Cooling Tower Effective Utilization

Diunggah oleh

karrtiktvDeskripsi Asli:

Hak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

Cooling Tower Effective Utilization

Diunggah oleh

karrtiktvHak Cipta:

Format Tersedia

CoolingTowerDesign,Selectionand EfficientUtilization

Prepared by: Vijay Bansal

CoolingTowerDesign,SelectionandEfficientUtilization

Page1

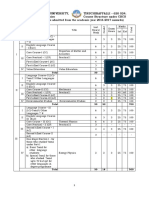

CONTENT

Sl. No.

1 2 2.1 3 3.1 3.2 3.3 3.4 4 5 6 6.1 6.2 6.3 7 8 9

Detail

Introduction and Objective Function of Cooling Tower Cooling Tower terminology Wet bulb temperature and its importance Thermodynamic wet bulb temperature Adiabatic wet bulb temperature Wet bulb depression Design wet bulb temperature of selected Indian cities Types of Cooling Towers Cooling Tower Theory Cooling Tower Design Capacity versus thermal capability of Cooling Towers Thermal performance assessment of Cooling Towers The Japanese Industrial standard JIS B 8609 Preventive maintenance schedule for Cooling Towers Water conservation by improving Cooling Tower efficiency Intelligent Cooling tower control system

Page No.

3-3 4-5

6-15

16-17 18-20 21-32

33-34 34-39 40

CoolingTowerDesign,SelectionandEfficientUtilization

Page2

1. INTRODUCTION AND OBJECTIVE INTRODUCTION

Cooling Towers are heat exchangers that are used to dissipate large heat loads to the atmosphere. They are used in a variety of Industries, including process cooling, power generation and air conditioning plants. All Cooling towers that are used to remove heat from an Industrial process or chemical reaction are referred to as Industrial process cooling tower. Cooling towers used for heating, ventilation and air conditioning (HVAC) are referred to as comfort cooling towers. Cooling towers are classified as either wet towers or dry towers.

OBJECTIVE

Cooling towers are more or less a neglected area of any utility system. However, there is good energy saving potential in Cooling Towers. Proper attention has to be provided from the design stage itself and during operation also. The energy saving potential varies from 5% to 10% of the actual energy consumption.

The main objective of this paper is to provide technical information about the Cooling towers. The most important part covered is to select the Cooling tower based on the right wet bulb temperature. The size and cost of any cooling tower depends upon the wet bulb temperature of the particular region. During commercial negotiation a vendor can offer low price for the Cooling tower by supplying the high design wet bulb temperature Cooling tower if technical person is not well acquaint of the effect of even 0.5 Deg C rise in WBT.

CoolingTowerDesign,SelectionandEfficientUtilization

Page3

The thrust on design, selection and energy conservation activities in Cooling towers has been covered in detail.

2. Function of Cooling Tower

A cooling tower primarily uses latent heat of vaporization (evaporation) to cool process water. Minor additional cooling is provided by the air because of its temperature increase. Principle of Cooling Tower The cooling towers operate on the principle of heat dissipation through partial evaporation of the circulating water.

It is a direct contact heat exchanger, generally used to dissipate the heat in circulating water. The heat is dissipated to the ambient air via a process of heat and mass transfer from the circulating water. The water thus cooled is circulated again through the process, heat exchanger or condenser. The heat is transferred to the water either in a condenser like refrigeration or air-conditioning system or chemical processes or heat exchangers in cooling process, generating sets, engines, furnaces etc. The water is an effective heat transfer medium and this is taken advantage of in cooling towers. The heat received by the circulating water from various kinds of process equipment is dissipated in the cooling tower for being re circulated. 2.1 Cooling Tower Terminology It is necessary to define the most common terms in the cooling tower operation. Range It is the difference in temperature between the inlet hot water and the cold water

CoolingTowerDesign,SelectionandEfficientUtilization Page4

leaving the tower.

For 40C inlet and 35C outlet, the range is 5C. Approach The difference between the temperature of the cold water leaving the tower and the wet bulb temperature of the air entering the tower. For 35C water out let and 27C wet bulb temperature, the approach is 8C. Wet bulb Temperature This is the lowest temperature water can be cooled by evaporation. Wet bulb temperature* is an important parameter in the cooling tower selection and design. Heat Load The amount of heat to be removed from the circulating water in an hour. Heat load is equal to the rate of water flow per hour multiplied by range. Blow Down Volume Due to continued evaporation of circulating water in the tower, the concentration of dissolved solids in the water increases. This is kept in check continuous bleed off a part of the basin water.

Make Up The amount of water required replacing the evaporation, drifting and blowing down volume. The quality of makeup water* should be within the range specified. Drift Losses The water carried over and discharged to the atmosphere. Circulating water It is the quantity of hot water entering the tower. Fills

CoolingTowerDesign,SelectionandEfficientUtilization Page5

These are placed within the tower to effect heat and mass transfer between the circulating water and the air flowing through the tower. Casing It is a vertical enclosing sidewall, which surrounds the fill and retains the water within the tower. Distribution system Begins with the inlet connection for distribution of circulating hot water within the tower to the points, where it comes in contact with air.

3.0 Wet Bulb Temperature and its importance on Cooling Tower Selection What is Wet bulb temperature? The wet-bulb temperature is a type of temperature measurement that reflects the physical properties of a system with a mixture of a gas and a vapor, usually air and water vapor. Wet-bulb temperature can have several technical meanings:

Thermodynamic wet-bulb temperature: the temperature a volume of air would have if cooled adiabatically to saturation at constant pressure by evaporation of water into it, all latent heat being supplied by the volume of air. The temperature read from a wet bulb thermometer Adiabatic wet-bulb temperature: the temperature a volume of air would have if cooled adiabatically to saturation and then compressed adiabatically to the original pressure in a moist-adiabatic process.

The thermodynamic wet-bulb temperature is the minimum temperature which may be achieved by purely evaporative cooling of a water-wetted (or ice-covered), ventilated surface. For a given parcel air at a known pressure and dry-bulb temperature, the thermodynamic wet-bulb temperature corresponds to unique values of relative humidity, dew point temperature, and other properties. The relationships between these values are illustrated in a psychrometric chart.

CoolingTowerDesign,SelectionandEfficientUtilization

Page6

For air that is less than saturated (100 percent relative humidity), the wet-bulb temperature is lower than the dry-bulb temperature; and the dew point temperature is less than the wetbulb temperature. Cooling of the human body through perspiration is inhibited as the wet-bulb temperature (and relative humidity) of the surrounding air increases in summer. Other mechanisms may be at work in winter if there is validity to the notion of a "humid cold." Lower wet-bulb temperatures in summer can translate to energy savings in airconditioned buildings due to: 1. Reduced dehumidification load for ventilation air 2. Increased efficiency of cooling towers 3.1 Thermodynamic wet-bulb temperature (Adiabatic Saturation Temperature) The thermodynamic wet-bulb temperature is the temperature a volume of air would have if cooled adiabatically to saturation by evaporation of water into it, all latent heat being supplied by the volume of air. The temperature of an air sample that has passed over a large surface of liquid water in an insulated channel is the thermodynamic wet-bulb temperature it has become saturated by passing through a constant-pressure, ideal, adiabatic saturation chamber. Meteorologist and others may use the term "isobaric wet-bulb temperature" to refer to the "thermodynamic wet-bulb temperature". It is also called the "adiabatic saturation temperature". Combining the dry bulb and wet bulb temperature in a psychrometric diagram or Mollier chart, gives the state of the humid air. Lines of constant wet bulb temperatures run diagonally from the upper left to the lower right in the Psychrometric Chart.

