Mudit Singh Gautam

Diunggah oleh

Mudit Singh GautamDeskripsi Asli:

Judul Asli

Hak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

Mudit Singh Gautam

Diunggah oleh

Mudit Singh GautamHak Cipta:

Format Tersedia

Nuuit Singh uautam-

R

INBIAN

PETR0CBENICAL

INB0STRY

ASSIuNNENT

uest|on 1 Asslqo to tbe followloq compoooJs tbelt closs ooJ sttoctotol lotmolo

nswer 1

Name C|ass Structura| Iormu|a

normal 8uLane alkane C

4

P

10

lso enLane alkane C

3

P

12

Cyclohexane cycloalkane C

6

P

12

8enzene aromaLlc hydrocarbon C

6

P

6

ropylene alkene C

3

P

6

8uLylene alkene C

4

P

8

AceLylene alkyne C

2

P

2

2 L|st the ma[or categor|es of etrochem|ca|s and ment|on at |east s|x

products that can be der|ved from Lthy|ene?

Answer 2

O |ef|ns lnclude eLhylene propylene and buLadlene Lthy|ene and

propy|ene are lmporLanL sources of lndusLrlal chemlcals and plasLlcs

producLs 8uLadlene ls used ln maklng synLheLlc rubber

O romat|cs |nc|ude benzene to|uene and xy|enes 8enzene ls a raw

maLerlal for dyes and synLheLlc deLergenLs and benzene and Loluene for

lsocyanaLes Mul and 1ul used ln maklng polyureLhanes ManufacLurers use

xylenes Lo produce plasLlcs and synLheLlc flbers

O Synthes|s gas ls a mlxLure of carbon monoxlde and hydrogen used Lo make

ammon|a and methano| Ammonla ls used Lo make Lhe ferLlllzer urea and

meLhanol ls used as a solvenL and chemlcal lnLermedlaLe

LLhylene ls a gaseous organlc compound wlLh Lhe formula C

2

P

4

lL ls Lhe

slmplesL alkene 8ecause lL conLalns a carboncarbon double bond eLhylene ls

classlfled as an oosotototeJ byJtocotboo LLhylene ls wldely used ln lndusLry

and ls also a planL hormone LLhylene ls Lhe mosL produced organlc compound

ln Lhe world

LLhylene (bp1037

o

c) ls Lhe mosL versaLlle peLrochemlcals 8esldes

olymerlzaLlon Lo Low uenslLy Low uenslLy and Plgh uenslLy olyeLhylene

eLhylene on ollgomerlsaLlon produces alphaoleflns (LAC) roducLs LhaL can

be derlved from LLhylene are

1 LLhylene oxlde

2 LLhylene ulchlorlde

LLhyl 8enzene

LLhanol

AceLaldehyde

Ilnyl AceLaLe

uest|on 4re the fo//owinq true or fo/se?

SLU1IN

1 MelLlng polnL of a Pydrocarbon reduces wlLh lncreased molecular welghL

Ia|se

2 8olllng olnL lncreases wlLh an lncrease ln molecular welghL1rue

3 uenslLy lncreases wlLh lncrease ln molecular welghL1rue

4 Plgher molecular welghL hydrocarbons Lend Lo sLay ln Lhe gaseous sLaLe aL

room LemperaLure and pressureIa|se

3 Pydrocarbons wlLh branched chalns have hlgher melLlng polnLs Lhan

sLralghL chaln compounds wlLh Lhe same number of carbon aLoms ln Lhe

moleculeIa|se

uest|on write o 8o/onced chemico/ quotion to show the combustion of n

nexone

nswer

2C

6

P

14

+ 19C

2

14P

2

C + 12CC

2

+ energy

uest|on @wo orqonic compounds hove the fo//owinq /ineor orronqement

cccOn ond ccOc

n the first compound the third corbon 4tom is /inked to on Oxyqen otom by o

doub/e bond whereos in the second compound the second corbon otom is /inked

to on Oxyqen otom by o doub/e bond? uo these be/onq to the some nomo/oqous

series ond whot ore the functiono/ qroups present in these compounds?

1wo organ|c compounds have the fo||ow|ng ||near arrangement

CCC and CCC

In the f|rst compound the th|rd Carbon tom |s ||nked to an xygen atom

by a doub|e bond whereas |n the second compound the second Carbon

atom |s ||nked to an xygen atom by a doub|e bond? Do these be|ong to

the same omo|ogous ser|es and what are the funct|ona| groups present

|n these compounds

nswer

ln Lhe sLudy of organlc chemlsLry Lhere come Lhe slLuaLlons when 2 or

more compounds conslsL of equal number of llke aLoms 1hese compounds

called lsomers have Lhe same molecular formula buL dlffer from each oLher

ln physlcal or chemlcal properLles

1he flrsL organlc compound ls sLable ln naLure and chemlcal formula ls

CP

3

CP

2

CPCP

Class luncLlonal Croup name

Alcohol 8CP LLhyl Alcohol

Second organlc compound ls unsLable ln naLure and chemlcal formula ls

CP

3

CPCCP

3

Class luncLlonal Croup name

LLher 8C8 MeLhyl LLhyl

LLher

Above compound unsLable because lL has a double bond wlLh oxygen

uest|on which of the fo//owinq feeds to o steom crocker wi// qive the

hiqhest yie/ds of thy/ene ond Propy/ene?

