Chemistry 9.2

Diunggah oleh

Matthew DuongDeskripsi Asli:

Hak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

Chemistry 9.2

Diunggah oleh

Matthew DuongHak Cipta:

Format Tersedia

Chemistry Stage 6

9.2 Production of Materials

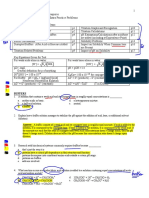

1. Fossil fuels provide both energy and raw materials such as ethylene, for the production of other substances 1.2.1 Identify the industrial source of ethylene from the cracking of some of the fractions from the refining of petroleum Ethylene is produced from natural gas or crude oil which are mixtures of hydrocarbons. Ethylene is often produced using thermal or catalytic cracking of fractions of petroleum. Eg. C11H24 --> C9H20 + H2C=CH2 1.2.2 Identify that ethylene, because of the high reactivity of its double bond, is readily transformed into many useful products Ethylene is readily transformed into many useful products because of the high reactivity of its double bond. It can be transformed into products such as polyethylene, ethanol (CH3CH2OH), ethylene glycol and ethane (CH3CH3). 1.2.3 Identify that ethylene serves as a monomer from which polymers are made Ethylene serves as a monomer from which polymers such as polyethylene, or polystyrene or polyvinyl chloride. 1.2.4 Identify polyethylene as an addition polymer and explain the meaning of this term

An addition polymer is a polymer formed by a polymerisation reaction. This is where a double or triple bond breaks and the reagent adds onto the molecule. Polyethylene is formed from a addition polymerisation reaction of ethylene. 1.2.5 Outline the steps in the production of polyethylene as an example of a commercially and industrially important polymer

Low density polyethylene (LDPE)

Organic peroxides or oxygen used as initiator

Disrupts close regular packing of linear chains and fewer chains

Requires temperature of 300C and atmospheric pressure Fewer side chains, therefore long chains are nearly linear and pack close on cooling Property Flexibility LDPE More flexible Used for sandwich bags, cling wrap and motor vehicle covers Irregular packing- less strong More amorphous ie. Non-crystalline regions Low, so lighter HDPE Rigid Used for freezer bags Strong due to regular packing Suitable for water pipes Less transparent (more crystalline) higher

op

Strength Transparency Density

yr

High density polyethylene (HDPE)

ig

Produces short molecular chains which can have many short branches (2-4C)

ht

Requires a temperature of 100-300C and a pressure of 1500-3000 atm.

Ti

Chain growth polymerisation is started by adding an initiator to the monomer. Most commonly, initiators (eg. Dibutyl peroxide) decompose in light and form free radicals. The feedstocks are provided by ethylene.

ot

hy

Li

Chemistry Stage 6

9.2 Production of Materials

1.2.6 Identify the following as commercially significant monomers: - vinyl chloride - styrene by both their systematic and common names Monomer Vinyl chloride Styrene Systematic name Chloroethene Ethenylbenzene Common name Vinyl chloride Styrene Systematic name for polymer Polychloroethene Poly(ethenylbenzene)

1.2.7 Describe the uses of the polymers made from the above monomers in terms of their properties

Styrene

Polystyrene

1.3.1 Gather and present information from first-hand or secondary sources to write equations to represent all chemical reactions encountered in the HSC course

States must always be included

Ionic equations must include the charges on each ion

1.3.2 identify data, plan and perform a first-hand investigation to compare the reactivities of appropriate alkenes with the corresponding alkanes in bromine water The reactivity of cyclohexane and cyclohexene can be compared directly using bromine water. They are appropriate because they are both liquids at room temperature and pressure.

