Genetic Algorithm For Robust H Infinity

Diunggah oleh

Md KaleemullahDeskripsi Asli:

Judul Asli

Hak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

Genetic Algorithm For Robust H Infinity

Diunggah oleh

Md KaleemullahHak Cipta:

Format Tersedia

IEEE TRANSACTIONS ON INDUSTRIAL ELECTRONICS, VOL. 43, NO.

5, OCTOBER 1996

575

Structured Genetic Algorithm for Robust H'>OControl Systems Design

K. S. Tang, K. F. Man, Member, ZEEE, and D.-W. Gu

Abstruct- A structured genetic algorithm (SGA) approach is developed for robust controller design based on the concept of an H" loop-shaping technique and the method of inequalities. Such an SGA is capable of simultaneously searching the orders and coefficients of the precompensator and postcompensator for the weighted plant. It is, therefore, not necessary to predefine the order of compensators as in usual practice. A multiple objective ranking approach is also incorporated so that the design criteria of extreme plants can be easily achieved. The effectiveness of such a technique is illustrated by a high-purity distillation column design example.

I. INTRODUCTION T IS well known that control system design problems can be naturally formulated as constrained optimization problems, the solutions of which will characterize acceptable designs. The numerical optimization approach to controller design can directly tackle design specifications in both the frequencydomain and the time-domain. The optimization problems derived, however, are usually very complicated with many unknowns, many nonlinearities, many constraints, and in most cases, they are multi-objective with several conflicting design aims which need to be simultaneously achieved. It is also known that a direct parameterization of the controller will increase the complexity of the optimization problem. On the other hand, during the last decade or so, H" optimization has emerged as a useful tool for robust control system design. It has a sound theoretical background for handling model uncertainties. Based on H" optimization, a variety of design methods have been developed. The H" loop shaping design procedure (LSDP) is one of these which has proven to be efficient in practical industrial design. The approach involves the robust stabilization to additive perturbations of normalized coprime factors of a weighted plant. Prior to robust stabilization the open-loop singular values are shaped using weighting functions to give a desired open-loop shape which corresponds to good closed-loop performance. A successful design using LSDP depends on the appropriate choice of weighting functions, which in turn relies on a designer's experience and familiarity with the design approach. In [I I], it is proposed to enhance the LSDP by combining it with numerical optimization techniques. In order to more effectively search for optimal solutions to the derived conManuscript received September 20, 1995; revised November 12, 1995. K. S. Tang and K. F. Man are with the Department of Electronic Engineering, City University of Hong Kong, Hong Kong. D.-W. Gu is with the Department of Engineering, Control Systems Research, University of Leicester, Leicester LE1 7RH, U.K. Publisher Item Identifier S 0278-0046(96)03301-1. 0278-0046/96$05,00 0 1996 IEEE

Fig. 1.

Robust stabilization with respect to coprime factor uncertainty

strained optimization problems, a multiple objective genetic algorithm is suggested in [12]. In this mixed optimization approach, the structures of the weighting functions are predefined by the designer. It is not possible to systematically search for an optimal design among various structured weights. In this paper, a structured genetic algorithm (SGA) is developed. The hierarchical structure of the chromosome makes it possible to optimize simultaneously over the structures and coefficients of the weighting functions. The paper is organized as follows. Section I1 gives a brief introduction to LSDP and the mixed optimization approach. SGA is explained in detail in Section 111. Such a technique is then applied to a design exercise of a high-purity distillation column. Several designs, with discussions, are presented in Section IV. Concluding remarks are given in Section V. 11. A MIXEDOPTIMIZATION DESIGN APPROACH LSDP is based on the configuration as depicted in Fig. 1 , where (fi,U ) E RH", the space of stable transfer function matrices, is a normalized left coprime factorization of the nominal plant G. That is, G = l k ' f i , and there exists V , U E RH" such that A h + f i U = I , and*,* +NN* = I , where for a real rational function of s , X * denotes X T (- s ) . For a minimal realization of G ( s )

G ( s )= D

I%[

+ C(s1- A)-lB

576

IEEE TRANSACTIONS ON INDUSTRIAL ELECTRONICS, VOL. 43, NO. 5, OCTOBER 1996

a normalized coprime factorization of G can be given by [7]

[N f i ] = A + H C

R-1/2C

B+HD

R-l/2D

H

R-112

(2)

]TwTHTky

Fig. 2.

where H = -(BD + ZC)R- R = I DD and the matrix 2 2 0 is the unique stabilizing solution to the algebraic Riccati equation (ARE)

( A - BS-IDC)Z + Z ( A - B S - l D / C ) / - ZCR-ICZ + BS-IB = 0

where S = I DID. A perturbed model G, of G is defined as

(3)

The 2-DOF scheme.