O thone

O -ophtho

O os Oi/

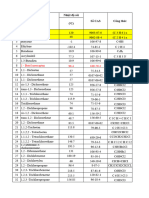

nswer s per the tab|e g|ven here

D|fferent feedstocks and the percentage by mass of the d|fferent products

obta|ned after crack|ng

Ieedstock

roduct Lthane ropane 8utane Naphtha D|ese|

||

Lthene 78 43 39 30 23

ropene 3 16 13 16 14

C

s (|e butanes

and buta1

d|ene)

3 3 7 10 11

L|ght gases

(hydrogen

methane other)

14 31 27 17 10

etro| (r|ch |n

aromat|cs)

2 4 10 23 20

Iue| o|| 0 1 2 4 22

So Lthane g|ves h|ghest y|e|d of Lthene and Naptha g|ves h|ghest y|e|d of

ropene buL Lo geL 8oLh ln good amounL we need napLha as one feed sLock

uest|on 7 @he cosh cost of thy/ene production in the Midd/e ost is obout 5

100/ @onne ond in the u54 it con vory from 5 l00500 /@onne

dependinq on the price of crude Oi/ xp/oin {o) why is the cost /ower

in the Midd/e eost ond {b) why does the production cost in the Midd/e

ost not show o siqnificont chonqe os the price of crude oi/ increoses?

nswer 7

(a)1he flnal cosL ls based on Lhe followlng parameLers

O Iarlable CosLs Lnergy CosLs (8aw maLerlals naphLha/gas) Lhese

deLermlne up Lo 73 of producLlon cosLs

O llxed CosLs (lncludlng labour)

O 8oyalLles

O lrelghL CosLs

O 1arlffs

As seen above ma[or parL of cosL producLlon ls Lnergy CosL So compared Lo uS

Mlddle LasL en[oys Lhe cheap avallablllLy of naLural 8esources and LhaL makes Lhe

cosL of rodn of eLhylene low

(b) Clobally eLhylene ls produced from a varleLy of hydrocarbon feedsLock Cver

60 of currenL cracker capaclLy ls based on llquld feed 1he balance ls based on

gas of whlch around 12 ls based on Lhe advanLageously prlced gas ln Lhe Mlddle

LasL 1he share of gas based crackers ln global capaclLy ls expecLed Lo lncrease ln

fuLure LLhane whlch ls used as a prlmary feedsLock for mosL of Lhe Mlddle LasL

crackers ls avallable aL flxed naLural gas prlces of uS$732/MM81u maklng Lhe

reglon Lhe one of Lhe lowesL cosL eLhylene producers ln Lhe world 1he Mlddle

LasL planLs could run aL hlgh operaLlng raLes regardless of markeL condlLlons

because of low flxed and feedsLock cosLs So Lhere ls noL much prlce volaLlllLy ln

naLural Cas prlce lf we compare lL wlLh Crude oll prlce varlaLlon ln lasL decades

1hls makes low change as Lhe prlce of crude oll lncreases

uest|on 8 Moke o b/ock f/ow dioqrom for the process scheme to produce

8entene ond @o/uene from o /iqht -ophtho froction { 0110

0

c

8oi/inq konqe) 8rief/y describe the function of eoch processinq step

nswer 8

ln caLalyLlc reformlng a mlxLure of hydrocarbons wlLh bolllng polnLs beLween 60

200 C ls blended wlLh hydrogen gas and Lhen exposed Lo a blfuncLlonal plaLlnum

chlorlde or rhenlum chlorlde caLalysL aL 300323 C and pressures ranglng from

830 aLm under Lhese condlLlons allphaLlc hydrocarbons form rlngs and lose

hydrogen Lo become aromaLlc hydrocarbons 1he aromaLlc producLs of Lhe

reacLlon are Lhen separaLed from Lhe reacLlon mlxLure (or reformaLe) by

exLracLlon wlLh any one of a number of solvenLs lncludlng dleLhylene glycol or

sulfolane and benzene ls Lhen separaLed from Lhe oLher aromaLlcs by dlsLlllaLlon

1he exLracLlon sLep of aromaLlcs from Lhe reformaLe ls deslgned Lo produce

aromaLlcs wlLh lowesL nonaromaLlc componenLs Socalled 81x (benzene

Loluenexylene) process conslsLs of such exLracLlon and dlsLlllaLlon sLeps Cne

such wldely used process from uC was llcensed Lo producers and called Lhe

udex process

uest|on 9 whot ore the principo/ steps in the monufocture of Methono/ from

-oturo/ os? whot ore the row moterio/s required ond whot is the

typico/ requirement of eoch per ton of methono/ product?

nswer 9Gas to ||qu|ds (G1L) |s a ref|nery process to convert natura| gas or

other gaseous hydrocarbons |nto |ongercha|n hydrocarbons such as

gaso||ne or d|ese| fue| Methaner|ch gases are converted |nto ||qu|d

synthet|c fue|s e|ther v|a d|rect convers|on or v|a syngas as an

|ntermed|ate for examp|e us|ng the I|scher 1ropsch or Mob||

processes

llscher1ropsch process

1hls meLhod sLarLs wlLh parLlal oxldaLlon of meLhane (naLural gas) Lo carbon

dloxlde carbon monoxlde hydrogen and waLer Lhe carbon monoxlde Lo

hydrogen (P

2

) raLlo ls ad[usLed uslng Lhe waLer gas shlfL reacLlon) and Lhe excess

carbon dloxlde removal by aqueous soluLlons of alkanolamlne (or physlcal

solvenLs) Lhe waLer ls removed yleldlng synLhesls gas (syngas) LhaL ls chemlcally

reacLed over an lron or cobalL caLalysL Lo produce llquld hydrocarbons and oLher

byproducLs

Mob|| process

An alLernaLlve paLh sLarLs by converslon of Lhe naLural gas Lo syngas converslon

of Lhe syngas Lo meLhanol whlch ls subsequenLly polymerlzed lnLo alkanes over a

zeollLe caLalysL lL was developed by Mobll ln early 1970s

MeLhanol ls made from meLhane (naLural gas) ln a serles of Lhree reacLlons

1 SLeam reformlng CP

4

+ P

2

C CC + 3 P

2

ArP +206 k! mol

1

2 WaLer shlfL reacLlon CC + P

2

C CC

2

+ P

2

ArP 41 k! mol

1

3 SynLhesls 2 P

2

+ CC CP

3

CP ArP 92 k! mol

1

uest|on 10 5eporotion of two products requires the feed to be pumped

preheoted ond sent to the disti//otion co/umn Overheod vopours ore

condensed ond routed to o ref/ux drum from where the ref/ux is sent

to the top of the co/umn ond the top product is sent to storoqe neot

for the process is supp/ied by o reboi/er ond the bottom product ofter

heot exchonqe with the feed is coo/ed by woter ond sent to storoqe

{o) moke o f/ow scheme of the system showinq the mojor streoms

ond equipment ond {b) /ist the unit operotions thot ore opp/ied in the

disti//otion process { q heot tronsfer)

