Hayward True Uni On Solenoi D Valves Hayward True Uni On Solenoi D Valves Hayward True Uni On Solenoi D Valves Hayward True Uni On Solenoi D Valves

Diunggah oleh

hassansafaDeskripsi Asli:

Judul Asli

Hak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

Hayward True Uni On Solenoi D Valves Hayward True Uni On Solenoi D Valves Hayward True Uni On Solenoi D Valves Hayward True Uni On Solenoi D Valves

Diunggah oleh

hassansafaHak Cipta:

Format Tersedia

HAYWARD TRUE UNI ON SOLENOI D VALVES

INSTALLATION, OPERATION, AND MAINTENANCE INSTRUCTIONS

PLEASE READ THE FOLLOWING INFORMATION PRIOR TO INSTALLING AND USING HAYWARD VALVES, STRAINERS, FILTERS, AND OTHER ASSOCIATED PRODUCTS. FAILURE TO FOLLOW THESE INSTRUCTIONS MAY RESULT IN SERIOUS INJURY.

1. 2. Hayward guarantees its products against defective material and workmanship only. Hayward assumes no responsibility for damage or injuries resulting from improper installation, misapplication, or abuse of any product. Hayward assumes no responsibility for damage or injury resulting from chemical incompatibility between its products and the process fluids to which they are subjected. Compatibility charts provided in Hayward literature are based on ambient temperatures of 70F and are for reference only. Customer should always test to determine application suitability. Consult Hayward literature to determine operating pressure and temperature limitations before installing any Hayward product. Note that the maximum recommended fluid velocity through any Hayward product is five feet per second. Higher flow rates can result in possible damage due to the water hammer effect. Also note that maximum operating pressure is dependent upon material selection as well as operating temperature. Hayward products are designed primarily for use with non-compressible liquids. They should NEVER be used or tested with compressible fluids such as compressed air or nitrogen. Systems should always be depressurized and drained prior to installing or maintaining Hayward products. Temperature effect on piping systems should always be considered when the systems are initially designed. Piping systems must be designed and supported to prevent excess mechanical loading on Hayward equipment due to system misalignment, weight, shock, vibration, and the effects of thermal expansion and contraction. Because PVC and CPVC plastic products become brittle below 40F, Hayward recommends caution in their installation and use below this temperature. Published operating torque requirements are based upon testing of new valves using clean water at 70F. Valve torque is affected by many factors including fluid chemistry, viscosity, flow rate, and temperature. These should be considered when sizing electric or pneumatic actuators. Due to differential thermal expansion rates between metal and plastic, transmittal of pipe vibration, and pipe loading forces DIRECT INSTALLATION OF METAL PIPE INTO PLASTIC CONNECTIONS IS NOT RECOMMENDED. Wherever installation of plastic valves into metal piping systems is necessary, it is recommended that at least 10 pipe diameter in length of plastic pipe be installed upstream and downstream of the plastic valve to compensate for the factors mentioned above.

3.

4. 5. 6.

7. 8. 9.

Hayward True Union plastic solenoid valves are designed for process systems requiring an instant ON-OFF actuated valve. They are designed for FAIL CLOSE service and will provide bubble-tight shutoff in the event of an electrical failure. The valves are manufactured from PVC (Polyvinyl Chloride) or CPVC (Chlorinated Polyvinyl Chloride) and will operate safely at pressures and temperatures as shown on the chart below. The valves are two-way direct acting, normally closed. They can be used for pressurized service to 120 PSIG, vacuum service to 26 HG or drainage applications. They do not require any line pressure to aid in opening or closing. There are no minimum pressure requirements. The TRUE UNION Design allows for ease of removal from the piping system without having to disconnect any piping or electrical connections. Visual inspection of the valve DIAPHRAGMS or replacement of the SEAL CARTRIDGE is recommended at fifty thousand cycle intervals to assure trouble free operation.

FEATURES

1. 2. 3. UL & CSA approved NEMA IV coil. Voltage 100% or Continuos duty cycle operation. 12 VAC TRUE UNION Design: Valve body can be removed without 24 VAC piping or electrical disconnection. 120 VAC 4. Body Mounting Lugs: For laboratory or panel mount. 5. All plastic construction: No metal parts in contact with process fluid. Current 1.6 amp 0.8 amp 1.6 amp Voltage 12 VDC 24 VDC 220 VAC Current 0.8 amp 0.8 amp 0.9 amp

INSTALLATION

The valve should be installed in an accessible location. This will allow for ease of inspection or service. 2. Reliable electrical line voltage supply must be provided to the coil, per table below. Low line voltage will reduce the operating performance and possibly the service life of the coil. 3. It is recommended that a Hayward Y-STRAINER be installed upstream of the valve to prevent clogging or premature wear of the diaphragms due to suspended solids in the process fluid. 1.

