Pioneer

Diunggah oleh

Umair ChishtiDeskripsi Asli:

Hak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

Pioneer

Diunggah oleh

Umair ChishtiHak Cipta:

Format Tersedia

Supply Chain Management Assignment#1 27-09-2011 Q.

1) John Smith, being the Vice President of the company s supply chain management, was heading planning, production and distribution departments. He had to maintain the company s reputation of being the largest seed company in the world as the industry is changing rapidly, so it would be difficult to maintain the same performance level. For this purpose, his decisions were critical to mark the company as the reliable supplier of high quality genetically produced seeds. The company forecasted the production plan. It took data for the last four years and, on the basis of that, forecasted the demand for the next year. As the company was operating in highly competitive market, biotechnological breakthroughs would lead to a decrease in company s seed s demand because it depends largely on one Hybrid corn seed. And it took 7-10 years to develop a new hybrid seed along with a lengthy production cycle of the seed. The demand forecast was uncertain due to changing climatic/weather conditions. To account for emergency and shortage of seed availability due to severe weather, the company maintained 33% carry-over inventory cushion. Moreover, Robert Johnson-head of productionconsidered 33% carry-over inventory critical due to the reasons stated. But in case of favorable weather the carry-over level reached 83.8% in 1995 and it took twice as much warehouse space as 33% carryover, just offsetting the gains due to large stock inventory management. It increased the risk of product obsolescence and damage. John Smith was worried as he had to decide on the supply chain after considering all these problems. All these decisions were to directly affect the company s revenue, costs and customer satisfaction. If the customers (farmers) are dissatisfied, it would directly affect the overall company s production planning and leading to high inventory management cost.

At Pioneer, demand forecast was based on historical data. The production yield was affected by growing climate conditions, legislation, customer preferences and increasing market competition. Here, close contact with the customers and placement of safeguard inventory are important to account for the uncertainty of demand forecast. Since, demand forecast and production yield were contingent on the occurrence and non-occurrence of future events let s consider two scenarios to get the understanding of effects on supply chain management decisions: A) Low demand and planned production yield In this case, if demand decreases due to biotechnological breakthrough and legislation like Freedom to Farm bill, the surplus production yield will lead to increased inventory,

transportation and logistical costs. The product runs the risk of obsolescence and damage. It will ultimately affect revenue of the company. Here, buffer stock would be damaging instead of providing a safeguard against shortage of seed. Moreover, off-season production costs 25% more than domestic production costs which is a point to be worried about. B) High demand and low production yield In this case, the company will not be able to satisfy customer s needs. Even if it uses off season production then this will lead to a 25% increase in cost, and there are capacity limitations too in off season production. Q.2) The main factors are the uncertainty of production and demand because of the changing climate conditions. Because the industry is changing rapidly so past data becomes less predictive. So smith should work to reduce safety stock. For this, smith needs to look at the cost of storing inventory, obsolescence cost and transportation costs and weighing them against the cost of shortages. As shown in exhibit 1 that with a carryover rate of 20% Pioneer is safe even when yield drop to even 90% we have a carryover of 5%, of 868534 80k units. Exhibit two further shows that even a carryover rate of 13.5% would be enough to satisfy an 80% yield. So on this analysis the carryover rate is high. But we need to analyze past data as 80% is just the drop from the mean and as explained above. Also the fact the even reducing carryover from 33% to 13.5% (19.5% drop) is safe means that 33% is high Q.3) While deciding a relationship between production yield of the northern and southern hemisphere, it should be considered that there has to be an inverse relationship between the two production yields. Also the amount of safety stock would determine the production in the northern hemisphere, a higher safety stock should reduce the need for an in increase in the off-season production. The Company operates in highly competitive market with unpredictable weather conditions, increased biotechnological breakthroughs and shorter product-life cycles. Increased off-season production would diversify company s operations. It would experience greater geographic and climatic conditions. Since, growth rate is 5% save North America, the company can benefit from its expansion by meeting greater customer needs in the less amount of time. It can tap into more markets worldwide expanding its business and maintaining its worldwide leadership. For this purpose, it would have to establish more distribution centers, post-harvest production facilities and customer service centers to facilitate normal supply chain channels to get access to larger markets worldwide. Since, the company s foreign countries share is exceeding 22.5%, it would be a viable option to expand its operations worldwide.