CoolingTowerDesign,SelectionandEfficientUtilization

Page7

The thermodynamic wet-bulb temperature is a thermodynamic property of a mixture of air and water vapor. The value indicated by a simple wet-bulb thermometer often provides an adequate approximation of the thermodynamic wet-bulb temperature. For an accurate wet-bulb thermometer, "the wet-bulb temperature and the adiabatic saturation temperature are approximately equal for air-water vapor mixtures at atmospheric temperature and pressure. This is not necessarily true at temperatures and pressures that deviate significantly from ordinary atmospheric conditions, for other gas-vapor mixtures.

CoolingTowerDesign,SelectionandEfficientUtilization

Page8

Temperature read from a wet-bulb thermometer Wet-bulb temperature is measured using a thermometer that has its bulb wrapped in cloth called a sockthat is kept wet with water via wicking action. Such an instrument is called a wet-bulb thermometer.

The wet-bulb thermometer reports the thermodynamic wet-bulb temperature if:

The sock is shielded from radiant heat exchange with its surroundings Air flows past the sock quickly enough to prevent evaporated moisture from affecting evaporation from the sock The water supplied to the sock is at the same temperature as the thermodynamic wetbulb temperature of the air

In usual practice, the value reported by a wet-bulb thermometer differs slightly from the thermodynamic wet-bulb temperature because:

The sock is not shielded so well from radiant heat exchange Air flow rate past the sock may be less than optimum And the temperature of the water supplied to the sock is not controlled

At relative humidity below 100 percent, water evaporates from the bulb, which cools the bulb below ambient temperature. To determine relative humidity, ambient temperature is measured using an ordinary thermometer, better known in this context as a dry-bulb thermometer.

CoolingTowerDesign,SelectionandEfficientUtilization Page9

At any given ambient temperature, less relative humidity results in a greater difference between the dry-bulb and wet-bulb temperatures; the wet bulb is colder. The precise relative humidity is determined by finding one's wet-bulb and dry-bulb temperatures on a psychrometric chart (or via complex calculation). Psychrometers are instruments which contain both wet-bulb and dry-bulb thermometers. A wet-bulb thermometer can also be used in combination with a globe thermometer (which is affected by the radiant temperature of the surroundings) in the calculation of the wet bulb globe temperature. Now-a-days digital meters are available in the market, which gives accurate reading of dry bulb temperature, relative humidity and wet bulb temperature. Units may have these instruments to periodically evaluate the cooling tower performance.

3.2 Adiabatic wet-bulb temperature

The adiabatic wet-bulb temperature is the temperature a volume of air would have if cooled adiabatically to saturation and then compressed adiabatically to the original pressure in a moist-adiabatic process. Such cooling may occur as air pressure reduces with altitude, as noted in the article on lifted condensation level. As the value referred to as "thermodynamic wet-bulb temperature" is also achieved via an adiabatic process, some engineers and others may use the term "adiabatic wet-bulb temperature" to refer to the "thermodynamic wet-bulb temperature". As stated in another section, meteorologists and others may use the term "isobaric wet-bulb temperature" to refer to the "thermodynamic wet-bulb temperature". "The relationship between the isobaric and adiabatic processes is quite obscure. Comparisons indicate, however, that the two temperatures are rarely different by more than a few tenths of a degree Celsius, and the adiabatic version is always the smaller of the two for unsaturated air. Since the difference is so small, it is usually neglected in practice.

CoolingTowerDesign,SelectionandEfficientUtilization

Page10

3.3 Wet-bulb depression The wet-bulb depression is the difference between the dry-bulb temperature and the wetbulb temperature. Wet Bulb Temperature - Twb The Wet Bulb temperature is the temperature of adiabatic saturation. This is the temperature indicated by a moistened thermometer bulb exposed to the airflow. Wet Bulb temperature can be measured by using a thermometer with the bulb wrapped in wet muslin. The adiabatic evaporation of water from the thermometer and the cooling effect is indicated by a "wet bulb temperature" lower than the "dry bulb temperature" in the air. The rate of evaporation from the wet bandage on the bulb, and the temperature difference between the dry bulb and wet bulb, depends on the humidity of the air. The evaporation is reduced when the air contains more water vapor. The wet bulb temperature is always lower than the dry bulb temperature but will be identical with 100% relative humidity (the air is at the saturation line).

Cooling tower selection and performance is based on: 1 Water flow rate 2. Water inlet temperature 3. Water outlet temperature 4. Ambient wet bulb temperature. Ambient wet bulb temperature and its affect on performance is the subject of this article.

Ambient wet bulb temperature is a condition measured by a device called a psychrometer. A psychrometer places a thin film of water on the bulb of a thermometer that is twirled in the air. After about a minute, the thermometer will show a reduced temperature. The low point when no additional twirling reduces the temperature is called the wet bulb temperature.

CoolingTowerDesign,SelectionandEfficientUtilization

Page11

The measured wet bulb temperature is a function of relative humidity and ambient air temperature. Wet bulb temperature essentially measures how much water vapor the atmosphere can hold at current weather conditions. A lower wet bulb temperature means the air is drier and can hold more water vapor than it can at a higher wet bulb temperature. For example: Dry Bulb Temperature 50F 60F 70F 85F 90F Relative Humidity 40% 50% 35% 55% 60% Resultant Wet Bulb Temperature 40F 50F 55F 73F 78F

When selecting a cooling tower cell, the highest or the design wet bulb temperature your geographical area will encounter must be used. Highest wet bulb temperatures occur during the summer, when air temperatures and humidity are highest. Again, by example, in a place the design wet bulb temperature is 78F. Historically this can expect less than 1 hour per year that the conditions exceed a 78F wet bulb. Typically, 6,000 hours a year will have a wet bulb of 60F or lower meaning that a cooling tower cell designed for a 78F wet bulb will be able to make 65 - 67F water for 6,000 hours per year ... nearly 70% of the year. Most cooling towers are capacity rated at a "standard" wet bulb temperature of 78F. That means on the days when the wet bulb temperature is 78F, the tower will produce its stated capacity. In other words, a tower rated to produce 135 tons of cooling will produce 135 tons of cooling at a 78F wet bulb temperature. At a higher wet bulb temperature, the tower cell capacity decreases.