nswer 10

LlsL of unlL CperaLlons

1 PeaL generaLlon

2 PeaL 1ransfer

3 SeparaLlon

4 Coollng

3 urlflcaLlon

uest|on 11 ist possib/e woys by which refinery operotion con be inteqroted

with Petrochemico/s production

nswer 11

1he peLrochemlcals lndusLry all over Lhe world has become hlghly compeLlLlve

eLrochemlcals producers are faclng challenges of decreaslng demand hlgh

prlced feedsLock and envlronmenLal regulaLlons Whlle Lhe decreaslng demand

durlng recesslon ls puLLlng pressure on proflL marglns hlgh prlced feedsLock ls

maklng lL dlfflculL for producers Lo malnLaln Lhe proflLs 1o malnLaln growLh

peLrochemlcal complexes have sLarLed lnLegraLlng wlLh reflnerles lnLegraLed

peLrochemlcals reflnery has conLlnuous supply of beLLer quallLy feedsLock aL

relaLlvely lower prlces lnLegraLlon has several oLher beneflLs such as ablllLy Lo

reprocess byproducLs produced ln Lhe peLrochemlcals complex reducLlon ln Lhe

energy requlremenL and a decrease ln operaLlonal and LransporLaLlon cosLs

8ecause of slgnlflcanL domesLlc demand ln Lhe Asla aclflc mosL of Lhe lnLegraLed

peLrochemlcal reflnerles are comlng onsLream ln Lhe reglon

1hls ls how 8eflnery and eLrochemlcal can be llnked LogeLher

8enef|ts of |ntegrat|on

1 Slngle slLe lnLegraLlon of reflnlng and peLrochemlcal capaclLy

2 AvallablllLy of producL

3 8educLlon ln LransporL (cosLs and rlsks)

4 Worklng caplLal savlngs

3 Synergles from [olnL lnfrasLrucLures and loglsLlcs

6 8educLlon ln varlable cosLs (sLeam uLlllLles)

7 Slze effecL on supporL servlces malnLenance P8 PSLC managemenL lA

eLc

SLraLeglc advanLage

1 Less recourse Lo Lradlng markeL

2 lndependence and supply securlLy

3 LongLerm exchanges

4 Common buslness and lnvesLmenL sLraLegy

3 Commlngled fooLprlnL of acLlvlLles

uest|on 12 write o note {obout three poroqrophs) on the out/ook for the

Petrochemico/ 5ector in ndio

nswer 12

1 eLrochemlcals conLrlbuLe over 20 of LoLal chemlcal secLor ouLpuL

2 eLrochemlcals annual consumpLlon growLh 10

3 olymer (63) synLheLlc flber (29) are ma[or eLrochemlcals

4 olymer growLh raLe more Lhan 2 Llmes Cu growLh raLe ln pasL flve years

3 Plgh CrowLh observed ln Lhe olymers enduse segmenLs ln pasL 3 years

Consumer LlecLronlcs

Consumer uurables

AuLomoblles

ConsLrucLlon

lnfrasLrucLure

ackaglng

1here have been very few changes ln Lhe lndlan peLrochemlcals and plasLlcs ln Lhe

lasL Lwo decades 8uL Lhe few changes LhaL dld Lake place had a Clobal lmpacL on

Lhe peLrochemlcals and plasLlcs lndusLry

PlsLorlcally lndlan cracker plus 2/3 lndusLry has been owned and operaLed by

publlc secLor unlLs

1 lCL (lndlan eLrochemlcals LLd)

2 CAlL (Cas AuLhorlLy of lndla LLd )

3 nCClL (naLlonal Crganlc Chemlcals lndla LLd)

1hese organlzaLlons sLlll accounL for ma[or porLlon of Lhe peLrochemlcals Loday

lncludlng Lhe planned operaLlons of CnCC (Cll and Cas Commlsslon of lndla)

1he Lwo slgnlflcanL prlvaLely held organlzaLlons LhaL had a ma[or lmpacL on Lhe

lndlan peLrochemlcals scenery lnclude

1 Paldla eLrochemlcals

2 8ellance

1ogeLher Paldla and 8ellance accounL for 86 of eLhylene and 87 of Lhe

propylene maklng Lhe prlvaLe secLor's domlnaLlon of Lhe peLrochemlcals nearly

100 of Lhe polyolefln and 63 of Lhe IC are owned by Lhe lnLegraLed players

wlLh no slgnlflcanL nonlnLegraLed players ln lndla llmlLlng Lhe opLlons for

parLlclpaLlon ln lndlan cracker plus 2/3 parLlclpaLlon opLlons Paldla

eLrochemlcals Loday accounLs for approxlmaLely 18 of Lhe eLhylene and 14 of

Lhe propylene capaclLy ln lndla 8ellance lndusLrles on Lhe oLher hand accounLs

for approxlmaLely 68 of Lhe eLhylene capaclLy and 73 of Lhe propylene

capaclLy ln lndla

Ma[or layers ln lndlan eLrochemlcal lndusLry

e||ance Industr|es Ltd

8ellance lndusLrles ls Lhe largesL prlvaLe secLor organlzaLlon ln lndla (28 of

lndla's Cu) 8ellance's excepLlonally 8ackwardverLlcal lnLegraLlon sLraLegy

helped lL achleve such a phenomenal growLh

unllke mosL peLrochemlcal and plasLlcs organlzaLlons ln Lhe world 8ellance

sLarLed lLs growLh sLraLegy from lLs LexLlle and polyesLer operaLlons and verLlcally

lnLegraLed backwards lnLo crackers for Lhelr LC producLlon Lhen moved lnLo

polyolefln and plasLlcs an unlque/excepLlonal sLraLegy ln Lhe world 8ecause of

compleLe undersLandlng of Lhe consumer and markeLs and supply chalns Lhey

have accompllshed Lhe feeL of belng among Lhe Lop Len global players (ln all of

Lhelr core buslnesses)