C6H12 (l) + Br2 (soln) ---> C6H11Br

1.3.3 analyse information from secondary sources such as computer simulations, molecular model kits or multimedia resources to model the polymerisation process Polymerisation can be modeled using chemical modeling kits. The double bond in the ethylene is broken, and allows for the monomer units to bond together.

op

Cyclohexene (C6H10) When added to bromine water, the brown colour of the bromine solution is quickly decolourised. It is an addition reaction. The reactivity of its double bond allows for this quick reaction. Br + H2O l HOBr + Br- + H+ C6H10 (l) + Br2 (soln) ---> C6H10Br2 (soln)

yr

ig

Cyclohexane (C6H12) When added to bromine water, the brown colour of Br2 remains, but slowly fades due to presence of UV light. It is a substitution reaction.

(soln)

ht

+ HBr (aq)

Ti

Equilibrium reactions can be denoted using the reversible arrow:

m

l

Equations must always be balanced

ot

hy

Good thermal, sound and insulation properties

Li

Monomer Vinyl chloride

Polymer Polyvinyl chloride (PVC)

Use Electrical conduit indoors Underground water pipers Transparent sheets and pipes Disposable cups

Property Not weather resistant

Chemistry Stage 6

9.2 Production of Materials

2. Some scientists research the extraction of materials and energy from biomass to reduce our dependence on fossil fuels 2.2.1 discuss the need for alternative sources of the compounds presently obtained from the petrochemical industry Alternative sources for petrochemical industries is required because the world's crude oil supply is limited and will be depleted in the future. Ethene is obtained from crude oil and when crude oil is no longer available, ethene will have to be obtained from alternative sources. Current research: ethanol can obtained from sugar cane crops and converted to ethene which is the starting point for compounds in the petrochemical industry.

A condensation polymer is the polymer formed from a condensation polymerisation reaction eg. nylon-66, proteins from amino acids 2.2.3 describe the reaction involved when a condensation polymer is formed The monomers will bond together and small molecule (usually water) is lost. eg. organic acid + alkanol --> ester + water

Cellulose is produced from glucose monomer units (produced during photosynthesis) with a flat, rigid and straight structure. It is insoluble in water. CH2OH groups on alternate sides of adjoining glucose units

hyxdroxy groups form H-bonding which in turn results in long, strong cellulose fibres each glucose unit is inverted; tipped "upside down"

ht C op yr ig

2.2.5 identify that cellulose contains the basic carbon-chain structures needed to build petrochemicals and discuss its potential as a raw material Cellulose structure has three carbon-chain and four carbon-chains present with glucose monomer units and attached hydrogen and hydroxy groups. These basic carbon-chain structures can be changed to be a raw material for production of petrochemicals. Cellulose is biomass and could be used as a fossil fuel. However, work and research must continue before cellulose can be economically viable and efficient to be able to be used as a raw material in today's society.

Ti

Cellulose is an example of a condensation polymer formed from glucose monomer units and the elimination of a water molecule. 50% of most dry plant material consists of cellulose. HO - C6H10O4 - OH HO - C6H10O4 - OH HO -

ot

2.2.4 describe the structure of cellulose and identify it as an example of a condensation polymer found as a major component of biomass

hy

Li

2.2.2 explain what is meant by a condensation polymer

Chemistry Stage 6

9.2 Production of Materials

2.3.1 use available evidence to gather and present data from secondary sources and analyse progress in the development and use of a named biopolymer. This analysis should name the specific enzyme(s) used or organism used to synthesise the material and an evaluation of the use or potential use of the polymer produced related to its properties Biopolymers are biodegradable because they are capable of being decomposed. Polylactic Acid (PLA)

Monomer is lactic acid Alcaligenes eutrophus can be fed starch, and produced the lactic acid monomers produced by the bacterial digestion of starch waste The bacteria then converts the lactic acid to the PLA polymer PLA is strong, flexible and biodegradable

op

yr

ig

ht

Ti

ot

hy

Potential use of PLA includes: medical implants, agricultural mulch films, disposable plastics.

