Viscoelastic Properties of Inject Able Bone Cements For Orthopeadic Applications State of The Art Review

Diunggah oleh

Adel Abdel-ghaffarDeskripsi Asli:

Judul Asli

Hak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

Viscoelastic Properties of Inject Able Bone Cements For Orthopeadic Applications State of The Art Review

Diunggah oleh

Adel Abdel-ghaffarHak Cipta:

Format Tersedia

Review

Viscoelastic properties of injectable bone cements for orthopaedic

applications: State-of-the-art review

Gladius Lewis

Department of Mechanical Engineering, The University of Memphis, Memphis, Tennessee 38152

Received 13 August 2010; revised 8 December 2010; accepted 10 February 2011

Published online 18 April 2011 in Wiley Online Library (wileyonlinelibrary.com). DOI: 10.1002/jbm.b.31835

Abstract: Injectable bone cements (IBCs) are used for a vari-

ety of orthopaedic applications, examples being poly (methyl

methacrylate) (PMMA) bone cements used for anchoring total

joint replacements (TJRs) (high load-bearing application),

PMMA bone cements used in the vertebral body augmenta-

tion procedures of vertebroplasty (VP) and balloon kypho-

plasty (BKP) (medium load-bearing application), and calcium

phosphate-based and calcium sulfate-based cements used as

bone void llers/bone graft substitutes (low load-bearing appli-

cation). For each of these applications, the viscoelastic proper-

ties of the cement are very important. For example, (1) creep of

the cement has an inuence on the longevity of a cemented

TJR (for example, creep allows the cement to remodel, thereby

maximizing the contact area of the cement-bone interface and,

hence, minimizing stress concentration at that interface); and (2)

in VP and BKP, the likelihood of cement extravasation is directly

related to the prole of the viscosity-versus-time elapsed from

commencement of mixing of the cement. There are a few

reviews of the literature on a number of viscoelastic properties

of some IBCs but a comprehensive review of the literature on

all viscoelastic properties of all IBCs is lacking. The objective of

this contribution is to present such a review. In addition, a num-

ber of ideas for future study in the eld of viscoelastic proper-

ties of IBCs are described. VC

2011 Wiley Periodicals, Inc. J Biomed

Mater Res Part B: Appl Biomater 98B: 171191, 2011.

Key Words: bone cement-PMMA, acrylic, calcium phos-

phates, mechanical properties

INTRODUCTION

Injectable bone cements (IBCs) are used in a wide assort-

ment of applications, notably bone augmentation procedures

(in, for example, orthopaedic and maxillo-facial surgeries)

and bone reconstruction (in, for example, lling of a bone

cyst). On the basis of chemistry, IBCs may be classied as

acrylic bone cements (ABCs), calcium phosphate-based

cements (CPCs), calcium sulfate-based cements (CSCs), and

lamentary composite materials. Alternatively, on the basis

of the nature of the orthopaedic application, IBCs may be

grouped into those for high load-bearing applications

(ABCs), medium load-bearing applications (ABCs, some

CPCs, and some CSCs), and low load-bearing applications

(some CPCs and CSCs).

For the past 50 or so years, ABCs specically, poly

(methyl methacrylate) (PMMA) bone cements have been

widely used as the anchoring/grouting agent in total hip

joint replacements (THJRs) and total knee joint replace-

ments (TKJRs)

1,2

as well as in a large variety of other joint

replacements (TJRs), such as those of the ankle,

3

elbow,

4

the proximal interphalangeal joint,

5

and shoulder.

6

In a

cemented TJR, the main functions of the cement are to im-

mobilize the implant, transfer body weight and service loads

from the prosthesis to the bone, and increase the load-car-

rying capacity of the prosthesis-bone cement-bone system.

7

ABCs, some CPCs, and a FCM are used in vertebroplasty

(VP) and balloon kyphoplasty (BKP), which are surgical

methods for treating osteoporosis-induced pathological

fractures of the vertebral body (vertebral compressive

fractures).

810

The essence of these methods involves injec-

tion of a dough of an IBC through a cannula and under uo-

roscopic guidance either directly into the fractured verte-

bral body (VP) or into a cavity created in the fractured

vertebral body by the ination of an inatable balloon tamp

(BKP).

810

The goals of these methods are to augment the

fractured vertebral body (VP and BKP),

810

stabilize it (VP

and BKP),

810

and/or restore it to as much of its normal

height and functional state as possible (BKP).

810

CPCs and CSCs are widely used as injectable bone void

llers/bone graft substitutes, in which they are injected into

surgically created osseous defects (for example, treatment

of complicated bone cysts in children

11

) or bone defects cre-

ated secondary to traumatic injury to the bone (for example,

augmentation of the xation of displaced intra-articular cal-

caneal fractures.

12

) In the US, there are $900,000 hospital-

izations per year to treat fractures

13

and $800,000 bone

graft procedures are performed each year.

14

For the purposes of the present review, viscoelastic

properties of an IBC refer to creep, stress relaxation, damp-

ing, the prole of the viscosity-versus time following

Correspondence to: G. Lewis; e-mail: glewis@memphis.edu

VC 2011 WILEY PERIODICALS, INC. 171

commencement of mixing of the cement constituents (mix-

ing time), and strain rate dependence of mechanical prop-

erties. In the case of ABCs, these viscoelastic properties are

important for the following reasons. First, in the case of

cemented TJRs, the viscosity of the cement dough at the

time of its insertion into the prepared bone bed exerts a sig-

nicant inuence on the nature and extent of interdigitation

of the cement into the contiguous bone, which, in turn,

affects the integrity of the cement-bone interface.

15

This

interface has been identied as one of the three weak zones

in a cemented TJR (the others being the cement mantle

itself and the cement-implant interface) and its integrity is

postulated to have a signicant impact on the in vivo lon-

gevity of a TJR.

16

Arguably, the most prominent difference

among the myriad commercially available PMMA bone

cement brands is in the viscosity of the polymerizing

cement-versus-mixing time prole.

17

Second, it has been

suggested that, in a cemented TJR, a small amount of

cement creep may, in fact, be benecial, especially in the im-

mediate post-implantation period.

15

For example, a polished,

tapered, collar-less femoral stem of a THJR relies on a

certain amount of cement subsidence for the implant to re-

model in the cement bed, which, in turn, facilitates cement-

implant interlocking, thereby increasing the stability of the

implant and increasing the in vivo longevity of the TJR.

15

Furthermore, cement creep may cause stresses in the

cement mantle to change from being tensile to being com-

pressive, a situation that is desirable because the compres-

sive strength of an ABC is much greater than its tensile

strength.

7

Also, it has been suggested that, in a cemented

TJR, cement creep may be benecial in helping to relieve

residual stresses built up in the cement during the polymer-

ization of the cement.

18

It is worth noting that, notwith-

standing the three aforementioned points on cement creep,

it is generally agreed that, in a cemented TJR, a high amount

of cement creep is undesirable as it leads or contributes to

loosening and/or subsidence of the implant.

19

Third, as far

as use of IBCs for applications such as VP and BKP is con-

cerned, the viscosity of the polymerizing cement-versus-mix-

ing time prole is directly correlated with the prole of the

variation of the pressure (force) required to inject the

cement paste through the cannula with time of injection. At

any time of injection, one component of that pressure is

that required to overcome the yield strength of the cement

paste and to initiate ow of the cement while the other

component is the pressure required to maintain the ow

of the cement dough/slurry. This latter component is

directly related to the viscosity of the cement slurry. The

cement viscosity is important from another perspective;

namely, upon injection into either the fractured vertebral

body (VP) or the void created in the fractured vertebral

body by the bone tamp (BKP), the viscosity of the cement

dough must be low enough to allow penetration through

the cancellous bone but not to permit extravasation, which

is a serious complication.

20

The aforementioned points indi-

cate that the cements viscosity-mixing time prole ulti-

mately affects both the feasibility and the outcome of VP

and BKP.

