12HighClassCA Hot Dip Galvanizing Lines SMS Siemag

Diunggah oleh

Rajib ChatterjeeDeskripsi Asli:

Hak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

12HighClassCA Hot Dip Galvanizing Lines SMS Siemag

Diunggah oleh

Rajib ChatterjeeHak Cipta:

Format Tersedia

Markus Jaenecke Senior Project Manager Sales Strip Processing Lines Division SMS Siemag AG

MINERALS METALS METTALLURGY & MATERIALS - 8th International Conference 2011 13 February, 2011

Confidential SMS Holding GmbH

High-class continuous annealing and hot-dip galvanizing lines for a growing market

Growing market

Steel consumption in India will increase enormously Consumption per capita in India only 10% compared to China Estimations forecast an increase of Indias steel consumption by 14% compared to a global increase of 5% (Source: FAZ, 01.02.2011) Steel consumption per capita (in kg/capita)

450 400 350 300 250 200 150 100 50 0 405

Total production of crude steel (in mio. t)

600 500 400 300 200

Confidential SMS Holding GmbH

48

100 0

2000 2003 2006 2009 2000 2003 2006 2009 Europe China India Source: Worldsteel Association, Steel Statistical Yearbook 2010

MINERALS METALS METTALLURGY & MATERIALS - 8th International Conference 2011 13 February, 2011

Rising demand of high strength steel

High-strength steels are required for modern small and light vehicles Use of high-strength steel grades in compact cars Percentage of steel grades in the overall weight of a vehicle

6%

10% 22%

4%

17%

50% 94% 90% 74% 33%

1980 Uno 1990 Punto 176 2000 Punto 188 2005 Punto 199

Ultra-high strength steels High-strength steels Low-carbon steels

MINERALS METALS METTALLURGY & MATERIALS - 8th International Conference 2011 13 February, 2011

Confidential SMS Holding GmbH

High-class processing lines for a growing market

Different line types for galvanizing and annealing Continuous Annealing Lines Combined Annealing or Galvanizing Lines Hot-dip Galvanizing Lines Hot-strip Continuous Galvanizing Lines (Heat-to-Coat)

MINERALS METALS METTALLURGY & MATERIALS - 8th International Conference 2011

13 February, 2011

Confidential SMS Holding GmbH

Galvanized and Annealed steel strip

Important process steps for manufacturing high-quality steel strip

Post-treatment Annealing Cleaning

w know-ho ction e produ nsiv mprehe Co

13 February, 2011

Confidential SMS Holding GmbH

Galvanizing

MINERALS METALS METTALLURGY & MATERIALS - 8th International Conference 2011

New developments

New developments & optimized concepts

Cleaning Cleaning section Annealing Ultra Fast Cooling Galvanizing Air-knife Post Treatment Nickel-Flash

DFI Oxyfuel

Water-Quench

Strip Stabilization

Roll-Coater

Comprehensive production know-how

MINERALS METALS METTALLURGY & MATERIALS - 8th International Conference 2011

13 February, 2011

Confidential SMS Holding GmbH

Cleaning section

Efficient cleaning section vertical spray and electrolytic cleaning cells, horizontal brush cleaning and cascade rinsing Simple roll change possible during production Energy saved through low evaporation losses Heated by exhaust gas of furnace section

Cleaning section in a Continuous Annealing Line

Brush cleaning

Brush rinsing

Cascade rinsing unit

Spray cleaning

Electrolytic cleaning

Dryers

13 February, 2011

MINERALS METALS METTALLURGY & MATERIALS - 8th International Conference 2011

Confidential SMS Holding GmbH

REBOX DFI Oxyfuel

Installation of a REBOX DFI oxyfuel system in a continuous annealing line Process Gaseous fuel is burnt with pure oxygen To preheat the strip, the flame is directed specifically at the steel strip. DFI = Direct Flame Impingement Advantages when used in proceesing lines Extremely efficient heat transfer Reduction in furnace length Increase in furnace output for modernization projects Residual oils and solid particles are removed from the strip Simplification of the pre-cleaning

SMS Siemag and the Linde Group have signed a cooperation agreement on the exclusive marketing of the process developed by Linde.