Despite these potential benefits, increased off-season production would cost 25% more than domestic production. The company has worked hard to protect its patented products over the course of its business. In case of expansion, it would have to abide by the laws of the country it would be operating in which makes it difficult for the company to protect its proprietary assets. It would lead to increased distribution and production costs. Research and development cost is likely to increase to inspect the growing ability of the soil. Contractual agreements with new seed growers will be an added cost. Q.4) Advantages:

The main advantage of expanding international production for Pioneer is the lower risk that it faces in its seed production. By diversifying its seed fields, Pioneer has a less chance of facing issues in supply due to adverse weather conditions, governmental regulations, insects and crop diseases. Producing in different countries meant that Pioneer would always have different options with regards to its supply and it will not be entirely dependent on a region to produce most of its supply. Disadvantages: The production costs for Pioneer will increase up to 25% more if more production is done worldwide than in North America. Other major issues such as the acquisition of proprietary assets would arise, as Pioneer had patented most of its research and worked very hard to protect its intellectual property. The issues of the capacity of these overseas locations would arise, as so far these overseas sites have been mostly used for off- season production which is considerably low than summer production. John Smith should continue producing most of the seed corn within North America. This is mainly due to the fact that in 1997, 95% of Pioneers seed corn production capacity was in the USA and Canada. This capacity would easily account for the overseas demand of 22.5 %. The remaining demand could be overcome by the already producing international sites. By doing this, John Smith would avoid all the disadvantages of overseas production. Pioneer would be able to more strictly monitor its quality control procedures and it would benefit from the less cost (25% less) of producing in the Northern Hemisphere. The international sites would continue to be used for the off-season production.

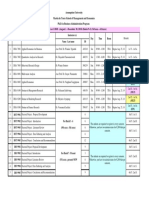

Exhibit1

Total carry in from 1997 Total Discard Exports New Crop Production Off-Season Production Total Supply Utilization Total carry over % Carry over

Supply Chain Management 1998 (Plan) 1998 (80%) 1998 (90%) 8322855 8322855 8322855 1665041 1665041 1665041 100000 100000 100000 12422684 9938147.2 11180416 1000000 1250000 1000000 19980498 17745961 18738230 16650415 16877427 16650415 3330083 868534.2 2087814.6 20.00% 5.15% 12.54%

Assumption= Carry over rate = 20% Appendix: Effects of changes in carryover rate Exhibit2

Total carry in from 1997 Total Dicard Exports New Crop Production Off-Season Production Total Supply Utilization Total carry over % Carry over

Supply Chain Management 1998 (Plan) 1998 (80%) 1998 (90%) 8322855 8322855 8322855 1665041 1665041 1665041 100000 100000 100000 11340407 9072325.6 10206366 1000000 1250000 1000000 18898221 16880140 17764180 16650415 16877427 16650415 2247806.03 2712.62 1113765.3 13.50% 0.02% 6.69%

Assumption= Carry over rate = 13.5%

Anda mungkin juga menyukai

- Bio Pharma Case StudyDokumen2 halamanBio Pharma Case StudyAshish Shadija100% (2)

- Halloran Metals FinalDokumen5 halamanHalloran Metals FinalUmair Chishti60% (5)

- KLF Electronics QuestionDokumen5 halamanKLF Electronics QuestionSumit GuptaBelum ada peringkat

- Overview - PrintingDokumen10 halamanOverview - Printingemman carlBelum ada peringkat

- Case Study Royal Bank of CanadaDokumen10 halamanCase Study Royal Bank of Canadandgharat100% (1)

- Mintendo Game GirlDokumen2 halamanMintendo Game GirlZarak MirBelum ada peringkat

- The Finance Director of Stenigot Is Concerned About The LaxDokumen1 halamanThe Finance Director of Stenigot Is Concerned About The LaxAmit PandeyBelum ada peringkat

- Merritt's BakeryDokumen1 halamanMerritt's BakeryNardine Farag0% (1)

- Boylston Shoe ShopDokumen2 halamanBoylston Shoe ShopClaire Marie ThomasBelum ada peringkat

- Assignment 3: Aggregate Planning: Name: Nguyen Khanh Linh ID: IELSIU18219Dokumen7 halamanAssignment 3: Aggregate Planning: Name: Nguyen Khanh Linh ID: IELSIU18219Khánh Linh NguyễnBelum ada peringkat

- Ajax Manufacturing Cost AnalysisDokumen7 halamanAjax Manufacturing Cost Analysisreva_radhakrish1834Belum ada peringkat

- Assigment 6 - Managerial Finance Capital BudgetingDokumen5 halamanAssigment 6 - Managerial Finance Capital BudgetingNasir ShaheenBelum ada peringkat