20

Over the years, a number of reviews of the literature on

IBCs have appeared but they are limited in a number of

respects as far as the viscoelastic properties of these materi-

als are concerned. First, in reviews that covered a wide

range of properties of ABCs, such as those by Lewis,

7

Saha

and Pal,

21

Hasenwinkel,

22

Serbetci et al.,

23

Deb,

24

and

Boesel,

25

treatment of viscoelastic properties was either

very brief and incomplete

7,2123,25

or absent.

24

Second, there

has been only one review that focused on viscoelastic prop-

erties of ABCs but it only covered the literature on apparent

viscosity-versus-mixing time proles and was published

nearly 30 years ago.

17

Third, a number of reviews have

appeared on the properties of CPCs and CSCs that have

been used or have the potential for use in VP and BKP,

2631

but viscoelastic properties were not discussed in any of

them. Fourth, the present author is unaware of any review

of viscoelastic properties of FCMs, as used in VP and BKP.

Fifth, viscoelastic properties were not included in reviews

of properties of bone void llers/bone graft substitutes.

3234

The purposes of the present contribution were to pres-

ent a comprehensive review of the literature on all the

viscoelastic properties of all chemistries of IBCs and to high-

light areas for future research in this eld. In support of the

rst-mentioned purpose, a detailed search was conducted of

relevant databases (such as MEDLINE

VR

/PubMed and

PubMed Central), science subjects-specic search engines

(such as SCIRUS

VR

) and the table of contents of relevant key

journals (such as Journal of Biomedical Materials Research

Part B: Applied Biomaterials, Biomaterials, and Journal of

Materials Science: Materials in Medicine) for relevant peer-

reviewed articles published, over the period 1975-date, in

English as well as in other languages. Furthermore, the

references list of each article, obtained from this search,

was manually examined to identify additional relevant

articles. The review is organized into four parts, with these

being containing, in order, reviews of the literature on ABCs,

reviews of the literature on CPCs, discussion of future

research topics, and a summary of the most salient points

made in the work.

ACRYLIC BONE CEMENT

Creep deformation

Specimen constraint and loading conditions in experi-

mental tests. In a creep test, a specimen is positioned in

the testing machine (typically, the specimen is enclosed in

an environmental chamber) and then subjected to a speci-

ed type of loading, with the response of the specimen (typ-

ically, its deformation) being continuously monitored until

either the specimen fractures or the test is terminated after

a certain length of time. Two types of specimen constraints

have been used; namely, unconstrained and constrained. In

the former case, the specimen is unsupported along its

sides

3552

while, in the latter case, the specimen is placed

between a steel outer jacket and a stainless steel inner

core, simulating the restraint between the implant and

the cancellous bone in a cemented TJR.

5355

Two types of

loading congurations have been used. One is quasi-

static;

3538,40,4246,4952

specically, a 10:1 lever-arm

172 LEWIS VISCOELASTIC PROPERTIES OF INJECTABLE BONE CEMENTS

deadweight set up,

36

a cantilever-type testing machine,

40

a

four-point bend test rig,

43

or a three-point bend test rig.

49,51

The other is dynamic/cyclical, under load control,

39,41,47,48,5255

with some of the tests run on commercially available universal

materials testing machines,

39,41,47,48

others on a commer-

cially available pneumatic actuator,

52

and others on a com-

mercially available hip joint simulator.

5355

Inuencing factors

Brand of commercially available cement. There are

many similarities and differences between the large number

of commercially available PMMA cement brands on the basis

of a number of parameters, such as composition (Table I),

size of the prepolymerized PMMA beads in the powder (D

b

),

powder particle size distribution, mean powder particle

size, molecular weight of the powder, molecular weight of

the cured cement, and the prole of change in viscosity of

the curing cement dough as a function of time following

mixing of the powder and liquid monomer.

For unconstrained specimens aged in water, at 37

C, and

then tested in water, at 37

C, using a pneumatic actuator,

(1) the creep strain of laboratory-fabricated Palacos R Cum

Gentamicin specimens was signicantly higher than that of

laboratory-fabricated CMW3G specimens; and (2) the creep

strain of Palacos R Cum Gentamicin specimens, fabricated

from retrievals following revision of THJRs for aseptic loos-

ening of the implant, was signicantly lower than when

Boneloc specimens, also fabricated from THHR retrievals,

were used.

52

It has been suggested that, under certain

circumstances, cement creep, in a cemented TJR, may be

benecial as it allows adaptation between the implant and

the cement. This postulate is supported by good outcomes

in two hospital series in which Boneloc was used to anchor

the femoral component of the Exeter THJR.

56

(It is noted

that, with most THJR designs, however, outcomes when

Boneloc was used were very poor, loading to withdrawal of

the cement from the market in 1994.

57

)

For constrained specimens, tested in body temperature

under dynamic loading conditions, the dynamic creep strain

(e

c

) values, at 250,000 cycles, were 5500 microstrain and

4500 microstrain for Palacos R and CMW1 specimens,

respectively.

54

The volume-weighted mean values of D

b

for

Palacos R and CMW1 are 55 lm and 44 lm, respectively.

54

The trends in these e

c

results

54

appear to be in consonance

with the suggestion that, with increase in D

b

, there is

increase in the potential for formation of crevice (which act

as stress risers), culminating in increased creep deformation.

54

The trends in the aforementioned e

c

results obtained

using constrained Palacos R and CMW1 specimens under

dynamic loading conditions have also been explained on the

basis of difference in two other cement parameters.

54

The

rst was the molecular weight of the cement powder

(MW

p

), with the postulate being that since MW

p

of Palacos

R cement is higher than that for CMW1, the beads of the

former cement swell less and dissolve less, leading to more

crevices in the specimens of the former cement.

54

The sec-

ond parameter was the difference between MW

p

and the

molecular weight of the cement matrix (MW

m

) for a given

cement, with this difference affecting the magnitude of the

contact stresses at the matrix-bead interface. These stresses

are implicated in debonding of beads from the matrix, cul-

minating in creation of microcracks. which, under dynamic

loading, may propagate through the specimen. In the case of

Palacos R, MW

m

< MW

p

, whereas, for CMW1, MW

m

>

MW

p

.

54

Under quasi-static compressive stress, the mean creep

strain, at a given combination of stress and time, of Omniplas-

tic (low-viscosity brand), Surgical Simplex P (medium-vis-

cosity brand), and Zimmer Regular (medium-viscosity

brand) specimens was between 8% and 83% higher than

that for Zimmer Low Viscosity

VR

specimens.

36

At any time

during a quasi-static four-point bending creep test on uncon-

strained specimens, at 37

C, creep deection of specimens of

Palacos R cement (high-viscosity brand) was signicantly

larger than that for specimens of CMW1 (high-viscosity

brand), Surgical Simplex P, CMW1, and Palacos LV40 (low-

viscosity brand).

43

These results point to the possibility of a

trend of decrease in creep resistance with increase in cement

viscosity.

For unconstrained specimens in a dynamic compression

test on specimens immersed in Ringers solution, at 37

C,

the mean creep strain, after 250,000 cycles, was higher for

Mendec specimens compared with that for KyphX speci-

mens, a trend that was consistent with the trend of higher

density (q) of KyphX cement (and, hence, lower porosity of

KyphX specimens).

47

The signicance of q in creep resist-

ance of a cement is claried when the results from speci-

mens fabricated from a family of cements with essentially

the same composition are considered. Thus, for uncon-

strained hand-mixed specimens immersed in Ringers

solution, at 38.5

C, dynamic compressive strain of Cemex

Isoplastic (high q) specimens were $16% to $34% lower

compared to the values obtained for Cemex System

(medium q) and Cemex RX (low q) specimens.

41

It thus

appears that low creep strain may be correlated with high

cement density.

For unconstrained specimens subjected to quasi-static

three-point bending, the creep deformation, under similar

loading proles and for a given specimen aging time (in

water, at 37

C), of SmartSet GHV specimens was, on

average, marginally higher than that of Palacos RG speci-

mens,

51

a trend that is not consistent with the fact that the

content of the gentamicin sulfate, which acts, in essence, as

a plasticizer, in the former cement is twice that in the latter.

It is noteworthy that there were no signicant differences in

either t

o

(which is one of the parameters in the expression

that relates the creep compliance to the time, as given in

the Kohmrausch creep law

58

for the cement) or g

0

(which is

the viscosity of the damper-element in a modied Burgers

creep constitutive model of the cement) between the two

cements.