MINERALS METALS METTALLURGY & MATERIALS - 8th International Conference 2011 13 February, 2011

Confidential SMS Holding GmbH

REBOX DFI Oxyfuel

Effects on the design of a continuous annealing line Thanks to REBOX DFI, a strip processing line can be set up much more economically Lower investment and operating costs In the furnace, the preheating zone and a part of the heating zone can be replaced In the cleaning zone, certain sections can be removed (electrolytic cleaning, brushes) Nitrogen oxide emissions are reduced through combustion with pure oxygen The production capacity can be increased by 30% if the plant is modernized Simplified cleaning section of a CAL CAL furnace with REBOX DFI syste,

MINERALS METALS METTALLURGY & MATERIALS - 8th International Conference 2011

13 February, 2011

Confidential SMS Holding GmbH

Ultra Fast Cooling System

Producing high-strength steel grades with high cooling rates Production of high-strength steel grades up to 980 MPa (TRIP & DP) Cooling rates of up to 130 K/s/mm are attained Direct supply of hydrogen into the cooling chamber enables a hydrogen content of 20 to 30% in the cooling area without increased hydrogen consumption Natural diffusion of hydrogen in the adjoining furnace sections - No complicated separation between cooling zone and neighboring zones - No additional hydrogen consumption compared to the traditional operation with 5% hydrogen in the shielding gas (forming gas)

MINERALS METALS METTALLURGY & MATERIALS - 8th International Conference 2011

13 February, 2011

10

Confidential SMS Holding GmbH

Water-Quench System

The only possibility of producing ultra-high strength steel grades in an annealing line Cooling rates of up to 1,000 K/s/mm possible Required for martensitic steel grades with yield strengths of more than 1000 MPa Manufacturing of ultra-high strength steel grades with yield strengths of up to 1550 MPa

Nozzle chamber Sealing rolls Anticrimping rolls

Modern nozzle design

Confidential SMS Holding GmbH

Slot-nozzle configuration with uniform cooling capacity over the strip width No strip distortions Prevention of flatness deviations Anticrimping rolls upstream of the nozzle chamber for strip shape monitoring

MINERALS METALS METTALLURGY & MATERIALS - 8th International Conference 2011 13 February, 2011

11

Combination of the cooling types High flexibility

Modular design - Two options for fast cooling Slow Cooling Ultra Fast Cooling System

Water-Quench

ction el dire rav Strip t

Confidential SMS Holding GmbH

After slow cooling there are two options available: Ultra Fast Cooling system with cooling rates of up to 130 K/mm/s Water-quench system for cooling rates of up to 1,000 K/mm/s with following flash pickling

MINERALS METALS METTALLURGY & MATERIALS - 8th International Conference 2011 13 February, 2011

12

Air-knife system

Optimizations of the FOEN Air-knife system Laser controlled air knife parallelism to strip Variable nozzle gap width adjustment Touch less edge coating control device Model based coating weight controller Each air-knife can be upgraded with latest features

MINERALS METALS METTALLURGY & MATERIALS - 8th International Conference 2011

13 February, 2011

13

Confidential SMS Holding GmbH

Electromagnetic Strip Stabilizer

Electromagnetic strip stabilizer DEMCO for reduction of over coating Zinc savings due to reduction of strip vibration and strip shape control More uniform coatings due to improving of strip shape at air-knife result in more uniform coatings The outer pairs of magnets are positioned at the strip edge, the inner pairs are adjusted to the problematic zones, while the center pair is fixed to the strip centre

MINERALS METALS METTALLURGY & MATERIALS - 8th International Conference 2011

13 February, 2011

14

Confidential SMS Holding GmbH

Roll-Coater technology for passivation

Extreme precisely and reliable coating thickness Separate circulation systems for different coating types Shuttle coater system for quick product change Motor system holds both rolls in an optimal position for even coating a controlled electric drive unit ensures the rolls turn in unison High efficiency and eco-friendliness, no waste water, no vapor

MINERALS METALS METTALLURGY & MATERIALS - 8th International Conference 2011

13 February, 2011

15

Confidential SMS Holding GmbH

Production Know-how

Customer benefit of comprehensive operation and process know-how Correct layout of the line according to requirements of European, Japanese, Korean or Chinese steel composition philosophy Entering the market for highly profitable steel grades Fast start up leads to earlier cash flow saves time and money for own developments

Advanced steel grades ease saleability of commodity grades by selling packages

MINERALS METALS METTALLURGY & MATERIALS - 8th International Conference 2011

13 February, 2011

16

Confidential SMS Holding GmbH

Know-how package

Steel treatment process

Basic production parameters Process description Technical consulting Energy management Environmental protection