G,

(A? + A,)-l(N + A,)

(4)

where A U , A N E RHm. To maximize the class of perturbed models such that the closed-loop system in Fig. 1 is stabilized by a controller K ( s ) , the K ( s ) must stabilize the nominal plant G and minimize y [5] where

system G are modified to give a desired loop shape. The nominal system and weighting functions W1 and W2 are combined to form the shaped system, G,, where G, = W2GW1. It is assumed that Wl and W2 are such that G, contains no hidden unstable modes. 2 ) A feedback controller, K,, is synthesized which robustly stabilizes the normalized left coprime factorization of G,, with a stability margin t. 3) The final feedback controller, K , is then constructed by combining the H controller K,, with the weighting function Wl and W2 such that

From the small gain theorem, the closed-loop system will remain stable if

K = W1KsW2.

(10)

For a tracking problem, the reference signal is generally fed ( 6 ) between K , and W l , so that the closed loop transfer function The minimum value of 7, y ) for all stabilizing controllers between the reference T and the plant output y becomes (o,

IIPN

aMlll,

< 7-l.

where A,,(.) represents the maximum eigenvalue, and X 0 i s the unique stabilizing solution to the following ARE:

2 where the reference T is connected through a gain K , (0) W2(0)

where

( A - BS-lDC)X + X ( A - L?S-lDC) - X B S - l B X + CR-lC = 0 .

A controller which achieves a y

S K=

(8)

K,(O)WZ(O) = s i 0 K,(s)W2(s) lim

(12)

> yo is given

in [7]by

+ B F + y2(Q)-1ZC(C+ D F )

+

/cz1-)/Q(2y

-

BIX

where F = - S - l ( D C

-D

(9)

B X ) and Q = (1 y 2 ) I X Z . A descriptor system approach may be used to synthesize an

optimal controller such that the minimum value yo is achieved. In practical designs, the plant needs to be weighted to meet closed-loop performance requirements. A design method, known as the loop shaping design procedure (LSDP), has been developed [7], to choose the weights by studying the open[8] loop singular values of the plant, and augmenting the plant with weights so that the weighted plant has an open-loop shape which will give good closed-loop performance. This loop shaping can be done by thle following design procedure. 1) Using a pre-compensator, W,, and/or a postcompensator, W;, the singular values of the nominal

to ensure unity steady-state gain. The above design procedure can be developed further into a two-degree-of-freedom (2-DOF) scheme as shown in Fig. 2. The philosophy of the 2-DOF scheme is to use the feedback controller K , (s) to meet the requirements of internal stability, disturbance rejection, measurement noise attenuation, and sensitivity minimization. The precompensator K p is then applied to the reference signal, which optimizes the response of the overall system to the command input. The precompensator K p depends on design objectives and can be synthesized together with the feedback controller in a single step via the H LSDP ~41. In LSDP the designer has the freedom to choose the weighting functions. Controllers are synthesized directly. The appropriate weighting functions will generate adequate optimal yo and will produce a closed-loop system with good robustness and satisfactory and nonconservative performance. The selection of weighting functions is usually done by a trial-and-error method and is based on the designers experience. In [ll], it is proposed to incorporate the method of inequalities (MOI) [ 141 with LSDP such that it is possible to search for optimal weighting functions automatically and to meet more explicit

TANG et al.: STRUCTURED GENETIC ALGORITHM FOR ROBUST Hm CONTROL SYSTEMS DESIGN

577

There are two types of genes, known as control genes and coefficient genes, in the chromosome. The control genes in the form of bits decide the activation or deactivation of the blocks. The coefficient genes define the value of the coefficients in each block. The following example explains such a hierarchical structure. Example: Control genes: [1,0, 0; 0, 0, 11 Coefficient genes: [0.1, #,

#; #, #, #, 0.7, 0.8, 1.51'

Fig. 3 . Chromosome structure.

design specifications in both the frequency domain and the time domain. In this mixed optimization approach, the weighting functions W1 and W2 are the design parameters. Control system design specifications are given in a set of inequality constraints. That is, for a given plant G(s), to find (W1, Wz) such that

These represent a transfer function of s 0.1 G ( s ) = 1.5 x s2 0.7s 0.8 The fundamental structures of Wl and W2 in the design example in Section IV are given as (s w d ( s Ulg)(SZ Ul7S Ulg)

w1= S ( S + ' u l l ) ( S + 7U2)(S2 + W3.9 + 204) + + + +

w = z

(s f w13)(s

(S Wl*)(S2

+ W14)(s2 + w15S + wl6) + ?Ug)(S + + + 2012)

WllS

(17)

(18) In general, Wl and W, can be diagonal matrices with different diagonal elements. The chromosome is a binary string describing the control and coefficient genes gc and g r , where

gc E BIZ

yo(G, WI, Wz) = [1+ Lax(ZX)]1'2 I ~y

and

(13)

(14)

