance by, ? Striving to go beyond compliance to applicable environmental legislation, regulations and other environmental requirements. ? Conserving natural resources such as Air, Water, Oil, Energy, and Raw Materials used at various processes and operations. ? Reduction, recycle, reuse and proper disposal of waste that include used Water, Oil, Plastics and Paints. ? Improving work environment. ? Creating awareness amongst all employees on environmental issues. Environmental policy is communicated to all persons working for or on behalf of us and is available to the public on request.

Issue No: 3 Date of Issue: 14.07.2007 Date of next Review :14.07.2010

Sd/[ R.K. Srivastava]

Director & Occupier

ISSUE NO. 2

REVISION NO. 0

DATE: - 15.12.2007

PAGE: 2 OF 2

KIRLOSKAR BROTHERS LIMITED

KIRLOSKARVADI 416 308, DIST. SANGLI (INDIA)

ENVIRONMENTAL APEX MANUAL DOCUMENT NO. EAM-431

ENVIRONMENTAL MANAGEMENT SYSTEMS ENVIRONMENTAL ASPECTS REVIEW (ASPECT IMPACT ANALYSIS)

1.0 PURPOSE: 1.1 To identify the environmental aspects of activities, products and services those can be controlled and those organization can influence; considering planned or new developments and new or modified activities, products and services. 1.2 To update information on environmental aspects and its impacts. 1.3 To ensure that significant environmental aspects are considered while setting environmental objectives. 2.0 SCOPE: Activities, Products and Services at KBL, Kirloskarvadi Plant and Township. Within the defined scope of environmental management system that KBL can control and those that KBL can influence taking into account planned or new developments, or new or modified activities, products and services. 3.0 RESPONSIBILITY: 3.1 HODs are responsible for the identification of environmental aspects, their impacts, & evaluating significance of these impacts. They are also responsible for formulating Objectives , Setting Targets and taking programme(s) for improving environmental performance considering prioritized significant aspects. 3.2 HOD (HRM&C) is responsible for carrying out survey of nearby society/community to understand concerns of interested parties and communicating same to all concerned HODs. 4.0 PROCEDURE: 4.1 Identification of Environmental Aspects. 4.2 Flow Chart and Listing Activities and its Environmental Aspects. 4.2.1 Define & document processes and activities carried out in the department to produce a product and service, in the form of 'EMS Flow Chart'. Put the activities in the sequence of operation in rectangle/square text box. Identify and write inputs related to environment including resources like raw materials, chemicals, energy directing into above the rectangle/square text box; then put activity/products/process/services in text box; then aspects (outputs) that interact with the environment at each stage direction showing coming out below the text box. ISSUE NO. 2 REVISION NO. 0 DATE: - 15.12.2007 PAGE: 1 OF 8 PREPARED & VERIFIED BY: REVIEWED & APPROVED BY: ( K.D. Gandhi) (R.K.Srivastava)

KIRLOSKAR BROTHERS LIMITED

KIRLOSKARVADI 416 308, DIST. SANGLI (INDIA)

ENVIRONMENTAL APEX MANUAL DOCUMENT NO. EAM-431

ENVIRONMENTAL MANAGEMENT SYSTEMS ENVIRONMENTAL ASPECTS REVIEW (ASPECT IMPACT ANALYSIS)

4.2.2 Select an activity, product and service. Consideration should be given to Normal Operations (Routine Operations) like pouring castings, machining, Assembly, testing of the products and material handling etc; identify Abnormal Operations (Non-Routine Operations) like overhauling, Cleaning, replacements, actions needed to improve change processes, activities done once in year or two years...etc. 4.2.3 Identify as many environmental aspects as possible which are associated with selected activity, product or service. Aspect refers to an element of an activity, product or service, which can interact with the environment and have a beneficial or adverse impact on environment. 4.3 Categorization of Situations. Categorization of aspects is done considering situations like Normal, Abnormal and Emergency to identify environmental emergencies as a input for preparation of Emergency Preparedness and Response Plan. 4.3.1 In Normal Situation , aspect is designed to happen. 4.3.2 In Abnormal Situation, aspect is not designed to happen. The spillages and leakages of any materials are abnormal. It is studied whether any emergency situation can occur due to abnormal situation and if so the separate aspect of the same like, Fire Hazard, Potential of Accident is identified & marked as Emergency Situation (`E') in respective column. E.g. Spillage of flammable material may lead to an emergency hence separate aspect of `Fire Hazard' shall be identified & marked as 'E'. 4.3.3 In Emergency Situation, aspect has potential to lead to an environmental emergency/accident resulting in loss of property, affecting to the health of group (majority) of human beings and has considerable effect on environment. E.g. Fire may lead to air pollution and loss of property, Release of toxic gases, which may affect health of group (majority) of human beings. Heavy spillage of Hazardous Chemica ls/Wastes may adversely affect flora, fauna and human beings.etc.

ISSUE NO. 2 REVISION NO. 0 DATE: - 15.12.2007 PAGE: 2 OF 8 PREPARED & VERIFIED BY: REVIEWED & APPROVED BY: ( K.D. Gandhi) (R.K.Srivastava)

KIRLOSKAR BROTHERS LIMITED

KIRLOSKARVADI 416 308, DIST. SANGLI (INDIA)

ENVIRONMENTAL APEX MANUAL DOCUMENT NO. EAM-431

ENVIRONMENTAL MANAGEMENT SYSTEMS ENVIRONMENTAL ASPECTS REVIEW (ASPECT IMPACT ANALYSIS)

Failure of pollution control equipment (wherever it is insta lled) shall be identified as Aspect & considered as environmental Emergency Situations. Concerned department identifies emergency situation(s) during Environmental Review. Safety Officer (HRM&C) along with HODs considers all Emergency Situations identified in Environmental Review and prepares Emergency Preparedness & Response Plan. Safety Officer also uses data on previous environmental incidents/accidents/emergencies and potential situations leading to emergency as input for preparation of Emergency Preparedness & Response Plan. Environmental aspects having emergency situation are not evaluated/rated (i.e. for their Significant or Non-Significance categorization). Refer Procedure on Emergency Preparedness and Response, document number EAM-447 of this manual. 4.4 Identification of Impacts and its categorization: Identify as many as possible the actual and/or potential environmental impacts, positive ( eneficial) and/or negative (adverse), wholly or partially, b associated with each identified aspect and categorize them as per following guidelines. 4.4.1 Air Pollution: This includes exhaust emissions, fumes, smoke, excessive dust generated in processes and fine dust/metal particles which are let out on shop-floor, in factory premises and through stacks/chimneys into air having Legal Concern. 4.4.2 Water Pollution: This includes water contamination due to oil, grease, heavy metals, chemicals, dust, rust, coolant, paints, sludge, slurry & other materials. 4.4.3 Land Contamination: Contamination of land due to spillage, leakage & flow during storage, use & disposal of contaminated water, liquids, rusty components, sludge, slurry, non-biodegradable materials and Hazardous Chemicals & Wastes. 4.4.4 Work Environment: This includes noise, sound, smell, odour, vibrations, slippery floor, dirt and dust (can be metallic also) in the surroundings and also things affecting good house keeping.