51

For unconstrained specimens aged in water, at

37

C, and then tested in water, at 37

C, using a pneumatic

actuator, the creep strain of laboratory-fabricated Palacos R

Cum Gentamicin specimens was signicantly higher than

that of laboratory-fabricated CMW3G specimens,

52

even

though the gentamicin sulfate content of both cements is

REVIEW ARTICLE

JOURNAL OF BIOMEDICAL MATERIALS RESEARCH B: APPLIED BIOMATERIALS | JUL 2011 VOL 98B, ISSUE 1 173

the same. These results

51,52

indicate that the inuence of

gentamicin sulfate on creep performance is unclear.

Composition of experimental cement. Under quasi-

static compressive stress, reinforcing PMMA bone cement

with either bers or particulates led to substantial reduc-

tion in a specied creep parameter.

35,36,50

These reductions

(relative to the value for unreinforced cement specimens)

amounted to between $33% and $64% in mean creep

strain after a given time when 2 wt/wt % chopped carbon

bers were added to the cement

35,36

; and between $37%

and $68% decrease in creep compliance at 10

5

s when ei-

ther 10 wt/wt % or 20 wt/wt % hydroxyapatite (HA) pow-

der was added to a PMMA bone cement, respectively.

50

For

the carbon ber-reinforced cement, the trends were attrib-

uted to the formation, at a given applied stress, of interpore

cracks in unreinforced cement specimens and their absence

in reinforced cement specimens.

36

For the HA-reinforced

cement, the trends were consistent with the fact that, after

a creep test, the reinforced cement specimens showed

slower and less complete recovery than the unreinforced

ones, which may be attributed to some separation of the HA

particles from the polymer matrix during creep.

50

For a hydrophilic, partially degradable and bioactive

cement, (1) an increase in the amount of the hydrophilic

monomer led to a signicant decrease in the cements creep

rate

45

; (2) consistent with a priori expectation, incorpora-

tion of glass particles into the cement led to a cement with

increased creep resistance under bending, a trend attribut-

able to the formation of an apatitic layer

46

; and (3) in free

swelling, its creep rate is higher than that of commercially

available cements.

45

Monomer-to-polymer ratio (MPR). In the case of two

cements used in VP (Osteopal V and Vertebroplastic), there

was no signicant difference in the creep deformation of

specimens, as obtained in quasi-static four-point bend tests

conducted in distilled water, at 37

C.

49

This trend is

TABLE I. Compositions of a Sample of Commonly Used Commercially Available Injectable Bone Cements

Cement Type/Brand Name Composition/Constituents

a,b

Manufacturer/Supplier

Acrylic Bone Cements

CMW

TM

1 Powder (40.00 g): 35.54 g PMMA, 3.64 g

BaSO

4

, 0.82 g BPO

DePuy CMW Blackpool, UK

Liquid (18.37 g): 18.22 g MMA, 0.15 g

DMPT, 25 ppm HQ

KyphX

VR

HV-R

TM

Powder (20.00 g): 13.60 g MMA-styrene co-

polymer; 6.00 g BaSO

4

, 0.40 g BPO

Medtronic Spinal & Biologics,

Sunnyvale, CA, USA

Liquid (9.00 g): 8.92 g MMA (monomer),

0.08 g DMPT, 75 ppm HQ

Palacos

VR

R Powder (40.00 g): 33.55 g poly(methyl acry-

late, MMA), 6.13 g ZrO

2

, 0.32 g BPO, 1.00

mg chlorophyll

Heraeus Kulzer GmbH, Hanau,

Germany

Liquid (18.78 g): 18.40 g MMA, 0.38 g

DMPT, 0.40 mg chlorophyll

Surgical Simplex

VR

P Powder (40.00 g): 29.40 g poly(MMA, sty-

rene), 6.00 g PMMA, 4.00 g BaSO

4

, 0.60 g

BPO

Liquid (18.79 g): 18.31 g MMA, 0.48 g

DMPT, 80 ppm HQ

Calcium phosphate-based

cements

Biopex

VR

a-TCP, TTCP, DCPD Mitsubishi Materials Corp., Tokyo,

Japan

chronOS Inject

VR

Powder: 42 wt.% b-TCP, 21 wt.% MCPM, 31

wt.% b-TCP granules, 5 wt.% Mg hydro-

gen phosphate trihydrate, < 1 wt.% so-

dium hydrogen pyrophosphate Mg(SO

4

)

2

Oberdorf, Switzerland

Liquid: 0.5% solution of sodium hyalurone

Norian

VR

Skeletal Repair

System

a-TCP, CaCO

3

, MCPM Synthes, Inc.,West Chester, PA, USA

Calcium sulfate-based cements

AlloMatrix

VR

CaSO

4

.0.5H

2

0; demineralized bone matrix Wright Medical Technology,

Arlington, TN, USA

MIIG

VR

X3 CaSO

4

.0.5H

2

0 Wright Medical Technology

Filamentary composite cement

Cortoss

VR

bis-GMA, bis-EMA, TEGDMA, glass

particles

Orthovita, Malvern, PA, USA

a

MMA, methylmethacrylate; BPO: benzoyl peroxide; DMPT, N, N-dimethyl-p-toluidie; HQ, hydroquinone; TCP, tricalcium phosphate; TTCP, tet-

racalcium phosphate; DCPD, dicalcium phosphate dihydrate; MCPM, monocalcium phosphate monohydrate; GMA, glycidyl dimethacrylate;

EMA, ethoxydimethacryylate; TEGDMA, triethyleneglycol dimethacrylate.

b

Compositional details for the acrylic bone cements and chronOs Inject

VR

cement were taken from products brochures.

174 LEWIS VISCOELASTIC PROPERTIES OF INJECTABLE BONE CEMENTS

inconsistent with the relative MPRs for the cements; speci-

cally, MPR for Osteopal V is lower than that of Vertebro-

plastic,

59

leading to the expectation of higher creep resist-

ance of specimens of the former cement.

Polymerization pressure. Polymerization pressure (p)

is the pressure that is applied to the cement dough during

the preparation of a test specimen. For both Mendec and

KyphX cement specimens, over a range 170 kPa p

3200 kPa, mean creep strain, as determined in dynamic

compression tests on specimens in Ringers solution, at

37

C, decreased with increase in p, a trend that was attrib-

uted to an increase in cement density (and, hence, decrease

in porosity of the specimens) accompanying the increase

in p.

47

Cement mixing method. Under quasi-static compressive

loading, over the stress range of 3050 MPa, the mean

creep strain of unconstrained specimens of Palacos R and

Zimmer R, kept moist, was signicantly lower on specimens

fabricated from vacuum-mixed cement compared to hand-

mixed cement, which was attributed to a signicant reduc-

tion in porosity brought about with vacuum mixing.

39

Duration of cement mixing. An increase in the time

interval between the beginning of vacuum mixing of the

cement constituents and injection of the curing dough into

the specimen mold (from 90 s (standard injection) to

270 s (delayed injection)) signicantly increased the creep

strain of unconstrained Palacos R specimens subjected to

quasi-static compressive loading while immersed in saline

at 37

C.

40

Similar trends in strength values were attributed

to the formation of laminations within delayed injection

specimens.

60

Length of aging time

Under quasi-static tension loading (stress 3 MPa), the

creep rate of specimens of a PMMA bone cement, at any

creep time, decreased with increase in length of aging (7

24 days) in a given test medium (air, water, Ringers solu-

tion, or Intralipid (a fat solution designed to simulate the

fat in the bone cavity)), a trend that was consistent with

work on physical aging.

42

For unconstrained Surgical Simplex P specimens sub-

jected to quasi-static four-point bending, creep deection

decreased signicantly with increase in the aging time of

the specimens, t

a

(dened as the time interval between

immersion of the specimen in saline at 37

C (1 h t

a

28 days) and testing in saline at 37

C).

43

This trend was

attributed to the reduction of the plasticizing inuence of

the liquid monomer with increase in t

a

as the monomer

content was reduced by continued polymerization.