Anda mungkin juga menyukai

- Contractor's Guide for Installation of Gasketed PVC Pipe for Water / for SewerDari EverandContractor's Guide for Installation of Gasketed PVC Pipe for Water / for SewerPenilaian: 5 dari 5 bintang5/5 (1)

- MIET2394 Assignment 1Dokumen6 halamanMIET2394 Assignment 1Stacey Skiba100% (1)

- RTHC Svn02c enDokumen16 halamanRTHC Svn02c enRicardo100% (1)

- Hopkinson Valves IOM Manual PDFDokumen7 halamanHopkinson Valves IOM Manual PDFGiorgiana RosuBelum ada peringkat

- Prevention of Valve Fugitive Emissions in the Oil and Gas IndustryDari EverandPrevention of Valve Fugitive Emissions in the Oil and Gas IndustryBelum ada peringkat

- Line Sizing Criteria PDFDokumen8 halamanLine Sizing Criteria PDFwaelBelum ada peringkat

- Allweiler NTT Series DimensionsDokumen2 halamanAllweiler NTT Series DimensionskrisornBelum ada peringkat

- HY14-3300 - Safety Guide PDFDokumen2 halamanHY14-3300 - Safety Guide PDFPartsGopher.comBelum ada peringkat

- Hose Usage Guide PDFDokumen10 halamanHose Usage Guide PDFKaustav SahaBelum ada peringkat

- Iron Hunter HD ManualDokumen22 halamanIron Hunter HD ManualGreg ReynekeBelum ada peringkat

- IDS GateDokumen3 halamanIDS GateEsteban CastellanoBelum ada peringkat

- Small Bypass Humidifier Model 500M and 500A: Attention InstallerDokumen2 halamanSmall Bypass Humidifier Model 500M and 500A: Attention InstallerbelzebudBelum ada peringkat

- Series LL40 and LLL40 Specification SheetDokumen2 halamanSeries LL40 and LLL40 Specification SheetWattsBelum ada peringkat

- Operating and Maintenance Manual For Power Burner Series Forced Draft Commercial Water HeaterDokumen27 halamanOperating and Maintenance Manual For Power Burner Series Forced Draft Commercial Water HeaterAmir EbrahimBelum ada peringkat

- Installation Instructions & Owner's Manual: Electronic Steam Unit - Power Humidifier MODELS S2000 AND S2020Dokumen16 halamanInstallation Instructions & Owner's Manual: Electronic Steam Unit - Power Humidifier MODELS S2000 AND S2020Franklin Ergueta100% (1)

- Model DUC-AUS: Dual Check ValvesDokumen2 halamanModel DUC-AUS: Dual Check ValvesWattsBelum ada peringkat

- Kenmore Power Miser 9 #153.327466 ManualDokumen32 halamanKenmore Power Miser 9 #153.327466 ManualjkwandmanBelum ada peringkat

- Cartridge Valves CT 198974Dokumen312 halamanCartridge Valves CT 198974oleg-spb100% (2)

- Hydraulic ActuationDokumen10 halamanHydraulic ActuationMuh IndrawanBelum ada peringkat

- Hopkinson Valves IOM ManualDokumen7 halamanHopkinson Valves IOM ManualGiorgiana RosuBelum ada peringkat

- Lennox 13acx IomDokumen15 halamanLennox 13acx IomJesus Nieto CantilloBelum ada peringkat

- Series 825Y: Reduced Pressure Zone AssembliesDokumen2 halamanSeries 825Y: Reduced Pressure Zone Assembliesmiljan trifkovicBelum ada peringkat

- Series 825Y Specification SheetDokumen2 halamanSeries 825Y Specification SheetFEBCOBelum ada peringkat

- Hydraulic DampersDokumen23 halamanHydraulic DampersRubenAntezanaVerdeBelum ada peringkat

- Ejector Cloro17Dokumen14 halamanEjector Cloro17Robinson SanchezBelum ada peringkat

- PFS Mcquay Manual 01 PDFDokumen30 halamanPFS Mcquay Manual 01 PDFevrimk75% (4)

- Water Cooled Fcu Piping DetailsDokumen14 halamanWater Cooled Fcu Piping Detailsfernandoreyes893Belum ada peringkat

- VRCA Relief ValveDokumen8 halamanVRCA Relief Valvenenad135Belum ada peringkat

- Hayward Pro Grid de 4820Dokumen12 halamanHayward Pro Grid de 4820Mike MannoBelum ada peringkat

- Catalogo de Industria Minera PoberajDokumen48 halamanCatalogo de Industria Minera PoberajWillintonPoloBelum ada peringkat