ISSUE NO. 2 REVISION NO. 0 DATE: - 15.12.2007 PAGE: 3 OF 8 PREPARED & VERIFIED BY: REVIEWED & APPROVED BY: ( K.D. Gandhi) (R.K.Srivastava)

KIRLOSKAR BROTHERS LIMITED

KIRLOSKARVADI 416 308, DIST. SANGLI (INDIA)

ENVIRONMENTAL APEX MANUAL DOCUMENT NO. EAM-431

ENVIRONMENTAL MANAGEMENT SYSTEMS ENVIRONMENTAL ASPECTS REVIEW (ASPECT IMPACT ANALYSIS)

4.5 Determination-Significant Environmental Aspects -having significant Impact(s): Significant environmental aspects-impacts are determined based on Overriding Factors/ Criteria and Impact Rating considering non existence/non-availability of any control/pollution control/abatement equipment to assess its correct significance to establish management control. Aspects having Emergency (`E') Situation are not further evaluated/assessed (neither by Overriding Factors nor by Impact Rating) for their Significance or Non-Significance. 4.5.1 Overriding factors/criteria: If the environmental impact of any aspect is falls in (happens to be/ governed by) any of overriding criteria it is directly treated as Significant Environmental Aspect-Impact without further impact rating. The following impacts are considered to be the overriding factors/criteria. a) Impacts having Legal Concern. The impacts, which are controlled by legal (legal limits/standards) and other requirements should be considered as Legal Concern. Refer procedure on Legal and Other Requirements Document Number EAM-432 of this manual. Refer Register of Regulations (Legal Register) applicable to respective department given by HRM&C based on applicable legal and other requirements to which KBL subscribes. Thus each impact is evaluated for its applicability of legal and other requirements to its environmental aspect. If it applies to environmental aspects it is first overriding factor and marked in legal concern column. If it is not applicable then this will not be overriding factor. b) Impacts identified as 'Interested Party Concern' (IPC). 1) Interested party concerns are identified through surveys of the interested parties i.e. staff, workers, sub-contractors, colony residents, local residents (neighbors) outside the factory premises etc. in surrounding area conducted by HRM&C. The interested party concerns are determined based on responses of people to a questionnaire prepared by KBL. 2) HOD (HRM&C) does department-wise analysis of the feedbacks received from interested parties and communicates to HODs to consider same during evaluation of departmental aspect and their impact. 3) HODs decide to include Interested Party Concern into Environmental Review: Aspect Impact Analysis if given feedback is genuine/justified based on fact/data of monitoring and has serious consequences. Formats EMS-0402 to EMS-0406 are used for recording the feedback received from Interested Parties. ISSUE NO. 2 REVISION NO. 0 DATE: - 15.12.2007 PAGE: 4 OF 8 PREPARED & VERIFIED BY: REVIEWED & APPROVED BY: ( K.D. Gandhi) (R.K.Srivastava)

KIRLOSKAR BROTHERS LIMITED

KIRLOSKARVADI 416 308, DIST. SANGLI (INDIA)

ENVIRONMENTAL APEX MANUAL DOCUMENT NO.

ENVIRONMENTAL MANAGEMENT SYSTEMS

ENVIRONMENTAL ASPECTS REVIEW EAM-431 (ASPECT IMPACT ANALYSIS) c) Impacts having Resource Saving Potential (RSP) of more than Rs. 1.0 Lac per Annum.

Individual departments considers the saving of more than Rs. 1.0 Lac per Annum during Aspect -Impact Analysis. 1) MR identify resource saving potential goals/projects where savings of more than Rs. 1.0 Lac per annum could be done at company level and sets objectives and targets and assign the same to respective departments. 2) HODs can also set objectives and targets resource saving might be workout to be less than Rs.1.0 Lac/Annum if they find natural resources saving will be worth. 2) Concerned Department identifies such Resource Saving Potential (RSP) in their AspectImpact Analysis. 3) Head of Department review & monitor the progress of RSP goals and report it in management reviews.

4.5.2 Impact Rating. Impacts not falling in overriding criteria/factors are rated as per following guidelines considering non -existence/non-availability of control/pollution control/abatement equipment to assess its correct significance. E.g. Aspect-Impact rating of sand/shot blasting activities will be done considering non-availability of dust collection system.

MEASURES FOR IMPACTS Extent (E) Severity (S) Restricted Minor : within work Low release of non-hazardous station. substances. Restricted to Low : part of the High release of non-hazardous shop. substances and or very low noise. Restricted Medium: within the Minor release of hazardous substances shop. and or medium noise and or exposure causing temporary dis-ability. Restricted High: within the Low release of hazardous substances Industry and and or high level of noise and or disTownship ability beyond period of exposure. premises. Spreads Very High: outside the High release of ha zardous substance industry and and or very high level of noise and or township permanent dis-ability rendered due to premises. exposure. Occurrence (O) Once in year or more than one year. Few times in a year but not monthly Few times in a month but not daily Few times in a day but not continuously Duration (D) Less than one hour One to four hours Four to eight hours RANKING Weightage 1

Eight to sixteen hours

Continuously for one shift or more

More than sixteen hours

ISSUE NO. 2 REVISION NO. 0 DATE: - 15.12.2007 PAGE: 5 OF 8 PREPARED & VERIFIED BY: REVIEWED & APPROVED BY: ( K.D. Gandhi) (R.K.Srivastava)

KIRLOSKAR BROTHERS LIMITED

KIRLOSKARVADI 416 308, DIST. SANGLI (INDIA)

ENVIRONMENTAL APEX MANUAL

ENVIRONMENTAL MANAGEMENT SYSTEMS

DOCUMENT NO.

ENVIRONMENTAL ASPECTS REVIEW EAM-431 (ASPECT IMPACT ANALYSIS) During impact rating consideration is given to normal and abnormal situations. ? Final Impact Rating: If the product of E*S*O*D, is more than 81 then the impact is considered as significant. This cut-off mark of ESOD-Rating more than 81 is decided by studying various combinations and actual Environmental Review: Aspect-Impact analysis. 81 rating works-out from 3X3X3X3(ie.EXSXOXD) =81 i.e. rating is more than 3 for each measure. The rating less than 3 means the effect o f impact on its measures contributes on low/minor scale. If any measure is rated below 3, but other measures have rating more than 3 rating and multiplication (product) of all measures works-out to be more than 81, then it will be Significant Impact. This cut-off mark will be reviewed and approved by members of management review once in 3 years, along with EMS policy review subject on MRM agenda. 4.6 Each department prepares a List of Aspects having significant environmental impacts'. ENVIRONMENTAL MANAGEMENT SYSTEMS IN DOCUMENT NO. "NAME OF DEPARTMENT" XXX-431-** LIST OF ASPECTS HAVING SIGNIFICANT ENVIRONMENTAL IMPACTS ER Sr. No. Activity/Product/ Services/Processes/ Interaction ER Environmental Aspect Aspects Sr. No. Significant Environmental Impact

ISSUE NO. REVISION NO. PREPARED & VERIFIED BY (Resp.) :-

DATE: PAGE: OF REVIEWED & APPROVED BY (Authority):-

Legend - XXX - Abbreviation of department and ** -Sr. No. of procedure in that clause.

