M.uzair Shaikh - Electronic Stability Control

Diunggah oleh

M Uzair ShaikhDeskripsi Asli:

Judul Asli

Hak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

M.uzair Shaikh - Electronic Stability Control

Diunggah oleh

M Uzair ShaikhHak Cipta:

Format Tersedia

EXPERIMENT DEMONSTRATING THE INFLUENCE OF REYNOLDS NUMBER IN PIPE FLOWS

Mohammad Uzair Shaikh Dept. of Mechanical Engineering, College of Electrical and Mechanical Engineering, National University of Science and Technology, Pakistan

Abstract This paper reviews and presents the experiment and its procedure to determine the influence of Reynolds Number in pipe flows. The experiment is similar to the one that Oswald Reynold carried out to determine the influence of Reynolds Number on a fluid flowing in a pipe. The main parameters impelling the behavior of the fluid are the flow rate of the fluid and the Head pressure. A different technique involving a colored die is used to study the behavior of the fluid. Keywords Reynoldss number, Head, Turbulence, Laminar turbulence flow downstream of the fill. The water enters the transparent observation tube through a rounded entrance. Blue dye is injected into the stream to provide the visual effect. A pump is used to force the dye into the injection tube and to control the rate at which it is injected. The pump ha s controls with a digital dial that can be set (on an arbitrary scale) to deliver dye from a very slow to a relatively fast rate. It also has a button (max) that when pressed delivers the maximum dye injection rate the pump is capable of delivering. It is useful for some flows to press and quickly release the max button to inject a spurt of dye and then observe the motion of the dye in the flow.

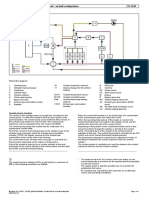

1.INTRODUCTION In fluid mechanics, the Reynolds number Re is a dimensionless number that gives a measure of the ratio of inertial forces to viscous forces and consequently quantifies the relative importance of these two types of forces for given flow conditions. Reynolds numbers frequently arise when performing dimensional analysis of fluid dynamics problems, and as such can be used to determine dynamic similitude between different experimental cases.They are also used to characterize different flow regimes, such as laminar or turbulent flow: laminar flow occurs at low Reynolds numbers, where viscous forces are dominant, and is characterized by smooth, constant fluid motion; turbulent flow occurs at high Reynolds numbers and is dominated by inertial forces, which tend to produce chaotic eddies, vortices and other flow instabilities. 2. EXPERIMENTAL MODEL 2.1 Purpose: The purpose of this experiment is to illustrate the influence of Reynolds number on pipe flows. Reynolds number is a very useful dimensionless quantity (the ratio of dynamic forces to viscous forces) that aids in classifying certain flows. For incompressible flow in a pipe, Reynolds number based on the pipe diameter, Re D = VaveD/, serves well. Generally, laminar flows correspond to Re D < 2100, transitional flows occur in the range 2100 < Re D < 4000, and turbulent flows exist for Re D > 4000. However, disturbances in the flow from various sources may cause the flow to deviate from this pattern. This experiment will illustrate laminar, transitional, and turbulent flows in a pipe. 2.2 Apparatus The apparatus used in this experiment provides a means of visually observing the different pipe-flow regimes of incompressible fluid, water in this case. A diagram of the apparatus is shown in Fig. 1. Water is supplied to the tank on the left through the water supply line and valve. A constant water level is maintained in the tank by overflow into the standpipe. The water in the tank flows through a section of "fill", a collection of small spheres held in place by screens. The purpose of this arrangement is to produce a low

F ig. 1 Apparatus for studying laminar, transitional, and turbulent pipe flow

Fig. 3 Schematic diagram of the head-orif ice water f low meter.

The apparatus includes the head-orifice flow meter shown in Fig. 1 and in more detail in Fig. 2. This allows rapid determination of the Reynolds number for the flow in the observation tube. The meter consists of a closed-end tube in which flow from the observation tube is collected. Three orifices that meter the flow are located in the bottom of the closed end. These can be used selectively by inserting rubber stoppers in orifices not used. As the head ,h, increases, the flow rate through an orifice (or a combination of orifices) increases. When the flow rate out of an orifice (or a combination of orifices) equals the flow rate into the meter from the observation tube, the head h will be established at a fixed value. The flow rate is related to the h and the size of the orifice (or orifices) selected. This flow rate can then in turn be used to determine the Reynolds number in the observation section of the apparatus. Thus, for a given orifice or (a selection of orifices), the observation tube Reynolds number based on inside diameter D (= 0.750 inches) is directly related to the head h. Table 1 gives information on the orifices of the head-orifice flow meter. The velocity coefficient defined in the table, accounts for non-ideal flow through an orifice. Videal = (2gh)1/2. Figure 4 is a graph of Re D vs. head for the head-orifice meter for each orifice and certain combinations of orifices. The curves incorporate the velocity coefficients

laminar to turbulent flow takes place. To minimize flow disturbances, a smooth properly-contoured entrance section to the observation tube is required. This may not be the case in the apparatus used in this experiment. The presence of the dye injection tube may cause flow disturbances that may affect transition. Injection of the dye at a velocity different from the water velocity may unduly disturb the flow. In some cases, disturbances related to dye injection will die out with distance along the observation tube and laminar flow will clearly exist. 4. ACKNOWLEDEGMENT I extend a sincere thanks to all my family and friends who supported me throughout this venture.