&(G, W1, W2) SE,. i = 1. 2 , . . . , n

where 4,'s are performance indices, which are algebraic or functional inequalities representing rise time, overshoot, etc., and and E , are real numbers representing the desired bounds on yo and &, respectively. Numerical search algorithms may then be applied to find solutions to the above optimization problems. 111. STRUCTURED GENETIC ALGORITHM The constrained optimization problems derived by the mixed optimization design approach described in the previous section are usually nonconvex, nonsmooth, and multiobjective with several conflicting design aims which need to be simultaneously achieved. In [ 121, a multiobjective genetic algorithm [3] is employed to find solutions to such optimization problems. Successful designs have been achieved. It has been, however, found that due to the order and structure of weighting functions being pre-fixed by the designer, the approach lacks flexibility in choosing weights of different forms, which in turn affects the optimality of the design. An SGA [lo] is thus considered in this paper to optimize over both the orders and coefficients of the weights, W1 and W2, used in the design.

where B = [0, 1 and R I , R defining the search domain 1 2 for the parameters, which usually represents an admissible region, e.g., ensuring that the weighting functions are stable and minimum phase.

B. Objective Function and Fitness Function

An objective function f is defined, for a chromosome if (13) is satisfied, as the number of violated inequalities in (14). The procedure of objective function evaluation is listed as follows. 1) For a chromosome I = ( W I ,W2) in hierarchy coded form, generate the corresponding W1 and Wz. 2) Calculate G, = WzGWl. 3) Find the solutions Z,, X , to (3) and (8). 4) Calculate y ( Wl , Wz) by (13). o 5 ) If yo < E T : a) synthesize K , by (9); b) calculate 4,(G, WI, W 2 )for the present chromosome; c) calculate f by

f =

A. Chromosome Coding

SGA differs from standard GA in its hierarchical structure in that each chromosome consists of a multilevel of genes. Fig. 3 shows the chromosome representation within SGA for a transfer function where the fundamental structure is

where

C rn,

z=1

mi =

0, if q5i 1, else.

5 ~i

6) if yo

f, = n

+ 1 +yo.

' # 'slands for Don't Care Value

578

IEEE TRANSACTIONS ON INDUSTRIAL ELECTRONICS. VOL 43, NO 5, OCTOBER 1996

To convert the objective function ( f )to the fitness value, a linear ranking approach [I31 is applied.

C. Genetic Operations Crossover and mutation on binary siring 121 are applied independently on different levels of a (chromosome as in a standard CA.

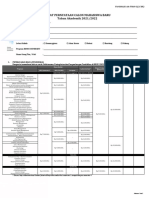

Population Size Generation Gap' Control Gene Resolution Range Crossover Mutation

Coeficient Gene

TABLE 1 PARAMETER SETTING SGA OF

40

0.2

1 bit

B

1-point Crossover

Bit Mutation

10. 11 Crossover Rate = 0.7 Mutation Rate = 0.05

D. Optimization Procedure 1) Define the plant G and define the functions &.

2) Define the values of E , and cy. 3) Define the fundamental form o f the weighting functions W, and W,, and the search domain of R I . Rz. 4) Define the parameters for SGA. 5) Randomly generate the first population. 6) Calculate the objective value and assign the fitness value to each chromosome. 7) Start the SGA cycle: a) select parents by the Stochastic Universal Sampling method [ I ] ; b) generate new chromosomes via crossover and mutation; c) calculate the objective values of the new chromosomes; d) reinsert the new chromosomes into the population and discard same number of old, low-ranked chromosomes. 8) Terminate if (13) and (14) are satisfied; otherwise, repeat the SGA cycle.

Resolution Range

10 bits

(0, 500) Crossover 3-point Crossover Crossover Rate = 0.8 Mutation Bit mutation Mutation Rate = 0.1 2Number of New Chromosomes Generated = Generation Gap x Population Size

RI R2

(0, 2 )

4) The output response to a step demand h ( t )[y] satisfies -0.1 5 y l ( t ) 5 0.5 for all t, -0.1 5 y 2 ( t ) 5 1.1 for

all t and g2(t) 2 0.9 for all t > 30. 5) The frequency response of the closed-loop transfer function between demand input and plant input is gain limited to 50 dB and the unity gain crossover frequency of its largest singular value should be less than 150 radlmin. Simulation A: Optimization of Nominal Plant SpecGCations with Time Delay r1 = r2 = 0.5: The proposed algorithm is used to satisfy the performance design specification for the nominal plant G, using the configuration of Fig. 2. The design criteria are derived from (13) and (14)