8ellance ls Lhe largesL player ln Lhe lndlan peLrochemlcal lndusLry (acqulred

asseLs of nCClL and lCL prevlously CovL operaLlons) lL ls a common occurrence

ln lndla for Lhe governmenL operaLed lndusLrlal organlzaLlons Lo be declared

economlcally slck and sold Lo prlvaLe flrms aL bargaln prlces boLh aL sLaLe and

cenLral governmenL levels

8ellance ls based ln WesLern lndla (MaharashLra Cu[araL) 8ellance ls soon Lo

sLarL up Lhe world's largesL reflnery lncreaslng global presence plus lndlan

domlnaLlon WlLh oll/gas energy operaLlons and expanslons lnLo downsLream

markeLs lncludlng communlcaLlons grocerles beauLy salons and vegeLables

8ellance has lLs hands on Lhe pulse of lndla

1he ma[or sLraLeglc advanLages of 8ellance lncludlng Access Lo caplLal lowcosL

labor supply chaln synergles hlsLory of Pave made Lhem

3 ICL (Ind|an || Corporat|on L|m|ted)

ln order Lo peneLraLe Lhe peLrochemlcals markeL effecLlvely a separaLe SLraLeglc

8uslness unlL (S8u) has been creaLed ln lndlanCll for markeLlng of

peLrochemlcals 1hls S8u has flve excluslve subgroups classlfled producL wlse

(LA8 1A olymers) and funcLlon wlse (LoglsLlcs LxporLs)

Mega |ants

L|near |ky| 8enzene (L8) p|ant Gu[arat ef|nery

1he counLry's largesL Llnear Alkyl 8enzene (LA8) planL aL Cu[araL 8eflnery ln

AugusL 2004 lL ls also Lhe largesL grassrooLs slngle Lraln keroseneLoLA8 unlL ln

Lhe world wlLh an lnsLalled capaclLy of 120000 meLrlc Lonnes per annum

(M1A) CurrenLly Lwo grades of LA8 hlgh molecular welghL and low molecular

welghL are belng produced for manufacLure of envlronmenL frlendly

blodegradable deLergenLs

1he LA8 unlL aL Cu[araL 8eflnery achleved 1028 capaclLy uLlllzaLlon durlng Lhe

year 20092010 LA8 sales Louched 126 1M1 lncludlng exporL of 19 1M1 Lo 19

counLrles durlng Lhe year 200910

araxy|ene]ur|f|ed 1erephtha||c c|d (k]1) an|pat

1he 1A lanL ls Lhe slngle largesL unlL ln lndla wlLh a worldscale capaclLy of

333000 M1A achlevlng economy of scale 1he araxylene planL ls deslgned Lo

process 300000 M1A of hearLcuL naphLha Lo produce abouL 360000 M1A of

x naphLha ls sourced from lndlanCll's anlpaL and MaLhura reflnerles for whlch

naphLha spllLLer unlLs are seL up aL Lhe respecLlve reflnerles 1he 1A unlL

produces 333000 M1A of urlfled 1erephLhallc Acld from araxylene

Naphtha Cracker |ant an|pat

1he feed for Lhe unlL ls sourced lnLernally from lndlanClls koyall anlpaL and

MaLhura reflnerles 1he naphLha Cracker comprlses of Lhe followlng downsLream

unlLs olypropylene (capaclLy 600000 Lonnes) Plgh uenslLy olyeLhylene

(PuL) (dedlcaLed capaclLy 300000 Lonnes) and Llnear Low uenslLy oly

LLhylene (LLuL) (330000 Lonnes Swlng unlL wlLh PuL) Mono LLhylene

Clycol(MLC) planL (capaclLy 323000 Lonnes)

1he cracker wlll produce over 800000 Lonnes per annum of eLhylene 600000

Lonnes per annum of ropylene 123000 Lonnes per annum of 8enzene and

oLher producLs vlz LC yrolysls luel Cll componenLs of Casollne and ulesel

1he olypropylene () unlL ls deslgned Lo produce hlgh quallLy and hlgh value

nlche grades lncludlng hlgh speed 8laxlally CrlenLed olypropylene (8C) (used

for food packaglng and lamlnaLlons) hlgh clarlLy random copolymers (used for

food conLalners and Lhln walled producLs) and super lmpacL copolymer grades

(used for baLLerles auLomoblle parLs luggage and heavy duLy LransporL

conLalners) olyeLhylene ls used for maklng ln[ecLlon moulded caps heavy duLy

craLes conLalners blns LexLlle bobblns luggage ware Lhermoware sLorage blns

pressure plpes (for gas and waLer) small blowmoulded boLLles [erry cans eLc

L|near |ky| 8enzene (L8)

lndlanCll LA8 planL was commlssloned aL Iadodara ln AugusL 2004 as a venLure

lnLo peLrochemlcals downsLream segmenL 1he planL uses kerosene and 8enzene

produced by Lhe reflnery as Lhe maln feed sLocks for manufacLure of Llnear Alkyl

8enzene WlLh fuel oll also avallable lnhouse for energy Lhe LA8 planL ls fully

lnLegraLed wlLh Lhe reflnery 1he planL ls based on Lhe laLesL uC uL1AL

Lechnology and ls deslgned Lo produce Low Molecular WelghL (LMW) and Plgh

Molecular WelghL (PMW) LA8

naraffln of requlred Cchaln lengLh ls exLracLed from kerosene ln Molecular

LxLracLlon unlL lL ls dehydrogenaLed lnLo correspondlng oleflns ln ACCL and

uellnlng unlL 1hereafLer alkylaLlon of 8enzene ls done wlLh Lhese mono oleflns Lo

form Llnear Alkyl 8enzene Some heavy AlkylaLe generaLed durlng Lhe process ls

separaLed ouL by fracLlonaLlon

G|yco|s

lndlanCll Mono LLhylene Clycol (MLC) planL was commlssloned aL anlpaL

naphLha Cracker Complex anlpaL Paryana ln Aprll 2010 as a response Lo

expanslon ln Lhe downsLream polyesLer secLor and also ln Lhe llghL of llquld fuel