The cooling tower design has changed over the years to incorporate new materials, as and when available. 1. 2. 3. 4. Perform to required specification. More compact Weigh less Consume least power

Page12

CoolingTowerDesign,SelectionandEfficientUtilization

5. Longer lasting, withstand corrosion and have good finish looks. With the introduction of Fiberglass Reinforced Plastics the above benefits are achieved in the Counter flow, Bottle shape FRP, induced Draft Cooling Towers

Every location has a unique design (worst case) wet bulb temperature that is published by organizations such as ASHRAE. For ready reference, a table showing design wet bulb temperature of some Indian cities is tabulated below.

3.4 Design Wet Bulb Temperature of selected Indian Cities.

City Ahmedabad Allahabad Banglore Bhubaneshwar Bombay Calcutta Cochin Coimbatore Dehradun Durgapur Goa Hyderabad Jamshedpur Kakinada Degree F 82.5 81.0 75.0 83.0 83.0 83.0 79.0 81.0 78.0 83.0 83.0 78.0 83.0 84.0 Degree C 28.0 27.2 23.9 28.3 28.3 28.3 26.1 27.2 25.6 28.3 28.3 25.6 28.3 28.9

CoolingTowerDesign,SelectionandEfficientUtilization

Page13

Kanpur Lucknow Madras Madurai Manglore Mysore Nagpur Nellore New Delhi Patna Ranchi Rourkela Salem Trichy Trivandrum Vijaywada Vishakapatnam 81.0 81.0 83.0 80.0 83.0 78.0 80.0 82.0 83.0 82.0 82.0 81.5 81.0 82.4 81.0 80.6 84.0 27.2 27.2 28.3 26.7 28.3 25.6 26.7 27.8 28.3 27.8 27.8 27.5 27.2 28.0 27.2 27.0 28.9

CoolingTowerDesign,SelectionandEfficientUtilization

Page14

What does it mean when a cooling tower water temperature is higher than the normal 5 - 7F above the current wet bulb temperature? Cooling tower may have lost efficiency Due to scale build up on the tower heat exchange surfaces. Due to loss of airflow across the heat exchange surfaces. Due to improper water flow What can we do to improve our tower performance? Add tower cell capacity. Check for the efficiency losses described above. Replace the heat exchange surfaces with new clean fill. Check for proper air flow. Adjust the water flow. Cooling tower performance is related to ambient wet bulb conditions. Higher wet bulb temperatures occur in the summer when higher ambient and relative humidity occurs. Initial system design and proper system maintenance is critical to be certain your cooling tower cell is providing proper cooling.

Cooling towers are a very important part of many plants. They represent a relatively inexpensive and dependable means of removing low-grade heat from cooling water.

Figure 1: Closed Loop Cooling Tower System The make-up water source is used to replenish water lost to evaporation. Hot water from heat exchangers is sent to the cooling tower. The water exits the cooling tower and is sent back to the exchangers or to other units for further cooling.

CoolingTowerDesign,SelectionandEfficientUtilization

Page15

4.0 Types of Cooling Towers

Cooling towers fall into two main sub-divisions:

Natural draft and Mechanical draft Natural draft designs use very large concrete chimneys to introduce air through the

media. Due to the tremendous size of these towers (500 ft high and 400 ft in diameter at the base) they are generally used for water flow rates above 200,000 gal/min. Usually these types of towers are only used by utility power stations.

Mechanical draft cooling towers are much more widely used. These towers utilize large

fans to force air through circulated water. The water falls downward over fill surfaces, which help increase the contact time between the water and the air. This helps maximize heat transfer between the two.

CoolingTowerDesign,SelectionandEfficientUtilization

Page16

Types of Mechanical Draft Towers

Figure 2: Mechanical Draft Counterflow Tower

Figure 3: Mechanical Draft Crossflow Tower

Mechanical draft towers offer control of cooling rates in their fan diameter and speed of operation. These towers often contain several areas (each with their own fan) called cells.

CoolingTowerDesign,SelectionandEfficientUtilization

Page17

5.0 Cooling Tower Theory

Heat is transferred from water drops to the surrounding air by the transfer of sensible and latent heat.

Figure 4: Water Drop with Interfacial Film This movement of heat can be modeled with a relation known as the Merkel Equation: (1)

where: KaV/L = tower characteristic K = mass transfer coefficient (lb water/h ft2) a = contact area/tower volume V = active cooling volume/plan area L = water rate (lb/h ft2) T1 = hot water temperature (0F or 0C) T2 = cold water temperature (0F or 0C) T = bulk water temperature (0F or 0C) hw = enthalpy of air-water vapor mixture at bulk water temperature (J/kg dry air or Btu/lb dry air)

CoolingTowerDesign,SelectionandEfficientUtilization Page18

ha = enthalpy of air-water vapor mixture at wet bulb temperature (J/kg dry air or Btu/lb dry air) Thermodynamics also dictate that the heat removed from the water must be equal to the heat absorbed by the surrounding air: (2) (3) where: L/G = liquid to gas mass flow ratio (lb/lb or kg/kg) T1 = hot water temperature (0F or 0C) T2 = cold water temperature (0F or 0C) h2 = enthalpy of air-water vapor mixture at exhaust wet-bulb temperature (same units as above) h1 = enthalpy of air-water vapor mixture at inlet wet-bulb temperature (same units as above) The tower characteristic value can be calculated by solving Equation 1 with the Chebyshev numerical method: (4)

CoolingTowerDesign,SelectionandEfficientUtilization

Page19

Figure 5: Graphical Representation of Tower Characteristic The following represents a key to Figure 5: C' = Entering air enthalpy at wet-bulb temperature, Twb BC = Initial enthalpy driving force CD = Air operating line with slope L/G DEF = Projecting the exiting air point onto the water operating line and then onto the temperature axis shows the outlet air web-bulb temperature. As shown by Equation 1, by finding the area between ABCD in Figure 5, one can find the tower characteristic. An increase in heat load would have the following effects on the diagram in Figure 5: 1. Increase in the length of line CD, and a CD line shift to the right 2. Increases in hot and cold water temperatures 3. Increases in range and approach areas

The increased heat load causes the hot water temperature to increase considerably faster than does the cold-water temperature. Although the area ABCD should remain

CoolingTowerDesign,SelectionandEfficientUtilization Page20

constant, it actually decreases about 2% for every 10 0F increase in hot water temperature above 100 0F. To account for this decrease, an "adjusted hot water temperature" is used in cooling tower design.

Figure 6: Graph of Adjusted Hot Water Temperatures The area ABCD is expected to change with a change in L/G, this is key in the design of cooling towers.