- ETFs vs Index Funds: What are Their Advantages and DisadvantagesDokumen2 halamanETFs vs Index Funds: What are Their Advantages and DisadvantagesdalematseoBelum ada peringkat

- OT Practice Exercise-1Dokumen3 halamanOT Practice Exercise-1Savita Choudhary0% (1)

- 101 Session FourDokumen45 halaman101 Session FourVinit PatelBelum ada peringkat

- Mission ProduceDokumen14 halamanMission ProducePratik JainBelum ada peringkat

- MECH 6076 Quiz II Supply Chain Modeling and OptimizationDokumen3 halamanMECH 6076 Quiz II Supply Chain Modeling and OptimizationCostina Luc0% (1)

- Chapter 4Dokumen45 halamanChapter 4Yanjing Liu67% (3)

- Abbott AnalysisDokumen35 halamanAbbott Analysisahmad bilal sabirBelum ada peringkat

- MANAC II - Morrissey Forgings CaseDokumen8 halamanMANAC II - Morrissey Forgings CaseKaran Oberoi100% (1)

- Case Questions - Chabros InternationalDokumen1 halamanCase Questions - Chabros Internationalsyedasana001Belum ada peringkat

- Balakrishnan MGRL Solutions Ch14Dokumen36 halamanBalakrishnan MGRL Solutions Ch14Aditya Krishna100% (1)

- Nview SolnDokumen6 halamanNview SolnShashikant SagarBelum ada peringkat

- SALES AND OPERATIONS PLANNING LP MODELDokumen1 halamanSALES AND OPERATIONS PLANNING LP MODELhfjffjBelum ada peringkat

- Solution 77Dokumen10 halamanSolution 77karthu48100% (1)

- PlazaDokumen7 halamanPlazaUmair Chishti0% (3)

- Merloni-Tranist Point ModelDokumen6 halamanMerloni-Tranist Point ModelUmair Chishti100% (1)

- AFAR - 07 - New Version No AnswerDokumen7 halamanAFAR - 07 - New Version No AnswerjonasBelum ada peringkat

- AXONIS – Mobility Solution for SMART CitiesDokumen33 halamanAXONIS – Mobility Solution for SMART CitiesrajimuruganBelum ada peringkat

- The Travels of A T-Shirt in The Global Economy SCRDokumen11 halamanThe Travels of A T-Shirt in The Global Economy SCRCarlos MendezBelum ada peringkat

- Frito Lay Has Flourished Since Its Origin The 1931 Purchases ofDokumen1 halamanFrito Lay Has Flourished Since Its Origin The 1931 Purchases ofAmit PandeyBelum ada peringkat

- Kookuburra Cricket Bats Excel SheetDokumen4 halamanKookuburra Cricket Bats Excel SheetChakri MunagalaBelum ada peringkat

- Baldwin Bicycle CaseDokumen10 halamanBaldwin Bicycle CaseDhurjati Majumdar100% (1)

- ReportDokumen8 halamanReportZain AliBelum ada peringkat

- Skycell Cell Phone Production PlanningDokumen3 halamanSkycell Cell Phone Production PlanningwillBelum ada peringkat

- Berkshire Toy Case - Calculation Groupe 4 18 FevDokumen9 halamanBerkshire Toy Case - Calculation Groupe 4 18 FevchandrakumaranBelum ada peringkat

- Aggregate Planning Classroom ProblemsDokumen9 halamanAggregate Planning Classroom ProblemsDarwin FishBelum ada peringkat

- Supply Chain Contract: Alok RajDokumen20 halamanSupply Chain Contract: Alok RajYash Aggarwal BD20073Belum ada peringkat

- Pricing For Industrial GoodsDokumen34 halamanPricing For Industrial GoodsPreeti MongaBelum ada peringkat

- Case 1 - Promoting A Breakfast CerealDokumen4 halamanCase 1 - Promoting A Breakfast CerealArpit ChaudharyBelum ada peringkat

- Goal Program - ExampleDokumen2 halamanGoal Program - ExampledluvjkpopBelum ada peringkat

- Chapter 4 Problems & SolutionsDokumen3 halamanChapter 4 Problems & SolutionsAhmed MohamudBelum ada peringkat

- Home Assignment - RevisedDokumen4 halamanHome Assignment - RevisedLê Quỳnh Anh100% (1)

- Merrimack Tractors and MowersDokumen10 halamanMerrimack Tractors and MowersAtul Bhatia0% (1)

