Nachi Hydraulic

Diunggah oleh

Dian PramadiDeskripsi Asli:

Hak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

Nachi Hydraulic

Diunggah oleh

Dian PramadiHak Cipta:

Format Tersedia

A

NACHI Hydraulic Pumps

Features

qNachi Fujikoshi hydraulic pumps are finished by high-grade, precision machining technology unique to the comprehensive manufacturer Nachi Fujikoshi using carefully selected materials and traditional heat treatment technology. High performance and quality are assured with all models of Nachi Fujikoshi hydraulic pumps. wNoise has been thoroughly reduced on hydraulic pumps, a general source of noise on machinery and equipment. All models such as the lownoise type IP series can be operated quietly with little noise. eAttention has been paid to surface treatment and selection of materials in NACHI hydraulic pumps so that they can be applied extensively with fire-resistant hydraulic operating fluid. oWhen inserting couplings into shafts, insert them gently. When removing couplings from shafts, be sure to use a pulley extractor. Avoid hitting the shaft when attaching or removing couplings. !0Connect to the suction port above the horizontal to keep oil inside hydraulic pumps. !1Provide an air bleed valve in circuits where it is difficult to release air at startup. !2Be sure to use only specified bolts on hydraulic pumps. Use 12T or equivalent.

Terms Used in This Catalog

The following describes the meanings of the following terms used in this catalog: Rated pressure: The maximum pressure at which a hydraulic pump can be used continuously. Maximum operating pressure: The maximum pressure (including surge pressure) at which a hydraulic pump can be used within six seconds at most within 1/10 of the cycle time. Allowable peak pressure: The maximum pressure (set pressure + surge pressure) that can be momentarily allowed The following shows the standards in Lists of Sealing Parts: JIS standard B2401 (O-ring) JIS standard B2407 (backup ring) SAE standard AS568 (O-ring) Pipe apertures mentioned in this catalog that are indicated as "G*/*" comply with JIS B2351 O-ring seal systems. Note, however, that G3/4 adopts dimensions before JIS revisions were made in 1990. Nachi Fujikoshi adopts P24 as the O-ring size whereas P22.4 is stated in current JIS standards.

Uni-pumps

Uni-pumps are compact pump/motor units which have a motor directly coupled to the hydraulic pump. Variable discharge volume type vane pumps and piston pumps are available. As each of these pumps are ideally integrated with the motor, they can be easily installed, and more compact equipment configurations can be achieved economically. Standard motor: totally-enclosed splashproof housing surface flange cooled self-actuating type (totally enclosed fan-cooled type) 3.7 kW to 4P or less: Class E insulation 5.5 kW to 4P or more: Class B insulation Voltage 200V50/60 Hz 220V60 Hz

Installation and Maintenance

qLimit the eccentricity between the drive shaft and hydraulic pump shaft to 0.05 mm, keep the angle error within 1 and use flexible couplings for connections. wWhen operating hydraulic pumps with belts, gears and chains, prevent a radial or thrust load exceeding the allowable value from being applied on the pump shaft. Also, if necessary, install a device that prevents a load (bending force) from being applied at right angles on the shaft. Mount hydraulic pumps so that the pump shaft is horizontal. eUse a rigid pump mounting base. rThe direction of rotation is determined on each hydraulic pump. Operate the hydraulic pump in the correct direction of rotation after checking the indicated model No. on the nameplate or the arrow indicating the direction of rotation on the body. The direction of rotation is clockwise when viewed from the shaft end. tLimit the suction pressure to within the range -0.03 to +0.03 MPa {-0.3 to +0.3 kgf/cm2}. yWith external drain type hydraulic pumps, directly connect the drain to the tank, insert the drain pipe under the oil level, and limit the drain back pressure to 0.03 MPa {0.3 kgf/cm2}. uWhen connecting steel pipes to the suction and discharge sides, prevent force pressure from being applied on the hydraulic pump by the piping. iSet the clamping length of couplings and hydraulic pump shafts so that it is within at least 2/3 or more of the coupling width. Also, use a size of coupling that matches the shaft diameter.

