Equations

Diunggah oleh

IbraximRamirezDeskripsi Asli:

Hak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

Equations

Diunggah oleh

IbraximRamirezHak Cipta:

Format Tersedia

~

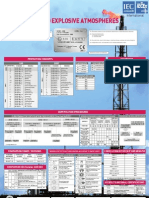

HOOD TYPE

DESCRIPTlON

-

AIR FLOW

SLOT

0.2 OR LESS

0 = 3.7 Lvx

FLANGED SLOT

0.2 OR LESS

0 = 2.6 LVX

X A = WL (Ft2)

H

W

PLAIN OPENING

0.2 OR GREATER

AND ROUND

0 = V(1OX +A)

FLANGED OPENING

m

X

0.2 OR GREATER AND ROUND

Q = 0.75V(10XZ+A)

BOOTH

TO SUIT WORK

Q=VA=VWH

CANOPY

0 = 1.4 PVD SEE FIG. VS-99-03

TO SUIT WORK

P = PERIMETER D = HEIGHT ABOVE WORK

ww

AMERICAN CONFERENCE OF GOVERNMENTAL INDUSTRIAL HYGIENISTS

PLAIN MULTIPLE SLOT OPENING 2 OR MORE SLOTS

0.2 OR GREATER

= V(lOXz+A)

FLANGED MULTIPLE SLOT OPENING 2 OR MORE SLOTS

0.2 OR GREATER

= D.75V(10X2+A)

HOOD TYPES'

DAm

d- 96

1FIGURE

From American Conference of Governmental Industrial Hygienists: Industrial Ventilation: A Manual of Recommended Practice, 24" Edition; Copyright 2001, Cincinnati, Ohio. Reprinted with permission.

14

HOOD TYPE

DESCRIPTION

HOOD ENTRY LOSS (F,,) COEFFICIENT

00

6 2

Qi

PLAIN OPENING

0.93

FLANGED OPENING

0.49

TAPER OR CONE HOOD

SEE CHAPTER 10

D-

BELL MOUTH INLET

0.04

ORIFICE

SEE CHAPTER 10

(STRAIGHT TAKEOFF) TYPICAL GRINDING HOOD

0.65

(TAPERED TAKEOFF)

0.40

ONFERENCE OF GOVERNMENTAL INDUSTRIAL HYGIENISTS

HOOD LOSS COEFFICIENTS

FIGURE

3-16

From American Conference of Governmental Industrial Hygienists: Industrial Ventilation: A Manual of Recommended Practice, 24 Edition; Copyright 2001, Cincinnati, Ohio. Reprinted with permission.

15

he= 0.93 VPd

he= 0.49 VPd

he= 0.04 VPd

PLAIN DUCT END

FLANGED DUCT END

toper ongle

BELLMOUTH ENTRY

, r Orifice

- 9

he=

1.5 VP,

he= 1.78 Wwke

SHARP-EDGE0 ORIFICE TAPERED HOOOS

Flonged or unflonged; round. square or rectongulor. 8 is the mojor ongle on rectongulor hoods.

c

w

V

k W

0

0

v, v,

9

>-

Foce ore0 (A,)

01 leost 2 times the duct oreo.

i'P = Duct = W,j Note: 1 8 0 volues represent round ducts butted into bock of booth or hood without o rectongulor to round tronsition.

E

W

I F

e.

~~

INCLUDED ANGLE IN DEGREES

COMPOUND HOODS

A compound hood, such 0s the slot/plenum shown to the right. would hove 2 losses, one through .the slot ond the other through the tronsition into the duct.

The slot entry loss coefficient. F , , would hove o volue typicolly in the ronge of 1.00 to 1.78 (see Chopters 3 and 10).

5

=

MISCELLANEOUS VALUES ENTRY LOSS h COEFFICIENT F Abrosive blost chomber 1.0 Abrosive blost elevator 23 . Abrosive seporotor 23 . Elevotors (enclosures) 0.69 Flmged pipe plus close elbow 0.8 Plain pipe plus dose elbow 1.60

The duct entry loss coefficient is given by the obove doto for topered hoods.

he

F s

w s

FhVPd

AMERICAN CONFERENCE OF GOVERNMENTAL 'INDUSTRIAL HYGIENISTS

TDATE

16

HOOD ENTRY LOSS COEEFICIENTS

1-95

FIGURE

5-15

From American Conference of Governmental Industrial Hygienists: Industrial Ventilation: A Manual of Recommended Practice 24IhEdition; Copyright 2001 Cincinnati, Ohio. Reprinted with permission.

Stamped (Smooth)

5-piece

4-piece

3-piece

Mitered

extropoloted from published doto

OTHER ELBOW LOSS COEFFICIENTS Mitered, no vanes 1.2 Mitered. turning vanes 0.6 Fiotbock (R/D = 2.5) 0.05

(see Figure 5- 23)

NOTE: Loss foctors ore assumed to be for elbows of "zero length." Friction losses should be included to the intersection of centerlines.