Li

Chemistry Stage 6

9.2 Production of Materials

3. Other resources, such as ethanol, are readily available from renewable resources such as plants 3.2.1 describe the dehydration of ethanol to ethylene and identify the need for a catalyst in this process and the catalyst used Dehydrating ethanol produces ethylene as shown by the equation below: CH3-CH2-OH (g) ---> CH2=CH2 (g) + H2O (l) An acid catalyst is needed in this process (usually concentrated H2SO4) and must be heated for the reaction to occur (approx. 180C)

Hydrating ethylene by adding water results in the production of ethanol as shown by the equation below: CH2=CH2 + H2O (g)

lCH3-CH2-OH (g)

This is done by passing ethylene and steam over a solid phosphoric acid catalyst. As this is a reversible exothermic reaction, large amounts of water and high pressure will favour the production of ethanol. A working temperature of 300C is needed for this reaction. 3.2.3 describe and account for the many uses of ethanol as a solvent for polar and non-polar substances Ethanol is used as a solvent for many polar and non-polar substances such as:

Glucose and sucrose Carboxylic acids Amino acids Water Food colourings Cosmetics

This is because ethanol is a very polar molecule: the C-O and O-H bonds. Hydrogen bonding also allows ethanol and water to be miscible, along with various other substances. As a result, ethanol can be used widely as a solvent due to bond polarity and hydrogen bonding. 3.2.4 outline the use of ethanol as a fuel and explain why it can be called a renewable resource Ethanol can be used as a fuel because it can readily combust: C2H5OH (l) + 3O2 (g) ---> 2CO2 (g) +3H2O (g) It has been used as a petrol extender in the past. Brazil in the '70s and '80s attempted using ethanol as its major fuel for cars, but the experiment proved too expensive and was abandoned.

3.2.5 describe conditions under which fermentation of sugars is promoted

op

Ethanol can be called a renewable resource because it is made from carbon dioxide, water and sunlight and when burnt produces carbon dioxide and water which can be reconverted to ethanol.

Conditions under which fermentation of sugars is promoted:

Suitable grain or fruit mashed with water Presence of yeast Air is excluded Temperature of approx 37C

yr

ig

ht

Ti

ot

hy

Li

3.2.2 describe the addition of water to ethylene resulting in the production of ethanol and identify the need for a catalyst in this process and the catalyst used

Chemistry Stage 6

9.2 Production of Materials

3.2.6 summarise the chemistry of the fermentation process Enzymes in the yeast convert the starch and sucrose into glucose and/or fructose. Other enzymes break down these sugars into ethanol and carbon dioxide. C6H12O6 (aq) ---> 2CH3-CH2-OH (aq) + 2CO2 (g) Yeast can produce ethanol contents up to 15%. When the concentration of ethanol is above this level, it kills the yeast and stops further fermentation. To produce higher concentrations, the liquid must be distilled. 3.2.7 define the molar heat of combustion of a compound and calculate the value for ethanol from first-hand data

DH = mCDt

Molar heat of combustion can also be defined as minus the enthalpy change for the combustion reaction.

3.2.9 identify the IUPAC nomenclature for straight-chained alkanols from C1 to C8

3.3.1 process information from secondary sources such as molecular model kits, digital technologies or computer simulations to model - the addition of water to ethylene - the dehydration of ethanol As before, the reactions were modelled using molecular model kits. Additions of water to ethylene: this caused ethylene to react to form ethanol Dehydration of ethanol: produces ethylene

op

The ending -ane/-ene is replaced with -anol eg. ethane and ethanol

yr

ig

ht

Stem MethEthButPropPentHexHeptOct-

Ethanol; while being promoted as a renewable resource, requires large amounts of energy such as fossil fuels for fertilisers and the distillation process. Ethanol currently has a potential as a liquid fuel when oil runs out, though current technologies have still yet to be developed. More research will have to be conducted to be able to use ethanol as a viable alternative for a fuel. Advantages Disadvantages Current engines can use ethanol up Large areas of agricultural land to 10 to 20% without modifications needed to produce ethanol Renewable resource Subsequent problems eg. Soil erosion, deforestation, disposal of Could reduce greenhouse gas fermentation liquors. emissions ie. Carbon dioxide released in combustion is equal to Less energy released in amount used in synthesis combustion