The concerned departments document and keep up to date list of Environmental Aspects (aspect impact analysis and review) taking into account planned or new developments, or new or modified activities, products and services considering any change in the processes, activities, products and services, layouts, materials, acquisition or modification of products & production equipments. The results of implementation/completion of Environmental Management Programmes may call for review of aspect-impact analysis. ISSUE NO. 2 REVISION NO. 0 DATE: - 15.12.2007 PAGE:6 OF 8 PREPARED & VERIFIED BY: REVIEWED & APPROVED BY: ( K.D. Gandhi) (R.K.Srivastava)

4.6

KIRLOSKAR BROTHERS LIMITED

KIRLOSKARVADI 416 308, DIST. SANGLI (INDIA)

ENVIRONMENTAL APEX MANUAL DOCUMENT NO. EAM-431

ENVIRONMENTAL MANAGEMENT SYSTEMS ENVIRONMENTAL ASPECTS REVIEW (ASPECT IMPACT ANALYSIS)

4.7 The changes in products, processes, activities and services and corresponding changes in Environmental Review (Aspect-Impact Analysis) will be reported by concerned HOD for management review. 4.8 Significant environmental aspects are taken into account in establishing, implementing and maintaining environmental management system by prioritizing the same as per procedure Document No. EAM -433 to exercise appropriate Management Controls like formulating Objectives & Targets and taking Environmental Management Programme/s (Refer Doc. No. EAM-433) and /or establishing Operation Control Procedures (refer Doc. No. EAM-446). 4.9 The reference of respective EMP o r OCP or Emergency Preparedness and Response Plan (EPRP) o r any other thing will be given in the last column of Environmental Aspects Review: Aspect-Impact Analysis Format/Procedure.

5.0

DOCUMENTS/RECORDS 5.1) EMS Flow-Chart by All Departments. 5.2) Environmental Aspects Review (aspect impact analysis and review) by All Departments. 5.2) Interested Party Concerns by Concerned Departments. 5.3) List of Significant Aspects by Concerned Departments.

ISSUE NO. 2 REVISION NO. 0 DATE: - 15.12.2007 PAGE: 7 OF 8 PREPARED & VERIFIED BY: REVIEWED & APPROVED BY: ( K.D. Gandhi) (R.K.Srivastava)

KIRLOSKAR BROTHERS LIMITED

KIRLOSKARVADI 416 308, DIST. SANGLI (INDIA)

ENVIRONMENTAL APEX MANUAL DOCUMENT NO. EAM-431

ENVIRONMENTAL MANAGEMENT SYSTEMS ENVIRONMENTAL ASPECTS REVIEW (ASPECT IMPACT ANALYSIS)

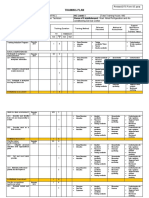

ENVIRONMENTAL ASPECTS REVIEW: ASPECT-IMPACT ANALYSIS AND REVIEW (Environmental Management Systems)

For Format this page, Refer IER Form.Doc file in same folder.

ISSUE NO. 2 REVISION NO. 0 DATE: - 15.12.2007 PAGE: 8 OF 8 PREPARED & VERIFIED BY: REVIEWED & APPROVED BY: ( K.D. Gandhi) (R.K.Srivastava)

KIRLOSKAR BROTHERS LIMITED

KIRLOSKARVADI 416 308, DIST. SANGLI (INDIA)

ENVIRONMENTAL APEX MANUAL DOCUMENT NO. EAM-431

ENVIRONMENTAL MANAGEMENT SYSTEMS

ENVIRONMENTAL ASPECTS REVIEW (ASPECT IMPACT ANALYSIS) 6.0 Format for Environmental Review: Aspect-Impact Analysis.

ENVIRONMENTAL MANAGEMENT SYSTEMS IN "NAME OF THE DEPARTMENT" DOCUMENT NO. XXX-431-** ENVIRONMENTAL ASPECTS REVIEW (ASPECT IMPACT ANALYSIS) (Environmental Management Systems) Division/Department/Function/Area:

Mark Star `*' appropriate

Aspect Sr. No.

SituationNormal/Abnormal/ Emergency

Impact Sr. No.

Interested Party Concern

Water Pollution

Resource Saving Potential

Legal Concern

Occurrence (O)

Land Contamination

N/A/E

Air Pollution

Work Environment

Duration (D)

Severity (S)

Total = EXSXOXD

Extent (E)

ISSUE NO. REVISION NO. DATE: PAGE: OF PREPARED & VERIFIED BY (Resp.) :REVIEWED & APPROVED BY (Authority):Legend-XXX Department Abbreviation and **- Sr number of Procedure in that clause in the department e.g. if second procedure then 02.

EMP-Environmental Management Programme, OCP-Operation Control Procedure, EPRP -Emergency Preparedness & Response Plan.

ISSUE NO. 2 PREPARED & VERIFIED BY

REVISION NO. 0 (Resp.) :- N.K.Rao

DATE: - 15.122007

PAGE: 8 OF 8

REVIEWED & APPROVED BY (Authority):- R.K.Srivastava

Significant/Not Significant (S/NS)

Activities/ Products/ Services/ Processes/ Interactions

Environmental Aspects [Elements of an organization's activities, products or services that can interact with the environment]

Sr No

Environmental Impacts

Overriding Factors/ Criteria

Impact Rating

Reference of EMP, OCP, EPRP or any other thing/ Remark (If any)

KIRLOSKAR BROTHERS LIMITED

KIRLOSKARVADI 416 308, DIST. SANGLI (INDIA)

ENVIRONMENTAL APEX MANUAL DOCUMENT NO. EAM-432

ENVIRONMENTAL MANAGEMENT SYSTEMS LEGAL AND OTHER REQUIREMENTS 1.0 PURPOSE:

To identify and have access to the applicable legal and other requirements (like Environmental Acts, Rules and Regulations and other requirements) to which the organization subscribes related to the environmental aspects of organization's activities, products and services. To determine how legal and other requirements apply environmental aspects and ensure their updation. To consider these requirements in establishing, implementing and maintaining EMS within defined scope. 2.0 SCOPE: This procedure is applicable to Legal and other requirements (the Statutory, Regulatory and Other Requirements subscribed by Kirloskar Brothers Limited, Kirloskarvadi that are directly attributable to the environmental aspects of activities, products and services. 3.0 RESPONSIBILITY: HOD -HRM&C is responsible for establishing system for getting latest environmental legal and other requirements (Acts, Rules, notifications, noticeetc) time to time and maintaining the same. HOD -HRM&C is also responsible for identification and updation of Legal and other requirements related to activities, processes, products and services. HODs-Product Engineering (Design & Developments) are responsible for iden tification and updation of Legal and Other Requirements related to products and communicating the same to HRM&C for its incorporation in the Register Of Regulations (ROR). All concerned HODs are responsible for complying with applicable legal and other requirements by undertaking Programme, goals and targets or by establishing operational Controls. HOD -HRM&C is responsible for ensuring compliance to legal and other requirements is done by Concerned.Reporting the status of the legal compliance to management under copy to CMR/AMR is responsibility of Legal and secretarial department at Corporate office.. ISSUE NO. 2 REVISION NO. 0 DATE: - 15.12.2007 PAGE: 1 OF 4 PREPARED & VERIFIED BY: REVIEWED & APPROVED BY: ( K.D. Gandhi) (R.K.Srivastava)

KIRLOSKAR BROTHERS LIMITED

KIRLOSKARVADI 416 308, DIST. SANGLI (INDIA)

ENVIRONMENTAL APEX MANUAL DOCUMENT NO.