Calculation Formula Required when Selecting Hydraulic Pumps and Motor

1.Pump discharge flow rate qNv Qp= (r/min) 1000 q=discharge volume per rotation (cm3/rev) -1 N=revolution speed(min ) v=volume efficiency 2.Power required for pump drive PQp WP1= (kW) 60 PQp (PS) = 44 P=discharge pressure(MPa) =overall efficiency 3.Motor revolution spee 120f N= (1S)(min-1) P f=frequency(50Hz, 60Hz) P=number of motor poles S=slip rate

Management of Hydraulic Operating Fluid

qUse mineral oil-based hydraulic operating fluid. wProvide a suction filter of about 100 to 150 mesh on the suction port. eWhen operating hydraulic pumps at a high pressure or when using fireresistant hydraulic operating fluid, oil contamination greatly affect pump service life. So, use a filter of 25m or less. rConsult your agent when using fireresistant hydraulic operating fluid. When using water- or glycol-based hydraulic operating fluid, refer to page N-3 for details on applicable models of hydraulic pumps. tFor details on the viscosity of hydraulic operating fluid, refer to the separate item "Hydraulic Operating Fluid."

A-1

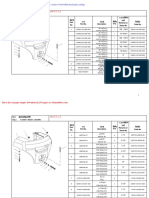

Hydraulic Pump Selection Table

A

Hydraulic Pumps

Pump Type

Name

Rated Type Pressure ClassifiMPa cation 2

{kgf/cm }

Displacement cm3/rev

1 2 5 10 20 50 100 200 500 1000 2000 5000

Page

Variable piston pumps

PVS series variable piston pump Uni-pump PZS series variable piston pump PZ load-sensitive variable piston pump PZH series high-pressure variable piston pump VDS series compact variable vane pump

PVS UPV PZS PZ PZH VDS USV VDR UVD VDR UVD VDC UVC UVN IPH IPH

21 {214} 21 {214} 21 {214} 21 {214} 35 {357} 7 {71.4} 7 {71.4} 14 {143} 7 {71.4} 6 {61.2} 6 {61.2} 14 {143} 7 {71.4} 8 {81.6} 25 {255} 21 {214}

3 3 42 8 28 3 3 5 5 4 4 5 5 8.1 3.6 7.2 8.3 8.3

45 45 220 220 40

A-3 A-19 A-22 A-35 A-42 B-1 B-4

Variable discharge volume vane pumps

Uni-pump VDR22 design series variable vane pump Uni-pump VDR13 design series variable vane pump Uni-pump VDC series high-pressure variable vane pump Uni-pump UVN series variable vane uni-pump

44.4 33.3 27.8 27.8 88.9 33.3 16.1 125.9 251.8

B-6 B-12 B-15 B-22 B-25 B-37 B-39 C-1 C-14

Internal gear pump

IPH series IP pump IPH series double IP pump

A-2

Anda mungkin juga menyukai

- Variable Vane Pumps: 1 P V 2 V 3 - / RA01MC A 1Dokumen8 halamanVariable Vane Pumps: 1 P V 2 V 3 - / RA01MC A 1Dias EliBelum ada peringkat

- SodaPDF Splitted LG856H.bookDokumen30 halamanSodaPDF Splitted LG856H.bookleogerguz100% (1)

- Wheeled Loader L956F Specs and FeaturesDokumen1 halamanWheeled Loader L956F Specs and FeaturesPrayoga Wahyu PratamaBelum ada peringkat

- Applicable Brand & Model: Ningbo Fix Machine Co.,LtdDokumen3 halamanApplicable Brand & Model: Ningbo Fix Machine Co.,LtdЕкатерина КалашниковаBelum ada peringkat

- 10 - Group - 16 - Engine - Electrical - Triton PDFDokumen4 halaman10 - Group - 16 - Engine - Electrical - Triton PDFlaudi shofaniBelum ada peringkat

- RS8140 Single Drum CompactorDokumen4 halamanRS8140 Single Drum CompactorMartin Lee100% (2)