IV. EXAMPLE: DISTILLATION THE COLUMN DESIGN

YO(Gn, Wl; W Z ) FE-, (22) (67(G,,, W1, WZ) I E ~ , i = 1, 2, ..., 16. (23) for

For stability robustness, the value of E~ should not be too The proposed algorithm is used to design a feedback control large, and is here taken as system for the high-purity distillation column described in [6]. The column is considered in its LV configuration [9] (LV E?. = 5.0. (24) indicates that the inputs used are reflux (L)-and boilup ( V ) ) , The performance functionals 4%(G,, W1, W2) are defined for which the following model is relevant: in the Appendix, and the respective prescribed bounds are decided from the design specifications- and are shown in the 1 [(Iyi8 -0.864 k l , '21 7 1 1 7-z) = second column of Table 111. The parameters of the SGA used 1,082 -1.096 in the simulation are tabulated in Table I. It takes about 135 generations to obtain the optimal com(21) 0 IC,e-r2s pensators. The weighting functions obtained are where 0.8 5 k 1 , IC2 5 1.2 and 0 5 7-1, 7-2 5 1, and all (s + 1.2800)(s + 1.5005)

time units are in minutes. The time-delay and actuator-gain

values used in the nominal model G, are I 1 = IC2 = 1 and C r1 = r2 = 0.5. The time-delay element is; approximated by a first-order Pad6 approximation for nominal plant. The design specifications are to design a controller which guarantees for all 0.8 5 k l , kz 5 1.2 and 0 5 TI, 2 5 1: 7 1) Closed-loop stability. satisfies 2) The output response to a step demand h(t) -0.1 5 y l ( t ) 5 1.1 for all t , yl(t) 2 0.9 for all t > 30 and -0.1 5 y ~ ( t 5 0.5 for all t; ) 3) The output response to a step demand h ( t )[:;I satisfies yl(t) 5 0.5 for all t , yl(t) 2 0.35 for all t > 30 and :y2(t) 5 0.7 for all t , and g2(t) 2 0.55 for all t > 30.

w - s ( s + 0.8215)(s + 1.4868) w = (ss + 1.7873)(s2 + 0.5620s + 1.9844) z ( + 1.7385)(s2+ 1.4946s + 1.8517)

36.0976

36.5854 I O

[A]

with yo = 3.6147 which successfully satisfy (22) and (23). The convergence of the objective value is plotted in Fig. 4. Extreme plants GI, G2, Gs, Gg with system parameters shown in Table I1 were used for testing the system's robustness. These extreme plant models were judged to be the most difficult to obtain simultaneously good performance and it was found that the final system was not very robust.

TANG et al.: STRUCTURED GENETIC ALGORITHM FOR ROBUST H- CONTROL SYSTEMS DESIGN

519

Objective Value

MI

07 .

0.6

0.5

50 . . .

hi I i

.,.

....

_._. . - .

_ I _ .

. ..1

. .

..

- 3 . .

..

0.4

0.3

0.2 01 .

..........

-0.21

20

'

I

40

60 time min

- +

80

100

-. 01

20

40 60 lime - min

80

100

(b)

-.(lain .dB

...

I

1

generations

-0.2' 0

20

'

'

40

Fig. 4.

Objective value versus generations. TABLE I1 EXTREME PLANTS G , FOR j = 1, 2 , 3, 4

60 time. min

'

60

1 W

lo-*

1 0 '

frequency - rad/min

102

(4

Fig. 5. System performance for simulation B. (a) (c) OIO - d14. (d) dl5 - 416

41 - &,.

(b)

46 - 49.

GI 0 G z 1

Gs

0

1 1

1

0.8

0.8

1.2 1.2

0.8

1.2

~i

TABLE I11 FINALSYSTEM PERFORMANCE SIMULATION B FOR

$i(Gm)

di(G1)

$i(Gz)

di(G3)

di(G4)

1

1

0.8

1.2

1.1

1.0212 -0.9732 0.3556

0

1.0410 -0.9655 0.3625

0

1.0377 -0.9898 0.2844

0.0001

1.0306 -0.9870 0.4290 0.0002 0.0477 0.4274 0.6162 0.3359 1.0372 -0.9841 0.0270 0.0002

10.000

1.0030 -0.9687 0.3471

0

G q

2

3

-0.9 0.5 0.1 0.1 '0.5 -0.35 0.7 -0.55 0.5

1.1

Simulation B: Optimization of Plant SpecGcations with Time Delay 71 = 7 2 = 1: The setting is the same as that for simulation A, except that the design criteria, (23), are modified. From simulation A, it is realized that the design criteria for T I = 7 2 = 1 are more difficult to achieve. Hence, the design criteria is modified to Yo(Gn, Wl, W2) I

