ChopHoop 6.3.10

Diunggah oleh

Hartono MorshidiDeskripsi Asli:

Hak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

ChopHoop 6.3.10

Diunggah oleh

Hartono MorshidiHak Cipta:

Format Tersedia

612 West Blackhawk St. Sioux Falls, SD 57104-0321 888-366-8265 www.designtanks.

com

CHOP/HOOP FILAMENT WOUND

CORROSION RESISTANT FIBERGLASS TANKS

CHOP/HOOP FILAMENT WOUND CORROSION RESISTANT FIBERGLASS TANKS

TABLE OF CONTENTS

1.0 2.0 3.0

Scope References Design 3.1 3.2 3.3 3.4 General Shell, Heads & Joints Laminate Tank Connections & Appurtenances

4.0

Materials 4.1 4.2 Resin Reinforcement

5.0 6.0

Drawings Fabrication, Inspection & Testing 6.1 6.2 Fabrication Inspection & Testing

CHOP/HOOP FILAMENT WOUND CORROSION RESISTANT FIBERGLASS TANKS 1.0 SCOPE 1.1 This standard covers the design, fabrication, and testing of fiberglass storage tanks for storage of liquids.

2.0

REFERENCES 2.1 All work performed and all materials furnished under this Standard shall conform to the applicable publications and standards of the organization listed below. Latest editions and revisions of the publications and standards listed below shall apply. 2.1.1 American Society for Testing and Materials. 2.1.1.1 Chop/Hoop filament-wound glass fiber reinforced vinyl ester and polyester chemical-resistant tanks shall be manufactured in accordance with ASTM D3299. 2.1.1.2 Classifying Visual Defects in Glass Reinforced Laminates and parts made there from, ASTM C582, table 5. 2.1.1.3 Test for Indentation Hardness of Plastics by means of a Barcol Impressor, ASTM D2583. 2.1.2 American National Standards Institute-B16.5 Steel Pipe Flanges Flanged Fittings.

3.0

DESIGN 3.1 General 3.1.1 It is the object of this specification to provide as much design information as possible. Therefore it is intended that Design Tanks will have ample opportunity to utilize our particular "know-how" in the design and details of the tank fabrication in order to produce tanks which will be adequate for the intended purpose. 3.1.2 Details are often indicated without being fully designed. This permits Design Tanks to submit a design for approval, and it is intended that Design Tanks furnish a design based on the information given which will meet the requirements of the job regarding strength, corrosion resistance, and practicality. 3.1.3 Tanks for installation outdoors should be checked for wind loading. Hold

down lugs would be recommended for all tanks installed outdoors or where there are seismic requirements. 3.1.4 Other design requirements shall be considered such as stiffening in top heads, flange lips for agitated tanks, lifting lugs, etc. When required to meet a specified design. 3.2 Shell, Heads & Joints 3.2.1 Shell thickness design shall be determined based on a full tank of liquid. The tank is designed for the required specific gravity. All thicknesses determined in accordance with this paragraph do not include liners or corrosion barriers. Liners and corrosion barriers shall not normally be considered as contributing structural strength to the laminate.

3.2.2 For chop/hoop filament wound storage tanks subject to hydrostatic head, the minimum wall thickness, shall be determined by the following formula: t = PD SH t = Wall thickness, inches; P = Pressure, psi; D = Inside diameter, inches; SH = Hoop Stress, psi SH = ET Z where: ET = hoop tensile modulus Z = allowable strain of 0.001 in./in. 3.2.3 For chop/hoop filament wound tanks subject to hydrostatic head the minimum physical properties are to be as follows: Tensile Strength (PSI) Flexural Strength (PSI) 29,000 30,000

3.2.4

In no case shall the minimum total wall thickness be less than 1/4" on

chop/hoop filament wound tanks. 3.2.5 On tanks equipped with agitators, suitable reinforcement of lips and wall shall be provided in order to supply required rigidity. The owner must supply agitator weights, downward loads, torque and bending moments, before a final design can be provided. 3.2.6 Open top, vertical tanks shall be constructed with a horizontal flange lip at the top of the tank which shall be of sufficient rigidity to maintain the shape of the tank. 3.2.7 Where top heads of vertical tanks are required to support operating personnel, auxiliary equipment or snow loads, stiffener ribs, thickening of heads or other means shall be used to provide structural rigidity. 3.2.8 Top heads of all vertical tanks shall be annular domes or dished unless otherwise specified on drawings. 3.2.9 All flat bottom, vertical tanks must be continuously supported unless otherwise specified on drawings.