- Hitachi Lx15-7 Part3Dokumen1 halamanHitachi Lx15-7 Part3AlastarBelum ada peringkat

- 3-1. Hydraulic System PDFDokumen30 halaman3-1. Hydraulic System PDFmarcelo rojasBelum ada peringkat

- Ficha Tecnica Lishide Escavadora Lishide SC220-8 - 1081Dokumen3 halamanFicha Tecnica Lishide Escavadora Lishide SC220-8 - 1081PABLO HERNAN PRADA MONCADABelum ada peringkat

- Sany SR235 TerbaruDokumen2 halamanSany SR235 TerbaruMenara Hijau MandiriBelum ada peringkat

- Komatsu Bulldozers D D60P-6 Cummins Nh220-Ci: Normal ModerateDokumen3 halamanKomatsu Bulldozers D D60P-6 Cummins Nh220-Ci: Normal Moderatesrabesh basnet50% (2)

- 3-1. Hydraulic SystemDokumen35 halaman3-1. Hydraulic SystemSumitomo ExcavatorBelum ada peringkat

- Toshiba Main Pump Solar-V PDFDokumen12 halamanToshiba Main Pump Solar-V PDFRonald AuquiBelum ada peringkat

- Chapter 12Dokumen50 halamanChapter 12Ubeimar RiveraBelum ada peringkat

- Basic Informations-Clg856 Dcec IiDokumen49 halamanBasic Informations-Clg856 Dcec IiNezar AminBelum ada peringkat

- NACHI Full Catalog Small RevDokumen468 halamanNACHI Full Catalog Small RevSombat MahamadBelum ada peringkat

- FAN Catalogue: Cosmi C Forkli FT PartsDokumen6 halamanFAN Catalogue: Cosmi C Forkli FT Partsعلی چیواییBelum ada peringkat

- Hitachi 75Dokumen24 halamanHitachi 75JENNIFER PINEDABelum ada peringkat

- Improved Boom 1 Spool Kit for Cold Weather PerformanceDokumen2 halamanImproved Boom 1 Spool Kit for Cold Weather PerformanceJorge RojasBelum ada peringkat

- Deutz 1013 Agricultural Specs PDFDokumen6 halamanDeutz 1013 Agricultural Specs PDFALWIBelum ada peringkat

- General: Section 1Dokumen30 halamanGeneral: Section 1Tú Xuân LươngBelum ada peringkat

- Excavator FunctionsDokumen18 halamanExcavator FunctionsVickyBelum ada peringkat

- EC210 - Track Motor, DisassemblyDokumen14 halamanEC210 - Track Motor, DisassemblyPreett Rajin MenabungBelum ada peringkat

- Part Book PC130F-7 PPC HoseDokumen1 halamanPart Book PC130F-7 PPC HoseChimanBelum ada peringkat

- EntryLevel1-Hydraulic-English AssessmentAndAnswer SheetDokumen30 halamanEntryLevel1-Hydraulic-English AssessmentAndAnswer SheetTrevor BurnettBelum ada peringkat

- Hue Truch of DenoDokumen136 halamanHue Truch of DenoKhincho ayeBelum ada peringkat

- EX60 Hydraulic Circuit Diagram: Attach To Vol. No.: TT152E-02Dokumen16 halamanEX60 Hydraulic Circuit Diagram: Attach To Vol. No.: TT152E-02Александр КулаковBelum ada peringkat

- Operator Seat AIR 569 - KabseatingDokumen20 halamanOperator Seat AIR 569 - KabseatingSolitario AntofaBelum ada peringkat

- 325B LN Excavator 3116 Engine Injector SyncDokumen1 halaman325B LN Excavator 3116 Engine Injector SyncSoufiane KadarBelum ada peringkat

- Kubota v3600 SMDokumen16 halamanKubota v3600 SMyeferson mora guerreroBelum ada peringkat

- Catepilar ParameterDokumen3 halamanCatepilar ParameterHAriantonoBelum ada peringkat