ROUND ELBOW LOSS COEFFICIENTS

(Ref. 5.13)

SC ARE __ RECT-NGULAR ELBOW LOSS COEFFICIENTS

AMERICAN CONFERENCE O F GOVERNMENTAL INDUSTRIAL HYGIENISTS

DUCT DESIGN DATA ELBOW L O S S E S

From American Conference of Governmental Industrial Hygienists: Industrial Ventilation: A Manual of Recommended Practice, 24"' Edition; Copyright 2001, Cincinnati, Ohio. Reprinted with permission.

17

15Omax.

Angle 0 Degrees

Loss Fraction of VP

in Branch

20 25 30 35 40 45 50 60 90

0.12 0.15 0.18 0.21 0.25 0.28 0.32 0.44 1.00

~

~.

Note: Branch entry loss assumed to occur in branch and is so calculated. Do not include an enlargement regain calculation for branch en try enlargements.

BRANCH ENTRY LOSSES

H, No. of Diamet ers

Loss Fraction of VP

1.0

0.75 0.70 0.65 0.60 0.55 0.50 0.45

D D D D D D D D

0.10 0.18

0.22 0.30 0.41 0.56 0.73 1.o

CAP LOSSES

See Fig. 5-30

AMERICAN CONFERENCE OF GOVERNMENTAL INDUSTRIAL HYGIENISTS

DUCT DESIGN DATA

DATE

1-95

FIGURE

5-1 7

From American Conference of Governmental Industrial Hygienists: Industrial Ventilation: A Manual of Recommended Practice, 24IhEdition; Copyright 2001, Cincinnati, Ohio. Reprinted with permission.

18

STATIC PRESSURE REGAINS FOR EXPANSIONS

4 1

t-4 D min

~~

Regoin (R). fraction of VP difference Toper onglel Diameter rotios

Reqoin (R). froction of inlet VP

D2/D,

When SP2 =O (atmosphere) SP, will be (-)

. I

The regain (R) will only be 70% of value shown above when expansion follows a disturbance or elbow (including a fan) by less than 5 duct diameters.

STATIC PRESSURE LOSSES FOR CONTRACTIONS

Ratio &/A,

01 . 0.2 0.3 0.4 0.4

0.6

L

0.48 0.46 0.42 0.37 0.32

0.26

0.7

0.20

AMERICAN CONFERENCE OF GOVERNMENTAL INDUSTRIAL HYGIENISTS

DUCT DESIGN DATA

'DATE

1-95

FIGURE

5-18

From American Conference of Governmental Industrial Hygienists: Industrial Ventilation: A Manual of Recommended Practice, 24" Edition; Copyright 2001, Cincinnati, Ohio. Reprinted with permission.

19

Anda mungkin juga menyukai

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDari EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RacePenilaian: 4 dari 5 bintang4/5 (895)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDari EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifePenilaian: 4 dari 5 bintang4/5 (5794)

- The Yellow House: A Memoir (2019 National Book Award Winner)Dari EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Penilaian: 4 dari 5 bintang4/5 (98)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDari EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FuturePenilaian: 4.5 dari 5 bintang4.5/5 (474)

- Shoe Dog: A Memoir by the Creator of NikeDari EverandShoe Dog: A Memoir by the Creator of NikePenilaian: 4.5 dari 5 bintang4.5/5 (537)

- The Little Book of Hygge: Danish Secrets to Happy LivingDari EverandThe Little Book of Hygge: Danish Secrets to Happy LivingPenilaian: 3.5 dari 5 bintang3.5/5 (399)

- On Fire: The (Burning) Case for a Green New DealDari EverandOn Fire: The (Burning) Case for a Green New DealPenilaian: 4 dari 5 bintang4/5 (73)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDari EverandNever Split the Difference: Negotiating As If Your Life Depended On ItPenilaian: 4.5 dari 5 bintang4.5/5 (838)

- Grit: The Power of Passion and PerseveranceDari EverandGrit: The Power of Passion and PerseverancePenilaian: 4 dari 5 bintang4/5 (588)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDari EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryPenilaian: 3.5 dari 5 bintang3.5/5 (231)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDari EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaPenilaian: 4.5 dari 5 bintang4.5/5 (266)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDari EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersPenilaian: 4.5 dari 5 bintang4.5/5 (344)

- The Emperor of All Maladies: A Biography of CancerDari EverandThe Emperor of All Maladies: A Biography of CancerPenilaian: 4.5 dari 5 bintang4.5/5 (271)

- Team of Rivals: The Political Genius of Abraham LincolnDari EverandTeam of Rivals: The Political Genius of Abraham LincolnPenilaian: 4.5 dari 5 bintang4.5/5 (234)

- Rise of ISIS: A Threat We Can't IgnoreDari EverandRise of ISIS: A Threat We Can't IgnorePenilaian: 3.5 dari 5 bintang3.5/5 (137)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDari EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You ArePenilaian: 4 dari 5 bintang4/5 (1090)