6.0 Cooling Tower Design

Although KaV/L can be calculated, designers typically use charts found in the Cooling Tower Institute Blue Book to estimate KaV/L for given design conditions. It is important to recall three key points in cooling tower design:

1. A change in wet bulb temperature (due to atmospheric conditions) will not change the tower characteristic (KaV/L) 2. A change in the cooling range will not change KaV/L 3. Only a change in the L/G ratio will change KaV/L

CoolingTowerDesign,SelectionandEfficientUtilization Page21

Figure 7: A Typical Set of Tower Characteristic Curves The straight line shown in Figure 7 is a plot of L/G vs KaV/L at a constant airflow. The slope of this line is dependent on the tower packing, but can often be assumed to be -0.60. Figure 7 represents a typical graph supplied by a manufacturer to the purchasing company. From this graph, the plant engineer can see that the proposed tower will be capable of cooling the water to a temperature that is 10 0F above the wet-bulb temperature. This is another key point in cooling tower design. Cooling towers are designed according to the highest geographic wet bulb temperatures. This temperature will dictate the minimum performance available by the tower. As the wet bulb temperature decreases, so will the available cooling water temperature. For example, in the cooling tower represented by Figure 7, if the wet bulb temperature dropped to 75 0F, the cooling water would still be exiting 10 0F above this temperature (85 0F) due to the tower design.

CoolingTowerDesign,SelectionandEfficientUtilization

Page22

Steps for Cooling tower design in industry

1. Plant engineer defines the cooling water flowrate, and the inlet and outlet water temperatures for the tower. 2. Manufacturer designs the tower to be able to meet these criteria on a "worst case scenario" (ie. during the hottest months). The tower characteristic curves and the estimate are given to the plant engineer. 3. Plant engineer reviews bids and makes a selection Design Considerations

Once a tower characteristic has been established between the plant engineer and the manufacturer, the manufacturer must design a tower that matches this value. The required tower size will be a function of:

1. Cooling range 2. Approach to wet bulb temperature 3. Mass flow rate of water 4. Web bulb temperature 5. Air velocity through tower or individual tower cell 6. Tower height In short, nomographs such as the one shown on page 12-15 of Perry's Chemical Engineers' Handbook 6th Ed. utilize the cold water temperature, wet bulb temperature, and hot water temperature to find the water concentration in gal/min ft2. The tower area can then be calculated by dividing the water circulated by the water concentration. General rules are usually used to determine tower height depending on the necessary time of contact: Approach to Wet Bulb (0F) 15-20 10-15 5-10 Cooling Range (0F) 25-35 25-35 25-35 Tower Height (ft) 15-20 25-30 35-40

Other design characteristics to consider are fan horsepower, pump horsepower, make-up water source, fogging abatement, and drift eliminators.

CoolingTowerDesign,SelectionandEfficientUtilization Page23

Operation Considerations Water Make-up Water losses include evaporation, drift (water entrained in discharge vapor), and blow down (water released to discard solids). Drift losses are estimated to be between 0.1 and 0.2% of water supply. Evaporation Loss = 0.00085 * water flow rate(T1-T2) Blow down Loss = Evaporation Loss/(cycles-1) where cycles is the ratio of solids in the circulating water to the solids in the make-up water Total Losses = Drift Losses + Evaporation Losses + Blow down Losses Cold Weather Operation Even during cold weather months, the plant engineer should maintain the design water flow rate and heat load in each cell of the cooling tower. If less water is needed due to temperature changes (ie. the water is colder), one or more cells should be turned off to maintain the design flow in the other cells. The water in the base of the tower should be maintained between 60 and 70 0F by adjusting air volume if necessary. Usual practice is to run the fans at half speed or turn them off during colder months to maintain this temperature range. (5) (6)

(7)

6.1CapacityversusThermalCapabilityofCoolingTowers

Do our cooling towers ever work properly? Mostly never, even though engineers often over specify the design capacity and/or the entering wet-bulb temperature, in the hope that the cooling towers will perform without trouble. We pay for 100% but do you get 100%? What can you do to be sure that the towers you purchased perform according to the specifications. We analyze poor performance at what consequences and the solutions we have to solve. Capacity versus capability

CoolingTowerDesign,SelectionandEfficientUtilization

Page24

Capacity: The design capacity, calculated from the heat exchange processes, given in the following forumla: HWT: Hot water entering temperature CWT: Cold water leaving temperature WBT: Design entering wet bulb temperature FLOW: The assigned water flow for transferring the heat load. HWT - CWT = range CWT - WBT = approach With these data, the cooling tower manufacturer calculates the size of the cooling tower required, with his typical references for heat transfer. If the tower is under designed, it might be understood that the tower does not reject the full heat load. This is a false conception. The tower always transfers the heat load given, but it will not reach the CWT at the given WBT. The cold-water temperature will not reach the design parameter, but the heat load will still be rejected to the ambient air. For example, if a tower is designed for a range of 5 degrees and an approach of 5 degrees, it needs a heat exchange surface of 100%. If the heat exchange surface is only 75%, then the approach will not reach 5 degrees, but perhaps 7 degrees. The CWT will approximately be 40% higher than the design criteria requested. Capability: This implicates the tower's ability to handle the heat load to its original design parameters. The capability is the percentage of the design water flow to handle the applied heat load. In practical terms: with how much water over the tower do we have the designed range and approach? It is the quantity of water, under 100% heat load on the tower, given for a test conducted under the test codes.

CoolingTowerDesign,SelectionandEfficientUtilization

Page25

6.2 Thermal performance assessment of Cooling Tower:

If a mechanical device is under designed for its duty, you will have immediate feedback if the device is not reaching its intended performance. For a cooling tower it may be suspected that the performance is not what it should be, but proving a capacity shortage is more difficult. Checking a tower on its design conditions will be a long wait until the operating temperatures, flow and wet bulb temperature do match the design parameters. Some testing methods do allow performance tests at conditions that vary from the design conditions. To test a tower accurately, one will have to do a little more than to wave a sling thermometer in the vicinity of the tower, take the flow rate from a pump curve and take the temperatures with an average household thermometer. High accuracy testing equipment is required to get close to 100% accuracy in the test results. An example, the table below gives a set of design conditions for a cooling tower and two sets of test conditions; Test A and Test B.

Capacity versus capability

CoolingTowerDesign,SelectionandEfficientUtilization

Page26

Test A is the set of figures from a careful run test. Test B however, gives results where a mistake of 4% has been made in the water flow calculations, and errors of 0.1 C have been made in the temperature readings for the hot and cold water and for the wet bulb reading. These errors may not seem to be significant, their impact however on the test result is. Results for the tests give a capability mark for Test A of 86.0% and for Test B 96.5%, more than a ten percent difference. Test B results would generally be judged a pass, for it has a capability of 95%. When one considers the price tag for a tower like this of about $US30,000, the real shortfall of 14% in capability in the example above is worth some $US4,000. Consider the cost difference on that tower when it delivers only 70% or less in capability! It is a cause of concern that despite the existence of a number of different thermal test standards for cooling towers, we still see this situation quite regularly. Effects of an undersized cooling tower: A cooling tower can under perform for various reasons:

Wrong selection of the type of tower Poor manufacturing and installation Poor maintenance Optimistic load ratings

These can have the following effects: 1. Initial cost: All things being equal, a cooling tower that is providing only 80% capability can be expected to be around 20% cheaper in its original cost compared to a 100% tower. In a competitive situation when bidding for a project, a small price difference can win or lose a job. 2. Running costs: Towers that are undersized will produce higher water temperatures than specified, and thus contribute to a less efficient operation of the total plant. A less efficient plant equates to a longer running time, causing higher energy costs.