- Group 3 Electrical Component SpecificationsDokumen9 halamanGroup 3 Electrical Component Specificationsibnu malkanBelum ada peringkat

- DR PG: Be Used in Conjunction With The Standard Hydraulic Schematic in This Service ManualDokumen1 halamanDR PG: Be Used in Conjunction With The Standard Hydraulic Schematic in This Service Manualrayendra100% (1)

- Everything You Need to Know About External Gear PumpsDokumen7 halamanEverything You Need to Know About External Gear PumpsPrince ShanBelum ada peringkat

- Lx70 ManualDokumen23 halamanLx70 Manualsrabani dashBelum ada peringkat

- Morris HoistDokumen44 halamanMorris Hoistvj0% (1)

- Esquema Hidraulico Cat cb22bcDokumen9 halamanEsquema Hidraulico Cat cb22bcgalvis1020Belum ada peringkat

- Two Way ValveDokumen68 halamanTwo Way ValveSoeAye100% (3)

- Technical Manual: TroubleshootingDokumen6 halamanTechnical Manual: TroubleshootingMaulana SaputraBelum ada peringkat

- Valve GP Pump ControlDokumen2 halamanValve GP Pump ControlglobalindosparepartsBelum ada peringkat

- J-Serise Engine-USADokumen29 halamanJ-Serise Engine-USACristian m VizcainoBelum ada peringkat

- KTR 2015 Attachment Catalogue - LowDokumen16 halamanKTR 2015 Attachment Catalogue - LowAlexander RuizBelum ada peringkat

- Power Shift TransmissionDokumen10 halamanPower Shift TransmissionEpure GabrielBelum ada peringkat

- Group 2 Main Control Valve: 1. StructureDokumen23 halamanGroup 2 Main Control Valve: 1. StructureАлексейBelum ada peringkat

- President Air Motors: 306-982 Instructions-Parts ListDokumen28 halamanPresident Air Motors: 306-982 Instructions-Parts ListAlexisAlejandroSandovalFloresBelum ada peringkat

- بيلهاي سنگين کاترپيلارDokumen75 halamanبيلهاي سنگين کاترپيلارMaryam100% (3)

- Part - Kobelco SK07 N2Dokumen3 halamanPart - Kobelco SK07 N2boy qsiBelum ada peringkat

- MTS ENERGY LIMITED Offers Skid Steer Loader and Wheel LoaderDokumen22 halamanMTS ENERGY LIMITED Offers Skid Steer Loader and Wheel LoaderCarlos Jimenez Maqui-cardanBelum ada peringkat

- Om S300LC VDokumen236 halamanOm S300LC Vnaim khchimi100% (1)

- Forklift and Lodar PDFDokumen17 halamanForklift and Lodar PDFJe MotorBelum ada peringkat

- Ew55b Pub95a9920020 CHNDokumen537 halamanEw55b Pub95a9920020 CHNDiego MontenegroBelum ada peringkat

- Otompar Cylinder Head ListDokumen10 halamanOtompar Cylinder Head Listvali_nedeleaBelum ada peringkat

- Hydraulic Piston Pump Start-Up ProcedureDokumen3 halamanHydraulic Piston Pump Start-Up ProcedureSami NcirBelum ada peringkat

- Data - DataDokumen6 halamanData - DataVerii WongBelum ada peringkat

- Case 1221Dokumen12 halamanCase 1221Foromaquinas50% (2)

- Spek ZX350Dokumen2 halamanSpek ZX350Sigit Adi P100% (1)

- Stage IV Emission StandardsDokumen18 halamanStage IV Emission StandardsGuptaBelum ada peringkat

- SANY C10 Series Rotary Drilling RigDokumen22 halamanSANY C10 Series Rotary Drilling RigmliugongBelum ada peringkat

- Catalogo Bombas NachiDokumen57 halamanCatalogo Bombas NachiCesar Muñoz OssesBelum ada peringkat

- Pumpapi675presentation 150805065440 Lva1 App6891 PDFDokumen42 halamanPumpapi675presentation 150805065440 Lva1 App6891 PDFsanthoshkumarplBelum ada peringkat