- Installation, Operation and Maintenance Manual: Date: October 2005 SupersedesDokumen20 halamanInstallation, Operation and Maintenance Manual: Date: October 2005 SupersedesYoyokaeBelum ada peringkat

- CASVDokumen17 halamanCASVvegaronBelum ada peringkat

- LF100XL Specification SheetDokumen2 halamanLF100XL Specification SheetWattsBelum ada peringkat

- SPRINKLER Zone Control ValveDokumen4 halamanSPRINKLER Zone Control ValveIonut SomneaBelum ada peringkat

- Manual de Usuario de Calentador EléctricoDokumen12 halamanManual de Usuario de Calentador Eléctricohxzg7d7w8dBelum ada peringkat

- Vpi SeriesDokumen27 halamanVpi Serieshumayra.tasneem1Belum ada peringkat

- Equator 1Dokumen48 halamanEquator 1sajkhdjksahdkjBelum ada peringkat

- Series LF25AUB-Z3 Installation InstructionsDokumen2 halamanSeries LF25AUB-Z3 Installation InstructionsWattsBelum ada peringkat

- Codeline - 80E Series: 8 Inch End Entry Membrane Housing For Ro ApplicationsDokumen29 halamanCodeline - 80E Series: 8 Inch End Entry Membrane Housing For Ro ApplicationsCecilia Guerra AburtoBelum ada peringkat

- Control Valve Selection PDFDokumen218 halamanControl Valve Selection PDFSyed Ali100% (2)

- 34100specsheet10 2004Dokumen2 halaman34100specsheet10 2004iranbodBelum ada peringkat

- X-Stream XS3 0406Dokumen20 halamanX-Stream XS3 0406akhileshkuniyilBelum ada peringkat

- How To Select An ActuatorDokumen12 halamanHow To Select An Actuatorforevertay2000100% (1)

- Advances in Automated Subsea ValvesDokumen3 halamanAdvances in Automated Subsea ValvesSyko GuyBelum ada peringkat

- CFI Multi Flow Choke ManualDokumen22 halamanCFI Multi Flow Choke ManualMauricio GarcíaBelum ada peringkat

- Lowseal Alve Anual: 1 ScopeDokumen20 halamanLowseal Alve Anual: 1 Scopecumpio425428Belum ada peringkat

- Operations Maintenance Manual Style 129 Reliant Fire Hydrant 3fd60382Dokumen14 halamanOperations Maintenance Manual Style 129 Reliant Fire Hydrant 3fd60382Abdul KarimBelum ada peringkat

- Series OF1465-75H Hot Water Systems OneFlow Anti-Scale System Installation InstructionsDokumen12 halamanSeries OF1465-75H Hot Water Systems OneFlow Anti-Scale System Installation InstructionsWattsBelum ada peringkat

- StainlessLite Plus Horizontal Manual LQDokumen32 halamanStainlessLite Plus Horizontal Manual LQrare781Belum ada peringkat

- In-Line Hydraulic TesterDokumen5 halamanIn-Line Hydraulic TesterMasterrBelum ada peringkat

- 2012 Plumbing Design Guides PDFDokumen29 halaman2012 Plumbing Design Guides PDFIonut SomneaBelum ada peringkat

- Duo Safe Double Cont InstallDokumen8 halamanDuo Safe Double Cont InstallahmedBelum ada peringkat

- Triton Rapide R2 ShowerDokumen24 halamanTriton Rapide R2 ShowerGepeszmernokBelum ada peringkat

- API - Valve StandardsDokumen38 halamanAPI - Valve StandardsK LandryBelum ada peringkat

- S1 AM019 C DenisonDokumen25 halamanS1 AM019 C DenisonEmerson MazzaroloBelum ada peringkat

- Hydronic Buffer Tank Install Manual 090811Dokumen6 halamanHydronic Buffer Tank Install Manual 090811Andres CarrascoBelum ada peringkat

- 08 6.H Pressure VesselDokumen32 halaman08 6.H Pressure VesselstargaxxxxBelum ada peringkat

- Zenith H20H52DT - Service ManualDokumen48 halamanZenith H20H52DT - Service ManualrolaperezBelum ada peringkat

- Total Product CatalogueDokumen37 halamanTotal Product CatalogueFARIDBelum ada peringkat

- Proflow Water Heater ManualDokumen20 halamanProflow Water Heater ManualPedro BurkaBelum ada peringkat

- Prevention of Actuator Emissions in the Oil and Gas IndustryDari EverandPrevention of Actuator Emissions in the Oil and Gas IndustryBelum ada peringkat