Ti

Number of carbon atoms 1 2 3 4 5 6 7 8

ot

3.2.8 assess the potential of ethanol as an alternative fuel and discuss the advantages and disadvantages of its use

hy

Li

The molar heat of combustion of a compound is the heat liberated when one mole of the compound undergoes complete combustion with oxygen at atmospheric pressure; with the products being carbon dioxide gas and liquid water.

Chemistry Stage 6

9.2 Production of Materials

3.3.2 process information from secondary sources to summarise the processes involved in the industrial production of ethanol from sugar cane In the industrial production of ethanol from sugar cane, the ethanol is produced by fermentation. Crushed sugar cane is placed into the fermenter and yeast is added. The concentration of ethanol is maintained at about 5%, by constantly removing the ethanol as it is produced. Eventually the ethanol is distilled to a high purity. 3.3.3 process information from secondary sources to summarise the use of ethanol as an alternative car fuel, evaluating the success of current usage Ethanol can be used as a petrol additive to reduce air pollution. Currently, up to 10% of petrol can contain ethanol, and no modifications are required for the engine. It is used as:

substitute for lead additives which are used to boost octane performance adding oxygen to petrol which lowers carbon monoxide emissions

However, it is currently uneconomical to use ethanol as a car fuel, as it is extremely expensive to produce it; especially in the distillation processes.

3.3.4 solve problems, plan and perform a first-hand investigation to carry out the fermentation of glucose and monitor mass changes Yeast and glucose were placed together into water inside a conical flask. The conical flask was sealed with Parafilm and the side had a rubber tube leading into a limewater solution. Before it was allowed to ferment, the entire flask was weighed, and it was also weighed afterwards. The limewater turned milky, indicating that carbon dioxide gas was indeed released during the fermentation. The mass changes were calculated using the data obtained by using the balance.

C6H12O6 (aq) ---> 2CH3-CH2-OH (aq) + 2CO2 (g)

op

Measure mass of spirit burner before lighting Burn fuel until water has changed by 10 degrees Measure mass of spirit after Use ethanol, 1- propanol, methanol

yr

ig

ht

3.3.6 identify data sources, choose resources and perform a first-hand investigation to determine and compare heats of combustion of at least three liquid alkanols per gram and per mole

Ti

3.3.5 present information from secondary sources by writing a balanced equation for the fermentation of glucose to ethanol

ot

hy

Li

Chemistry Stage 6

9.2 Production of Materials

4. Oxidation-reduction reactions are increasingly important as a source of energy 4.2.1 explain the displacement of metals from solution in terms of transfer of electrons A displacement reaction is one in which a metal converts the ion of another metal to the neutral atom. This results in the transfer of electrons. 4.2.2 identify the relationship between displacement of metal ions in solution by other metals to the relative activity of metals The more reactive metal will displace the other metal from a solution of its ions. This reactivity is given in the activity series.

4.2.3 account for changes in the oxidation state of species in terms of their loss or gain of electrons

A gain of electrons is reduction; while a loss is oxidation. In oxidation, the oxidation state of the ion increases and decreases in reduction. 4.2.4 describe and explain galvanic cells in terms of oxidation/reduction reactions

4.2.5 outline the construction of galvanic cells and trace the direction of electron flow

4.2.6 define the terms anode, cathode, electrode and electrolyte to describe galvanic cells Anode- produces free electrons from oxidation Cathode- accepts free electrons due to reduction reaction. Electrode- either anode or cathode, they are connected to an external circuit. Electrolyte- a substance which in solution or molten state conducts electricity. Mnemonic to remember: REDOX: RED(reduction) CAT(cathode) --- AN(anode) OX(oxidation)