ENVIRONMENTAL MANAGEMENT SYSTEMS

LEGAL AND OTHER REQUIREMENTS EAM-432 4.0 PROCEDURE: 4.1 All Legal, statutory, regulatory and other r quirements applicable to KBL e Kirloskarvadi factory and colony environmental aspects are identified and compiled in the Register Of Regulations (ROR) i.e. Legal Register. Those are related to and in the form of, 4.1.1 Specific to activities and processes. 4.1.2 Specific to our products and services. 4.1.3 General environmental Laws, Rule, Acts, Notifications & Amendments. 4.1.4 Various Consents, Authorizations, Licenses and Permits. 4.2 HOD (HRM&C) Kov. Identifies and establish access to all the legal and other requirements on the basis of information through various sources described below. 4.2.1 Legal Environmental Requirements: ? Applicable environmental Acts, Rules, Regulations, like Air (Prevention and Control of Pollution) Act, Factories Act, Maharashtra Factories Rules, Environmental Protection Acts, rules, and notifications issued there under by Central Government (GOI), MoEF and CPCB. ? CII guide to Environmental Legislations. ? State legal requirements by State Govt. (GOM) and MPCB. ? Local governmental legal requirements addressed directly to the company. (District Level Departments, Collector, ZP, Taluka -Panchyat Samitee). 4.2.2 Other Environmental Requirements: ? Agreements with community groups, non-governmental organization, public authorities, other government departments. ? Corporate/Company Requirements. ? Public commitment of the organization. ? Voluntary principles, Non -regulatory guidelines and code of practice. ? Instructions/Guidelines issued by local bodies, Grampanchayat, Tahasil and District Collector regarding environment protection and control e.g. Bombay Smoke-Nuisance Control in 1912, Tahasil rules about cutting of Trees and Use of Soil and Instructions issued by District Collector for use of plastic bags. ? Product Related Legal Requirements. ? Corporate Guidelines. ISSUE NO. 2 REVISION NO. 0 DATE: - 15.12.2007 PAGE: 2 OF 4 PREPARED & VERIFIED BY: REVIEWED & APPROVED BY: ( K.D. Gandhi) (R.K.Srivastava)

KIRLOSKAR BROTHERS LIMITED

KIRLOSKARVADI 416 308, DIST. SANGLI (INDIA)

ENVIRONMENTAL APEX MANUAL DOCUMENT NO.

ENVIRONMENTAL MANAGEMENT SYSTEMS

LEGAL AND OTHER REQUIREMENTS EAM-432 4.3 HOD--Product Engineering (Design & Development) departments identifies the product & System related environmental legal and other requirements from statutory and regulatory requirements and standards of the country where product is used through interaction with customers or his representatives regarding design, material of construction and product operation/function ing in national and international market including specific customer requirements and laws of land. These external origin documents of national and international standards, rules, acts, and regulations are controlled through technical library. These requirements are compiled, ensured continued compliance by considering design input and communicated to HRM&C to add in Register of Regulation and to verify continued compliance. 4.4 Legal/Safety Officer/HRM & C Department maintains the updated information about applicable Legal and Other Requirements. 4.5 Determination of applicability of legal and other requirements:4.5.1 Legal/Safety Officer studies the Environmental Aspects (Aspect-Impact analysis) of all departments. 4.5.2 He studies the relevant legal and other requirements (rules, acts, notifications) applicable to the environmental aspects impacts in purview of all activities, processes, products and services. 4.5.3 He identifies the legal and other requirements applicable to each process/ activity/product/ service department/area wise. He identifies specific applicable point/clause/section based on given limits, types, aspect and impacts. 4.5.4 He gets inputs from concerned departments reports changes in activities, products, processes and services during management reviews, internal audits and periodic inspection rounds. 4.5.5 Any changes in scope of EMS are studies by him for identification of legal and other requirements. 4.5.6 All Capital Goods, Layout changes are done with due consideration of Legal/Safety Officer hence he gets before hand information on change in processes/activities. 4.5.7 List of chemicals maintained by Materials/Purchase functions and list of Hazardous wastes centrally handled by General Stores-Scrap Yard is addressed to Legal/Safety Officer and any change in the same is also communicated by appropriate revisions to him. 4.6 HOD (HRM&C) maintains the Register of Regulations (Legal Register) which contains all applicable legal and other requirements to KBL factory and colony. It is kept up to date for changes/amendments. ISSUE NO. 2 REVISION NO. 0 DATE: - 15.12.2007 PAGE: 3 OF 4 PREPARED & VERIFIED BY: REVIEWED & APPROVED BY: ( K.D. Gandhi) (R.K.Srivastava)

KIRLOSKAR BROTHERS LIMITED

KIRLOSKARVADI 416 308, DIST. SANGLI (INDIA)

ENVIRONMENTAL APEX MANUAL DOCUMENT NO.

ENVIRONMENTAL MANAGEMENT SYSTEMS

LEGAL AND OTHER REQUIREMENTS EAM-432 4.7 The register of regulations is be made in following the format and controlled copy is issued to respective departments by HRM&C. ENVIRONMENTAL MANAGEMENT SYSTEMS IN HRM & C DEPARTMENT

Sr No

DOCUMENT NO. HRM-432-**

Register Of Regulations (Legal Register) for #############

Legal and Other Applicable Rule, Specific Requirement Present Applicable/ Requirement Clause, Schedule, (Standard/ Limit/ Level/ Status Done by/ Of Imposing/ Point, Annexure permission) Applicable against Resp./ Statutory Body reference and details to Respective requirement Remark Department

Legend: ** Serial Numbers of procedures in that clause 4.7 HRM & C keeps list of authorized recyclers and buyers of the waste. 4.8 HRM&C maintains list of various Consents, Authorizations, Licenses and Permits applicable to entire factory along with copy of actual permission and Certificate . HRMC monitors consent conditions . 4.9 Status of compliance to all legal and other requirements is periodically evaluated ensured by Legal & Secretariat dept (Corporate office) and reported in management reviews. 5 REFERENCES: 5.1 Register of Regulations (ROR). Doc. No. HRM-432-01. 5.2 Various publications of the Acts, Rules, notice, notifications, public notice and External Communications. (HRM&C) 5.5List of authorized recyclers/buyers of waste.(By HRM&C copy to General Stores) 5.6 List of chemicals (By Materials/Purchase and copy to HRM&C) 5.7 List of Hazardous Waste (By General Stores-Scrap Yard and copy to HRM&C) 5.8 List of various Consents, Authorizations, Licenses and Permits (HRM&C and Concerned Departments) 5.9 Data of monitoring and measurement results.(HRM &C and Concerned Deptts) 5.10 MSDS of Hazardous Chemicals.(Materials/Purchase, General Stores and User Departments)