E y

5 6

7

0.0159 0.4177 -0.3981 0.6012 -0.5972 0.3837 1.0124 -0.9832 0.0171

0

0.0305 0.4198 -0.3966 0.6023 -0.5967 0.3912 1.0242 -0.9786 0.0330

0

0.0232 0.4272 0.6149 -0.5838 0.4300 1.0299 -0.9748 0.0417 0.0003 9.8627

0.0054 0.4308 -0.3843 0.6191 0.3746 1.0138 -0.9660 0.0058

0

-0.3851 -0.3873

8 9

10

-0.5873 -0.5777

(25) for

q5%(Gm, W1,

W2) I E,,

i = I, 2, . . . , 16 (26)

11

where G, is the plant with k-1 = k2 = 1 and 71 = 7 2 = 1 using a fifth-order Pad6 approximation. It takes about 800 generations to obtain Wl and W2 for robust feedback control. The parameters of Wl and W2 are

12

13

-0.9

0.1

14 16 r16

0.1

50.0

w, s(ss+ 0.8878)(s2 + 0.3161s + 1.1044) = ( + 1.1278)(s2 + 1.1356s + 0.1444)

w

13.1707 0 13.1707I O (s + 0.1678)(s2 0.3727s 0.7161) -(s 1.5727)(s2+ 1.0049s + i.8946) 50.2439 0 52.1951I O

48.4479 49.7050 51.0427 51.0167 9.0773 10.7159

47.76 9.8627

150.0

are satisfied except that the 50-dB gain limit is marginally

exceeded by +15(GZ) and +15(G3).

where yo = 3.3047. The closed-loop performances are tabulated in Table I11 and depicted in Fig. 5. All the design criteria

Simulation C: Optimization of Overall Plants Specifications with Extreme Conditions: Since it may not be easy to obtain a controller satisfying the performance specifications for those extreme plant models by optimization of the nominal plant or a typical plant, an alternative will simultaneously optimize all

580

lEEE TRANSACTIONS ON lNDUSTRIAL ELECTRONICS, VOL. 43, NO. 5, OCTOBER 1996

the extreme plants. The design criteria are now redefined as

q5i(G',,

YO(W1: W2) WI; W2)

<ET,

<E;,

f o r i = 1, 2, . . . , 16; j = 1; 2, 3, 4.

A multiple objective SGA (MO-SGA) has been applied here. MO-SGA is a modified version of SGA for dealing multiple objective problems. A multiple objective ranking [3] approach is used. The chromosome I is ranked as

100

200

300

400

GeneraRon

Generanon

runk(1) = 1+ p

(29)

I,

. . . '.

if I is dominated by other p chromosomes in the population. Dejinition: For an n,-objective optimization problem, I L is dominated by U if v i =1,

. .

-'.

..

.'

...1

" ' , n,

fi(U)

2 fi(U)

f,(u)

and

io

-! 1 1 k.!.

-

-,.

3j =I, ..., n, s.t.

> f,(,u).

(30) -

'

Generotion

OO

1w

200 300 GeneroHon

4w

From (28), 64 objectives need to be achieved. Such huge amounts of objectives demand a large number of comparison operations. Hence, it is simplified into 4 objectives to indicate the fitness for each extreme plant as before. Define mz1for extreme plant i = 1. 2, . . . , 16 and j = 1, 2, 3 , 4 as

Fig. 6 . Multiple objective values versus generations.

TABLE IV FINAL SYSTEM PERFORMANCESIMULATION FOR C

Ei

h(G1)

~ ( G z ) h(G3)

h(G4)

1.1

1.0477 -0.9159 0.3843

0

1.0142 0.3204

0.0001

1.0401 0.4193 0.0001 0.0392 0.4251 -0.3963 0.6034 0.3569 1.0315 -0.9921 0.0328

0.0001

1.0024 0.3578 0.0001 0.0018 0.4218 -0.3998 0.6003 -0.5969 0.3786 1.0015 -0.9709 0.0019

0.0002

The objective f J for extreme plant

16

is

2 3

-0.9 0.5 0.1

0.1

-0.9791 -0.9125 -0.9525

fJ =

a=1

mL3 for j = 1, 2, 3 , 4.

(32)

4 5

6

After 448 generations, W1 and W2 are obtained and expressed as follows:

(s w -s(s + 0.8956)(s2 + 0.7161s + 1.4888) + 1.7249)(s2+ 1.9122s + 0.1444)

-

0.0363 0.4266 -0.3960 0.6030 0.4065 1.0292 0.0384

0

0.0168 0.4242 -0.3967 0.6023 0.4604 1.0128 0.0139

0.0002

0.5 -0.35

0.7

8 9 10

11

W,

( s + 1.4537)(s2 + 0.1990s + 0.5444) ( s + 1.4498)(s2 1.2741s 1.9551) 17.0732 0 17.5610

76.0976 0

-0.55 0.5

1.1

-0.5938 -0.5915 -0.5976

47.3171

12 13 14 15

16

-0.9 0.1 0.1 50.0

-0.9478 -0.9409

with yo = 3.1778. Fig. 6 demonstrates the multiple objective optimization process of the proposed MO-SGA. Trade-offs between different objective values can be noticed. The closed loop system responses for the extreme plants are tabulated in Table IV and depicted in Fig. 7.