3.2.10 The knuckle radius of all flat bottom tanks shall be 1-1/2" minimum.. The knuckle area shall be reinforced on the chop/hoop filament wound tanks. It shall be reinforced as specified in ASTM D-3299. 3.3. Laminate 3.3.1 If the outer surface of the fabricated product shall be exposed to a corrosive environment, the addition of surface chop over the exterior is available on chop/hoop filament wound tanks if specified. 3.3.2 An ultraviolet outdoor stabilizer can be incorporated in the final coat of resin or pigmentation if specified. The amount of stabilizer shall be per the resin manufacturer's recommendations. 3.3.3 Cut edges exposed to the chemical environment shall be coated with resin. The resin used shall be that designated in the tank design materials and must contain paraffin to assure adequate surface cure. 3.3.4 The laminate shall consist of an inner surface, an interior layer, and an exterior layer or structural laminate.

3.3.5 The compositions specified for the inner surface and the interior layer are

intended to achieve optimum chemical resistance. This portion is also called the inner "corrosion barrier". 3.3.6 The inner surface shall be free of cracks and crazing with a smooth finish and with an average of not over 10 pits per square foot, providing the pits are less than 1/8 inch diameter and not over 1/32 inch deep and are covered with sufficient resin to avoid exposure of inner surface fabric. Some waviness is permissible as long as the surface is smooth and free of pits. Between 7-20 mils of reinforced resin rich surface shall be provided. This surface is reinforced with glass surfacing veil or a synthetic fiber veil. 3.3.7 A minimum of 90 mil of laminate is required in the corrosion barrier and will be reinforced with not less than 27 percent nor more than 33 percent by weight of noncontinuous glass strands having fibers lengths from 0.5 and 2.0 inches.

3.3.8 The exterior layer or body of the laminate shall provide the additional strength necessary to meet the tensile and flexural requirements. Where separate layers such as mat is used, all layers shall be lapped a minimum of one inch. Laps shall be staggered as much as possible. The exterior surface shall be relatively smooth with no exposed fibers or sharp projections. 3.3.9 The overall glass content of hand laminated construction shall be between 27 and 33 weight %. The structural wall glass content of filament wound laminate construction shall be about 50% by weight. 3.3.10 The laminate shall be allowed to cure to tackfree condition at ambient temperature prior to any post cure. 3.4 Tank Connections and Appurtenances 3.4.1 All connections on equipment and tanks will be FRP flanged or female NPT (threads) coupling unless otherwise specified.

3.4.2 Hand lay up flanges are the standard and will be used on all flange connections, unless the owner specifies in writing something other than the standard. 3.4.3 The machine facing of the back of the flanges is permitted. All bolt holes shall be spot faced for SAE size washers if required. 3.4.4 Flange drilling on pipe connections shall be in accordance with ANSI B16.5 for 150# bolting configuration.