5.References [1] http://hyunitech.blogspot.com/2010/08l [2] FREEPATENTSONLINE.COM [3] HOWSTUFFWORKS.COM

Fig.4 Observ ation tube Rey nolds number v ersus head. T

H2O

=60F

2.3:Procedure 1. Prepare a data spreadsheet to record all of the pertinent information. 2. Conduct a series of runs. Use a digital camera (if available) to record the patterns made by the dye in the observation tube or sketch the pattern if the camera is not available. Start with a very low flow rate (and Reynolds No.) by closing the flow control valve and using the small bypass control valve to regulate the flow. Increase the flow rate gradually and eventually reach the fully turbulent regime. Select orifices as necessary to cover the three flow regimes. Make sure the equilibrium value of h is established before using Fig. 4 to obtain Reynolds number. Be sure to identify as closely as possible the Reynolds number for transition from laminar to turbulent flow. 3. DISCUSSION: Disturbances in the flow from several sources may alter the Reynolds number at which transition from

Anda mungkin juga menyukai

- CIP Report ofDokumen15 halamanCIP Report ofM Uzair ShaikhBelum ada peringkat

- Rigging Study Plan 250 Ton Final-ModelDokumen1 halamanRigging Study Plan 250 Ton Final-ModelM Uzair ShaikhBelum ada peringkat

- Air Compressor 132KW ZR 3 Atlas Copco ManualDokumen27 halamanAir Compressor 132KW ZR 3 Atlas Copco ManualM Uzair Shaikh67% (3)

- Valve Reclamation ProcedureDokumen6 halamanValve Reclamation ProcedureM Uzair ShaikhBelum ada peringkat

- Beam Deflection FormulaeDokumen2 halamanBeam Deflection Formulae7575757575100% (6)

- Safety Presentation1Dokumen28 halamanSafety Presentation1M Uzair ShaikhBelum ada peringkat

- Document Hndover ChecklistDokumen3 halamanDocument Hndover ChecklistM Uzair ShaikhBelum ada peringkat

- Introduction To Solid Mechanics by Irving ShamesDokumen788 halamanIntroduction To Solid Mechanics by Irving ShamesM Uzair Shaikh82% (17)

- Vapour Absorption Refregiration CycleDokumen26 halamanVapour Absorption Refregiration CycleM Uzair Shaikh100% (1)

- Shoe Dog: A Memoir by the Creator of NikeDari EverandShoe Dog: A Memoir by the Creator of NikePenilaian: 4.5 dari 5 bintang4.5/5 (537)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDari EverandNever Split the Difference: Negotiating As If Your Life Depended On ItPenilaian: 4.5 dari 5 bintang4.5/5 (838)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDari EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FuturePenilaian: 4.5 dari 5 bintang4.5/5 (474)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDari EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifePenilaian: 4 dari 5 bintang4/5 (5782)

- Grit: The Power of Passion and PerseveranceDari EverandGrit: The Power of Passion and PerseverancePenilaian: 4 dari 5 bintang4/5 (587)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDari EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RacePenilaian: 4 dari 5 bintang4/5 (890)

- The Yellow House: A Memoir (2019 National Book Award Winner)Dari EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Penilaian: 4 dari 5 bintang4/5 (98)

- On Fire: The (Burning) Case for a Green New DealDari EverandOn Fire: The (Burning) Case for a Green New DealPenilaian: 4 dari 5 bintang4/5 (72)

- The Little Book of Hygge: Danish Secrets to Happy LivingDari EverandThe Little Book of Hygge: Danish Secrets to Happy LivingPenilaian: 3.5 dari 5 bintang3.5/5 (399)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDari EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryPenilaian: 3.5 dari 5 bintang3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnDari EverandTeam of Rivals: The Political Genius of Abraham LincolnPenilaian: 4.5 dari 5 bintang4.5/5 (234)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDari EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaPenilaian: 4.5 dari 5 bintang4.5/5 (265)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDari EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersPenilaian: 4.5 dari 5 bintang4.5/5 (344)

- The Emperor of All Maladies: A Biography of CancerDari EverandThe Emperor of All Maladies: A Biography of CancerPenilaian: 4.5 dari 5 bintang4.5/5 (271)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDari EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyPenilaian: 3.5 dari 5 bintang3.5/5 (2219)

- The Unwinding: An Inner History of the New AmericaDari EverandThe Unwinding: An Inner History of the New AmericaPenilaian: 4 dari 5 bintang4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDari EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You ArePenilaian: 4 dari 5 bintang4/5 (1090)

- Rise of ISIS: A Threat We Can't IgnoreDari EverandRise of ISIS: A Threat We Can't IgnorePenilaian: 3.5 dari 5 bintang3.5/5 (137)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Dari EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Penilaian: 4.5 dari 5 bintang4.5/5 (119)