Operation of equipment

Start-up and process optimization Operational assistance and technical support Classroom training of customer personnel Management training Practical training at SMS cooperation partners site On-the-job training of customer personnel

Quality control

Plant descriptions Process parameters Failure management Process requirements Quality control/ assurance Maintenance requirements Job description Sample selection and management

Confidential SMS Holding GmbH

MINERALS METALS METTALLURGY & MATERIALS - 8th International Conference 2011

13 February, 2011

17

MINERALS METALS METTALLURGY & MATERIALS - 8th International Conference 2011

13 February, 2011

18

Confidential SMS Holding GmbH

Anda mungkin juga menyukai

- Spot Welding Interview Success: An Introduction to Spot WeldingDari EverandSpot Welding Interview Success: An Introduction to Spot WeldingBelum ada peringkat

- Arvedi First Thin Slab Endless CastingDokumen10 halamanArvedi First Thin Slab Endless CastingprasenjitsayantanBelum ada peringkat

- X 341E CEM Technology Compact Endless Cast and Rolling MillDokumen2 halamanX 341E CEM Technology Compact Endless Cast and Rolling MillGowtham VishvakarmaBelum ada peringkat

- To PM Technology: A Guide For Designers and EngineersDokumen30 halamanTo PM Technology: A Guide For Designers and EngineersBasliu DoinaBelum ada peringkat

- SMS Seimag - Twenty Years of CSPDokumen27 halamanSMS Seimag - Twenty Years of CSPnvc_vishwanathanBelum ada peringkat

- Year Minimills 2010Dokumen8 halamanYear Minimills 2010mishtinilBelum ada peringkat

- EPMA-Final - HIP - Brochure - Introduction To PM HIP TechnologyDokumen30 halamanEPMA-Final - HIP - Brochure - Introduction To PM HIP TechnologygillougillouBelum ada peringkat

- Technical Achievements in Wire-Rod Production: Technologies and Processes of The H SystemDokumen17 halamanTechnical Achievements in Wire-Rod Production: Technologies and Processes of The H SystemsaikatBelum ada peringkat

- RHI MR Services Bulletin 1 2012-DataDokumen64 halamanRHI MR Services Bulletin 1 2012-DataSuphi Yüksel100% (1)

- IMU Basic Knowledge English Final 11-03-14Dokumen102 halamanIMU Basic Knowledge English Final 11-03-14ramchandra rao deshpandeBelum ada peringkat

- Brochure Offshore&Linepipe EDokumen24 halamanBrochure Offshore&Linepipe Epark1112Belum ada peringkat

- Hazardous Engineering Solutions - Feb 2013Dokumen40 halamanHazardous Engineering Solutions - Feb 2013michael3511Belum ada peringkat

- Aluminium Plate-Fin Heat Ex Changers - LindeDokumen12 halamanAluminium Plate-Fin Heat Ex Changers - LindesoxalBelum ada peringkat

- MTI Assignment - Antesh Kumar - EPGP-13A-021Dokumen8 halamanMTI Assignment - Antesh Kumar - EPGP-13A-021Antesh SinghBelum ada peringkat

- Long Products Bulletin 2011Dokumen60 halamanLong Products Bulletin 2011a2345Belum ada peringkat

- TMS 2002Dokumen3 halamanTMS 2002Daniel StuparekBelum ada peringkat

- Training 1 LF IntroductionDokumen14 halamanTraining 1 LF IntroductionprasenjitsayantanBelum ada peringkat

- ALPEMA Standards LeafletDokumen2 halamanALPEMA Standards Leaflet최우혁Belum ada peringkat

- Recent Technology of Powder Metallurgy and ApplicationsDokumen32 halamanRecent Technology of Powder Metallurgy and ApplicationsMuralli Jayaganesan100% (2)

- Rizhao Steel Esp LinesDokumen7 halamanRizhao Steel Esp LinesSS making technical teamBelum ada peringkat

- 1484 V0qusf PL Impexmetal Katalog en 09-WwwDokumen32 halaman1484 V0qusf PL Impexmetal Katalog en 09-Wwwmuamer1Belum ada peringkat

- The New Copper Casting-Machine: Experiences at FerroatlanticaDokumen8 halamanThe New Copper Casting-Machine: Experiences at FerroatlanticaJuan Bautista HernándezBelum ada peringkat