3.4.5 Bolt holes in flanged nozzles are to straddle the vertical centerline. 3.4.6 On all flanges, that require blind flanges, full face elastomeric gaskets having a Shore A 40-50 durometer hardness may be specificed. Type 304 bolting hardware will be supplied as a Design Tanks standard with all blind flanges. 4.0 MATERIALS 4.1 Resin 4.1.1 The resin shall be selected by Design Tanks, based on the resin suppliers corrosion guide for the service specified. 4.1.2 For application requiring fire-retardant resins, the level of retardance shall be determined by the owner. Antimony trioxide will be added to the resin selected to meet the retardance level if required. (Not applicable to corrosion liner). 4.1.3 The resin used shall not contain fillers unless specified. When specified, up to 2 to 4% by weight of thixotropic agent Cab-O-Sil, or equal, may be used for viscosity control in the parafinated top coat on vertical surfaces, provided it will not interfere with visual inspection. 4.1.4 The cure system will be catalyzed with MEKP (Methly Ether Ketone Peroxide) with cobalt naphthenate and in some cases, DMA promoters as recommended by the resin supplier. All tanks fabricated to this specification shall be cured to at least 90% of the minimum Barcol hardness specified by the resin manufacturer. This requirement applies to both interior and exterior surfaces. (Note: The use of paraffin wax in the resin or the use of organic fiber veil may lower the Barcol hardness readings without necessarily indicating undercure. A BPO (Benzoyl peroxide) curing agent system is provided for certain chemical contents where specified by resin suppliers. 4.1.5 Ultra violet absorbers and/or pigments may be added to the final resin exterior layer to improve weather resistance. 4.1.6 Wax must be added to the final resin layer in order to prevent air inhibition. 4.1.7 FRP tanks shall be designed and constructed to meet all requirements specified herein and shall be suitable for continuous, 24 hour/day service.

4.2

Reinforcement 4.2.1 Chemical surfacing mat (veil) shall be Type C (Chemical) glass, 10 mils thick, with a silane finish and a binder compatible with the resin on all chop/hoop filament wound tanks. No additives shall be used in corrosion barrier. 4.2.2 Where services require, a type 1012 open Dacron polyester fiber 12 to 16 mils thick, as manufactured by Burlington Industries is utilized (Nexus Liner). Thixotropic agents shall not be used for this service. Equivalent materials may be substitued if specified and agreed to by Owner. Some of the services (contents) where the above is required are: hydrofluoric acid, hydro-fluosilicic acid, sodium hypochlorite, and sodium hydroxide. 4.2.3 Chopped strand mat shall be Type E (electrical borosilicate) glass, minimum 1-1/2 oz. per sq. ft., with silane finish and a styrene soluble reactive binder.

4.2.4 Chopped roving where used in the chop/hoop filament winding will be a type E glass with a silane type finish. 4.2.5 All materials shall be new and be of the best quality of their respective kind.

5.0

DRAWINGS 5.1 Upon acceptance of the purchase order, Design Tanks shall prepare specification sheets or approval drawings, for fabrications. These drawings shall be submitted to Owner for review and approval prior to the start of fabrication, unless approval is not required. The tank service, tank overall dimensions and the Design Tanks name shall appear prominently in all drawing title blocks. The detail drawings shall show the following: 5.3.1 Location and details of all nozzle attachments. 5.3.2 Type of resin. 5.3.3 Thickness of shell and heads (if required for construction).

5.2

5.3

5.3.4 Service temperature. 5.3.5 Specific gravity. 5.3.6 Nozzle schedule, including size. 5.3.7 Requirements for ladder, lifting, hold down, or support lugs. 5.3.8 Equipment capacity (gals). 5.3.9 UV Absorbers or other pigments, if applicable. 5.4 After review of drawings by Owner, any subsequent revisions will be notes on the drawing and approved by Owner.

6.0

FABRICATION, INSPECTION & TESTING 6.1 Fabrication 6.1.1 The tanks shall be constructed in accordance with ASTM D 3299 for filament-wound tanks. 6.1.2 All cured resin surfaces where parts are to be joined shall first be roughened by sanding or grinding. The roughened area shall extend beyond the work area so that no lay-up is made on a mold surface. Surfaces shall be clean and dry before lay-up. The entire roughened area must be resin coated when the joint is made. 6.1.3 All cut edges shall be coated with resin so that no glass fibers are exposed and all voids are filled. 6.1.4 The exterior surface shall be relatively smooth with no exposed fibers or sharp projections. Air bubbles, dry spots, pinholes, pimples and delaminations should be as defined in para. 6.2.3 of this spec. 6.1.5 Tolerances on tank diameter and height shall be in accordance with ASTM D-3299. 6.2 Inspection and Testing 6.2.1 Design Tanks shall make a dimensional check including nozzle dimensions or orientation, tank diameter, height, and thickness.