CoolingTowerDesign,SelectionandEfficientUtilization

Page27

3. Critical plant operations: For critical conditions such as computer rooms, air conditioning temperatures that are higher than design can cause problems with computer operational malfunctions. In industrial applications, loss of production, or a downgraded product can be the result of high water temperature. 4. Plant life: Add to the above the reduced life that can be expected from a plant because of the additional stresses caused by higher operational temperatures, and the benefit of the lower initial cost of an undersized cooling tower quickly diminishes.

How to protect from undersized cooling towers:

Which protective measures could you make to ensure that the installation performs satisfactorily? Most buyers of cooling towers will try to avoid buying a malfunctioning tower using the criteria below.

1. Do business with manufacturers or representatives who state that they guarantee the

tower's capacity.

2. Acquire cooling towers from a member of the Cooling Tower Institute (CTI) or buy cooling

towers that carry their logo sticker or printed logo on technical bulletins.

3. Acquire a cooling tower of which the manufacturer claims the tower is tested in accordance

with the Japanese Standard JIS B 8609.

4. Acquire a cooling tower of which the manufacturer claims the tower is tested in accordance

with the Chinese Standard GB7190.1

5. Insist on a test on site carried out by the manufacturer.

Unfortunately, even if all of the above conditions apply, the tower's capability cannot be guaranteed. Please consider the following: If a manufacturer quotes a particular sized cooling tower to a set of design conditions, it could be assumed that the manufacturer is guaranteeing that the tower will perform to those conditions. Unfortunately, this is not always the case and some manufacturers are overrating their towers as much as 40%. CoolingTowerDesign,SelectionandEfficientUtilization Page28

A number of manufacturers are member of the Cooling Tower Institute, a worldwide organization headquartered in the USA. More than any other organization, the CTI has played a part in elevating the status of cooling towers, by promoting the truthful rating of them.

Being a member of the CTI allows the member to use the CTI logo with member printed beneath on letterheads and promotional information. The use of the CTI logo in such a way does not provide any guarantee of performance of the manufacturer's range of products; it just proves they are a member.

6.3 The Japanese Industrial Standard, JIS B 8609 - Performance Tests of Mechanical Draft Cooling Tower It covers thermal performance, sound, drift and electrical power. Some cooling tower manufacturers proclaim that their towers are tested in accordance with JIS B 8609. This standard states that it is for use with cooling towers of capacity of 233 kW or less at standard design conditions. This is an approximate water flow rate of 11 l/s, which is a very small machine. There is nothing to prevent the principles outlined in the standard from being used for larger towers. JIS B 8609 is a code for laboratory practice and is not suitable for field-testing cooling towers. In JIS B 8609, once rated the performance of the tower, there is no requirement, compulsory or voluntary, to use the actual capacity found from testing in the published rating for that tower. As with the Japanese standard discussed above, the Chinese standard, GB 7190.1 covers thermal performance requirements and other matters pertaining to cooling towers. Different to the Japanese standard is that this Chinese standard also covers a form of certification of the cooling tower's thermal performance. However, this standard has a number of problems with its approach to thermal performance testing. Some problems are:

CoolingTowerDesign,SelectionandEfficientUtilization

Page29

The test tolerance of 10% is too high, too much for a mission critical cooling tower. The required instrument precision is low, making the end result dubious. As discussed and shown before, seemingly small measurement tolerances can lead to large errors in the final calculated capability of the cooling tower. To overcome the problems caused by undersized cooling towers, some consultants demand a site test on the cooling tower to verify its capability. As it might not be in the best interest of the manufacturer to be very critical on the performance of its own products, manufacturers tests might not be the most reliable.

Most manufacturers would do a test using minimal equipment of dubious quality. In such circumstances, errors are common, and usually favor the manufacturer. Small differences in the measured quantities can lead to large difference in the result. Errors in the (handling of) measurement devices are not the only problem; there are other tricks of the trade that can be used to bias a test result in the favour of the tower manufacturer. Therefore, even specifying a site test with all the best intentions will not necessarily ensure that the end result is a tower delivering the performance required. If it is critical that a tower provides the performance that is specified (and shouldn't all installations be considered as such?), there are two ways to ensure receipt of a right sized tower. These are: 1. Specify a test to a competent standard such as the CTI Test Code ATC-I05, with the test to be carried out by an independent testing authority that possesses the necessary skills and high quality instrumentation. 2. Purchase a cooling tower that has certified thermal performance. At this point of time, the only certification scheme of merit in existence is the one conducted by the CTI.

Independent cooling tower thermal performance testing

A well conducted site test true to the test codes involves the measurement of quantities CoolingTowerDesign,SelectionandEfficientUtilization Page30

1. Water flow rate; 2. Hot and cold water temperatures 3. Entering air wet bulb temperatures 4. Fan motor electrical characteristics 5. Wind speed and direction. These quantities are specified to be within certain limits of the design conditions. Because water cooling towers rely on both heat and mass transfer to affect the cooling function, they are rated at steady state conditions. While it is impossible to obtain a steady state condition on site, the test codes stipulate the maximum rate of change that the various measured quantities can vary over the test period. Instrumentation is of paramount importance and, of course, should be calibrated to an acceptable standard. Logging of test measurements should preferably be automatic, particularly for larger towers where a large number of instruments are used in gathering of information. It is essential to the interests of all parties, that confidence exists in the ability of the tester to conduct the test and interpret the accumulated data. To ensure confidence, the CTI has a scheme where it licenses testing agencies to conduct thermal performance testing under their auspices. Such a license is only granted after rigorous examination by CTI of the applicant. The aim of the examination is to assure quality in the conduct of the test, the reporting of results and the complete independence of the licensee without the possibility of any conflict of interest. We do not promote that every cooling tower needs to be tested. However, for larger towers and for towers on critical installations, the test price can be justified when compared with the initial cost of the tower and the impact on the life cycle costs of the overall plant that an undersized tower can cause.

CoolingTowerDesign,SelectionandEfficientUtilization

Page31

Should a test prove that the tower is deficient in its capability by more than 5% then, as part of contractual obligations, the tower manufacturer should be required to upgrade the tower and retest at their own expense. Should the tower still be deficient, then further upgrading and retesting is to be carried out. It is not surprising that where such specifications are invoked, the chance of an undersized cooling tower being installed considerably diminishes.

Conclusion

Cooling towers have a poor reputation. It is generally believed that they do not deliver the performance they are rated at. To overcome the possibility of a low performing tower, design conditions are specified which are higher than required. This "solution" may be contributing to the perpetuation of the original problem. It is possible to demand and obtain cooling towers that have 100% capability, either by specifying a site test conducted by an independent and experienced testing agency, or by the purchase of a tower with certified thermal ratings. In the competitive process of bidding, the various products offered should be compared on size of the tower, the wet surface and the motor power ratings instead of only towers price. This already expels in an early stage those manufacturers who, willingly or not, offer underrated towers in order to win the project. One could also invite a professional independent institute to support the purchase process.