- Flow Switches BarksdaleDokumen20 halamanFlow Switches BarksdaleDian PramadiBelum ada peringkat

- Temperature Switch T12X-L1X-DSDokumen2 halamanTemperature Switch T12X-L1X-DSDian PramadiBelum ada peringkat

- Yuken DSHGDokumen28 halamanYuken DSHGDian PramadiBelum ada peringkat

- Accessories enDokumen24 halamanAccessories enDian PramadiBelum ada peringkat

- Pressure MechanicalDokumen67 halamanPressure MechanicalDian PramadiBelum ada peringkat

- Nutork Air Filter Regulator-EnDokumen2 halamanNutork Air Filter Regulator-EnDian PramadiBelum ada peringkat

- RexrothDokumen55 halamanRexrothDian Pramadi100% (1)

- 349 SeriesDokumen4 halaman349 SeriesDian PramadiBelum ada peringkat

- Pressure TransducerDokumen17 halamanPressure TransducerDian PramadiBelum ada peringkat

- PVS Series NachiDokumen19 halamanPVS Series NachiDian Pramadi100% (1)

- Hydraulic Fitting CatalogDokumen165 halamanHydraulic Fitting CatalogDian Pramadi100% (1)

- Swagelok CatalogDokumen66 halamanSwagelok Catalogfeelmybeat100% (1)

- Variable Vane Pump VDCDokumen14 halamanVariable Vane Pump VDCDian PramadiBelum ada peringkat

- Gear Pump IPHDokumen13 halamanGear Pump IPHDian PramadiBelum ada peringkat

- Parker FittingDokumen34 halamanParker FittingDian PramadiBelum ada peringkat

- Asco Numatic (Pneumatic)Dokumen70 halamanAsco Numatic (Pneumatic)Dian PramadiBelum ada peringkat

- Parker PV016 - PV360Dokumen68 halamanParker PV016 - PV360Dian PramadiBelum ada peringkat

- PVS Series NachiDokumen19 halamanPVS Series NachiDian Pramadi100% (1)

- P9S 90 SeriesDokumen2 halamanP9S 90 SeriesDian PramadiBelum ada peringkat

- P3S 300 SeriesDokumen2 halamanP3S 300 SeriesDian PramadiBelum ada peringkat

- Hydraulic Motor ParkerDokumen56 halamanHydraulic Motor ParkerDian PramadiBelum ada peringkat

- P1S 100 SeriesDokumen2 halamanP1S 100 SeriesDian PramadiBelum ada peringkat

- Gear Pump ParkerDokumen36 halamanGear Pump ParkerDian Pramadi100% (3)

- Hydraulic Cylinder Parker 3lDokumen48 halamanHydraulic Cylinder Parker 3lDian Pramadi100% (2)

- Pump VP1 ParkerDokumen8 halamanPump VP1 ParkerDian PramadiBelum ada peringkat

- Gear Pump ParkerDokumen36 halamanGear Pump ParkerDian Pramadi100% (3)

- Cilindros Hidráulicos Parker - 2H - 1110-UkDokumen42 halamanCilindros Hidráulicos Parker - 2H - 1110-UkPeterson MagroBelum ada peringkat

- Parker Vane PumpDokumen76 halamanParker Vane PumpDian PramadiBelum ada peringkat

- Yuken HydraulicDokumen24 halamanYuken HydraulicDian Pramadi100% (1)

- 9320A423GDokumen9 halaman9320A423GJuan Gabriel Ochoa100% (1)

- Diagrama Ammco 3000-4000-4100 - 3Dokumen16 halamanDiagrama Ammco 3000-4000-4100 - 3jmartinezmo67% (3)

- Condition Monitoring of Diesel GeneratorsDokumen49 halamanCondition Monitoring of Diesel GeneratorsjyotidahiyaBelum ada peringkat

- Jastram Model H Helm Pumps: Engineered For Life at SeaDokumen2 halamanJastram Model H Helm Pumps: Engineered For Life at SeaingdanilocfBelum ada peringkat