6.2.2 Evidence or cure will be an established Barcol hardness, which shall be no less than 90% of the resin manufacturer's recommended figure. A cured resin surface shall not become tacky when rubbed with an acetone impregnated cloth. 6.2.3 The level of laminate defects allowable shall be in accordance with ASTM C 582 table 5, "Critical areas" shall be regarded as the internal surfaces in contact with the process solution, flanges, and highly stressed areas such as supports, seams, knuckles, etc. 6.2.4 The owner shall be permitted access, upon request, to the plant area at all times during fabrication. Notification of owner prior to shipping can be arranged by specifying lead time on the purchase order. 6.2.5 Design Tanks shall maintain a quality control program adequate to insure that all fabrications comply with these specifications. All tests shall be witnessed by the quality control inspector.

s:\chophoop.doc- Version2.0, 6.3.10

Anda mungkin juga menyukai

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDari EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifePenilaian: 4 dari 5 bintang4/5 (5794)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDari EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You ArePenilaian: 4 dari 5 bintang4/5 (1090)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDari EverandNever Split the Difference: Negotiating As If Your Life Depended On ItPenilaian: 4.5 dari 5 bintang4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDari EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RacePenilaian: 4 dari 5 bintang4/5 (894)

- Grit: The Power of Passion and PerseveranceDari EverandGrit: The Power of Passion and PerseverancePenilaian: 4 dari 5 bintang4/5 (587)

- Shoe Dog: A Memoir by the Creator of NikeDari EverandShoe Dog: A Memoir by the Creator of NikePenilaian: 4.5 dari 5 bintang4.5/5 (537)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDari EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FuturePenilaian: 4.5 dari 5 bintang4.5/5 (474)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDari EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersPenilaian: 4.5 dari 5 bintang4.5/5 (344)

- Her Body and Other Parties: StoriesDari EverandHer Body and Other Parties: StoriesPenilaian: 4 dari 5 bintang4/5 (821)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Dari EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Penilaian: 4.5 dari 5 bintang4.5/5 (119)

- The Emperor of All Maladies: A Biography of CancerDari EverandThe Emperor of All Maladies: A Biography of CancerPenilaian: 4.5 dari 5 bintang4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingDari EverandThe Little Book of Hygge: Danish Secrets to Happy LivingPenilaian: 3.5 dari 5 bintang3.5/5 (399)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDari EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyPenilaian: 3.5 dari 5 bintang3.5/5 (2219)

- The Yellow House: A Memoir (2019 National Book Award Winner)Dari EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Penilaian: 4 dari 5 bintang4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDari EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaPenilaian: 4.5 dari 5 bintang4.5/5 (265)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDari EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryPenilaian: 3.5 dari 5 bintang3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnDari EverandTeam of Rivals: The Political Genius of Abraham LincolnPenilaian: 4.5 dari 5 bintang4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealDari EverandOn Fire: The (Burning) Case for a Green New DealPenilaian: 4 dari 5 bintang4/5 (73)

- The Unwinding: An Inner History of the New AmericaDari EverandThe Unwinding: An Inner History of the New AmericaPenilaian: 4 dari 5 bintang4/5 (45)

- Rise of ISIS: A Threat We Can't IgnoreDari EverandRise of ISIS: A Threat We Can't IgnorePenilaian: 3.5 dari 5 bintang3.5/5 (137)

- Block Moulding Machine Metalika - Katalog - Eng PDFDokumen40 halamanBlock Moulding Machine Metalika - Katalog - Eng PDFPrecious EsuaBelum ada peringkat

- Asme Section Ii A-2 Sa-1008 Sa-1008mDokumen10 halamanAsme Section Ii A-2 Sa-1008 Sa-1008mAnonymous GhPzn1xBelum ada peringkat

- Socketweldspacerrings SoluGapBrochureDokumen2 halamanSocketweldspacerrings SoluGapBrochureRamzi BEN AHMEDBelum ada peringkat