CoolingTowerDesign,SelectionandEfficientUtilization

Page32

7.0 Preventive Maintenance schedule for Cooling Towers

Daily: Check if 1. Vibrations are normal / Noise normal. 2. Water distribution proper. 3. Fan Motor current normal in all three phases. 4. Inlet / outlet temperature of water normal.

Weekly: 1. Clean inlet wire mesh to remove entrained matter. 2. Clean inlet water filter. 3. Clean sprinklers / nozzles if choked. 4. Check growth of algae etc. and remove from sump.

Monthly: 1. Drain Tank, flush out and remove any sediment. 2. Check fills if clogged due to Algae, sediment / salts, etc. 3. Check structural / FRP casing and Basin damage and rep. 4. Clean from outside with soap and water. 5. Check and tighten all bolts. 6. Smear Bolts with grease to facilitate easy opening the next time.

Every Six Months: 1. Grease all bearings of motors. CoolingTowerDesign,SelectionandEfficientUtilization Page33

2. Grease all bearings of sprinklers. 3. Check run out on fan motor shaft 4. Clean blades of foreign matter. 5. Check fills if damaged and replace. 6. Replace bearings of sprinkler assembly after 2 years and fill with grease.

8.0WaterConservationbyImprovingCoolingTowerEfficiency

Though an abundant supply of freshwater has been taken for granted in many parts of the world, its availability is certainly becoming less. Water is a valuable resource and commodity that needs to be efficiently managed to minimize waste, reduce energy consumption, and control cost, especially for power generation. The industry must respond by seeking out more efficient ways to use water, such as by implementing water recycling and reuse strategies, especially for critical equipment like cooling towers. The purpose of a cooling tower is to conserve water. It fulfills its purpose by rejecting heat to the atmosphere by convective and evaporative heat transfer. As water cascades through the cooling tower, it comes into contact with air that is pushed or pulled through the fill by mechanical draft fans. Some of the waste heat is transferred from the warmer water to the cooler air by convection. The remaining heat is removed by evaporation of a small percentage of the re-circulated water. The evaporation rate is determined by the following equation: Evaporation (E) = (0.0085) * (Recirculation rate, R) * (Temperature differential across tower, dT) The water that is evaporated from the tower is pure; that is, it doesnt contain any of the mineral solids that are dissolved in the cooling water. Evaporation has the effect of concentrating these dissolved minerals in the remaining tower water. If these were to occur without restriction, however, the solubility limit of the dissolved minerals would soon be reached. When the solubility limit is reached, dissolved minerals (most commonly calcium and magnesium salts) precipitate as an insoluble scale or sludge. This is the off-white, mineral scale that is frequently found in heat exchangers, in the tower fill, or deposited in the sump. To prevent the tower from over concentrating minerals, a percentage of the cooling water is discharged to drain. The bleed or blow down rate is adjusted to control the concentration of dissolved minerals to

CoolingTowerDesign,SelectionandEfficientUtilization

Page34

just below their solubility limit. This limit is commonly set and controlled by specific conductance (micro mhos/cm) or total dissolved solids (mg/l) measurements. The water that is lost by evaporation and bleed must be replaced by fresh makeup to maintain a constant system volume. Makeup is typically obtained from potable water sources, but it may also come from treated wastewater or recycled water supplies (Figure 7): Makeup (MU) = Evaporation (E) + Bleed (B) + Uncontrolled losses

Water-balancing act. A typical power plant evaporative cooling system must add makeup water to balance out evaporation and cooling tower blow down. One indicator of cooling tower efficiency is cycles of concentration, or concentration ratio. This is the ratio of the makeup rate to the bleed rate, MU/B, assuming the uncontrolled losses are negligible. Cycles of concentration are also estimated by the ratio of the specific conductance of the cooling water and the makeup water: Cycles of concentration (C) = MU / B CoolingTowerDesign,SelectionandEfficientUtilization Page35

From these relationships, the amount of bleed required to maintain a specific cycle of concentration is determined by: B = E / (C 1) If E is held constant, reducing the bleed causes the cycles to increase. Conversely, increasing the bleed causes the cycles to decrease. Operating the cooling tower at maximum cycles of concentration reduces the amount of water sent to drain and thereby decreases the freshwater makeup demand. Overall, higher cycles of concentration translate into greater efficiency as measured by a decrease in freshwater consumption and wastewater discharge (Figure 8).

Cooling tower basics. Increasing the cycles of concentration or cooling tower water dissolved mineral content will decrease the cooling tower blow down and thereby decrease makeup water requirements. However, increased minerals in the water can degrade tower performance over a period of time. The diminishing returns curve (Figure 8) indicates that major gains in water conservation can be achieved by increasing the cycles from two to three. As we approach higher cycles, however, the incremental gains decrease. From a practical view, windage, leaks, and other uncontrolled losses limit the cycles to a maximum of about 10. This is a reasonable goal for most cooling towers and would further suggest that cooling towers operating below 10 cycles of concentration are less than 100% efficient as measured by makeup consumption and wastewater generation (see table).

CoolingTowerDesign,SelectionandEfficientUtilization

Page36

Cooling tower efficiency is determined by cycles of concentration. The table data assume that 10 cycles of concentration represent 100% cooling tower efficiency for comparison purposes. These figures suggest that cooling towers that operate at fewer than five cycles of concentration (less than 90% efficient) are not achieving their full potential and would benefit from retrofits that would reduce freshwater consumption and decrease waste. Towers operating at six to eight cycles are acceptable for most applications. Towers in the 9- to 10-cycles range have reached their peak. Achieving more than 10 cycles would be difficult while deriving a reasonable return on investment, unless zero discharge is the ultimate goal. Strategies for Improving Performance Cooling tower cycles can be maximized in a variety of ways. These include pH adjustment, chemical scale inhibitors, and pretreatment of the tower makeup.

CoolingTowerDesign,SelectionandEfficientUtilization

Page37

PH Adjustment Traditionally, cooling towers operating on high-hardness, high-alkalinity makeup water utilized pH adjustment with sulfuric acid to maximize cycles of concentration. One part of 66 Baume acid is required to neutralize one part of alkalinity. Sufficient acid is injected into the makeup to maintain the total alkalinity of the cooling water in the range of 50 to 100 ppm or at a level that will maintain the pH within the range of 6.8 to 7.5. The Langelier, Ryznar, or Practical scaling index is used as an additional control measure to correlate the calcium hardness, total alkalinity, pH, total dissolved solids, and temperature to maintain water chemistry at the neutral point of the index (neither scaling nor corrosive). The problem with using acid to increase cycles is one of control. Accidental overfeed conditions (low pH) make the cooling water very corrosive to system metals. And, reducing the M alkalinity removes the natural passivating effect that carbonate and bicarbonate alkalinity have on steel. Operating the cooling tower at pH levels above 8.5 creates an environment that passivates steel and minimizes corrosion of galvanized steel and copper. Unlike scale deposition, which can be removed by chemical or mechanical cleaning, damage caused by acid corrosion cannot be reversed and is very expensive to repair. In addition, the handling, transporting, and feeding of concentrated sulfuric acid creates additional environmental, health, and safety issues. Chemical Scale Inhibitors Various chemical additives and formulations are marketed that enhance the solubility of calcium and magnesium salts while at the same time controlling corrosion to within acceptable rates. These chemicals are generally phosphonates (organically bound phosphate compounds), polymers (mono-, co-, and ter-), and organic corrosion inhibitors. These products are used alone or in combination with supplemental acid feed to maximize tower cycles. Proven effective in lab tests and in the field, cooling water additives are usually limited to keeping calcium and magnesium salts soluble up to a Langelier Index value of about +2.5. Other chemical programs push through the calcium solubility limit by claiming to maintain clean heat transfer surfaces at even higher cycles, despite the precipitation of hardness salts, which are chemically conditioned into a fluid, nonadherent sludge that is removed by routine bleed.