ISSUE NO. 2 REVISION NO. 0 DATE: - 15.12.2007 PAGE: 4 OF 4 PREPARED & VERIFIED BY: REVIEWED & APPROVED BY: ( K.D. Gandhi) (R.K.Srivastava)

KIRLOSKAR BROTHERS LIMITED

KIRLOSKARVADI 416 308, DIST. SANGLI (INDIA)

ENVIRONMENTAL APEX MANUAL DOCUMENT NO. EAM-433

ENVIRONMENTAL MANAGEMENT SYSTEMS OBJECTIVES & TARGETS AND ENVIRONMENTAL MANAGEMENT PROGRAMME (S)

1.0 PURPOSE: To establish objectives and set targets to meet the commitments of environmental policy to protect environment by prevention of pollution by reducing or eliminating impacts of identified significan t aspects. To implement environmental management programme(s) for achieving objectives and targets. 2.0 SCOPE: This procedure covers the environmental objectives and targets of KBL, Kirloskarvadi. 3.0 RESPONSIBILITIES: To establish and achieve objectives and set targets HODs through Environmental Management Programme(s). Provide resources and Review of objectives and Top Management and targets Management Representative 4.0 PROCEDURE:

4.1 The significant aspects identified based on evaluation as per procedure of Environmental Aspects Document Number EAM-431 are prioritized as High (H), Medium (M) and Low (L) for setting objectives by HOD in the format given below. ENVIRONMENTAL MANAGEMENT SYSTEMS IN "NAME OF DEPARTMENT" DOCUMENT NO. XXX-433-**

PRIORITIZATION OF ASPECTS OF THE SIGNIFICANT IMPACTS

Legal Concerns Policy Requirement

Aspect/Impact Elimination Aspect/Impact Reduction

Operational

Status (N/A/E)

Y/N Y/N

Y/N

Y/N

Y/N

Y/N Y/N

Economical

ER Activity Environmental Sr Aspect No Description

Significant Environmental Impact

Possibility of

Feasibility

Technical

Priority High / Medium/ Low

H/M/L

ISSUE NO. REVISION NO. PREPARED & VERIFIED BY (Resp.) :-

DATE: PAGE: OF REVIEWED & APPROVED BY (Authority):-

Legend- XXX - Abbreviation of department and **-Sr. No. of procedure in that clause.

ISSUE NO. 2 REVISION NO. 0 DATE: - 15.12.2007 PAGE: 1 OF 7 PREPARED & VERIFIED BY: REVIEWED & APPROVED BY: ( K.D. Gandhi) (R.K.Srivastava)

KIRLOSKAR BROTHERS LIMITED

KIRLOSKARVADI 416 308, DIST. SANGLI (INDIA)

ENVIRONMENTAL APEX MANUAL DOCUMENT NO. EAM-433

ENVIRONMENTAL MANAGEMENT SYSTEMS OBJECTIVES AND TARGETS ENVIRONMENTAL MANAGEMENT PROGRAMME (S)

4.2) The criteria for prioritization is as follo ws: 4.2.1) Significant Aspects are assessed-based on possibility of Aspect/Impact Elimination, Reduction and Technical, Operational & Economical Feasibility. The Guidelines are as given in table below.

Legal Concerns Sr No Possibility of Policy Requirement

Aspect/Impact Elimination Aspect/Impact Reduction

Feasibility Operational Economical Technical

Priority High / Medium/ Low

Y/N 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 Y or N Y or N Y or N Y or N Y or N Y or N Y or N Y or N Y or N Y or N Y or N Y or N Y or N Y or N Y or N Y or N Y or N N N

Y/N Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y N N N

Y/N N N N N N N N N Y Y Y Y Y Y Y Y Y N Y or N

Y/N Y Y Y Y Y Y Y Y ---------Y Y or N

Y/N Y N Y Y Y N N N Y N Y Y Y N N N Y Y

Y/N Y Y N Y N N Y N Y Y N Y N N Y N Y Y

Y/N Y Y Y N N Y N N Y Y Y N N Y N N Y Y

H/M/L H L M M L L L L H L M M L L L L M M L

Any one or more `N'

Legend: Y= Yes, N=No, -- = Not Applicable H-High Priority, M-Medium Priority and L-Low Priority

4.2.2) It is ensured before setting any objectives and targets that these are consistent with the environmental policy, including commitment to prevention of pollution. ISSUE NO. 2 REVISION NO. 0 DATE: - 15.12.2007 PAGE: 2 OF 7 PREPARED & VERIFIED BY: REVIEWED & APPROVED BY: ( K.D. Gandhi) (R.K.Srivastava)

KIRLOSKAR BROTHERS LIMITED

KIRLOSKARVADI 416 308, DIST. SANGLI (INDIA)

ENVIRONMENTAL APEX MANUAL DOCUMENT NO.

ENVIRONMENTAL MANAGEMENT SYSTEMS

OBJECTIVES & TARGETS AND ENVIRONMENTAL EAM-433 MANAGEMENT PROGRAMME (S) 4.3 Setting/Establishing and Reviewing Objectives and Targets. All HODs propose Objectives and Targets with due consideration to above points, for each financial year. New objectives and targets ma y be taken at anytime, if, Aspect/ Impact Analysis is revised. 4.3.1) Initially HODs proposes Objective and Targets for all High Priority Significant Aspect-Impacts considering Legal & Other Requirements and Views of Interested Parties. 4.3.2) O nce Objectives and Targets for High Priority Significant Aspects/impacts are achieved, HODs decide Objectives and Targets for Medium Priority Significant Aspects. 4.3.3) Once Objectives and Targets for High and Medium Priority significant aspects are achieved Objectives and Targets are set for Low priority significant aspects/impacts. Initially if any department has only medium or low priority significant aspects then they should consider the same for setting the Ob jectives and Targets. 4.3.4) The significant Aspects and Impacts of low priority or medium priority where it is not feasible to eliminate or reduce the Aspect-Impact Technically, Operationally or Economically then Operation Control Procedures are established and implemented to control impact. E.g. Personnel Protective Equipments are used to control impact of Noise. 4.3.5) Top Management and Management Representative may propose company level Objectives and Targets in line with Environmental Policy and assign responsibility to concerned Department, Individual or Committee/Team. MR or concerned Committee/Team Head monitors and reports the progress of such objectives and targets. 4.3.6) The Heads of the department ensure that the objectives and targets are specific, measurable, achievable and time bound. Resource requirements to achieve objectives, are assessed by HOD/Functional Head. Targets should specify present level and planned level of performance indicator/key environmental parameter & time frame within which it will be achieved. Target should be co-related to Output/Production/Sales...etc to measure absolute achievement. 4.3.7) The Head of the department proposes Objectives and Targets for their approval in management review where financial sanction is required. E.g. Capital Goods. 4.3.8) Objectives and Targets are approved in management review considering available Technological Option and its Financial, Operational & Business Requirements, and the views of Interested Parties. ISSUE NO. 2 REVISION NO. 0 DATE: - 15.12.2 007 PAGE: 3 OF 7 PREPARED & VERIFIED BY: REVIEWED & APPROVED BY: ( K.D. Gandhi) (R.K.Srivastava)