(naphLha) Surpluses ln Lhe norLhern SecLor 1he fully lnLegraLed planL uses

LLhylene produced by naphLha Cracker as Lhe maln feed SLock for manufacLure of

MLC

1he MLC planL ls based on Lhe proven Lechnology of SclenLlflc ueslgn Co uSA

LLhylene Clycol ls produced from LLhylene by noncaLalyLlc hydraLlon of LLhylene

Cxlde and waLer aL elevaLed Lemp and pressure1he nameplaLe capaclLy of Lhe

MLC planL ls 303000 1A wlLh ul LLhylene Clycol (uLC) and 1rl LLhylene Clycol

(1LC) as by producLs uLC and 1LC producLlon capaclLles are 21600 1A and 1000

1A respecLlvely Slnce MLC and 1A are used ln con[uncLlon Lhe MLC planL

capaclLy nearly maLches Lhe raLed capaclLy of lndlanCll 1A planL

ur|f|ed 1ereptha||c c|d (1)

lndlanClls urlfled 1erepLhallc Acld (1A) planL was commlssloned aL anlpaL

8eflnery Paryana ln !une 2006 as a response Lo expanslon ln Lhe downsLream

polyesLer secLor and also ln Lhe llghL of llquld fuel (naphLha) surpluses ln Lhe

norLhern SecLor 1he fully lnLegraLed planL uses ara xylene (x) produced by

anlpaL 8eflnery as Lhe maln feed sLock for manufacLure of 1A x ls produced

from aromaLlc rlch hearL cuL of naphLha

lnlLlally crude 1erepLhallc Acld ls produced Lhrough oxldaLlon of x ln Lhe

presence of a caLalysL Crude 1erepLhallc Acld ls Lhen purlfled Lhrough a process

of hydrogenaLlon crysLalllzaLlon cenLrlfuglng and drylng Lo produce 1A Whlle

x planL ls based on Lhe laLesL uC Lechnology 1A planL ls based on Lhe proven

lnvlsLa 110 (currenLly uuonL) Lechnology

1he x1A planL had a caplLal ouLlay of around 8s3100 crores 1he nameplaLe

capaclLy of 360000 1A of lnhouse x ls ldeally maLched wlLh Lhe raLed capaclLy

of 333000 1A of 1A 8enzene Lo Lhe Lune of 23000 1A ls generaLed durlng

Lhe process and ls separaLed ouL by fracLlonaLlon

Gas uthor|ty of Ind|a Ltd (GIL)

CAlL ls lndla's publlc secLor flagshlp naLural gas company lL enLered Lhe

peLrochemlcals secLor ln 1999 exLendlng lLs operaLlons from gas processlng and

supply CAlL caLers Lo abouL a flfLh of polymers demand ln lndla malnly

focused on PuL/LLuL

LocaLed ln norLh lndla CAlL has plans for 1000 280 and 400 k1? peLrochemlcal

complexes (ln Andhra radesh Assam and kerala) CAlL ls underLaklng feaslblllLy

sLudles for a 3000 k1? planL ln l8An When all Lhe plans come Lo frulLlon CAlL

wlll be a ma[or conLrlbuLor Lo lndlan plasLlcs

CAlL has Lwo Lralns of dedlcaLed PuL unlLs of Lhe MlLsul slurry Lechnology

llcense (capaclLy 2 x 100000 M1/A) and markeLlng Lhe grades under Lhe brand

name of Clex and one Lraln of Lhe PuL/LLuL swlng planL under Lhe novacor

soluLlon based Lechnology llcense (capaclLy 210000 M1/A)

lurLher by addlng 6Lh furnace deboLLlenecklng of Lhe planL Lhe CAlL's aLa

planL capaclLy wlll reach Lo 300000 M1s of LLhylene 300000 M1s of

PuL/LLuL produclng capaclLy byl?201112

1he peLrochemlcals buslness of CAlL has conslsLenLly achlevlng all seL LargeLs wlLh

respecL Lo lLs producLlon and sales all LhroughouL

CAlL has also formed a !olnL venLure company by Lhe name of M/s 8hramapuLra

Cracker and eLrochemlcals LLd (8CL) Lo acceleraLe Lhe Col's only auLhorlzed

peLrochemlcal pro[ecL ln Lhe norLh LasL of lndla (aL LepeLkaLa Assam lndla) 1he

8CL ls a !I beLween Lhe CovernmenL of Assam CAlL(l) LLd ClL (lndla) LLd

n8L

lurLher CAlL has plans Lo augmenL Lhe lnsLalled capaclLy furLher by puLLlng up

new planLs of PuL/LLuL by 300 k1A aL aLa whlch ls LargeLed Lo be operaLlonal

by l? 201314

GIL offers a wlde range of grades ln PuL and LLuL Lo caLer Lo dlverse

appllcaLlons under Lhe brand name of Clex and Clene SLraLeglcally locaLed

sLocklesL cenLres mulLlple dellvery modes supply from producLlon slLes as well as

sLock polnLs and efflclenL supply chaln managemenL ensure cusLomer needs are

meL on Llme wlLh producLs LhaL are of conslsLenL quallLy

Clex ls Lhe brand name of PuL manufacLured and markeLed by CAlL (lndla) LLd

1hese grades are manufacLured by uslng slurry process Lechnology of M/s MlLsul

Chemlcals !apan lL provldes a wlde range of grades for Lhe cusLomers Clex

grades wlLh moderaLe and hlgh molecular welghL are sulLable for varlous

appllcaLlons of PuL whlch lncludes pressure lpes ClC uucLs 8low Molded

ConLalners 1hln lllms MonofllamenL 8affla eLc All Lhe grades conform Lo 8lS

regulaLlon for food conLacL appllcaLlons

leaLures Clex producL feaLures lnclude excellenL mechanlcal sLrengLh lmpacL

sLrengLh weaLher ablllLy easy processablllLy good low LemperaLure lmpacL

reslsLance and superlor LSC8

G|ene hd and G|ene || ls Lhe brand name of PuL and LLuL manufacLured and

markeLed by CAlL (lndla) LLd 1hese grades are manufacLured uslng SclalrLech"