48.8978 49.5575 49.7752 45.8310 150.0 16.9133 13.1862 11.6430 11.9696

V. CONCLUSION

The use of structured genetic algorithm to select weighting functions in a mixed optimization approach appears to be novel. The proposed SGA enables the simultaneous searching on the rtructures and on the coefficients of the weighting functions. SGA is particularly suitable for such design approaches. Compared with other numerical search methods, several advantages have been shown in the paper. First, SGA

can easily handle the constraints to ensure the stability of the weight functions. Secondly, a multiple objective approach can be adopted to address the conflicting control design specifications. Finally, the structures of the weighting functions need no longer be pre-fixed; only a fundamental structure is required, which provides the optimality for the solution over several different types of weights. In the design example, the performance was evaluated for a selection of extreme plant models chosen by the designer. The

TANG et al.: STRUCTURED GENETIC ALGORITHM FOR ROBUST H m CONTROL SYSTEMS DESIGN

581

O.r--

4 = 8

49

410

mpxy2([0.4

t>30

0.6], t )

0.6],t )

(40)

(41)

(42) (43)

= - min y2([0.4 = mpxy1([0

lI,t) 11%

1l, t )

411 = mpxy2([0

412 = -0.2 I

y2([0

(44)

I

20

40 60 time - min

60 100 0

20

40 60 time min

80

100

$13

$14

-r$nYl([o

- mjny2([0

l17t)

(45)

(46)

(b)

gain - d 8

1],t).

0.8

I 7

1

20 40

The steady-state specifications are satisfied automatically by the use of integral action. From the gain requirement in the design specifications, 415 is the HW-norm (in dB) of the closed-loop transfer function between the reference and the plant input

415

= S U P 5 { [ I- K(.jw)GD(jw)]-lW1 (,/w)Ks(O)W2(0)}.

W

-0.2 0

60

80

100

-50

1o-z

1oo

1o2

time - min

frequency. radimin

(47) From the bandwidth requirement in the design specification, 4 1 6 is defined (in radlmin) as

49.

such that

416

Fig. 7. System performance for simulation C. (a) (c) 010 - 6 1 4 . (d) $15 - $16

$1 - $ 5 .

(b) & ,

= max {U}

problem of efficiently determining the worst-case performance over the range of plants still remains. Since the proposed algorithm follows the formulation of an MO1 which requires the choice of several plants only, it is necessary to choose the most representative plants out of all possible plant models. The design may be further improved if a 2-DOF scheme is used.

5 { [ l -K(jw)G~(jw)]-l1 j ) s O W ( ) w(wK()20}

2 1.

(48)

REFERENCES

J . E. Baker, Reducing bias and inefficiency in the selection algorithms, in Genetic Algorithms: Proc. 2nd Int. Con6 Hillsdale, NJ: Lawrence Erlbaum Associates, 1987, pp. 14-21. L. Davis, Handbook of Generic Algorithms. New York: Van Nostrand Reinhold, 1991. C. M. Fonseca and P. J. Fleming, Genetic algorithms for multiobiective optimization: Formulation, discussion, and generalization, in Genetic Algorithms: Proc. Fifth Int. Conf, S. Forrest, Ed. San Mateo, CA: Morgan Kaufmann, 1993, pp. 4 1 6 4 2 3 . D. J. Hoyle, R. A. Hyde, and D. J. N.Limebeer, An H approach to two degree of freedom design, in Proc. 30th IEEE Con$ Dec. Contr., Brighton, England, pp. 1581-1585, 1991. K. Glover and D. McFarlane, Robust stabilization of normalized coprime factor plant descriptions with H -bounded uncertainty, IEEE Trans. Automat. Contr., vol. 34, pp. 821-830, 1989. D. J. N. Limebeer, The specification and purpose of a controller design case study, in Proc. 30th IEEE Conj: Dec. Contr., Brighton, England, 1991, pp. 1579-1580. D. McFarlane and K. Glover, Robust controller design using normalized coprime factor plant descriptions, Lecture Notes Control & Information Sciences. Berlin, Germany: Springer-Verlag, 1990, vol. 138. D. C. McFarlane and K. Glover, A loop shaping design procedure using Hm synthesis, IEEE Trans. Automat. Contr., vol. 37, pp. 749-769,

APPENDIX CLOSED-LOOP PERFORMANCE FUNCTIONALS

A

set of closed-loop performance functionals,

{ & ( G DW1, W2),i= 1 , 2 , . . . ,16}, are defined based on the , design specifications given in Section IV. Functionals 41-&4

are measures of the step-response specifications. Functionals 41, $6, $8 and are measures of the overshoot; 44, 413 45, and 414 are measures of the undershoot; 4 2 , 4 7 , 4 9 and 412 are measures of the rise time; and 43 and 410 are measures of the cross-coupling. Denoting the output response of the closed-loop system with a plant GD at a time t to a reference step demand h ( t ) by y%([hl h ~ ] ) , = 1, 2, i the step-response functionals are