CoolingTowerDesign,SelectionandEfficientUtilization

Page38

Notwithstanding the benefits of a sound chemical treatment program, if the cooling tower cycles are limited to fewer than five, significant water savings can be realized by improving the quality of the tower makeup. Pretreatment of Cooling Tower Makeup The primary limiting factor for cycles of concentration is calcium hardness. As a general rule of thumb, the calcium hardness in the cooling tower should be maintained within the range of 350 to 400 ppm on a non-acid treatment program. If the makeup water contains, say, 100 ppm calcium hardness, the cycles of concentration are restricted to 3.5 to 4.0. This is equivalent to 75% to 85% water efficiency. Reducing the calcium hardness to 50 ppm allows the tower to run at seven to eight cycles, which is equivalent to over 96% water efficiency. Hardness reduction or removal can be accomplished by lime softening, sodium ion exchange (water softener), or reverse osmosis. Low-hardness makeup is often available from recycled and reused plant wastewater such as spent rinse water and steam condensate. Water of any desired hardness can be obtained by the controlled blending of softened water with untreated raw or recycled water. Benefits of Increasing Concentration Cycles Maximizing cooling tower cycles offers many benefits in that it reduces water consumption, minimizes waste generation, decreases chemical treatment requirements, and lowers overall operating costs. As a simple example, a cooling tower handling a 1,000-ton load operating at 3.5 cycles of concentration with a 12F temperature drop across the tower has a makeup demand of 61,775 gallons per day (gpd). Increasing the cycles to eight has the effect of decreasing the makeup demand to 50,400 gpd. This reduces the makeup requirement by 18.4%. The wastewater produced by the cooling tower decreases from 17,640 gpd at 3.5 cycles to 6,336 gpd at eight cycles, which is equivalent to a 64% decrease. And by using less water, chemical treatment consumption and disposal requirements are proportionately reduced. Potential cost savings vary from plant to plant, depending on the cost for raw water, waste disposal costs, chemical treatment dosages, and energy. Nevertheless, in addition to the environmental, health, and safety improvements, the return on investment for improving cooling tower efficiency is typically less than one year.

CoolingTowerDesign,SelectionandEfficientUtilization

Page39

9.0 Intelligent Cooling Tower System

Electro-Chemical Devices new plug-and-play Model 2122 Cooling Tower Control System (CTCS) is designed to apply the various chemicals used to prevent corrosion, scaling, and fouling in water-based wet cooling towers. The system also controls acid feed via pH monitoring, blow down via conductivity, and the inhibitor via a user-selected time basis. Model 2122 CTCS features a unique timer-based overfeed function that locks out the blow down cycle or the acid/base feed function, and that triggers a process alarm if the acid feed or blow down cycle proceeds longer than the operators predetermined cycle time. The system consists of ECDs Model 22 Controller, a Model PHS10 pH sensor, and a Model CS10 conductivity sensor. The C22 features four SPDT relays and is rated NEMA 4X for rugged environments. An optional digital input card can be added to monitor no-flow conditions for extra safety.

More details about this instrument is available on ( www.ecdi.com)

CoolingTowerDesign,SelectionandEfficientUtilization

Page40

Anda mungkin juga menyukai

- Tactical Guide For Deploying Mbe InitiativesDokumen26 halamanTactical Guide For Deploying Mbe InitiativeskarrtiktvBelum ada peringkat

- LLR Test General Driving Principles EnglishDokumen23 halamanLLR Test General Driving Principles Englishu2mailrahulBelum ada peringkat

- Geometric ModellingDokumen137 halamanGeometric ModellingintelchinoBelum ada peringkat

- So You Think Hearing Protection Is Boring..Dokumen1 halamanSo You Think Hearing Protection Is Boring..karrtiktvBelum ada peringkat

- 9A02404 Electromagnetic FieldsDokumen1 halaman9A02404 Electromagnetic FieldskarrtiktvBelum ada peringkat

- 3 - 5!6!30 Eye Protection Requird Good PDFDokumen1 halaman3 - 5!6!30 Eye Protection Requird Good PDFkarrtiktvBelum ada peringkat

- Unit 9 CRCDokumen21 halamanUnit 9 CRCEr Manpreet ChahalBelum ada peringkat

- Murex Arc Gas Conumables 3Dokumen58 halamanMurex Arc Gas Conumables 3karrtiktvBelum ada peringkat

- Don't Put It On The Bench... Put It On Your Ears!Dokumen1 halamanDon't Put It On The Bench... Put It On Your Ears!karrtiktvBelum ada peringkat

- Electrical Measurement & InstrumentationDokumen462 halamanElectrical Measurement & InstrumentationEr. Amar Kumar86% (7)

- Shortcuts in ExcellDokumen15 halamanShortcuts in ExcellkarrtiktvBelum ada peringkat

- New Microsoft Office Word DocumentDokumen4 halamanNew Microsoft Office Word DocumentkarrtiktvBelum ada peringkat

- Electromagnetic FieldsDokumen2 halamanElectromagnetic FieldskarrtiktvBelum ada peringkat

- 1 Jagadeesh 2 Guru 3 Noor 4 Raghu 5 Rajesh: #J #G #N #R #RADokumen6 halaman1 Jagadeesh 2 Guru 3 Noor 4 Raghu 5 Rajesh: #J #G #N #R #RAkarrtiktvBelum ada peringkat

- Silambarasan ResumeDokumen2 halamanSilambarasan ResumekarrtiktvBelum ada peringkat

- Biogas PresentationDokumen13 halamanBiogas PresentationkarrtiktvBelum ada peringkat

- Chapter 15 Transformer Design:: N + (T) - + (T) - (T) (T)Dokumen40 halamanChapter 15 Transformer Design:: N + (T) - + (T) - (T) (T)elmanlucian100% (2)

- Shoe Dog: A Memoir by the Creator of NikeDari EverandShoe Dog: A Memoir by the Creator of NikePenilaian: 4.5 dari 5 bintang4.5/5 (537)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDari EverandNever Split the Difference: Negotiating As If Your Life Depended On ItPenilaian: 4.5 dari 5 bintang4.5/5 (838)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDari EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FuturePenilaian: 4.5 dari 5 bintang4.5/5 (474)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDari EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifePenilaian: 4 dari 5 bintang4/5 (5782)