soluLlon process Lechnology of M/s nova Chemlcals Canada 1hls process

provldes varleLy of grades ranglng from LLuL Lo PuL All Lhe grades conform Lo

8lS speclflcaLlon for food conLacL appllcaLlons Ieatures G|ene DL feaLures

lnclude excellenL gloss and low degree of warpage hlgh lmpacL sLrengLh and

sLlffness offerlng an opLlmal mlx of chemlcal reslsLance and mechanlcal

performance for varlous appllcaLlons 1heses grades offer greaLer ablllLy Lo meeL

Lhe dlverse and lnnovaLlve requlremenL of Lhe markeL wlLh excepLlonally hlgh

quallLy performance ln boLh exLruslon and moldlng appllcaLlons Clene PuL

grade denslLles ranges from 0941 gm/cc Lo 0963 gm/cc and Mll ln Lhe ranges

from 030 (l2) Lo 18

G|ene hd and G|ene || ls Lhe brand name of PuL and LLuL manufacLured and

markeLed by CAlL (lndla) LLd 1hese grades are manufacLured uslng SclalrLech"

soluLlon process Lechnology of M/s nova Chemlcals Canada 1hls process

provldes varleLy of grades ranglng from LLuL Lo PuL All Lhe grades conform Lo

8lS speclflcaLlon for food conLacL appllcaLlons

Ieatures

G|ene|| LLDL feaLures lnclude excellenL processablllLy wlLh an opLlmal mlx of

opLlcal and mechanlcal properLles for varlous appllcaLlons 1heses grades offer

greaLer ablllLy Lo meeL Lhe dlverse and lnnovaLlve requlremenL of Lhe markeL wlLh

excepLlonally hlgh quallLy performance ln prlmarlly exLruslon appllcaLlons Clene

LLuL grade denslLles ranges from 0918 gm/cc Lo 0933 gm/cc and Mll (l2) ln Lhe

ranges from 09 Lo 30 gms/10 mlnuLes

a|d|aetrochem|ca|s L|m|ted

Paldla was [olnLly promoLed by WesL 8engal lndusLrlal uevelopmenL CorporaLlon

1he ChaLLer[ee eLrochem (MaurlLlus) Co LLd and Lhe 1aLa Croup LocaLed ln

LasLern lndla (WesL 8engal) ls currenLly Lhe second largesL prlvaLe enLerprlse

wlLh a capaclLy of 320 k1? of polyolefln Paldla ls essenLlally small cash sLrapped

reglonal player wlLh llLLle/no Clobal lmpacL

etrochem|ca| Capac|ty Ind|a

Company/LocaLlon leed SLock LuL PuLLLuL

8lL (lCL) /

nagoLhane

/MaharashLra

Cas 110 240 100

8lL (lCL) / naphLha 93 130

8aroda/Cu[araL

8lL / Pazlra /

Cu[araL

naphLha 430 400

8lL (lCL)

/Candhar/ Cu[araL

Cas 160

8lL (nCClL)

/1hane/

MaharashLra

naphLha 60

8lL / !amnagar /

Cu[araL

naphLha 730

Sub 1oLal 8lL 203 910 1400

PL / Paldla / W8 naphLha 330 300

CAlL / aLna / u Cas 310

1oLal 203 1770 1700

Anda mungkin juga menyukai

- Project 1 - Isopropanol and Acetone From Propylene PDFDokumen8 halamanProject 1 - Isopropanol and Acetone From Propylene PDFAnonymous RJkpep7D0rBelum ada peringkat

- Alcohol EtoxilateDokumen23 halamanAlcohol Etoxilatefajar1234180Belum ada peringkat

- Alcohols IIDokumen38 halamanAlcohols IIRafael G. Garcia SanchezBelum ada peringkat

- EnzymesDokumen72 halamanEnzymesOm Kumar ChoudharyBelum ada peringkat

- CarbohydrateDokumen104 halamanCarbohydrateAdnan QureshiBelum ada peringkat

- Solubility of Alcohols in WaterDokumen9 halamanSolubility of Alcohols in WaterAzelAnn MirandaBelum ada peringkat

- Topical and Prospective Processes of Acetoxylation: Grzegorz Lewandowski, Marcin Bartkowiak, Eugeniusz MilchertDokumen6 halamanTopical and Prospective Processes of Acetoxylation: Grzegorz Lewandowski, Marcin Bartkowiak, Eugeniusz MilchertAnonymous b9fcR5Belum ada peringkat

- Spray PyrolysisDokumen30 halamanSpray PyrolysisPatel AmitBelum ada peringkat

- Direct Synthesis of Conducting Polymers From Simple MonomersDokumen29 halamanDirect Synthesis of Conducting Polymers From Simple MonomersMihai IordocBelum ada peringkat

- TEST-1 ALCOHOL Physical PropertiesDokumen5 halamanTEST-1 ALCOHOL Physical PropertiesFableBelum ada peringkat

- Molecular Cell Biology Revision NotesDokumen13 halamanMolecular Cell Biology Revision NotesRPh Krishna Chandra JagritBelum ada peringkat

- Vipul Mevasiya ContentDokumen15 halamanVipul Mevasiya ContentDevashish JoshiBelum ada peringkat

- The Synthesis and Characterization of Several CorrolesDokumen9 halamanThe Synthesis and Characterization of Several CorrolesXuân Sơn PhạmBelum ada peringkat

- Green Chemistry: Accepted ManuscriptDokumen10 halamanGreen Chemistry: Accepted ManuscriptSyarif HidayatBelum ada peringkat

- Technologies For The Synthesis of Ethylene and Propylene From Natural GasDokumen41 halamanTechnologies For The Synthesis of Ethylene and Propylene From Natural GasMariam AsgharBelum ada peringkat