I;:[

1992. S. Skogestad, M. Morari, and J. C. Doyle, Robust control of illconditioned plants: High-purity distillation, lEEE Trans. Automat. Contr., vol. 33, pp. 1092-1105, 1988. K. S. Tang, C. Y . Chan, K. F. Man, and S . Kwong, Genetic structure for NN topology and weights optimization, in First IEE/IEEE lnt. Conf Genetic Algorithms in Engineering Systems: Innovations and Applications, Sheffield, U.K., 1995, pp. 250-255. J. F. Whidbome, I. Postlethwaite, and D. W. Gu, Robust controller design using H loop-shaping and the method of inequalities, IEEE Trans. Contr. Syst. Technol., vol. 2, pp. 455-461, Dec. 1994. J. F. Whidbome, D. W. Gu, and I. Postlethwaite, Algorithms for solving the method of inequalities-A comparative study, in Proc. American Control Con$, Seattle, WA, June 1995.

582

IEEE TRANSACTIONS ON INDUSTRIAL ELECTRONICS, VOL 43, NO. 5, OCTOBER 1996

[I31 D Whitley, The GENITOR algorithm and selection pressure Why ranking based allocation of reproductive trials is beyt, in Genetic Algorithm Proc 3rd Int Conf San Mateo, CA Morgan Kaufmann,

1989, pp 116-121 [14] V Zakian and U Al-Naib, Design of dynamical and control systems by the method of inequalit~es, Proc Inst Elect Eng , vol 120, no 11, pp 1421-1427, 1973

K. S. Tang, for a photograph and biography, see this issue, p. 534.

R. F. Man (M91), for a photograph and biography, see this issue, p 518

D.-W. Gu was born in Shanghai. China He graduated from the Department of Mathematics, Fudan University, Shanghai, China, in 1979, and received the M Sc degree in applied mathematics from Shanghai Jiao Tong university, China, in 1981, and the Ph D degree in control system theory from the Department of Electrical Engineering, Imperial College of Science and Technology, London, U K , in 1985 From 1981 to 1982, he was a Lecturer at Shanghai Jiao Tong university He was a postdoctoral research assistant in Department of Engineering Science, Oxford University, U K , from 1985 to 1989 In 1989, he was appointed to a University Lectureship in Department of Engineering at Leicester University, U K His current research interests include robust control, optimal control, optimization algorithms, and control system computer-aided design. He is particularly interested in combining sophisticated numerical optimization techniques, including semi-intinitive optimization, neural network techniques, and genetic algorithms in robust control system design ,

Anda mungkin juga menyukai

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDari EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifePenilaian: 4 dari 5 bintang4/5 (5794)

- Shoe Dog: A Memoir by the Creator of NikeDari EverandShoe Dog: A Memoir by the Creator of NikePenilaian: 4.5 dari 5 bintang4.5/5 (537)

- The Yellow House: A Memoir (2019 National Book Award Winner)Dari EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Penilaian: 4 dari 5 bintang4/5 (98)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDari EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RacePenilaian: 4 dari 5 bintang4/5 (895)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDari EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersPenilaian: 4.5 dari 5 bintang4.5/5 (344)

- The Little Book of Hygge: Danish Secrets to Happy LivingDari EverandThe Little Book of Hygge: Danish Secrets to Happy LivingPenilaian: 3.5 dari 5 bintang3.5/5 (399)

- Grit: The Power of Passion and PerseveranceDari EverandGrit: The Power of Passion and PerseverancePenilaian: 4 dari 5 bintang4/5 (588)

- The Emperor of All Maladies: A Biography of CancerDari EverandThe Emperor of All Maladies: A Biography of CancerPenilaian: 4.5 dari 5 bintang4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDari EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaPenilaian: 4.5 dari 5 bintang4.5/5 (266)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDari EverandNever Split the Difference: Negotiating As If Your Life Depended On ItPenilaian: 4.5 dari 5 bintang4.5/5 (838)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDari EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryPenilaian: 3.5 dari 5 bintang3.5/5 (231)

- On Fire: The (Burning) Case for a Green New DealDari EverandOn Fire: The (Burning) Case for a Green New DealPenilaian: 4 dari 5 bintang4/5 (73)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDari EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FuturePenilaian: 4.5 dari 5 bintang4.5/5 (474)

- Team of Rivals: The Political Genius of Abraham LincolnDari EverandTeam of Rivals: The Political Genius of Abraham LincolnPenilaian: 4.5 dari 5 bintang4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDari EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyPenilaian: 3.5 dari 5 bintang3.5/5 (2259)