4.3.1 perform a first-hand investigation to identify the conditions under which a galvanic cell is produced A galvanic cell is produced when metal plates are placed in their metal solutions, and a salt bridge connecting the two electrolyte solutions. An external circuit must be present so that electrons can flow around. emf generated depends on the nature of the half-cells and the concentration of the electrolytes and the temperature.

op

yr

ig

ht

Ti

Galvanic cells consist of two-half cells with electrolyte solutions connected by a salt bridge (usually KNO3). Electrons flow through the electrodes into the external circuit, while the salt bridge allows for the migration of ions to maintain electrical neutrality in both electrolyte solutions. The salt bridge must not form any precipitates with ions traveling through it. Electrons flow from the anode to the cathode.

Redox (reduction-oxidation) reactions involve transferring electrons, and resulting in electricity. Galvanic cells are constructed so that one half-cell oxidation produces free electrons, while the reduction half-cell requires electrons. When they are connected, electrons will flow from one half-cell to the other and produce electricity.

ot

hy

The oxidation state of monatomic ions is the charge on the ion. A change in the oxidation state represents a loss or gain of electrons eg. Fe2+ ---> Fe3+ + e-

Li

K Na Li Ba Ca Mg Al Zn Fe Sn Pb Cu Ag Pt Au

Chemistry Stage 6

9.2 Production of Materials

4.3.2 perform a first-hand investigation and gather first-hand information to measure the difference in potential of different combinations of metals in an electrolyte solution The potential difference generated can be calculated by adding the oxidation and reduction potentials together. It can also be measured by placing a voltmeter in the circuit where the electrons flow. 4.3.3 gather and present information on the structure and chemistry of a dry cell or lead-acid cell and evaluate it in comparison to one of the following: - button cell - fuel cell - vanadium redox cell - lithium cell - liquid junction photovoltaic device (eg the Gratzel cell) in terms of: - chemistry - cost and practicality - impact on society - environmental impact Dry Cell Chemistry Oxidation: Zn --> Zn2+ +2eReduction: NH4 + MnO2 + H2O + e- --> Mn(OH)3 + NH3 Relatively cheap Easily mass produced Easy to store and use Useful where only small currents are required Leakage problems imminent Not very efficient; low current for its large size Button cell Oxidation reaction: Zn + 2OH- --> ZnO + H2O + 2e-

ht

Impact on society

ig

4.3.4 solve problems and analyse information to calculate the potential requirement of named electrochemical processes using tables of standard potentials and half-equations The emf generated can be calculated by:

op

Environmental impact

First largely commercialised battery cell Made portable objects such as torches and clocks possible and feasible Effect on environment is extremely small. The Mn3+ is oxidised to insoluble manganese(IV) oxide and as a result it is immobilised. Small amounts of zinc, NH4 salts and carbon are harmless. Not rechargeable, causing increased landfill

yr

taking the more positive reduction potential (further down the table); this is the reduction reaction changing the less positive reduction potential (higher up) adding the two values together

Ti

Cost and practicality

ot

Reduction reaction: Ag2O + H2O + 2e- --> 2Ag + 2OHVery small Considerable amounts of electricity can be produced Constant voltage is produced (1.6V) Long lifespan Easy to store and use Much more expensive to produce than dry cells Can be easily lost due to small size Allows for miniature electrical appliances (watches, hand-held calculators, hearing aids) Non-toxic (so possible inside the body) Not rechargeable, causing increased landfill Small amounts of zinc and silver are harmless to the environment.

hy

Li

Chemistry Stage 6

9.2 Production of Materials

5. Nuclear chemistry provides a range of materials 5.2.1 distinguish between stable and radioactive isotopes and describe the conditions under which a nucleus is unstable Radioactive isotopes emit radiation in the form of alpha, beta, positron or gamma rays to become a stable isotope of any given particular element. This is caused by the instability of the nucleus of the atom. The stabilising process in which unstable atoms undergo is known as radioactive decay. Isotopes that are stable do not emit radiation. Eg. Carbon-12 is stable and carbon-14 is radioactive.