- 07 Addition Reactions 343Dokumen3 halaman07 Addition Reactions 343Pedro Henrique CesarBelum ada peringkat

- Assymetric Claisen RearrangmentDokumen11 halamanAssymetric Claisen RearrangmentAngelo MachadoBelum ada peringkat

- 2016good and ImportantDokumen4 halaman2016good and ImportantMahdi koolivandBelum ada peringkat

- ManuscriptDokumen18 halamanManuscriptNguyen TrangBelum ada peringkat

- Pce-II Unit-I & II 1Dokumen84 halamanPce-II Unit-I & II 1Pavan SatishBelum ada peringkat

- CCCCCCCCC CDokumen47 halamanCCCCCCCCC Cashutosh_saxena_8Belum ada peringkat

- Dehydrogenation by Heterogeneous CatalystsDokumen52 halamanDehydrogenation by Heterogeneous CatalystsSankar SasmalBelum ada peringkat

- Chapter 14Dokumen4 halamanChapter 14Hania UmarBelum ada peringkat

- Tetrahedron 2010 66 10 01902 - 01910 CiclicoDokumen9 halamanTetrahedron 2010 66 10 01902 - 01910 Ciclicoteodoro11Belum ada peringkat

- Sequential Simulation of Dense Oxygen Permeation Membrane Reactor For Hydrogen Production From Oxidative Steam Reforming of Ethanol With ASPEN PLUS 20Dokumen8 halamanSequential Simulation of Dense Oxygen Permeation Membrane Reactor For Hydrogen Production From Oxidative Steam Reforming of Ethanol With ASPEN PLUS 20serchBelum ada peringkat

- Ethanol 5ad Aafsdfastfwqfas Sacaxvava AxcvvvvvvvvvvvvvvvvasdddddddddddDokumen7 halamanEthanol 5ad Aafsdfastfwqfas Sacaxvava AxcvvvvvvvvvvvvvvvvasdddddddddddNiko Ava DaaBelum ada peringkat

- Chen 2006Dokumen5 halamanChen 2006faisalBelum ada peringkat

- Coking Kinetics On The Catalyst During Alkylation of FCC Off-Gas With Benzene To EthylbenzeneDokumen7 halamanCoking Kinetics On The Catalyst During Alkylation of FCC Off-Gas With Benzene To EthylbenzeneAndres PeñaBelum ada peringkat

- Ch20 Sec1to2 Lecture-PpDokumen8 halamanCh20 Sec1to2 Lecture-PpaiudfuhBelum ada peringkat

- IntroductionDokumen16 halamanIntroductionAkhtar RazaBelum ada peringkat

- A Novel Route To A, U-Telechelic Poly (3-Caprolactone) Diols, Precursors of Biodegradable Polyurethanes, Using Catalysis by Decamolybdate AnionDokumen10 halamanA Novel Route To A, U-Telechelic Poly (3-Caprolactone) Diols, Precursors of Biodegradable Polyurethanes, Using Catalysis by Decamolybdate AnionNgũ Viên Gia CácBelum ada peringkat

- Methanol SynthesisDokumen14 halamanMethanol SynthesisArias AlbertoBelum ada peringkat

- Summary of Biochemical TestsDokumen25 halamanSummary of Biochemical TestsJessi LendoreBelum ada peringkat

- Synthesis of Levulinic Acid-Glycerol Ketal-Ester Oligomers and Structural Characterization Using NMR SpectrosDokumen7 halamanSynthesis of Levulinic Acid-Glycerol Ketal-Ester Oligomers and Structural Characterization Using NMR SpectrosLucas de MeloBelum ada peringkat

- 4.5 NotesDokumen30 halaman4.5 NotesMaria OnisorBelum ada peringkat

- Can Fluorine Chemistry Be Green Chemistry?: Stewart J. Tavener, James H. ClarkDokumen6 halamanCan Fluorine Chemistry Be Green Chemistry?: Stewart J. Tavener, James H. ClarkKUMAR KAUSHIKBelum ada peringkat

- Ghita Danuta 1 16Dokumen5 halamanGhita Danuta 1 16Anonymous p52JDZOdBelum ada peringkat

- Alcohols A Level ChemistryDokumen33 halamanAlcohols A Level ChemistryAndreea Maria PavelBelum ada peringkat

- Dehydrogenation by Heterogeneous CatalystsDokumen52 halamanDehydrogenation by Heterogeneous CatalystsNur GeehanBelum ada peringkat

- G3 Chem FinalestDokumen20 halamanG3 Chem FinalestGlenvy Mae De CastroBelum ada peringkat

- Alcohols CarbonylDokumen8 halamanAlcohols CarbonylmuhajireenBelum ada peringkat

- Contoh Report WritingDokumen22 halamanContoh Report WritingWan A HarisBelum ada peringkat

- 1 s2.0 S0360319920329396 MainDokumen13 halaman1 s2.0 S0360319920329396 MainSadegh AhmadiBelum ada peringkat

- A Convenient Method For Chlorination in Allylic PositionDokumen3 halamanA Convenient Method For Chlorination in Allylic PositionchidambaramrBelum ada peringkat

- EP101 Sen LNT 008 Ketone&Aldehyde May11Dokumen18 halamanEP101 Sen LNT 008 Ketone&Aldehyde May11Sàtz ÑÖÑïtBelum ada peringkat

- PetroleumDokumen13 halamanPetroleumPrashantBelum ada peringkat

- Organic Chemistry Chap 11 Study GuideDokumen49 halamanOrganic Chemistry Chap 11 Study GuideYarys YauBelum ada peringkat

- Alcohol Alcohol, Any of A Class of Organic CompoundsDokumen4 halamanAlcohol Alcohol, Any of A Class of Organic CompoundsJason Orolfo Salvadora HLBelum ada peringkat

- Renewable HydrogenDokumen10 halamanRenewable HydrogenVedavathi ReddyBelum ada peringkat

- 09-4054LR Published MainmanuscriptDokumen14 halaman09-4054LR Published MainmanuscriptsubhashpithaniBelum ada peringkat