- Sluice Valve With ISI MarkDokumen3 halamanSluice Valve With ISI Markatul.mankarBelum ada peringkat

- What Is PCB ElectroplatingDokumen10 halamanWhat Is PCB ElectroplatingjackBelum ada peringkat

- PDF Hardiflex Walls Installation Manual DLDokumen8 halamanPDF Hardiflex Walls Installation Manual DLClouds Blue SkiesBelum ada peringkat

- Informacion Tecnica Valvula Motora Gas de AltaDokumen8 halamanInformacion Tecnica Valvula Motora Gas de AltaGuille MVBelum ada peringkat

- Ebro Butterfly Valves For FGD ApplicationDokumen5 halamanEbro Butterfly Valves For FGD Applicationsrivatsa2219Belum ada peringkat

- Elems 15Dokumen101 halamanElems 15Reynald de VeraBelum ada peringkat

- Ritz Avenue Presentation New 5Dokumen12 halamanRitz Avenue Presentation New 5Aa BbBelum ada peringkat

- Bill of Quantities of RasuwagadhiDokumen6 halamanBill of Quantities of RasuwagadhiIndra DhakalBelum ada peringkat

- Stainless Steel 321 Plus Related MetalsDokumen3 halamanStainless Steel 321 Plus Related MetalsEl BaranBelum ada peringkat

- Victaulic IT 995NDokumen6 halamanVictaulic IT 995Nsatriani20Belum ada peringkat

- BS3974 Pipe SupportsDokumen20 halamanBS3974 Pipe SupportsTony100% (1)

- Fisa Tehnica Robineti Sertar R55Dokumen2 halamanFisa Tehnica Robineti Sertar R55Petrisor FilipBelum ada peringkat

- FED-STD-H28-23 Screw Thread Standards For Federal Services Section 23 Class 5 Interference-Fit SDokumen8 halamanFED-STD-H28-23 Screw Thread Standards For Federal Services Section 23 Class 5 Interference-Fit Sahmed AwadBelum ada peringkat

- 10C0003X0 Anixter Wire&Cable Catalog 2010 Sec14 High Tempurature Cable en USDokumen16 halaman10C0003X0 Anixter Wire&Cable Catalog 2010 Sec14 High Tempurature Cable en USAziz HassanBelum ada peringkat

- CASTING Design GuideDokumen54 halamanCASTING Design GuideXin Yu75% (4)

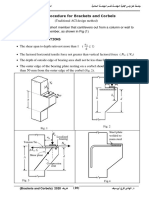

- Brackets and Corbels ACI 318 L # 1Dokumen7 halamanBrackets and Corbels ACI 318 L # 1soran azizBelum ada peringkat

- Construction materials price list from local suppliersDokumen6 halamanConstruction materials price list from local suppliersicBelum ada peringkat

- Rail Clip Mounting GuideDokumen2 halamanRail Clip Mounting Guidejhon jairo arangoBelum ada peringkat

- Hardening Mechanism of An Alkaline-Activated Class F Fly AshDokumen5 halamanHardening Mechanism of An Alkaline-Activated Class F Fly AshDilip Kumar RajakBelum ada peringkat

- Pds - Floor Hardener NMDokumen2 halamanPds - Floor Hardener NMkasivisanadhBelum ada peringkat

- ACI Manuals and Standards ListDokumen20 halamanACI Manuals and Standards ListVELOCIRAPTORABelum ada peringkat

- SPC Ak 62 016Dokumen18 halamanSPC Ak 62 016MatteoBelum ada peringkat

- How To Build A Shed With A Slanted Roof Step-by-Step GuideDokumen39 halamanHow To Build A Shed With A Slanted Roof Step-by-Step GuideFederico BarberisBelum ada peringkat

- Aa CPS 000433Dokumen3 halamanAa CPS 000433stignzBelum ada peringkat

- LUBRICACIONDokumen48 halamanLUBRICACIONdamian_k19Belum ada peringkat

- Shielding Gas: The Right Gas Working For YouDokumen32 halamanShielding Gas: The Right Gas Working For YouSharad ShahBelum ada peringkat