43

For unconstrained Palacos RG and SmartSet GHV speci-

mens subjected to quasi-static three-point bending, creep

compliance decreased signicantly with increase in aging

time (dened as the time interval between immersion of

the specimen in water, at 37

C, and testing in Ringers solu-

tion, at 37

C) (over the range 45 min to 2.5 years), a trend

that was related to the mobility of the polymer chains.

51

For both SmartSet GHV and Palacos RG specimens, the

inuence of length of the time the specimens were aged (in

demineralized water, at 37

C) prior to the creep test (t

e

), on

the creep of the specimens was the same; specically, linear

increase of log t

o

with log t

e

and linear increase of g

0

with log t

e

.

51

While the experimental evidence shows unanimity that

increase in aging time led to decrease in a given creep

parameter,

42,43,51

various explanations have been put

forward for this trend.

Test medium composition. Under quasi-static loading, the

mean creep strain rate of Sulx 6 and Zimmer LVC speci-

mens was signicantly lower when tested in water than in

air, which points to the possibility that the creep resistance

of the bone cement in a cemented TJR may not be compro-

mised.

61

Under quasi-static compressive loading, the mean

creep strain rate of unconstrained Surgical Simplex P speci-

mens tested in intramedullary fat at a given temperature

(37

C or 40

C) was between 2.34 and 2.52 times that when

the testing medium was saline, a trend that was attributed

to the plasticizing effect of the fat.

43

Under quasi-static tension loading, the creep rate of

specimens of a poly(ethyl methacrylate) (PEMA) bone

cement (aged and tested in the same solution, at 24

C), at

any test temperature, was signicantly inuenced by the

test medium, with the rate being similar in distilled water

and Ringers solution, each rate of which was higher than in

Intralipid, which, in turn, was higher than in air. These

trends were explained by the plasticization by each of the

water-based media (water and Ringers solution) and the

increase of leaching of the monomer from specimens tested

in Intralipid.

42

Test medium temperature. Under quasi-static tension load-

ing (stress 3 MPa), the creep rate of specimens of a

PEMA bone cement, tested in a given medium (air, water,

Ringers solution, saline, or Intralipid) increased with

increase in the medium temperature (T); for example, in air,

in the range 24

C T 50

C, there was a very small

increase in the rate in going from 24

C to 30

C and from

30

C to 40

C, and a very large increase between 40

C and

50

C.

42

In dynamic loading tests on restrained hand-mixed

CMW 1 and Palacos R specimens, creep strain when the

specimens were tested at body temperature was substan-

tially higher than when tested at room temperature, after

the initial creep stage (i.e., at number of test cycles >

1,271,400 cycles).

54

These trends

54

suggest that an increase

in test medium temperature increases the effects of plastici-

zation and are consistent with creep in a given test medium

being considered a thermally activated process.

62

Constraint of test specimen. Under dynamic creep condi-

tions, the creep strain of fully restrained hand-mixed

CMW2000 specimens, in room-temperature air, was signi-

cantly lower than when the specimens were semi-

restrained.

53

This trend is consistent with creep being

described as a consequence of stretching and realignment of

REVIEW ARTICLE

JOURNAL OF BIOMEDICAL MATERIALS RESEARCH B: APPLIED BIOMATERIALS | JUL 2011 VOL 98B, ISSUE 1 175

TABLE II. Empirical Relationships for Creep Strain of Commercially Available PMMA Bone Cement Specimens

Cement brand Test Conditions Empirical Relationship

a,b

Reference

Cemex Dynamic compression log e 0.3386 log N 4.449 Verdonschot and Huiskes

41

Isoplastic Hand-mixed

Unconstrained

Saline, at 38.5

C

Cemex RX Dynamic compression log e 0.3743 log N 4.366 Verdonschot and Huiskes

41

Hand-mixed

Unconstrained

Saline, at 38.5

C

Cemex Dynamic compression log e 0.3101 log N 4.148 Verdonschot and Huiskes

41

System Mixed within a syringe

Unconstrained

Saline, at 38.5

C

CMW1 Dynamic tension log e [0.13 log r 0.42] log N Jeffers et al.

48

Vacuum-mixed [3.12 log r 2.61]

Unconstrained

Distilled water, at 37

C

CMW1 Dynamic compression e (%) 0.099 ln N 1.178 Liu et al.

54

Hand mixed

Fully constrained

Test medium temperature:

Room temperature

CMW1 Dynamic compression e (%) 0.176 ln N 2.151 Liu et al.

54

Hand mixed

Fully constrained

Test medium temperature:

Body temperature

CMW2000 Dynamic compression e (%) 0.088 ln N 1.029; Liu et al.

53

Hand-mixed r

2

0.925

Fully constrained

CMW2000 Dynamic compression e (%) 0.088 ln N 0.7989; Liu et al.

53

Hand-mixed r

2

0.898

Semiconstrained

Palacos R-40 Dynamic compression e (%) 0.069 ln N 0.622 Liu et al.

54

Hand-mixed

Fully constrained

Test medium temperature:

Room temperature

Palacos R-40 Dynamic compression e (%) 0.2002 ln N 2.371 Liu et al.

54

Hand mixed

Fully constrained

Test medium temperature:

Body temperature

SmartSet Dynamic compression e (%) (0.448N)/(1,063,111 N); Liu et al.

55

GHV Hand mixed r

2

0.96

Semiconstrained

Test medium temperature:

Room temperature

SmartSet Dynamic compression e (%) (1.787N)/(180,332 N); Liu et al.

55

GHV Hand mixed r

2

0.99

Semiconstrained

Test medium temperature:

Body temperature

SmartSet Dynamic compression e (%) (0.410N)/(1,184,562 N); Liu et al.

55

GHV Hand mixed r

2

0.97

Fully constrained

Test medium temperature:

Room temperature

Surgical Dynamic compression e

c

1.22 10

5

N

0.31

10

0.03r

Verdonschot and Huiskes

39

Simplex P Hand-mixed

Unconstrained

Saline, at 38.5

C

Surgical Dynamic compression log e 0.3488 log N 4.426 Verdonschot and Huiskes

41

Simplex P Hand-mixed

Unconstrained

Saline, at 38.5

C

Zimmer Quasi-static compression e 1.76 10

9

r

1.858

t

0.283

Chwirut

36

Regular Hand-mixed e 3.02 10

4

e

(9.37 10-4r)

t

0.283

Unconstrained

Saline, at 37

C

a

e is creep strain; r is applied stress (in MPa) (except, Chwirut,

36

in which r is in lbs in

2

); t is test time (in h); N is number of loading cycles.

b

r

2

is the coefcient of multiple determination of the tted equation.

molecule chains in the cement in that, in a fully restrained

specimen, there is a limited amount of these processes.

54

Nature of applied loading. The number of test cycles (N)

(and, hence, time) required until the creep strain equals the

elastic strain of an unconstrained cement specimen

(applied stress on specimen/elastic modulus of cement),

at a given stress level, may be computed using a best-t

relationship (derived from experimental results; for exam-

ples, see Table II). This time (which is inversely pro-

portional to the creep rate) was signicantly shorter under

cyclical tensile load than under cyclical compressive load, at

stresses > 5 MPa.

39

Furthermore, these times, as obtained

from dynamic compression tests, were signicantly higher

than under quasi-static compression, at stresses > 5

MPa.

36,39

Magnitude of applied stress

Under quasi-static tension loading, the creep rate of speci-

mens of a PEMA bone cement, in a given test medium (air,

distilled water, Ringers solution, or Intralipid), increased

markedly with increases in the magnitude of the applied

stress, which reects the fact that, with increase in stress in

a given test medium, there is increase in the plasticization

effect of the medium.

42

Empirical relationships and modeling. A number of em-

pirical relationships have been derived from experimental

results (Table II), any of which may be used to obtain esti-

mates of long-term creep strain.

In terms of modeling, the time-temperature superposi-

tion principle (TTSP), Struiks effective time method

(SETM),

63

and the integrated time function method (ITFM)

have been applied to compliance (or creep) results for a

commercial acrylic cement and an experimental cement

(PEMA cement).