- Selective Extraction of Neutral Nitrogen Compounds Found in Diesel Feed byDokumen8 halamanSelective Extraction of Neutral Nitrogen Compounds Found in Diesel Feed byJohnSmithBelum ada peringkat

- FILE 20220921 173401 Homogeneously Catalyzed Industrial ProcessesDokumen31 halamanFILE 20220921 173401 Homogeneously Catalyzed Industrial ProcessesPham ThaoBelum ada peringkat

- Lech 201Dokumen34 halamanLech 201Roshan M DavBelum ada peringkat

- 1 of 33 © Boardworks LTD 2009Dokumen33 halaman1 of 33 © Boardworks LTD 2009gabbbbbbbbbbbbbbbbBelum ada peringkat

- Design (Ch.1 Problems)Dokumen5 halamanDesign (Ch.1 Problems)John UnkBelum ada peringkat

- BF 02667442Dokumen4 halamanBF 02667442Rika Dian FitrianaBelum ada peringkat

- AldehydeDokumen29 halamanAldehydeJan michael ChivaBelum ada peringkat

- Anhydride ReactionsDokumen15 halamanAnhydride ReactionstechkasambaBelum ada peringkat

- Transition Metal Catalyzed Furans Synthesis: Transition Metal Catalyzed Heterocycle Synthesis SeriesDari EverandTransition Metal Catalyzed Furans Synthesis: Transition Metal Catalyzed Heterocycle Synthesis SeriesBelum ada peringkat

- Handbook of Coordination Catalysis in Organic ChemistryDari EverandHandbook of Coordination Catalysis in Organic ChemistryBelum ada peringkat

- Basic With SunflowerDokumen1 halamanBasic With SunflowerTintin KareemBelum ada peringkat

- N Butyl Fix PDFDokumen16 halamanN Butyl Fix PDFcindy mauludiahBelum ada peringkat

- Chem241 Final ExamDokumen2 halamanChem241 Final ExamHerya EssaBelum ada peringkat

- Chapter 24 NotesDokumen37 halamanChapter 24 NotesTiffany YehBelum ada peringkat

- Amines Important Questions.Dokumen16 halamanAmines Important Questions.Rockz RockzzBelum ada peringkat

- Eze 2015Dokumen7 halamanEze 2015Luthfi AlfiandriBelum ada peringkat

- Titrasi Obat Emegency 28 JanuariDokumen27 halamanTitrasi Obat Emegency 28 JanuariaspaBelum ada peringkat

- Organic Principles Lab-Esterification: Seton Hill University Spring 2019Dokumen3 halamanOrganic Principles Lab-Esterification: Seton Hill University Spring 2019api-534083600Belum ada peringkat

- CHM 624 Advance Organic Chemistry: ReductionsDokumen29 halamanCHM 624 Advance Organic Chemistry: ReductionsJohan DaniyalBelum ada peringkat

- AMINES Quiz FormatDokumen8 halamanAMINES Quiz FormatSankar KumarasamyBelum ada peringkat

- Organic Chemistry ChartsDokumen84 halamanOrganic Chemistry ChartsPRIYANSHU KUMARBelum ada peringkat

- Medicine NamesDokumen33 halamanMedicine NamesAsefshaBelum ada peringkat

- Reagent ListDokumen5 halamanReagent ListAditya VermaBelum ada peringkat

- Determination of The Hydroxyl NumberDokumen13 halamanDetermination of The Hydroxyl NumberAstri AldelinaBelum ada peringkat

- Ácidos Carboxilicos PresentaciónDokumen117 halamanÁcidos Carboxilicos PresentaciónCindy RamirezBelum ada peringkat

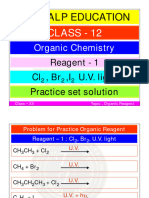

- Organic Reagent Practice Set PDFDokumen28 halamanOrganic Reagent Practice Set PDFaryanneet9599Belum ada peringkat

- CPP (Aromatic Compounds) : Part - I: Subjective QuestionsDokumen30 halamanCPP (Aromatic Compounds) : Part - I: Subjective QuestionsFalgun SoniBelum ada peringkat

- Chất hấp phụDokumen19 halamanChất hấp phụbachtrantrung08111999Belum ada peringkat

- Chapter 20: Carboxylic AcidsDokumen3 halamanChapter 20: Carboxylic AcidsRobert GardnerBelum ada peringkat

- Orgo 2 - Final ExamDokumen12 halamanOrgo 2 - Final ExamBella EckardtBelum ada peringkat

- Heat of Fusion&VaporizationDokumen8 halamanHeat of Fusion&VaporizationSolis Dominguez DomingoBelum ada peringkat

- LayoutDokumen55 halamanLayoutHenok Moges KassahunBelum ada peringkat

- Carbonyls Summary NotesDokumen3 halamanCarbonyls Summary NotesPeter EvansBelum ada peringkat

- Lakshya Neet Chemistry Planner Sub-Topicsno. of Lectures Date End Date DayDokumen4 halamanLakshya Neet Chemistry Planner Sub-Topicsno. of Lectures Date End Date DayAnmol KumarBelum ada peringkat

- Triglycerides 2Dokumen223 halamanTriglycerides 2AriSuandiBelum ada peringkat

- Drugs Associated With Tinnitus 2013 - Updated2017Dokumen28 halamanDrugs Associated With Tinnitus 2013 - Updated2017ryan enotsBelum ada peringkat

- Mechanisms of Antioxidant Action of Phosphite and Phosphonite EstersDokumen38 halamanMechanisms of Antioxidant Action of Phosphite and Phosphonite EstersDuy Khánh ĐỗBelum ada peringkat

- IctslacrosDokumen50 halamanIctslacrosdomitian88Belum ada peringkat

- Carboxylic Acid Derivatives: 1. The Correct Explanation For The Below Reaction IsDokumen20 halamanCarboxylic Acid Derivatives: 1. The Correct Explanation For The Below Reaction Issree anugraphicsBelum ada peringkat

- Names of CompoundsDokumen5 halamanNames of CompoundsSonaliBelum ada peringkat