- The Unwinding: An Inner History of the New AmericaDari EverandThe Unwinding: An Inner History of the New AmericaPenilaian: 4 dari 5 bintang4/5 (45)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDari EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyPenilaian: 3.5 dari 5 bintang3.5/5 (2259)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Dari EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Penilaian: 4.5 dari 5 bintang4.5/5 (120)

- Her Body and Other Parties: StoriesDari EverandHer Body and Other Parties: StoriesPenilaian: 4 dari 5 bintang4/5 (821)

- 10.9. Gas Liquid Separators: Chemical EngineeringDokumen6 halaman10.9. Gas Liquid Separators: Chemical EngineeringsterlingBelum ada peringkat

- Gas TurbineDokumen43 halamanGas TurbineMuhammad Qusyairi50% (2)

- Wet Gas Measurement ISO TR 11583Dokumen36 halamanWet Gas Measurement ISO TR 11583Aldrin HernandezBelum ada peringkat

- Tutorial: Water Flooding and WAG Application Builder Grid Properties (Field Units)Dokumen5 halamanTutorial: Water Flooding and WAG Application Builder Grid Properties (Field Units)Erick Morales SánchezBelum ada peringkat

- Dunbar Field Life Extended Using Sulzer Multiphase Pumps PDFDokumen4 halamanDunbar Field Life Extended Using Sulzer Multiphase Pumps PDFAttabik AwanBelum ada peringkat

- Gas Flaring Basic InformationDokumen4 halamanGas Flaring Basic InformationFriday IjokgwungBelum ada peringkat

- Effects of Flash and Vapor Injection On The Air-toAir Heat Pump SystemDokumen9 halamanEffects of Flash and Vapor Injection On The Air-toAir Heat Pump SystemDaniel MilosevskiBelum ada peringkat

- Team 32 - Overall Team ReportDokumen381 halamanTeam 32 - Overall Team Reportapi-20007190100% (4)

- Hydrocracker Complex Presentation For BPST 23Dokumen50 halamanHydrocracker Complex Presentation For BPST 23fbriandityaBelum ada peringkat

- Momentum Transfer IntroductionDokumen7 halamanMomentum Transfer IntroductionEzekielBelum ada peringkat

- Standard Clamping Elements PDFDokumen175 halamanStandard Clamping Elements PDFGiannis IoannouBelum ada peringkat

- Filter Feed PumpDokumen1 halamanFilter Feed Pumpnas_mech8208Belum ada peringkat

- Models - Cfd.droplet BreakupDokumen20 halamanModels - Cfd.droplet Breakuppaler35Belum ada peringkat

- ManualsDokumen34 halamanManualsTreeBelum ada peringkat

- RESONANCE ALP Sol P Fluid Mechanics EDokumen6 halamanRESONANCE ALP Sol P Fluid Mechanics EChandrakant Bokade100% (1)

- SMAW DuniDokumen4 halamanSMAW DuniMuhammad Fitransyah Syamsuar PutraBelum ada peringkat

- Startup Fish BoneDokumen1 halamanStartup Fish BoneAkhmad RoyaniBelum ada peringkat

- H Section 1 Conventional Heat Generation Boiler General Description PDFDokumen579 halamanH Section 1 Conventional Heat Generation Boiler General Description PDFNicolas Pallero FernandezBelum ada peringkat

- Nozzle Joints / Two-Fluid Nozzles Spray Nozzles: Male, Female Ends Female, Female EndsDokumen1 halamanNozzle Joints / Two-Fluid Nozzles Spray Nozzles: Male, Female Ends Female, Female EndsAmpera marzelaBelum ada peringkat

- LV-110120-110220 35-35112 3in ANSI 300Dokumen12 halamanLV-110120-110220 35-35112 3in ANSI 300mggz_15Belum ada peringkat

- MFH Fi CalcDokumen26 halamanMFH Fi CalcNethajiBelum ada peringkat

- Mechanical EquipmentDokumen38 halamanMechanical EquipmentBinodh DanielBelum ada peringkat

- AeroEngineTech 2 FransLoekito 4776887Dokumen9 halamanAeroEngineTech 2 FransLoekito 4776887Frans LoekitoBelum ada peringkat

- Lcie Bureau Veritas Atex Poster PDFDokumen1 halamanLcie Bureau Veritas Atex Poster PDFAncaOniscuBelum ada peringkat

- of PCV ValveDokumen7 halamanof PCV ValveDevesh JaiswalBelum ada peringkat

- 4915 PDFDokumen79 halaman4915 PDFyyamidBelum ada peringkat

- Air Velocity MeasurementDokumen8 halamanAir Velocity Measurementfakursanat3618Belum ada peringkat

- Ge Gas Turbine Frame (9fa)Dokumen7 halamanGe Gas Turbine Frame (9fa)ajo zinzoBelum ada peringkat

- Electrical Nomenclature 02-07Dokumen4 halamanElectrical Nomenclature 02-07Nebur Mtza100% (2)

- Past Board Objective Question HgeDokumen3 halamanPast Board Objective Question HgeFely Joy RelatoresBelum ada peringkat