44,50

TTSP involves three steps. The rst is to compute the

horizontal shift factor, a

T

, using, in most cases, the Struik

equation for compliance, D, at a given test temperature and

test time, t, along with a

T

. Thus, the governing equation for

D(t) is

63

Dt D

o

expt:a

T

=s

m

; (1)

where D

o

is the initial compliance and s and m are con-

stants. For the PEMA cement, at T 37

C, the best-t val-

ues of the constants were: D

o

3.33 GPa

1

, s 7305 s,

and m 0.276.

50

The second step is to determine the qual-

ity of the t of the Williams-Landel-Ferry (WLF) equation to

the experimentally obtained results for the variation of a

T

with T. This equation is given as

64

loga

T

C

1

T T

s

C

2

T T

s

(2)

where T is the temperature of the test medium, T

s

is a ref-

erence temperature (usually, taken to be the glass transition

temperature of the cement) and C

1

and C

2

are constants

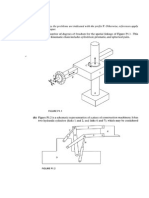

(Figure 1). The third step is to generate the master time-

temperature extrapolated creep compliance (or creep rate)

plot. For the commercial acrylic cement, it was found that,

with C

1

17.4 and C

2

75 K, the t to the experimental

creep compliance (and, hence, rate) results was excellent

(Figure 2).

SETM is used to account for the inuence of aging of

the specimen. The essence of this method is that it may be

used to determine the effective time of a creep test (k),

which is dened as the time required to achieve the same

creep strain if aging had been ongoing. The expression used

to compute k is as follows:

k t

e

t

c

a

t

e

1

_ _

1=a

1

_ _

(3)

where t

e

is the aging time, t

c

is the actual creep time, and

a (1-l), with l (the aging rate) being the slope of the

plot of log a

T

versus log t

e

. For a PEMA cement with experi-

mentally obtained compliance-time results, at 1 MPa, 37

C,

and 1 day of prior aging, the superior performance of

SETM compared with when TTSP was used is evident

50

(Figure 3).

ITFM involves three steps. The rst is to generate the

momentary creep curve, with physical aging not being con-

sidered important. This is done by obtaining the t between

the experimental creep data, on one hand, and either the

Struick equation [Eq. (4)] or the Williams-Watts equation

65

[Eq. (5)], on the other.

Dt D

0

exp

t

s

_ _

m

(4)

Dt D

o

DD

a

1 expt=s

m

(5)

FIGURE 1. Variation of shift factor, a

T

, with test temperature, T, and

the t between the Williams-Landel-Ferry (WLF) equation and the ex-

perimental results, for a poly (ethyl methacrylate) bone cement. (With

kind permission from Springer ScienceBusiness Media; Journal of

Materials Science: Materials in Medicine, Prediction of the long-term

creep behaviour of hydroxyapatite-lled polyethylmethacrylate bone

cements, volume 18, 2007, page 1854, J. C. Arnold and N. P. Venditti,

Figure 6).

REVIEW ARTICLE

JOURNAL OF BIOMEDICAL MATERIALS RESEARCH B: APPLIED BIOMATERIALS | JUL 2011 VOL 98B, ISSUE 1 177

where D, t, D

o

, s, and m have the same meanings as given

before and DD

a

is a material constant.

The second step is to use results from a long-term creep

test, where aging is important, to obtain values of C and b

as used in the integrated time function. This is accom-

plished thus: (1) plot the equation

FDt

t

st

(6)

with the F(D(t)) applicable to the Struik equation [see

Eq. (7)] or to the Williams-Watts equation [see Eq. (8)].

Dt D

0

exp

_

t

0

du

u

_

_

_

_

m

(7)

Dt D

0

DD

a

1 exp

_

t

0

du

u

_

_

_

_

m

_

_

_

_

(8)

where u is a dummy time variable.

(2) The slope of this plot [i.e., of Eq. (6)] gives the varia-

tion of s(t), whence C and b may be obtained using the

following equation

_

t

0

du

su

where s

2

t s

2

C

2

t

2b

(9)

The third step is to use the values of the constants

obtained (D

o

, s, m, C, and b, if Eq (7) is used or D

o

, s, m, C,

b, and DD

a

if Eq (8) is used) to construct predictive curves

from which the long-term creep data may be read. For a

PEMA cement, the best-t values of the material constants

found were found to be: D

o

2.558, s 2.097 s, m

0.245, C 0.240, and b 0.817 (for t between Eq. (7)

and the experimental data) and D

o

3.900, s 8.00 10

7

s, m 0.601, C 2820, b 0.674, and DD

a

400 GPa

1

,

(for t between Eq. (8) and the experimental data).

50

A

comparison of the creep compliance versus creep time

results, for one set of experimental conditions, to the predic-

tions using the two variants of the ITFM [i.e., via use of

Eq (7) or of Eq (8)] is shown in Figure 4.

FIGURE 3. Experimentally obtained long-term creep compliance-ver-

sus-test time data (recorded data) for a poly (ethyl methacrylate) bone

cement, together with the master curve generated using the time-tem-

perature superposition method and the data computed using Struiks

effective time method. (Experimental data obtained at 1 MPa; Ringers

solution, at 37

C; and 1 day of aging in Ringers solution, at 37

C.)

(With kind permission from Springer ScienceBusiness Media; Jour-

nal of Materials Science: Materials in Medicine, Prediction of the

long-term creep behaviour of hydroxyapatite-lled polyethylmethacry-

late bone cements, volume 18, 2007, page 1855, J. C. Arnold and N.

P. Venditti, Figure 11).

FIGURE 2. Extrapolated creep compliance results at 37

C and 2 MPa

for a commercial acrylic cement, obtained using the time-tempera-

ture superposition method. The temperatures shown are the test tem-

peratures used. Plots were obtained using the following best-t

values for the parameters in the Williams-Landel-Ferry equation: C1

17.4 and C2 75 K. (With kind permission from Springer Science-

Business Media; Journal of Materials Science: Materials in Medicine,

Creep behavior of bone cement: a method for time extrapolation

using time-temperature equivalence, volume 14, 2003, page 324, R. l.

Morgan, D. F. Farrar, J. Rose, H. Forster, and I. Morgan, Figure 5(b)).

FIGURE 4. Experimentally obtained long-term creep compliance-ver-

sus-test time data (recorded data) for a poly (ethyl methacrylate) bone

cement, together with predictions computed using integrated time

functions given by Sruik [Eq. (7)] and Williams and Watts [Eq. (8)].

(Experimental data obtained at 1 MPa; Ringers solution, at 37

C; and

1 day of aging in Ringers solution, at 37

C.) (With kind permission

from Springer ScienceBusiness Media; Journal of Materials Science:

Materials in Medicine, Prediction of the long-term creep behaviour of

hydroxyapatite-lled polyethylmethacrylate bone cements, volume 18,

2007, page 1857, J. C. Arnold and N. P. Venditti, Figure 12).

178 LEWIS VISCOELASTIC PROPERTIES OF INJECTABLE BONE CEMENTS

A phenomenological description of the creep compliance

(J(t)) of Palacos RG and SmartSet GHV specimens,

obtained in three-point bending (range of specimen aging

time in demineralized water, at 37

C: 45 min to 2.5 years;

test medium: Ringers solution, at 37

C; applied stress (r):

10 MPa or 25 MPa) has been given in terms of the Struik 3-

parameter creep law.

51

This law is given as

Jt J

0

exp

t

t

0

_ _

m

_ _

(10)

where J

o

, t

o

, and m are the parameters.

A physical description of the creep deformation of the

aforementioned Palacos RG and SmartSet GHV specimens

was presented in terms of the modied Burgers model,

51

which is given by

et r

1

E

0

1

E

r

1 e

t=sr

t

g

1

E

c

1 e

t=sc

_ _

(11)

where E

o

is the modulus of elasticity of the cement; 1/E

r

and s

r

are the weight and time constant of the viscoelastic

relaxation, respectively; g is the viscosity of the cement;

and 1/E

c

and s

c

are the weight and time constant of the pri-

mary creep phase, respectively.