KIRLOSKAR BROTHERS LIMITED

KIRLOSKARVADI 416 308, DIST. SANGLI (INDIA)

ENVIRONMENTAL APEX MANUAL

ENVIRONMENTAL MANAGEMENT SYSTEMS OBJECTIVES & TARGETS AND ENVIRONMENTAL MANAGEMENT PROGRAMME (S)

DOCUMENT NO. EAM-433

4.3.9) HODs take objectives and targets that are non-expenditure based (where no need of financial investment) and report the same in subsequent management review as an information as per agenda of management review. E.g. If any target that could be achieved by doing some kind of maintenance or method improvement or replacement of parts. 4.3.10) Objectives and Targets are entered in the format given below by concerned HODs. ENVIRONMENTAL MANAGEMENT SYSTEMS IN DOCUMENT NO. "NAME OF DEPARTMENT" XXX-433-** ENVIRONMENTAL OBJECTIVE AND TARGETS

Sr No Objective Target(s) Investment Responsibility Ref. No. of Actual achievement against (Rs.) EMP(s)/ target after completion of Action EMP/Actions. OCP Plan/Goals reference (Achieved on)

ISSUE NO. REVISION NO. PREPARED & VERIFIED BY (Resp.) :-

DATE: PAGE: OF REVIEWED & APPROVED BY (Authority):-

Legend - XXX - Abbreviation of department and ** -Sr. No. of procedure in that clause.

4.3.11) The Objectives and Targets that are not approved are documented in management review with the reasons of non-approval as the case may be. The non-approved objectives and targets may be re-submitted after making suitable amendments in subsequent management review. 4.3.12) The progress of the attainment of the objectives and targets is reviewed in the management reviews. The Head of the department submit progress reports in the management reviews as advised by MR. 4.3.13) On satisfactory completion and attainment of the objectives and targets, concerned department retains the record of achievement and relevant back-up data. The actual achievement against target is recorded in last column of format given under point 4.3.10 above and the date of achievement is put in bracket below. 4.3.14) HODs may take further Objectives and Target (if possible & feasible) for same high priority aspect/impact once initial target is met.

ISSUE NO. 2 REVISION NO. 0 DATE: - 15.12.2007 PAGE: 4 of 7 PREPARED & VERIFIED BY: REVIEWED & APPROVED BY: ( K.D. Gandhi) (R.K.Srivastava)

KIRLOSKAR BROTHERS LIMITED

KIRLOSKARVADI 416 308, DIST. SANGLI (INDIA)

ENVIRONMENTAL APEX MANUAL DOCUMENT NO. EAM-433

ENVIRONMENTAL MANAGEMENT SYSTEMS OBJECTIVES & TARGETS AND ENVIRONMENTAL MANAGEMENT PROGRAMME (S)

4.4 Taking environmental management programme(s). 4.4.1 Environmental management programme are set in detail to achieve objective and targets. The detailed activity based time bound action plan is derived and responsibility of each activity is assigned to concerned responsible persons by HODs. 4.4.2 A detailed action plan considering following aspects is worked out in Section-A of EMPs Format given below. ? Activities related to data collection & analysis, p lanning, design, production, maintenance, civil work, purchasing, erection, commissioning, disposal and further Monitoring & Measurement. ? The means (i.e. resource requirements & methods) and time frame. ? Assigning responsibilities to relevant function, personnel and level. ? Commitments of departments involved in execution of EMP. 4.6 Entire format with Section-A, & B duly approved by approving authority & dated is maintained by concerned HOD for its execution. 4.7 Progress review of Environmental Management Programme and Reporting. 4.7.1 The progress of the EMP is reviewed monthly by HODs to check the status of activities and achievements w.r.to time frame. 4.7.2 During monthly review, only `Record of EMP/s' is updated i.e. Section A and Section B of the format is filled. (Note: It is not necessary to add EMP in the manual.) 4.7.3 Status of each activity due as on review date is given in Section -A under `Remark/Status Column' as `Completed ' or `Pending'. 4.7.3 In Section-B `Review Date' is put in Review Date Column. 4.7.4 Section C is left blank as it is till completion of EMP. 4.7.5 If all due activities are completed as per plan then write `Nil' in `Delayed Stages/Activities Column' and dash mark in `Reason' and `Corrective Action Column'. 4.7.6 If any activity (activities) is (are) delayed as on review date against planned dates then mention respective Sr. Nos. of activities in `Delayed Stage/Activities Column'. Write reason for delay in `Reason Column' and `Corrective Actions Taken/Planned' to make up the delay. 4.7.7 Take approval of approving authority on the Monthly Progress Review Report and send it to all responsible/involved functions/persons. 4.7.8 The status of EMPs is reported in management reviews along with monthly progress report as on that month only. ISSUE NO. 2 REVISION NO. 0 DATE: - 15.12.2007 PAGE: 5 OF 7 PREPARED & VERIFIED BY: REVIEWED & APPROVED BY: ( K.D. Gandhi) (R.K.Srivastava)

KIRLOSKAR BROTHERS LIMITED

KIRLOSKARVADI 416 308, DIST. SANGLI (INDIA)

ENVIRONMENTAL APEX MANUAL DOCUMENT NO. EAM-433

ENVIRONMENTAL MANAGEMENT SYSTEMS OBJECTIVES & TARGETS AND ENVIRONMENTAL MANAGEMENT PROGRAMME (S)

4.8 If some of the activities are delayed due to reasons not in control of concerned HODs/Department/Function then Target Dates given in EMP may be suitably Re-scheduled by keeping old / previous target dates in bracket. The Procedure of EMP and Record of EMPs shall be suitably updated. Such changes should be informed during management reviews. 4.9 On completion/conclusion of Environmental Management Programme `Final Report of EMP' is prepared by filling all Sections-A, B & C of the format'. Copy of final report is send to Management Representative for information. 4.10 EMS Departmental manual is updated by concerned department to update Environmental Aspects (Aspect-Impact analysis and review) for project related to new development or induction or modification of products, processes & services and to take effect of completed EMPs as per procedure on Environmental Aspects, Doc No. EAM-431 of this manual and also procedure Objective and Targets is updated to put achievements details. 4.12 On completion of EMP an Operational Control Procedure is made/revised (if required). 4.13 Concerned department maintains various records generated during implementation of Environmental Management Programme. 5.0) DOCUMENTS/RECORDS: 5.1) Prioritization of aspects of the significant impacts. (Concerned Depts.) 5.2) List of Objective and Target. (Concerned Departments) 5.3) Records related to Completed Objectives and Targets. (Concerned Depts.) 5.4) Environmental Management Programmes. (Concerned Departments) 5.4) Records generated during implementation of EMP. (Concerned Departments)

ISSUE NO. 2 REVISION NO. 0 DATE: - 15.12.2007 PAGE: 6 OF 7 PREPARED & VERIFIED BY: REVIEWED & APPROVED BY: ( K.D. Gandhi) (R.K.Srivastava)

KIRLOSKAR BROTHERS LIMITED

KIRLOSKARVADI 416 308, DIST. SANGLI (INDIA)

ENVIRONMENTAL APEX MANUAL DOCUMENT NO.