- 9600232dgdadgdb PDFDokumen58 halaman9600232dgdadgdb PDFJovanBelum ada peringkat

- Air Conditioning and RefrigerationDokumen21 halamanAir Conditioning and Refrigerationrajnikanth pBelum ada peringkat

- Ash HandlingDokumen12 halamanAsh HandlingKhemant OdBelum ada peringkat

- Camless Two Stroke Main Propulsion engine-B&W ME - CDokumen21 halamanCamless Two Stroke Main Propulsion engine-B&W ME - CNarayana Prakash96% (52)

- Fuel System Pressure - TestDokumen7 halamanFuel System Pressure - TestHamilton MirandaBelum ada peringkat

- OpGL Product Instruction ManualDokumen16 halamanOpGL Product Instruction ManualRicardo NapitupuluBelum ada peringkat

- Parts IR5000-IR6000Dokumen256 halamanParts IR5000-IR6000Watcharapong KesornsombutBelum ada peringkat

- GEELY 2008 Fc-VisionDokumen211 halamanGEELY 2008 Fc-VisionКостя ДолинськийBelum ada peringkat

- 307-01bZF 6HP26Dokumen91 halaman307-01bZF 6HP26luke89% (9)

- How To Diagnose Vp44 Fuel System IssuesDokumen17 halamanHow To Diagnose Vp44 Fuel System Issuesมนต์ชัย บุญธนลาภBelum ada peringkat

- 2011 ZX-10r Race Kit ManualDokumen79 halaman2011 ZX-10r Race Kit ManualStefaan PhilipsBelum ada peringkat

- Cavities DimensionsDokumen10 halamanCavities DimensionsLuis Carlos Gomez MontoyaBelum ada peringkat

- 793F Off-Highway Truck and Air System 793F Water OEM: Component LocationsDokumen2 halaman793F Off-Highway Truck and Air System 793F Water OEM: Component Locationsmarix12Belum ada peringkat

- Fluid CouplingDokumen21 halamanFluid CouplingSoumyasubhra SinhaBelum ada peringkat

- Components 103 203 PumpDokumen60 halamanComponents 103 203 PumpChristopher BessinasBelum ada peringkat

- Braking of DC MotorDokumen18 halamanBraking of DC MotorBangariBelum ada peringkat

- TM 9-6115-464-34 Mep-004a, - 103a, - 113aDokumen493 halamanTM 9-6115-464-34 Mep-004a, - 103a, - 113aAdvocateBelum ada peringkat

- HVAC Course Outline-2018Dokumen3 halamanHVAC Course Outline-2018Prasanna DevilsBelum ada peringkat

- Hangcha R Series 5 10t Forklift Truck Parts CatalogDokumen20 halamanHangcha R Series 5 10t Forklift Truck Parts Cataloghelen100% (48)

- Johnson Demountable Bearing BrochureDokumen20 halamanJohnson Demountable Bearing BrochureJulio FerrerBelum ada peringkat

- Ecomat Opertors ManualDokumen36 halamanEcomat Opertors Manualryanswj50% (2)

- A Little About My Analysis of The ZF4hp14 Automatic Transmission. Upd. No Car, I Don't Answer QuestionsDokumen21 halamanA Little About My Analysis of The ZF4hp14 Automatic Transmission. Upd. No Car, I Don't Answer QuestionsMiguel Bento100% (1)

- Fog Alphabetical Index Subgroup GridDokumen15 halamanFog Alphabetical Index Subgroup GridRenato AssisBelum ada peringkat

- Gearless Transmission Research PaperDokumen10 halamanGearless Transmission Research PaperresonancebansalBelum ada peringkat

- Index: Energy Savings in Home AppliancesDokumen7 halamanIndex: Energy Savings in Home Appliancesraj1379Belum ada peringkat

- Report On Turbo Cooling SystemDokumen33 halamanReport On Turbo Cooling SystemDeepakKumarBelum ada peringkat