Summary. Two observations are in order here. First, in

spite of the existence of results from a multitude of studies,

the inuence of various intrinsic and extrinsic factors on

the creep performance of commercially available PMMA

bone cement brands is unclear. This is because the majority

of these studies were not designed to delineate these

aspects. As a result, many of the studies are limited by the

presence of confounding variable(s), the most common of

which was the use of different commercially available

brands. This situation makes it difcult to, for example,

assess the impact of a combination of extrinsic factors that

are clinically relevant (for example, cement mixing method,

nature of applied stress, and magnitude of stress) on the

creep performance of a given cement brand. Second, there

is limited information on the appropriate model(s) for the

creep behavior of PMMA bone cements. This hampers the

development of rational method(s) of synthesizing a cement

brand from the perspective of creep deformation.

Stress relaxation

Cement composition and cement brand. For a surgical

grade cement, at a constant compressive strain of 1%, at a

given value of time during the test, the extent of stress

relaxation increased when the cement was reinforced by

incorporating 2 wt/wt % chopped carbon ber into the

cement powder.

35

The rate of stress relaxation was signicantly higher in

Palacos R (stress relaxed to practically zero after 6 weeks)

compared with both CMW1 and Simplex P (in both, stress

relaxed to 100 kPa after one year).

66

During unconstrained stress relaxation tests, conducted

under quasi-static four-point bending, the relaxation of the

load in Surgical Simplex P specimens, with time, when

tested in saline solution at 37

C, was not signicantly differ-

ent from that for Palacos

VR

R specimens tested in the same

medium.

44

The loads for both of these sets of specimens

were, however, signicantly different than those obtained

when specimens fabricated from the family of CMW were

used.

43

The trend in the above results for Surgical Simplex P

and CMW1

43

were different from that determined from

three-point bend tests on CMW1-G and Surgical. Simplex P

specimens, at initial strain of 0.3% or 0.6%, or 0.9%.

67

In

the latter case, the reduced stress functions for these two

cements were the same.

67

For a given combination of con-

stant strain and time, the stress in specimens of either

CMW1-G and Surgical Simplex P was higher than in speci-

mens of another commercially available cement, Braxell.

67

Aging time. At any time during unconstrained stress relaxa-

tion tests, conducted under quasi-static four-point bending,

the stress in Surgical Simplex P specimens, when tested in

saline solution at 37

C, increased signicantly with increase

in conditioning time of specimens in the solution, t

m

(1 h

t

m

10 weeks).

43

This same trend was seen when the

tests were carried out, in air at room temperature under

tension (1 h t

m

7 days)

43

and in another series of four-

point bending tests (conducted in water, at 37

C.)

68

The trend in these results

43,68

was attributed to reduction

of the plasticizing effect of the monomer with increase

in t

m

.

43

Empirical relationships and modeling. The experimental

evidence (Table III) indicates that, for a given cement, the

relaxation of compressive stress with time in the specimen

may be modeled using the Maxwell viscoelastic model.

Experimental data obtained on hand-mixed Surgical Sim-

plex P specimens, tested in four-point bending, in water at

37

C, were described by the Maxwell double-exponential

model (Figure 5); thus, the stress (r)-versus-t relationship

is of the form

r ae

t=b

ve

t=d

c; (12)

where a, b, v, d, c are constants, each of which is related to

a material property; for example, b g

1

/E

1

and d g

2

/E

2

.

For specimens aged, in air, at 37

C, for 70 days, the best-t

values of a, b, v, d, c were found to be 3.51, 5.10, 10.52,

159.31, and 10.70, respectively.

68

From the results on three-point bend tests on Braxell,

CMW1-G, and Surgical Simplex P specimens, conducted in

water at 37

C (together with those from damping tests

these are discussed in the next section of this review), the

constitutive equation that links the drop of elastic modulus,

E, with time, t, was found to be

67

Et E

1

DEt E

1

C

1

expt=s

1

_

1

0

Ks expt=sds (13)

REVIEW ARTICLE

JOURNAL OF BIOMEDICAL MATERIALS RESEARCH B: APPLIED BIOMATERIALS | JUL 2011 VOL 98B, ISSUE 1 179

with K(s) C

2

/s C

3

/s

n

and E

1

, C

1

, C

2

, C

3

, s, and n are

constants. That is, this drop is describable using one main

relaxation time (s

1

) superimposed on a continuous spec-

trum of relaxation times. For example, for Surgical Simplex

P specimens, the best-t values of E

1

, C

1

, C

2

, C

3

, s, and n

were found to be 1000 MPa, 1300 MPa, 130 MPa, 15, 9

10

4

s, and 1.1, respectively.

67

Each of these models [Eqs. (12) and (13)] allows a pre-

diction of the long-term extent of stress relaxation of a

cement specimen on the basis of results obtained in the

short-term.

Summary. The literature is very limited in a number of

respects, such as studies on only a few commercially avail-

able cement specimens, investigations of only a few inu-

encing factors, and a few contributions in the area of

modeling.

Damping

Background. The ability of a viscoelastic material, such as

an ABC, to dissipate strain energy as heat can be deter-

mined using a dynamic test. Such a testing mode is relevant

to ABC being used in a TJR, in which, during activities of

daily living, the cement mantle is subjected to cyclical load-

ing. The essential relationship in damping studies recog-

nizes that a given modulus of the cement is a complex

parameter; for example, the complex elastic modulus (E) is

E E

0

iE

00

(14)

where E

0

is the storage modulus and characterizes the mate-

rials elasticity, and E is the loss modulus and characterizes

its internal damping capacity.

Thus,

Loss=damping factor; tan d E

00

=E

0

(15)

(Note that Eqs. (14) and (15) may also be written in terms

of the shear modulus, G.)

Test mode. With one exception, dynamic mechanical ther-

mal analysis (DMTA) (sometimes referred to as dynamic

mechanical analysis, DMA), operated in three-point bending

mode, has been used to determine E

0

, E

00

, and tan d, as a

function of the cured cement specimens temperature, T

0

(at

a xed test frequency, f).

6971

In a DMTA test, typical speci-

men size is 25.040.0 mm 10.0 mm 1.01.5 mm, and

typical test conditions are: displacement, 64 lm; static force,

60 mN; dynamic force, 40 mN; rate of heating of specimen,

24

C min

1

; range of T

0

: 20200

C; and range of f 1

30 Hz.

6971

The exception is a study in which the DMTA

tests were performed on cured cement specimens, in a dis-

placement control mode; that is, using a frequency sweep

(0.01100 Hz) and a temperature sweep (1757

C).

67

Damping properties may also be obtained using a plate-

plate congured rheometer (typical radius of plates and gap

between them 2025 mm and 2 mm, respectively), oper-

ated in a dynamic oscillation (constant strain) mode

FIGURE 5. Schematic drawing of the spring-dashpot model for the

stress relaxation behavior of a PMMA bone cement. (Reprinted from

Proceedings of the Institution of Mechanical Engineers, Part H: Jour-

nal of Engineering in Medicine, volume 216, number 3, O. R. Eden, A.

J. C. Lee, and R. M. Hooper, Stress relaxation modeling of polyme-

thylmethacrylate bone cement, pages 195-199, copyright (2002), with

permission from Professional Engineering Publishing).

TABLE III. Empirical Relationships for Stress Relaxation of Commercially Available PMMA Bone Cement Specimens

Cement Test Conditions Empirical Relationship

a,b

Unit for t Reference

Braxell Hand-mixed r 4.18 e

0.0054t

; s De Santis et al.

67

Stored in distilled water, at 37

C, r

2

0.643

for 21 d

Tested in water

Three-point bend loading

Palacos R Hand-mixed r 20.49 e

0.020t

; h Lee et al.

43

Stored in saline, at 37

C, for 7 d r

2

0.766

Tested in saline, at 37

C

Four-point bend loading

Simplex P Hand-mixed r 19.14 e

0.0104t

; min Eden et al.

68

Stored in air, at 37

, for 6 h r

2

0.889

Tested in water, at 37

C

Four-point bend loading

Surgical grade r 18.91 e

0.286t

h Pal and Saha

35

a

r is stress, in MPa.

b

Empirical relationship was given explicitly in the article by Pal and Saha,

35

but each of the other three empirical relationships was derived

by the present author from experimental results given in the original article.