ENVIRONMENTAL MANAGEMENT SYSTEMS

OBJECTIVES & TARGETS AND ENVIRONMENTAL EAM-433 MANAGEMENT PROGRAMME (S) 5 Format for Environmental Management Programme (EMP)

ENVIRONMENTAL MANAGEMENT SYSTEMS IN "Name of the Department" DOCUMENT NO. XXX-433-0 1-**

Environmental Management Programme (EMP) or Action Plan for #################

SECTION-A 1) Department: 2) Objective : 3) Target(s) : 4) Scope : 5) Overall Responsibility : 6) Performance Indicator : 7) Action Plan : SR No Stages/Activities

Individual Responsibility

Deadline (Dates)

Remark/ Status

8) Records : @@@ 9) Approved by (HOD)__________________________ 10) This EMP is forwarded to:--------------------------------------------------------------? ? ? ? ? ? ---------------------------------------------------------SECTION-B 1) Status of monthly review by HODs. Review Date Delayed Stages/ Activities Reason Corrective action Notes:1) During monthly review give status as `Completed' or `Pending' in Remark/Status column of Section-A Sr. No. 7-Action Plan for Stages/Activities due as on review date against deadline. 2) In Section-B Status of monthly review by HOD put review date in specified column and; 2.1) If Delayed Stages/Activities are `NIL' write `NIL in specified column and dash marks in other columns. 2.2) If some activities are delayed as on review date give details in each column. --------------------------------------------------------------? ? ? ? ? ? ---------------------------------------------------------SECTION-C After completion of Environment Management Programme the achievement shall be recorded in the list of objectives and OCP as desired shall be prepared

Legend - XXX-Dept. Abbreviation, ** -Sr. No. of EMP in that Dept. since implementation of EMS. ##########- Describe title of EMP. @@@- Records needs to be maintained for EMP/Action Plan.

ISSUE NO. 2 REVISION NO. 0 DATE: - 15.12.2007 PAGE: 7 OF 7 PREPARED & VERIFIED BY: REVIEWED & APPROVED BY: ( K.D. Gandhi) (R.K.Srivastava)

KIRLOSKAR BROTHERS LIMITED

KIRLOSKARVADI 416 308, DIST. SANGLI (INDIA)

ENVIRONMENTAL APEX MANUAL DOCUMENT NO.

ENVIRONMENTAL MANAGEMENT SYSTEMS

RESOURCES, ROLES, RESPONSIBILITY AND EAM-441 AUTHORITY. 1.0 PURPOSE: 1.1 To define, document and communicate Organization, Roles, Responsibilities and Authorities of personnel who carry out activities related to EMS in order to facilitate effectiveness of environmental management system. 2.0. SCOPE: 2.1 To define Overall Organization for EMS. 2.2 To define Roles, Responsibilities and Authorities of Top Management, MR, HODs and others. 3.0.RESPONSIBILITIES: Mr.R.K.Srivastava, Director is responsible for providing (ensuring availability of) resources essential to establish, implement, maintain and improve EMS and defining Roles, Responsibilities and Authorities of MR, HODs and Others. 4.0. PROCEDURE: 4.1) ORGANIZATION STRUCTURE. A) ORGANIZATION CHART FOR EMS Mr.R.K.Srivastava, Director & Occupier

Corporate Management Representative Associate Management Representative

SBGH (IP) & OPERATIONAL HEAD(PEP) Head of the Departments (Representing SBUs and Corporate Functions) Legal & Secretariat at CO

Departmental Representatives/ Staff

Workers/Operators ISSUE NO. 2 REVISION NO. 0 DATE: - 15.12.2007 PAGE: 1 OF 4 PREPARED & VERIFIED BY: REVIEWED & APPROVED BY: ( K.D. Gandhi) (R.K.Srivastava)

KIRLOSKAR BROTHERS LIMITED

KIRLOSKARVADI 416 308, DIST. SANGLI (INDIA)

ENVIRONMENTAL APEX MANUAL

ENVIRONMENTAL MANAGEMENT SYSTEMS

DOCUMENT NO.

RESOURCES, ROLES, RESPONSIBILITY AND EAM-441 AUTHORITY. B) MANAGEMENT: 1) Top Management. The top management is Mr.R.K.Srivastava, Director and Occupier. In absence of Mr.R.K.Srivastava charge of EMS related activities goes to Mr. SS Date VP(CQA) Management Representative, Associate Management Representative, SBU Head, Location Heads and Heads of all Departments (HODs) at Kirloskarvadi take directives from Top-Management. 2) Management Representative. Corporate Management Representative is Mr.K.D.Gandhi, C.O., Pune and Associate Management Representative is Mr. S.S. More , AMR(KOV). In absence of Mr.K.D.Gandhi charge of Management Representative function and MR related activities go to Mr. S.S. More , AMR (KOV). 3) Head of the Departments (HODs) All HODs Establish, Implement and Maintain EMS under guidance of Management Representative. The list of Departments/Sections/Areas covered under Environmental Management System is given in the procedure Environment Management System Documentation refer Document Number EAM -444 of this manual. C) ROLES, RESPONSIBILITY and AUTHORITY: Roles Responsibilities Director 1) Provide overall direction to the EMS. 2) Provide resources essential for implementation and maintenance of the EMS. 3) Review the Environmental Management Systems, to ensure its continuing suitability, adequacy and effectiveness. 4) Define responsibilities and authorities of HOD. Authorities Issue En vironmental Policy. Approve Environmental Apex Manual. Appointment of MR and AMR. Approval of financial resources required for EMS to improve environmental performance. Stop processes/activities having considerable impact on environment. Approve Objectives and Targets

1) 2) 3) 4)

5)

6)

ISSUE NO. 2 REVISION NO. 0 DATE: - 15.12.2007 PAGE: 2 OF 4 PREPARED & VERIFIED BY: REVIEWED & APPROVED BY: ( K.D. Gandhi) (R.K.Srivastava)

KIRLOSKAR BROTHERS LIMITED

KIRLOSKARVADI 416 308, DIST. SANGLI (INDIA)

ENVIRONMENTAL APEX MANUAL DOCUMENT NO. EAM-441

ENVIRONMENTAL MANAGEMENT SYSTEMS RESOURCES, ROLES, RESPONSIBILITY AND AUTHORITY. C) ROLES, RESPONSIBILITY and AUTHORITY: Roles Responsibilities SBG Head IP 1.Ensure Effective and implementation of EMS as per Operation ISO:14001 at KOV Plant Head (PEP) 2.This is in addition applicable Responsibilities of HODs MR/AMR: 1) Prepare EMS Apex Manual. Establish, 2) Organize Management Implement Reviews. and maintain 3) Reporting on the performance the EMS as per of EMS to Top Management ISO-14001. for review and improvements in the management reviews. 4) Conducting Internal Audits and provide information on the results of audits to management. 5) Liaise with external agencies in matters related to EMS certification. 6) To set company level Objectives and Targets 7) To ensure necessary competence for 'Auditing of EMS'. 8) Ensure effectiveness of EMS through Internal Audits and Management Reviews. 9) Give recommendation for improvement to top management.