There are three situations in which radioactive decay results:

Nucleon number too large: The nucleon number is reduced by alpha decay Excess protons: Positrons are released when protons decay

Excess neutrons: Beta radiation is produced when neutrons decay. One extra proton is formed during decay. Alpha Helium nucleus 4 He

2

Composition

An isotope is unstable if: 1. If the atomic number is greater than 83

2. If its ratio of neutrons to protons lies outside the zone of stability 5.2.2 describe how transuranic elements are produced

5.2.3 describe how commercial radioisotopes are produced

op

5.2.4 identify instruments and processes that can be used to detect radiation The Geiger-Miller counter can be used to detect radiation by the radiation entering through the end window of the tube and hitting a gas molecule (usually argon). This ionises the argon by knocking an electron off. The high voltage accelerates the electron and ionises more argon molecules and so a cascade of electrons reach the end electrode. This electrical pulse can be amplified and measured. The scintillation counter uses the fact that certain substances when emitting radiation, also emit a flash of light which can be collected and amplified in a photomultiplier. The electrical signal then operates an electronic counter.

yr

Commercial radioisotopes are produced by placing fuel elements into the reactor core for about one week. The uranium decays to molybdenum-99. During its time in the technetium-99m generator, the Molybdenum-99 continually decays to technetium-99m. When the generator reaches its final destination, the technetium-99m can be extracted without removing it from the heavily shielded container. This is achieved by flowing normal saline solution through the alumina.

ig

ht

Transuranic (elements with larger mass than uranium) were originally produced by bombarding nuclei with neutrons. As technology developed, transuranic elements were produced by bombarding large nuclei with positive particles of a high velocity such as helium and carbon.

Ti

ot

Beta Electron 0 e

-1

hy

Gamma Electromagnetic radiation

Li

The conditions under which becomes unstable depends primarily on the ratio of neutrons to protons and the combined number of nuclear particles (nucleons).

Chemistry Stage 6

9.2 Production of Materials

5.2.5 identify one use of a named radioisotope: - in industry - in medicine Technetium-99m is used in medical diagnosis, especially to detect circulation disorders. Americium-241 is used in thickness gauges. 5.2.6 describe the way in which the above named radioisotope is used and explain its use in terms of its chemical properties Technetium-99m is used because it has a short half-life (6 hrs) and causes minimal damage to the patient. It can also be detected with a scintillation counter. Cobalt-60 is used in thickness gauges because it has fairly low energy emissions and a long half-life (5 yrs) so that the source does not have to be frequently replaced. The amount of radiation passing through the material is detected and it controls the manufacturing process.

5.3.2 use available evidence to analyse benefits and problems associated with the use of radioactive isotopes in identified industries and medicine

Low energy emission level is just enough for gamma cameras to detect, yet cause very little damage to the patient

No side effects on patient

Requires nuclear reactor for production

Americium-241 in medicine: Benefits:

op

Low energy emissions mean that safety is enhanced, leading to minimal safety precautions Long half-life means source does not need to be replaced frequently

Problems:

Use of such a radioisotope/detector system requires precision and often requires computer controlled feedback systems; which can be expensive to maintain Radioactive waste must be disposed of using safety procedures; despite its low energy emission levels and long half-life.

yr

Requires technetium-99m generator for production

ig

Problems:

ht

Different forms of technetium-99m means that it will travel to different organs in the body, thus allowing for specific diagnostics

Ti

Short half-life of 6 hours means that radioisotope decays very quickly and causes very little damage to the patient

Technetium-99m in medicine: Benefits:

ot

23 additional elements with atomic numbers up to 118 have been produced. The first transuranic element was produced in the 1940s within the containment of a nuclear reactor. This element was Neptunium. The most recent production of a transuranic element is element 118 at Russias Joint Institute for Nuclear Research in Dubna.