180 LEWIS VISCOELASTIC PROPERTIES OF INJECTABLE BONE CEMENTS

(typically, strain amplitude and frequency 1% and 1

5 Hz, respectively), with the curing cement being tested at a

xed temperature.

7275

Typically, results in a damping study are presented as

(1) the variation of the storage modulus, the loss modulus,

and/or tan d with specimen temperature, at a xed test fre-

quency [Figure 6(a)] and/or (2) the variation of the storage

modulus, the loss modulus, and/or tan d with test time (t)

at a xed combination of T

0

and f [Figure 6(b)].

Inuence of cement composition. In the case of a PMMA

bone cement, in which the radiopacier was provided by

BaSO

4

particles (10% p/p) in the cement powder, when dry

cured specimens were used, the storage modulus, at a given

T

0

, was practically the same as when radiopacity was pro-

vided by incorporating an iodine-containing monomer, 4-

iodophenol methacrylate (IPMA) (520% v/v), in the liquid

phase.

70

The same trend was found for the tan d results.

70

In the case of a PMMA bone cement in which the radio-

pacier was provided by BaSO

4

particles (10%) in the

cement powder, when dry cured specimens were used,

the storage modulus, at a given T

0

(f xed), was practically

the same as when radiopacity was provided by any one of

three other radiopaciers (10% bismuth salicylate (BS)

incorporated in the powder; BS coated with polyethylene

oxide incorporated in the powder (BSPEO); and BS dis-

solved in the liquid monomer (BSDM)).

71

The same trend

was found for the tan d results.

71

Up to t

m

$16 min, the

pattern of increase of G

0

with increase in time from com-

mencement of mixing of the cement, t

m

(at a xed combina-

tion of T

0

and f) was practically the same when the radiopa-

cier was 10 wt % BaSO

4

particles in the powder as when

any one of three other radiopaciers incorporated in the

cement powder (10 wt % strontium hydroxyapatite (SrHA),

10 wt % SrHA treated with MMA (SrHA-m), and 20 wt %

SrHA-m).

75

For t

m

> $16 min, there were similarities and

differences seen in the plots for the four cements: for the

10 wt % BaSO

4

-containing cement, there was a sharp rise

in G

0

(corresponding to an increase in polymerization); for

the 20 wt % SrHA-m-containing cement, there was a slow

rise in G

0

for up to t

m

$10 min, followed by a sharp rise

thereafter; and for each of the other two cements, G

0

increased at the same rate as during t

m

$16 min.

75

All of

the aforementioned patterns were also seen in the G

00

results.

75

Inuence of cement brand. In a displacement control

mode experiment, (1) up to f 10 Hz, the mean value of

tan d for the cured Braxell specimens was about the same

as for the cured CMW1 and Surgical Simplex P specimens;

(2) in the range 10 Hz < f < 100 Hz, tan d for the cured

Braxell specimens was marginally higher than for the other

two cured cement specimens; and (3) the increase in tan d,

with increase in f, was slightly greater for the cured Braxell

specimens compared with those of the other cements.

67

These results suggest that the main factor that inuences

the damping factor in a PMMA bone cement is the constitu-

ent of the main polymer chain; in other words, since PMMA

is the main polymer in Braxell, CMW1, and Surgical Simplex

P, their tan d-f prole was about the same.

67

Inuence of size of PMMA beads. For experimental PMMA

bone cements designed for use in VP and BKP, at a given

value of t

m

(for a xed combination of T

0

and f), a decrease

in the ratio of large PMMA beads (mean diameter 118

lm) to small ones (mean diameter 70 lm) (we designate

this ratio R, in wt /wt %) in the powder led to an increase

in both G

0

and G

00

.

72

This trend was attributed to the disso-

lution of the small beads (and, hence, the beginning of

increasing polymerization rate) appearing earlier as R

increases.

72

Inuence of state of hydration of test specimens. In the

case of a PMMA bone cement in which the radiopacier was

provided either by adding BaSO

4

particles (10% p/p) to the

cement powder or by incorporating IPMA (520% v/v) in

the liquid phase, for both dry and wet cured specimens, at a

given T

0

(f xed), the pattern of change of storage modulus

with test temperature was unaffected by the state of hydra-

tion of the test specimen.

70

For the tan d results, (1) for

each cement, there was a broadening of the plots when wet

specimens were used compared to when dry ones were

used, which was attributed to a plasticizing process

70

; and

FIGURE 6. (a) Typical variation of the storage modulus and the loss

angle (tan d) with temperature of a cured PMMA bone cement speci-

men, obtained at 2 Hz. (b) Typical variation of storage modulus, loss

modulus, and tan d of a curing PMMA bone cement dough, with test

time, obtained at room temperature of 22

C and test frequency of

1 Hz.

REVIEW ARTICLE

JOURNAL OF BIOMEDICAL MATERIALS RESEARCH B: APPLIED BIOMATERIALS | JUL 2011 VOL 98B, ISSUE 1 181

(2) there was a slight reduction of the temperature at which

the peak occurred, dropping from a mean of $127

C when

dry cured specimens were used to a mean of $115

C when

wet cured ones were used in the case of the BaSO

4

-contain-

ing cement and from a mean of $129

C to a mean of

$116

C when dry and wet cured IPMA-containing cement

specimens were used, respectively.

70

These same trends

were obtained in the case of a PMMA bone cement in which

the radiopacity was provided by BS, BSPEO, or BSDM.

71

Inuence of test frequency, f. In a displacement control

mode experiment, for a given cement (Braxell, CMW1, or

Surgical Simplex P), with tests conducted on cured speci-

mens immersed in water, after conditioning them in distilled

water, at 37

C, for 21 days, each of the dynamic properties

(storage modulus, loss modulus, and loss factor) increased

with increase in f.

67

It has been suggested that this phenom-

enon may provide an explanation for the fact that, although

PMMA bone cement is brittle, under quasi-static loading,

it provides excellent resistance to dynamic loading (that

is, it acts as a shock absorber), as is experienced in

the cement in a TJR during many activities of daily living,

notably gait.

76

Inuence of test temperature (T). In a displacement con-

trol mode experiment on Surgical Simplex P specimens, at a

given value of f (0.1 Hz 1 f 10.0 Hz), there was a trend

of increase of tan d with increase in T,

67

a trend that is con-

sistent with damping of the cement being a thermally acti-

vated process.

62

Modeling. From the results on three-point bend tests on

cured Braxell, CMW1, and Surgical Simplex P specimens,

conducted in water (together with those from stress relaxa-

tion testsstress relaxation results are presented in a pre-

vious subsection of this review), it was found that an appli-

cable model is one that contains an exponential part (which

would provide an excellent t to the stress relaxation

results) and a continuous spectrum (which will provide an

excellent t to the DMTA results) [see Eq. (13)].

67

Thus, the

following expressions were found to describe the increase

of E

0

and E

00

with increase in f (x 2pf)

77

:

E

0

x E

1

x

_

1

0

DEs sinxsds (16)

E

00

x x

_

1

0

DEs cosxsds (17)

where E

1

is a material constant and E is the viscoelastic

modulus.

Summary. There is a modest number of studies on inu-

encing factors, from which it appears that a signicant

intrinsic parameter is the powder particle size distribu-

tion while test frequency and test temperature are signif-

icant extrinsic factors. Furthermore, there is a plasticizing

effect on tan d and there is a dearth of work on

modeling.

Rheological properties

Variation of viscosity of cement with time. The primary

rheological parameter is the variation of the viscosity of the

polymerizing cement with time. Four approaches have been

taken for such determination.

In the rst, a rotational or capillary extrusion rheo-

meter/viscometer was used.

7881

With this set-up, the vari-

ation of the pressure gradient (P) with t

m

is obtained,

which leads to the variation of the apparent or false viscos-

ity of the cement (l) through use of the Hagen-Poiseuille

equation:

l

pPR

4

8LQ

(18)

where R is the radius of the capillary/die, L is the length of

the capillary, and Q is the volumetric ow rate of the

cement dough (or the rate at which the cement dough is

injected into the capillary). A typical l-time plot is given in

Figure 7(a).