- Grit: The Power of Passion and PerseveranceDari EverandGrit: The Power of Passion and PerseverancePenilaian: 4 dari 5 bintang4/5 (587)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDari EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RacePenilaian: 4 dari 5 bintang4/5 (890)

- The Yellow House: A Memoir (2019 National Book Award Winner)Dari EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Penilaian: 4 dari 5 bintang4/5 (98)

- On Fire: The (Burning) Case for a Green New DealDari EverandOn Fire: The (Burning) Case for a Green New DealPenilaian: 4 dari 5 bintang4/5 (72)

- The Little Book of Hygge: Danish Secrets to Happy LivingDari EverandThe Little Book of Hygge: Danish Secrets to Happy LivingPenilaian: 3.5 dari 5 bintang3.5/5 (399)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDari EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryPenilaian: 3.5 dari 5 bintang3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnDari EverandTeam of Rivals: The Political Genius of Abraham LincolnPenilaian: 4.5 dari 5 bintang4.5/5 (234)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDari EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaPenilaian: 4.5 dari 5 bintang4.5/5 (265)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDari EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersPenilaian: 4.5 dari 5 bintang4.5/5 (344)

- The Emperor of All Maladies: A Biography of CancerDari EverandThe Emperor of All Maladies: A Biography of CancerPenilaian: 4.5 dari 5 bintang4.5/5 (271)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDari EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyPenilaian: 3.5 dari 5 bintang3.5/5 (2219)

- The Unwinding: An Inner History of the New AmericaDari EverandThe Unwinding: An Inner History of the New AmericaPenilaian: 4 dari 5 bintang4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDari EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You ArePenilaian: 4 dari 5 bintang4/5 (1090)

- Rise of ISIS: A Threat We Can't IgnoreDari EverandRise of ISIS: A Threat We Can't IgnorePenilaian: 3.5 dari 5 bintang3.5/5 (137)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Dari EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Penilaian: 4.5 dari 5 bintang4.5/5 (119)

- Her Body and Other Parties: StoriesDari EverandHer Body and Other Parties: StoriesPenilaian: 4 dari 5 bintang4/5 (821)

- Science Form 1 - Chapter 3Dokumen15 halamanScience Form 1 - Chapter 3Beevy GB71% (14)

- Chemical Solution Density & ViscosityDokumen18 halamanChemical Solution Density & ViscosityLee JianBelum ada peringkat

- Chapter 5 Answers To Examination Style QuestionsDokumen6 halamanChapter 5 Answers To Examination Style QuestionsRosa Wells0% (1)

- Spreadsheet - Gas Blanketed Tanks - Outbreathing Process Calculations & Control Valve Sizing - Rev2Dokumen33 halamanSpreadsheet - Gas Blanketed Tanks - Outbreathing Process Calculations & Control Valve Sizing - Rev2MaheshBelum ada peringkat

- ANALYSIS OF PIPELINE STRESS IN GEOTHERMAL PIPING SYSTEMDokumen15 halamanANALYSIS OF PIPELINE STRESS IN GEOTHERMAL PIPING SYSTEMAbdul Haris SiregarBelum ada peringkat

- Fundamentals of Ultrasonic Phased Arrays - 1-10Dokumen10 halamanFundamentals of Ultrasonic Phased Arrays - 1-10Kevin HuangBelum ada peringkat

- Goldstein Classical Mechanics PDFDokumen3 halamanGoldstein Classical Mechanics PDFAdam50% (2)

- Bharathidasan University, Tiruchirappalli - 620 024. B.Sc. Physics Course Structure Under CBCSDokumen27 halamanBharathidasan University, Tiruchirappalli - 620 024. B.Sc. Physics Course Structure Under CBCSSarjithBelum ada peringkat

- Dynamics (Linear Impulse and Momentum)Dokumen4 halamanDynamics (Linear Impulse and Momentum)YadanaBelum ada peringkat

- Corrosion 2Dokumen8 halamanCorrosion 2alyBelum ada peringkat

- PhysicsDokumen147 halamanPhysicsMâñøj Thę ŠtrįkėrBelum ada peringkat

- Nova - The Race For Absolute Zero WorksheetDokumen3 halamanNova - The Race For Absolute Zero Worksheetemily petersBelum ada peringkat

- Energy Skatepark Student GuideDokumen4 halamanEnergy Skatepark Student GuideZilvinas Griskevicius GriskeviciusBelum ada peringkat

- Resonant Column Last VersionDokumen34 halamanResonant Column Last Versionkabasy2015Belum ada peringkat

- PhysicsDokumen26 halamanPhysicsShashikiran MBelum ada peringkat

- Geometric:Clifford Algebra For PhysicsDokumen25 halamanGeometric:Clifford Algebra For PhysicsBho Bho0% (1)

- Kimet JusufiDokumen7 halamanKimet JusufiFatlum RushitiBelum ada peringkat

- Dynamic Stabilisation of Biped Lucy Powered by ActuatorsDokumen340 halamanDynamic Stabilisation of Biped Lucy Powered by ActuatorstakinabreakBelum ada peringkat

- QUIZ 3 OF LP3 (Fluid Kinematics) OF MC PHYSICS 1 (FLUID MECHANICS)Dokumen3 halamanQUIZ 3 OF LP3 (Fluid Kinematics) OF MC PHYSICS 1 (FLUID MECHANICS)fj damayoBelum ada peringkat

- Curve of A Baseball: Index Bernoulli ConceptsDokumen1 halamanCurve of A Baseball: Index Bernoulli Conceptspepe.booksBelum ada peringkat

- Homework 3 FebDokumen42 halamanHomework 3 FebEmmanuel Olowosulu100% (3)

- Issa 1986Dokumen17 halamanIssa 1986andersson benito herreraBelum ada peringkat

- Statics of Rigid BodiesDokumen12 halamanStatics of Rigid BodiesJoanne-chan Mingi100% (1)

- Modeling and Analysis of Soil-Pile InteractionDokumen21 halamanModeling and Analysis of Soil-Pile InteractionLhester NavascaBelum ada peringkat

- DYNROT: A Matlab Toolbox For Rotordynamics Analysis: January 1994Dokumen27 halamanDYNROT: A Matlab Toolbox For Rotordynamics Analysis: January 1994saurabhchandrakerBelum ada peringkat

- RF Behaviour of Passive ComponentsDokumen4 halamanRF Behaviour of Passive ComponentsAmbbiga JaiBelum ada peringkat

- Grade 9 Lesson Plan 01Dokumen2 halamanGrade 9 Lesson Plan 01RahmonGreenBelum ada peringkat

- Assignment-Ray OpticsDokumen2 halamanAssignment-Ray OpticstejvanshsandhuBelum ada peringkat

- YZ250F Matlab DocumentationDokumen12 halamanYZ250F Matlab DocumentationvivekpattniBelum ada peringkat