hy

5.3.1 process information from secondary sources to describe recent discoveries of elements

Li

Anda mungkin juga menyukai

- Shoe Dog: A Memoir by the Creator of NikeDari EverandShoe Dog: A Memoir by the Creator of NikePenilaian: 4.5 dari 5 bintang4.5/5 (537)

- Grit: The Power of Passion and PerseveranceDari EverandGrit: The Power of Passion and PerseverancePenilaian: 4 dari 5 bintang4/5 (587)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDari EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RacePenilaian: 4 dari 5 bintang4/5 (890)

- The Yellow House: A Memoir (2019 National Book Award Winner)Dari EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Penilaian: 4 dari 5 bintang4/5 (98)

- The Little Book of Hygge: Danish Secrets to Happy LivingDari EverandThe Little Book of Hygge: Danish Secrets to Happy LivingPenilaian: 3.5 dari 5 bintang3.5/5 (399)

- On Fire: The (Burning) Case for a Green New DealDari EverandOn Fire: The (Burning) Case for a Green New DealPenilaian: 4 dari 5 bintang4/5 (73)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDari EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifePenilaian: 4 dari 5 bintang4/5 (5794)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDari EverandNever Split the Difference: Negotiating As If Your Life Depended On ItPenilaian: 4.5 dari 5 bintang4.5/5 (838)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDari EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FuturePenilaian: 4.5 dari 5 bintang4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDari EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryPenilaian: 3.5 dari 5 bintang3.5/5 (231)

- The Emperor of All Maladies: A Biography of CancerDari EverandThe Emperor of All Maladies: A Biography of CancerPenilaian: 4.5 dari 5 bintang4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDari EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You ArePenilaian: 4 dari 5 bintang4/5 (1090)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDari EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyPenilaian: 3.5 dari 5 bintang3.5/5 (2219)

- Team of Rivals: The Political Genius of Abraham LincolnDari EverandTeam of Rivals: The Political Genius of Abraham LincolnPenilaian: 4.5 dari 5 bintang4.5/5 (234)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDari EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersPenilaian: 4.5 dari 5 bintang4.5/5 (344)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDari EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaPenilaian: 4.5 dari 5 bintang4.5/5 (265)

- Rise of ISIS: A Threat We Can't IgnoreDari EverandRise of ISIS: A Threat We Can't IgnorePenilaian: 3.5 dari 5 bintang3.5/5 (137)

- The Unwinding: An Inner History of the New AmericaDari EverandThe Unwinding: An Inner History of the New AmericaPenilaian: 4 dari 5 bintang4/5 (45)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Dari EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Penilaian: 4.5 dari 5 bintang4.5/5 (119)

- Her Body and Other Parties: StoriesDari EverandHer Body and Other Parties: StoriesPenilaian: 4 dari 5 bintang4/5 (821)

- Mixed Gas Laws WorksheetDokumen6 halamanMixed Gas Laws WorksheetMarkJin is LIFEBelum ada peringkat

- Performance Evaluation of Reciprocating Compressors Operating Wit PDFDokumen7 halamanPerformance Evaluation of Reciprocating Compressors Operating Wit PDFAnonymous KTQZaIBelum ada peringkat

- Separation Process 1Dokumen86 halamanSeparation Process 1hanisshi50% (4)

- Questions On ISE Choose The Correct AnswerDokumen3 halamanQuestions On ISE Choose The Correct Answerنيرمين احمدBelum ada peringkat

- Chemical Bonding ExplainedDokumen10 halamanChemical Bonding ExplainedMYLENE B. ZABALLEROBelum ada peringkat

- Statlyte C Plus User ManualDokumen36 halamanStatlyte C Plus User ManualtantoBelum ada peringkat