FIGURE 7. (a) Typical results for false or apparent viscosity of a

curing PMMA bone cement dough, obtained at ambient temperature

of 22

C, and a shear rate of 0.5 s

1

. (b) Typical results for complex

viscosity of a curing PMMA bone cement dough, obtained at ambient

temperature of 22

C.

182 LEWIS VISCOELASTIC PROPERTIES OF INJECTABLE BONE CEMENTS

In the second approach, the viscosity tests were per-

formed using a commercially available device that basically

involved placing the cement dough in a cartridge and con-

tinuously recording the force needed to immerse a cone-

shaped measuring tool (diameter and surface area 28

mm and 610 mm

2

, respectively), at a dened speed (typi-

cally, 0.03 mm/s), into the dough as it polymerizes. In the

present review, we shall designate the plot of the results

obtained using this device as the force viscosity-versus-t

m

plot.

82,83

In the third approach, the cement dough was placed into

the cup of a rheometer that has a cup-and-plate congura-

tion (or on the lower plate of a rheometer that has a plate-

plate conguration), bringing the plate or top plate to touch

the dough, and then performing the test in a dynamic

oscillation mode (i.e., the plate or top plate is subjected to a

displacement (typically, 6 10 lm) at a xed frequency (typ-

ically, 15 Hz).

7275,8486

) The rheometer is a force-reso-

nance analyzer which means that the peak compressive

force transferred from the curing cement (F) to the plate is

tracked by a force transducer, as a function of t

m

. The F

t

m

results are exported to a computer containing a soft-

ware that converts these results to complex viscosity (g*)-

versus-t

m

results.

8486

Typical g*-t

m

results are given in

Figure 7(b).

The fourth approach involved using a coaxial cylinder-

type self-sensing rheometer that is comprised of an oscillat-

ing spindle that is inserted in the cement dough and is driven

by a computer-controlled electromagnetic actuator.

87

The

actuator uses a model to obtain both the displacement and

the torque without the use of sensors, from which the

storage modulus (G

0

) and the loss modulus (G

00

) of the curing

are obtained. A software package in the computer converts

these moduli to g* using the following relationships:

g

0

G

00

=x; g

00

G

0

=x; g g

0

ig

00

(19)

The issue of comparability in the viscosity-t

m

results

based on the viscosity measurement method used has

received very limited attention, with one study being on

CMW3.

84

For this cement, at a given value of t

m

, it was

found that g* is markedly higher than l, a nding that is in

consonance with the Cox-Merz rules.

88

A caveat should be

attached to this result because, g* was experimentally

determined in one study

84

but the corresponding l result

was taken from another study/report.

17

Categorization of cement brands. Results of the variation

of l with t

m

has been used to categorize commercially avail-

able cements into low-viscosity cements (for example,

Zimmer LVC; l 1 kPa s at t

m

5 min); medium-viscos-

ity cements (for example, Surgical Simplex P; l 5 kPa s

at t

m

5 min) and high-viscosity cements (for example,

Palacos R; l 14 kPa s at t

m

5 min).

89

Explanation of viscosity-time prole. When g* is deter-

mined, it is seen that, with increase in t

m

, there is an initial

steady rise, followed by a nal rapid rise. The former stage

is due to swelling and dissolution of the polymer beads in

the liquid monomer as the powder is wetted by the mono-

mer, while the latter stage is due to the polymerization

reaction.

84,90

Inuencing factors. The importance of the composition of

the powder beads in a PMMA bone cement is exemplied

by the clear differences in the force viscosity-versus-t

results for two commercially available PMMA bone cements;

specically, a tobramycin-loaded cement (Simplex with

Tobramycin) showed a lower initial value of median force

viscosity than a gentamicin-loaded cement (Palacos RG).

In Simplex with Tobramycin, the beads are of MMA-styrene

copolymer and, thus, are more hydrophobic (take longer to

dissolve in the liquid monomer) than the MMA-MA beads in

Palacos RG.

83

On the basis of the force viscosity-versus-time results

obtained from three variants of a commercially available

gentamicin-loaded PMMA bone cement (Refobacin Palacos

R, Palacos RG, and Refobacin Bone Cement), it was sug-

gested that, for a gentamicin-loaded cement, the median

force viscosity, at a given t

m

, may be inuenced by varia-

tion in the polymer/copolymer particle size ratio.

82

Appa-

rent contradictions in the force viscosity-versus-t

m

results

for Palacos RG and Refobacin Bone Cement from the same

research group

82,83

point to the need for further study of

the issue of the signicance of variation in composition of a

given gentamicin-loaded PMMA bone cement vis a vis curing

cement properties.

The fact that cements belong to the same viscosity cate-

gorization group (i.e., high-viscosity, medium-viscosity or

low-viscosity) does not necessarily mean that their g*-t

m

proles are of the same form. Thus, differences were noted

in this prole for Cemex Isoplastic, CMW1, and Palacos R,

each of which is a high-viscosity brand.

73

Specically, dur-

ing the early stages of curing, Cemex Isoplastic was the

most viscous, and Palacos R the least viscous, with CMW1

becoming the most viscous in the latter stages of curing.

73

For an experimental cement, whose radiopacity was pro-

vided by ZrO

2

(530%), for a given amount of ZrO

2

, l was

signicantly higher when cross-linked PMMA nanospheres

were added to the powder than when cross-linked PMMA

macrospheres were added. This was attributed to (1) the

higher surface area of the nanospheres, which translates to

high diffusion of the liquid monomer

81

; and (2) increase in

the volume fraction of particles in the powder mixture.

91

Each of three experimental cements designed for use in

VP and BKP (radiopacier: 10%BaS0

4

; radiopacier: 10%

BaSO

4

5% ciprooxacin (CFX); and radiopacier: 10%

BaS0

4

3% CFX 3% vancomycin) displayed g*-t

m

char-

acteristics, in the initial stage, that are very similar to those

for a commercially available PMMA bone cement (Osteopal

G) at t

m

< $6 min.

74

Because of delayed setting, however,

g* remains constant and low for much longer (up to t

m

>

$11 min) before a nal sharp rise in the case of the experi-

mental cements.

74

The inuence of radiopacier on the g*-t prole of an

ABC depends on the section of the curve being considered.

REVIEW ARTICLE

JOURNAL OF BIOMEDICAL MATERIALS RESEARCH B: APPLIED BIOMATERIALS | JUL 2011 VOL 98B, ISSUE 1 183

Thus, for an experimental cement, for t

m

$15 min, the

g*-t curve was practically the same when the radiopacier

was 10 wt % BaSO

4

particles in the powder as when any

one of three other radiopaciers (10 wt % SrHA, 10 wt %

SrHA treated with MMA (SrHA-m), and 20 wt % SrHA-m)

was blended into the powder.

75

For t

m

> $15 min, there

were similarities and differences seen in the plots for the

four cements. For the 10 wt % BaSO

4

-containing cement,

there was a very sharp rise in g* (which corresponds to an

increase in polymerization). For the 20 wt % SrHA-m-con-

taining cement, there was a slow rise in g* for 10 min, fol-

lowed by a sharp rise, whereas for each of the other two

cements, g* rose at a moderate rate.

75

Reducing the modulus of a PMMA cement for use in VP

or BKP, by adding N-methyl-pyrrolidone to the liquid mono-

mer (5060%), led to a signicant reduction in the poly-

merization rate, as manifest through a signicant reduction

in g*, at any given t

m

.

80

This trend is attractive in that it

shows an approach that may be taken to widen the window

for injecting the cement into the cannula during VP or BKP.

The importance of the dispersal of an additive in the

cement on the viscosity-time characteristics is illustrated by

results from two variants of an experimental cement, one in

which a clay (2% sodium montmorillonite (SMMT) or 2%

organophilic montmorillonite (OMMT)) was blended with

the powder and the other in which the clay was added to

the liquid monomer. In each variant, there was an increase

in g*, at a given t

m

(relative to case for the plain cement),

with this trend being likely due to the clay increasing the

shear modulus of the cement.

85

More importantly, however,

at a given t

m

, a cement in which OMMT was added to the

liquid monomer showed the highest g*, this trend being

attributed to the clay in this cement being well dispersed.

85