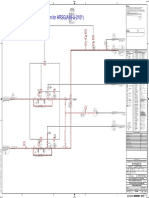

- A10 A Pid Va 718589 203Dokumen1 halamanA10 A Pid Va 718589 203zhangBelum ada peringkat

- Potter - Purgador de Aire PAARDokumen3 halamanPotter - Purgador de Aire PAARJames HansonBelum ada peringkat

- Process IsolationDokumen13 halamanProcess IsolationBhuran AkshayBelum ada peringkat

- 4 Floating SublineDokumen4 halaman4 Floating SublineSavoBelum ada peringkat

- Aquamite 50 125 40mmDokumen1 halamanAquamite 50 125 40mmAng Xi CongBelum ada peringkat

- Lect - 10 Fanno Flow 1Dokumen8 halamanLect - 10 Fanno Flow 1Ameena AimenBelum ada peringkat

- Valves in IndustryDokumen18 halamanValves in IndustryJia Kai LowBelum ada peringkat

- 88HST (12.5) Pump Curve PDFDokumen1 halaman88HST (12.5) Pump Curve PDFDaylis GonzalezBelum ada peringkat

- Valve Sizing and Selection: FREE ResourcesDokumen6 halamanValve Sizing and Selection: FREE ResourcesSARATH KRISHNAKUMARBelum ada peringkat

- Lecture-4-Kinematics of Fluid FlowDokumen34 halamanLecture-4-Kinematics of Fluid FlowDaanyal Ibn UmarBelum ada peringkat

- Fluid-Mechanics Boundary LayerDokumen19 halamanFluid-Mechanics Boundary LayerDustin WhiteBelum ada peringkat

- Astm-g32-16-Standard Method of Vibratory Cavitation Erosion TestDokumen16 halamanAstm-g32-16-Standard Method of Vibratory Cavitation Erosion TestIMSBelum ada peringkat

- HAWE Products: Our Current Product RangeDokumen299 halamanHAWE Products: Our Current Product RangeSudipta Das100% (1)

- Proportional Remote Control Valves Series PVC6: December, 2007Dokumen4 halamanProportional Remote Control Valves Series PVC6: December, 2007Taller PahrBelum ada peringkat

- Components of FRAMO SystemDokumen26 halamanComponents of FRAMO SystemtomryanBelum ada peringkat

- Vishwakarma Institute of Technology: Issue 01: Rev No. 0: Dt. 16/03/16 Course Plan FormatDokumen4 halamanVishwakarma Institute of Technology: Issue 01: Rev No. 0: Dt. 16/03/16 Course Plan FormatnikBelum ada peringkat

- Bernoulli ExperimentDokumen6 halamanBernoulli ExperimentKiki AkiraBelum ada peringkat

- HP Hydraulic Manual Override: Hpa / HPB / HPC / Hp1Dokumen8 halamanHP Hydraulic Manual Override: Hpa / HPB / HPC / Hp1mar mayoBelum ada peringkat

- 1 Darcy Friction CalculatorDokumen2 halaman1 Darcy Friction CalculatorRraffrizal ChandsBelum ada peringkat

- Cairo University Design of Pipelines and Pumping Stations Faculty of Engineering 4 Year Civil Eng. IHD 443 2012-2013Dokumen5 halamanCairo University Design of Pipelines and Pumping Stations Faculty of Engineering 4 Year Civil Eng. IHD 443 2012-2013Ahmed AsimBelum ada peringkat

- Pumps and Gas-Moving Equipment PumpsDokumen20 halamanPumps and Gas-Moving Equipment PumpsAnonymous K3FaYFlBelum ada peringkat

- Head Loss Calculation Head Loss Calculation Using: No. DN MM M MM L/s 1/1 M M/sDokumen23 halamanHead Loss Calculation Head Loss Calculation Using: No. DN MM M MM L/s 1/1 M M/sMohamedHanyBelum ada peringkat

- Diaphragm Control Valve Solutions - BrochureDokumen20 halamanDiaphragm Control Valve Solutions - BrochureMusaab AliBelum ada peringkat

- (Flow in Pipe) A Pressure: 1-Reynold's ExperimentDokumen21 halaman(Flow in Pipe) A Pressure: 1-Reynold's Experimentnurul athirahBelum ada peringkat

- CE8403-Applied Hydraulic EngineeringDokumen15 halamanCE8403-Applied Hydraulic EngineeringHussain Deen100% (1)

- Lab 1a Wind Tunnel Testing Principles & Drag Coefficients of Golf BallsDokumen9 halamanLab 1a Wind Tunnel Testing Principles & Drag Coefficients of Golf BallsSaadBelum ada peringkat

- Occasional Load in P PDFDokumen2 halamanOccasional Load in P PDFboyzesBelum ada peringkat