- BBC's Proposal to Manufacture Bicycles for Hi-ValuDokumen19 halamanBBC's Proposal to Manufacture Bicycles for Hi-ValuMannu83Belum ada peringkat

- Group 7 - Morrissey ForgingsDokumen10 halamanGroup 7 - Morrissey ForgingsVishal AgarwalBelum ada peringkat

- Apple Inc Class DiscussionDokumen34 halamanApple Inc Class DiscussionmdnhllBelum ada peringkat

- Supply Chain Planning Quiz 3Dokumen11 halamanSupply Chain Planning Quiz 3Rahul NandakumarBelum ada peringkat

- Anagene Case StudyDokumen1 halamanAnagene Case StudySam Man0% (3)

- 11 7Dokumen2 halaman11 7Mesut SarıtemurBelum ada peringkat

- CVP Analysis SolutionsDokumen23 halamanCVP Analysis SolutionsAdebayo Yusuff AdesholaBelum ada peringkat

- FALL2019 ECON2113 HomeworkDokumen9 halamanFALL2019 ECON2113 HomeworkNamanBelum ada peringkat

- 03 Standards of Professional ... Egrity of Capital MarketsDokumen14 halaman03 Standards of Professional ... Egrity of Capital MarketsIves LeeBelum ada peringkat

- Asthma Annals 2019Dokumen18 halamanAsthma Annals 2019Maria Camila Osorno LondoñoBelum ada peringkat

- W2 - Concepts and ApplicationsDokumen13 halamanW2 - Concepts and ApplicationsKim Yến100% (1)

- Wilkerson SpreadsheetDokumen6 halamanWilkerson SpreadsheetMandar DeshpandeBelum ada peringkat

- Manual de MPLDokumen377 halamanManual de MPLpraxtorres52Belum ada peringkat

- Use MoreDokumen5 halamanUse Moreg14032Belum ada peringkat

- MADM - IN-CLASS QUIZ SOLUTIONSDokumen11 halamanMADM - IN-CLASS QUIZ SOLUTIONSPiyush SharmaBelum ada peringkat

- Abhishek 2 - Asset Id 1945007Dokumen3 halamanAbhishek 2 - Asset Id 1945007Abhishek SinghBelum ada peringkat

- Bill French - Write Up1Dokumen10 halamanBill French - Write Up1Nina EllyanaBelum ada peringkat

- Chapter 5 - Cost-Volume-Profit Relationships: Click On LinksDokumen34 halamanChapter 5 - Cost-Volume-Profit Relationships: Click On LinksRena AfrianiBelum ada peringkat

- Est For BTECHDokumen2 halamanEst For BTECHRakesh SharmaBelum ada peringkat

- Table 7.1 Quarterly Demand For Tahoe Salt: Year, QTR Period DemandDokumen13 halamanTable 7.1 Quarterly Demand For Tahoe Salt: Year, QTR Period DemandФилипп СибирякBelum ada peringkat

- Sport Zone Shoe Sourcing & Profit MaximizationDokumen2 halamanSport Zone Shoe Sourcing & Profit MaximizationJotham HensenBelum ada peringkat

- Case Study Cap BudgetingDokumen4 halamanCase Study Cap BudgetingghazsanusiBelum ada peringkat

- Supply Chain MGMT ProjectDokumen10 halamanSupply Chain MGMT Projectapi-3730425Belum ada peringkat

- SWOT Analysis: Project: Pioneer Hi-Bred International, IncDokumen10 halamanSWOT Analysis: Project: Pioneer Hi-Bred International, IncVaibhavi GargeBelum ada peringkat

- SWOT Analysis: Project: Pioneer Hi-Bred International, IncDokumen10 halamanSWOT Analysis: Project: Pioneer Hi-Bred International, IncVaibhavi GargeBelum ada peringkat

- Islamic Micro FinanceDokumen18 halamanIslamic Micro FinanceUmair ChishtiBelum ada peringkat

- Halloran MetalsDokumen2 halamanHalloran MetalsUmair Chishti100% (2)

- Barilla SpaDokumen4 halamanBarilla SpaUmair ChishtiBelum ada peringkat

- Velky PotravinyDokumen4 halamanVelky PotravinyUmair ChishtiBelum ada peringkat

- L.L BeanDokumen4 halamanL.L BeanUmair Chishti100% (2)