- Rise of ISIS: A Threat We Can't IgnoreDari EverandRise of ISIS: A Threat We Can't IgnorePenilaian: 3.5 dari 5 bintang3.5/5 (137)

- The Unwinding: An Inner History of the New AmericaDari EverandThe Unwinding: An Inner History of the New AmericaPenilaian: 4 dari 5 bintang4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDari EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You ArePenilaian: 4 dari 5 bintang4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Dari EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Penilaian: 4.5 dari 5 bintang4.5/5 (120)

- Her Body and Other Parties: StoriesDari EverandHer Body and Other Parties: StoriesPenilaian: 4 dari 5 bintang4/5 (821)

- SprinkCAD FlyerDokumen2 halamanSprinkCAD FlyerGerardo ClementeBelum ada peringkat

- Apple Supplier List 2014Dokumen29 halamanApple Supplier List 2014Wizard LeoBelum ada peringkat

- Is Now Part ofDokumen9 halamanIs Now Part ofAgung SetyonoBelum ada peringkat

- Agile TermsDokumen36 halamanAgile Termskerlos ZakryBelum ada peringkat

- Famous Parabolic Arches - PPTX AdinggggggggDokumen8 halamanFamous Parabolic Arches - PPTX AdinggggggggChrissel May Paras DoronioBelum ada peringkat

- SAG Mill Liner StudyDokumen109 halamanSAG Mill Liner StudyAclariont100% (1)

- IRM Press - ERP Solutions and ManagementDokumen263 halamanIRM Press - ERP Solutions and ManagementFakhar Imran100% (1)

- Surat Pernyataan Calon Mahasiswa Baru Tahun Akademik 2021/2022Dokumen6 halamanSurat Pernyataan Calon Mahasiswa Baru Tahun Akademik 2021/2022Nathania AisyaBelum ada peringkat

- Tower Climbing and Material LiftingDokumen24 halamanTower Climbing and Material Liftingpapis100% (4)

- Coventry UniversityDokumen104 halamanCoventry Universitymz-documentsBelum ada peringkat

- Project Management (Self-Development For Success) by Peter HobbsDokumen96 halamanProject Management (Self-Development For Success) by Peter HobbsRaji Pilipia100% (1)

- BestendigheidstabelDokumen32 halamanBestendigheidstabeldroessaert_stijnBelum ada peringkat

- Technology of Sweets (Mithai) With FormulaeDokumen97 halamanTechnology of Sweets (Mithai) With Formulaeeiribooks42% (24)

- SEO Proposal For AidanDokumen4 halamanSEO Proposal For AidanRitu BansalBelum ada peringkat

- Apliedd MSSASDokumen713 halamanApliedd MSSASuserkennyBelum ada peringkat

- Final ExamDokumen8 halamanFinal Examviraivil9417Belum ada peringkat

- The Space RaceDokumen15 halamanThe Space RaceRadu Petrusan100% (1)

- Double Surface TreatmentDokumen9 halamanDouble Surface TreatmentAdrian FrantescuBelum ada peringkat

- Aws C3.6M-C3.6-2008Dokumen28 halamanAws C3.6M-C3.6-2008juliusexBelum ada peringkat

- Buckling Analysis of Composite Laminated Plate With CutoutsDokumen11 halamanBuckling Analysis of Composite Laminated Plate With Cutoutsசெல்வ குமார்Belum ada peringkat

- How Do I Calculate Tonnage in Progressive Stamping - TheFabricatorDokumen9 halamanHow Do I Calculate Tonnage in Progressive Stamping - TheFabricatorSanjeev ParasharBelum ada peringkat

- Failure Mode and Effect AnalysisDokumen9 halamanFailure Mode and Effect AnalysisameliaBelum ada peringkat

- United States Patent: Mattsson Et Al. (10) Patent N0.: (45) Date of PatentDokumen17 halamanUnited States Patent: Mattsson Et Al. (10) Patent N0.: (45) Date of Patentdavid19775891Belum ada peringkat

- Helicopter Dynamic Stability-1Dokumen7 halamanHelicopter Dynamic Stability-1KaradiasBelum ada peringkat

- 1 Cutting ToolDokumen27 halaman1 Cutting ToolKemalMalovcicBelum ada peringkat

- The Whitehead Torpedo Deck TubeDokumen148 halamanThe Whitehead Torpedo Deck TubeDongelxBelum ada peringkat

- Automatic GearboxDokumen8 halamanAutomatic Gearboxmasterash02Belum ada peringkat

- Lathe Machine DataDokumen10 halamanLathe Machine DataRaju MalhotraBelum ada peringkat

- Introduction To Engineering EconomicsDokumen13 halamanIntroduction To Engineering EconomicsAqib Ali100% (1)