- Her Body and Other Parties: StoriesDari EverandHer Body and Other Parties: StoriesPenilaian: 4 dari 5 bintang4/5 (821)

- CHE 3164 Chemical Reaction Engineering Tutorial Problems Set 7Dokumen16 halamanCHE 3164 Chemical Reaction Engineering Tutorial Problems Set 7Divya KariaBelum ada peringkat

- Thermostatic Expansion Valves: Tle Thermo Expansion ValveDokumen26 halamanThermostatic Expansion Valves: Tle Thermo Expansion ValveMeher YoussfiBelum ada peringkat

- External Forced ConvectionDokumen44 halamanExternal Forced ConvectionEnesEmreTaşBelum ada peringkat

- Internal Components Optimization in Cyclone Separators: Systematic Classification and Meta-AnalysisDokumen18 halamanInternal Components Optimization in Cyclone Separators: Systematic Classification and Meta-Analysisshanmuga prakashBelum ada peringkat

- Assignment 009Dokumen6 halamanAssignment 009KahledBelum ada peringkat

- Grade 7 Science Solutions and Separation TechniquesDokumen32 halamanGrade 7 Science Solutions and Separation TechniquesMargareth RiveraBelum ada peringkat

- Simple & Complex RefineriesDokumen6 halamanSimple & Complex RefineriesFernanda Guerrero100% (1)

- Compressible fluid flow chapter covering speed of sound, Mach number, isentropic flow processes, nozzles, and shock wavesDokumen35 halamanCompressible fluid flow chapter covering speed of sound, Mach number, isentropic flow processes, nozzles, and shock wavesIndraBelum ada peringkat

- Hvac - Supplier List UpdatedDokumen218 halamanHvac - Supplier List UpdatedMohammad Altaf Hussain100% (1)

- MANUAL Evo CS CS GEN2Dokumen27 halamanMANUAL Evo CS CS GEN2Luke greenawayBelum ada peringkat

- Index: 3-A Sanitary Standards, 3-A Accepted Practices, & P3-A Sanitary StandardsDokumen4 halamanIndex: 3-A Sanitary Standards, 3-A Accepted Practices, & P3-A Sanitary StandardsMario de Jesus CastañedaBelum ada peringkat

- Operating Manual 1250 SeriesDokumen18 halamanOperating Manual 1250 SeriesZainuddin CIEBelum ada peringkat

- Books: This Thermodynamics Ansorpuen ColumnDokumen4 halamanBooks: This Thermodynamics Ansorpuen ColumnJunaid ParkerBelum ada peringkat

- HDND3+3 - GB PDFDokumen9 halamanHDND3+3 - GB PDFTania SilvaBelum ada peringkat

- VCTDS-01042 Models Y1 BV-1 RA-Blanketing Regulator-EnDokumen6 halamanVCTDS-01042 Models Y1 BV-1 RA-Blanketing Regulator-EnvipinBelum ada peringkat

- Coolant Circuit - As-Built ConfigurationDokumen1 halamanCoolant Circuit - As-Built ConfigurationviethungBelum ada peringkat

- Wirth Piston PumpsDokumen10 halamanWirth Piston PumpsMark TiczonBelum ada peringkat

- SPECIAL CORE ANALYSIS RELATIVE PERMEABILITYDokumen36 halamanSPECIAL CORE ANALYSIS RELATIVE PERMEABILITYchaymaa MRHARBelum ada peringkat

- 4 Boq Plumbing 06.12.15Dokumen7 halaman4 Boq Plumbing 06.12.15shefali chaudharyBelum ada peringkat

- System Components of Mobile Hydraulics LUDV Control Block M6Dokumen6 halamanSystem Components of Mobile Hydraulics LUDV Control Block M6luisBelum ada peringkat

- Final Demo NoreiDokumen16 halamanFinal Demo NoreiArnold GarcinesBelum ada peringkat

- Mechanical Testing of MaterialsDokumen8 halamanMechanical Testing of Materialsdecent mrdBelum ada peringkat

- Linde FinalDokumen6 halamanLinde FinalAnonymous 0zrCNQBelum ada peringkat

- Closed Cooling Water SystemDokumen29 halamanClosed Cooling Water Systemrahul_choubey_9100% (1)

- Complete WF Manual CobbDokumen532 halamanComplete WF Manual CobbBogdan DavidescuBelum ada peringkat

- P&ID Symbol Desk Reference - Assured AutomationDokumen3 halamanP&ID Symbol Desk Reference - Assured AutomationJesus N Rodriguez100% (3)

- Energy Balance LabDokumen6 halamanEnergy Balance LabKristian PetrovBelum ada peringkat

- rinhs science 10 activity 1 properties of gas and kmtDokumen2 halamanrinhs science 10 activity 1 properties of gas and kmtRyan BersaminBelum ada peringkat

- Checklist For Installation of Chemical Fire Suppression SystemDokumen1 halamanChecklist For Installation of Chemical Fire Suppression Systembeho2000100% (1)