- Endpoint ModelDokumen5 halamanEndpoint ModelUmair ChishtiBelum ada peringkat

- World Co IncDokumen5 halamanWorld Co IncUmair ChishtiBelum ada peringkat

- Velky Q1 & 2Dokumen3 halamanVelky Q1 & 2Umair ChishtiBelum ada peringkat

- MerloniDokumen2 halamanMerloniUmair ChishtiBelum ada peringkat

- Volker RuleDokumen3 halamanVolker RuleUmair ChishtiBelum ada peringkat

- MerloniDokumen2 halamanMerloniUmair ChishtiBelum ada peringkat

- Nalysis Of: Third Time's The CharmDokumen47 halamanNalysis Of: Third Time's The CharmUmair ChishtiBelum ada peringkat

- India's Central Bank Reserve Bank of India Regional Office, Delhi, Foreign Remittance Department. New Delhi: 110 001, India, 6, Sansad MargDokumen2 halamanIndia's Central Bank Reserve Bank of India Regional Office, Delhi, Foreign Remittance Department. New Delhi: 110 001, India, 6, Sansad MargvnkatBelum ada peringkat

- Operation Management DocumentDokumen7 halamanOperation Management DocumentYogesh KumarBelum ada peringkat

- Marketing Research and MISDokumen20 halamanMarketing Research and MISMithun KanojiaBelum ada peringkat

- PH.D BA - Class Schedule 1-2018Dokumen1 halamanPH.D BA - Class Schedule 1-2018Adnan KamalBelum ada peringkat

- Enterprise System Engineering: Course Code: SWE - 304Dokumen8 halamanEnterprise System Engineering: Course Code: SWE - 304syed hasnainBelum ada peringkat

- Profit & Loss: Velka Engineering LTDDokumen10 halamanProfit & Loss: Velka Engineering LTDparthsavaniBelum ada peringkat

- O-1 Visa Lawyer in San JoseDokumen2 halamanO-1 Visa Lawyer in San JoseAlison YewBelum ada peringkat

- Agency v4Dokumen59 halamanAgency v4Roxanne Daphne Ocsan LapaanBelum ada peringkat

- MS CAL Licensing Cheat SheetDokumen1 halamanMS CAL Licensing Cheat SheetbitoogillBelum ada peringkat

- MKT 412 Lecture 12 - Crafting The Service EnvironmentDokumen34 halamanMKT 412 Lecture 12 - Crafting The Service EnvironmentEhsan Karim100% (1)

- CDM Regulations EbookDokumen14 halamanCDM Regulations EbookZeeshan BajwaBelum ada peringkat

- Return Note - BRH12188307Dokumen1 halamanReturn Note - BRH12188307JamesBelum ada peringkat

- 6 Entrepreneur Networks. Final VerDokumen26 halaman6 Entrepreneur Networks. Final VerSAURAV SAURAVBelum ada peringkat

- 0 - 265454387 The Bank of Punjab Internship ReportDokumen51 halaman0 - 265454387 The Bank of Punjab Internship Reportفیضان علیBelum ada peringkat

- Nueva Ecija Elwctric Coop vs. NLRCDokumen2 halamanNueva Ecija Elwctric Coop vs. NLRCJholo AlvaradoBelum ada peringkat

- Cathay Pacific v. VasquezDokumen2 halamanCathay Pacific v. Vasquezrgtan3Belum ada peringkat

- Sample of Application Letter and CVDokumen4 halamanSample of Application Letter and CVSaleh Al ArifinBelum ada peringkat

- Japan - Success, Problems and ImpactDokumen17 halamanJapan - Success, Problems and ImpactYujia JinBelum ada peringkat

- Frequently Asked Questions Transition From UL 508C To UL 61800-5-1Dokumen6 halamanFrequently Asked Questions Transition From UL 508C To UL 61800-5-1nomeacueroBelum ada peringkat

- Account Payable Tables in R12Dokumen8 halamanAccount Payable Tables in R12anchauhanBelum ada peringkat

- Marketing Manager Coordinator Programs in Dallas FT Worth TX Resume KeJaun DuBoseDokumen2 halamanMarketing Manager Coordinator Programs in Dallas FT Worth TX Resume KeJaun DuBoseKeJuanDuBoseBelum ada peringkat

- Group 6 - Mid-Term - PNJ PosterDokumen1 halamanGroup 6 - Mid-Term - PNJ PosterMai SươngBelum ada peringkat

- Building Productsspring 2010Dokumen84 halamanBuilding Productsspring 2010Adrian GhabbhalBelum ada peringkat

- Fundamental RulesDokumen18 halamanFundamental RulesrakeshBelum ada peringkat