- Anodes and Cathodes in Corrosion ReactionsDokumen10 halamanAnodes and Cathodes in Corrosion ReactionsSyed50% (4)

- Calculus of Variation 1Dokumen56 halamanCalculus of Variation 1Enny MurwaningtyasBelum ada peringkat

- HuckelDokumen167 halamanHuckelShivansh BhatnagarBelum ada peringkat

- 1 s2.0 S0038092X19308205 Main1Dokumen29 halaman1 s2.0 S0038092X19308205 Main1fguiriBelum ada peringkat

- AFE Cavite: Product BulletinDokumen2 halamanAFE Cavite: Product BulletinyfcozBelum ada peringkat

- Nernst EquationDokumen10 halamanNernst Equationaceyourchemistry.blogspot.com.sgBelum ada peringkat

- Inorganica Chimica Acta: Research PaperDokumen7 halamanInorganica Chimica Acta: Research Paperhenry martinez quiñonezBelum ada peringkat

- Materials Science & Engineering B: SciencedirectDokumen10 halamanMaterials Science & Engineering B: SciencedirectMuhammad BramansyahBelum ada peringkat

- Calculation of Planck Constant Using Photocell: Name: Shivam Roll No.: 20313127Dokumen13 halamanCalculation of Planck Constant Using Photocell: Name: Shivam Roll No.: 20313127shivamBelum ada peringkat

- J Eurpolymj 2020 109485Dokumen63 halamanJ Eurpolymj 2020 109485MZeeshanAkramBelum ada peringkat

- A-Ele-Lst-000-47961-B - Test Facility Schedule For Pipeline Cathodic Protection SystemDokumen23 halamanA-Ele-Lst-000-47961-B - Test Facility Schedule For Pipeline Cathodic Protection SystemBadiBelum ada peringkat

- Controlling Steam HeatersDokumen12 halamanControlling Steam HeatersSreedhar Patnaik.MBelum ada peringkat

- TUTORIAL 3 Thermodynamics PDFDokumen5 halamanTUTORIAL 3 Thermodynamics PDFNelson0% (1)

- Iodine Spectrum AnalysisDokumen3 halamanIodine Spectrum AnalysisShouvik MitraBelum ada peringkat

- Fundamentals of Cooling II - Humidity in The Data Center Transcript-LVDokumen14 halamanFundamentals of Cooling II - Humidity in The Data Center Transcript-LVJean Constantin Eko MedjoBelum ada peringkat

- Chapter 2Dokumen49 halamanChapter 2Umesh Chandra100% (1)

- Survey of Worldwide Experience with Metal DustingDokumen12 halamanSurvey of Worldwide Experience with Metal Dustingsoubhadra nag100% (1)

- Test3 Ch17b Buffer Titration Equilibrium Practice Problems Answers Full 2015Dokumen18 halamanTest3 Ch17b Buffer Titration Equilibrium Practice Problems Answers Full 2015Anas SaadBelum ada peringkat

- Measure Moisture Content Using Direct and Indirect MethodsDokumen8 halamanMeasure Moisture Content Using Direct and Indirect MethodsJet Ronnie DacayaBelum ada peringkat

- 3M Fluorinert Liquids For Electronics ManufacturingDokumen4 halaman3M Fluorinert Liquids For Electronics ManufacturingIon ZabetBelum ada peringkat

- Acetaldehyde SsDokumen26 halamanAcetaldehyde Sssangmesh shivpureBelum ada peringkat

- A Single Step Non-Catalytic Esterification of Palm Fatty Acid Distillate (PFAD) ForDokumen8 halamanA Single Step Non-Catalytic Esterification of Palm Fatty Acid Distillate (PFAD) ForNestor Armando Marin SolanoBelum ada peringkat

- FTIRDokumen5 halamanFTIRAllisya HaneeBelum ada peringkat

- General Chemistry Exam 1Dokumen10 halamanGeneral Chemistry Exam 1Bethany Wong100% (1)