1.Approve resources

Authorities

required for implementation of EMS 1) Close internal audit NCRs. 2) Stop processes/activities having considerable impact on environment. 3) Stop equipments/ machines/ processes those are malfunctioning due to which affecting environmental performance. 4) Appointment of EMS Cross Functional Teams (if required). 5) To review environmental performance thru respective HODs and HRM&C.

ISSUE NO. 2 REVISION NO. 0 DATE: - 15.12.2007 PAGE: 3 of 4 PREPARED & VERIFIED BY: REVIEWED & APPROVED BY: ( K.D. Gandhi) (R.K.Srivastava)

KIRLOSKAR BROTHERS LIMITED

KIRLOSKARVADI 416 308, DIST. SANGLI (INDIA)

ENVIRONMENTAL APEX MANUAL DOCUMENT NO. EAM-441

ENVIRONMENTAL MANAGEMENT SYSTEMS RESOURCES, ROLES, RESPONSIBILITY AND AUTHORITY. Roles HODs : Maintain and Improve Environmental Performance of functions under his control. Responsibilities

Staff

Workers/ Operators

1) Establish, Implement and Maintain EMS as per ISO:14001 -2004 and EMS Apex. 2) Implement Environmental Policy. 3) Identification of Aspects & Impacts. 4) To comply with Legal and Other Requirements. 5) Proposing Objectives and Targets. 6) Assessing, identification and availability of resource requirements to improve Environmental Performance by setting Objectives & Targets and EMPs thru AOPs. 7) Developing and reviewing implementation of Environment Management Programmes and Operational Control Procedures. 8) Monitoring and Measurement of key characteristics of operations and activities related to significant aspects. 9) Initiation & implementation of correction, corrective & preventive actions on noncompliances. 10)Identification of training needs to develop competence of personnel working in his department/area. 11)Implement action and report progress/data as per agenda of management review.. 1) Establish, implement & maintain EMS as 1) Stop equipments/ per ISO: 14001 & Policy. machines those are 2) To do continual improvements in malfunctioning and environmental performance. inform to HODs 1) To do activities/processes as per OCPs, 2) Stop equipments/ instructions, training, experience in line machines those are with EMS. malfunctioning and inform to Staff.

Authorities 1) Approval of EMPs 2) Approval of departmental level manual/procedures 3) Stop equipments/ machines those are Malfunctioning and affecting environmental performance.

ISSUE NO. 2 REVISION NO. 0 DATE: - 15.12.2007 PAGE: 4 OF 4 PREPARED & VERIFIED BY: REVIEWED & APPROVED BY: ( K.D. Gandhi) (R.K.Srivastava)

KIRLOSKAR BROTHERS LIMITED

KIRLOSKARVADI 416 308, DIST. SANGLI (INDIA)

ENVIRONMENTAL APEX MANUAL DOCUMENT NO. EAM-442

ENVIRONMENTAL MANAGEMENT SYSTEMS COMPETENCE, TRAINING AND AWARENESS

1.0 PURPOSE 1) To identify training needs and impart appropriate training to personnel whose work create significant impact on environment. 2) To bring awareness about the impacts of activities performed by individual on environment, their roles and responsibilities in achieving conformance to environmental policy, procedures, emergency preparedness and response requirements. 3) To develop competence by imparting training to personnel whose work can cause significant environmental impacts. 2.0 SCOPE 2.1) Awareness Training: All employees and persons working for or on behalf of KBL, Kirloskarvadi like floating/temporary manpower, vendors and residents. 2.2) Competence Training: Any person(s)/employee(s) performing tasks for KBL or on behalf of KBL that have potential to cause a significant environmental impact(s). 3.0 RESPONSIBILITIES 3.1) Competency Related Training and re-training needs are collected (identified) and provided to all persons performing task for or on behalf of KBL that have potential to cause a significant environmental impact(s) by HRM&C-HRD. 3.2) EMS Awareness related training and re-training needs are collected (identified) and provided to all employees and persons working for or on behalf of KBL and maintaining relevant records is responsibility of HRM&C -HRD. 3.3) Evaluation of effectiveness of training imparted by HRM&C -HRD. 3.4) Imparting Internal Audit Training by HRM&C in consultation with MR/AMR. 3.5) Maintain record of competency of all persons performing tasks for or on behalf of KBL that have potential to cause a significant environmental impact(s) on the basis of appropriate education, training or experience. 4.0 PROCEDURE A) Awareness Training: 1) List of persons working for or on behalf of KBL those need training is prepared with details like grade, department by HRM&C -HRD w.r.t. identified needs and/or decision of management.

ISSUE NO. 2 REVISION NO. 0 DATE: - 15.12.2007 PAGE: 1 OF 3 PREPARED & VERIFIED BY: REVIEWED & APPROVED BY: ( K.D. Gandhi) (R.K.Srivastava)

KIRLOSKAR BROTHERS LIMITED

KIRLOSKARVADI 416 308, DIST. SANGLI (INDIA)

ENVIRONMENTAL APEX MANUAL DOCUMENT NO. EAM-442

ENVIRONMENTAL MANAGEMENT SYSTEMS COMPETENCE, TRAINING AND AWARENESS

2) Different training modules are designed by HRD, for all persons at various levels, grades and locations. 3) Training modules are revised based on feedback received, as and when necessary. 4) A schedule of training or training calendar is formulated by HRD and same is communicated to concerned HODs/Employees/Personnel. 5) Keeping record of competency of people based on education, training or experience. 6) To develop competent internal faculty, suitable personnel are identified and necessary training is provided. 7) Awareness/Refresher training programs will be organized every two years to all employees, and persons working on behalf of KBL including temporary personnel. 8) For new employees recruited as temporary workmen, an assessment will be made to check whether they have completed awareness training earlier and if found necessary, awareness training will be imparted. 9) For new employee recruited at the staff cadre, awareness training will be imparted either after the formation of a convenient batch size or every six-month one module or by circulation of training material. 10) The awareness training to ITI-Apprentice, Apprentice/GET Engineers, Other staff will be imparted at the time of recruitment every year. B) Competence Training: 1) HRD collects competence-training needs by sending forms/circular to HODs. 2) HODs identify the training needs of the relevant personnel based on the environmental significance of their activities and the associated operational control procedures. 3) While identifying training needs, the HODs consider following aspects. 3.1) The comp etency requirements about operational control procedure. 3.2) The significant environmental impacts (actual and potential) of their work activities and the expected benefits of improved environmental and personnel performance. 3.3) Their roles and responsibilities in achieving conformance with the environmental policy, procedures and EMS that also includes emergency preparedness and response requirements.

ISSUE NO. 2 REVISION NO. 0 DATE: - 15.12.2007 PAGE: 2 OF 3 PREPARED & VERIFIED BY: REVIEWED & APPROVED BY: ( K.D. Gandhi) (R.K.Srivastava)

KIRLOSKAR BROTHERS LIMITED

KIRLOSKARVADI 416 308, DIST. SANGLI (INDIA)

ENVIRONMENTAL APEX MANUAL

ENVIRONMENTAL MANAGEMENT SYSTEMS COMPETENCE, TRAINING AND AWARENESS

DOCUMENT NO. EAM-442