- Aluminium Welding ESABDokumen40 halamanAluminium Welding ESABKarthikeyan Shanmugavel100% (2)

- Secondary Metallurgy Solut enDokumen20 halamanSecondary Metallurgy Solut enjframiniBelum ada peringkat

- Pumps For Heat Transfer TechnologyDokumen12 halamanPumps For Heat Transfer TechnologybmsengineeringBelum ada peringkat

- Strip Casting Technology A Key To Product QualityDokumen5 halamanStrip Casting Technology A Key To Product Qualityjijith njBelum ada peringkat

- Roofing Tech - EngDokumen36 halamanRoofing Tech - EngwindyBelum ada peringkat

- Sheet Pile Design HandbookDokumen368 halamanSheet Pile Design HandbookLandon Mitchell92% (12)

- Piling Handbook (2008)Dokumen368 halamanPiling Handbook (2008)RUXUS100% (1)

- Siemens 1LEDokumen96 halamanSiemens 1LELuis Fernando BelloBelum ada peringkat

- Power Air Preheater Ljungstrom-Air-preheatersDokumen16 halamanPower Air Preheater Ljungstrom-Air-preheatersmoorthymtps_54120305Belum ada peringkat

- Lotprospekt e 10 12 SCDokumen16 halamanLotprospekt e 10 12 SCAmit PatelBelum ada peringkat

- SGT 750Dokumen24 halamanSGT 750andmar2011Belum ada peringkat

- Purlin & Cladding RailDokumen67 halamanPurlin & Cladding RailPrima AdhiyasaBelum ada peringkat

- Bollhoff Armstrong HeliCoilDokumen28 halamanBollhoff Armstrong HeliCoilAce Industrial Supplies100% (1)

- Introduction To Steel ConstrDokumen96 halamanIntroduction To Steel Constrlucas100% (1)

- EspDokumen36 halamanEspprasenjitsayantanBelum ada peringkat

- A Century of Aluminium A Product of The FutureDokumen3 halamanA Century of Aluminium A Product of The FutureEvo CasagrandeBelum ada peringkat

- Elgi PG Series Diesel DrivenDokumen8 halamanElgi PG Series Diesel DrivenSatyajeet Sahu100% (1)

- W7 304E Plating Lines MontageDokumen9 halamanW7 304E Plating Lines MontageAnonymous wtK1AZBi100% (1)

- Svetsaren 1 2 1999Dokumen80 halamanSvetsaren 1 2 1999adrian_stoBelum ada peringkat

- Siemens Loher Flameproof & Special Designed MotorsDokumen21 halamanSiemens Loher Flameproof & Special Designed Motorspokiri100% (1)

- Metals 107908 PDFDokumen20 halamanMetals 107908 PDFiban tecnaliaBelum ada peringkat

- Svetsaren 1 2009Dokumen72 halamanSvetsaren 1 2009João Diego FeitosaBelum ada peringkat

- Silyzer-200-PEM Based Electrolyser For Hydrogen GenerationDokumen11 halamanSilyzer-200-PEM Based Electrolyser For Hydrogen GenerationKirtiraj Nalawade100% (1)

- Alp General ACCESORIESDokumen74 halamanAlp General ACCESORIESsas_uu100% (1)

- 2016 Aluminum Formwork Brochure-Email PDFDokumen10 halaman2016 Aluminum Formwork Brochure-Email PDFJenelle Marie MedinaBelum ada peringkat

- Optim Raex FenatranDokumen56 halamanOptim Raex Fenatrancostelino72Belum ada peringkat

- SSSSDokumen3 halamanSSSSArjun M NairBelum ada peringkat

- Orange Peel Grabs PDFDokumen13 halamanOrange Peel Grabs PDFweffwdfBelum ada peringkat

- 469 SuezSteelDokumen5 halaman469 SuezSteelSeshadri Deb RoyBelum ada peringkat

- New Era in SteelmakingDokumen6 halamanNew Era in SteelmakingjtpmlBelum ada peringkat

- Information Symposium Measurement and Control Techniques in Rolling: Luxembourg, 2 and 3 September 1981Dari EverandInformation Symposium Measurement and Control Techniques in Rolling: Luxembourg, 2 and 3 September 1981Belum ada peringkat

- Thermal Insulation Handbook for the Oil, Gas, and Petrochemical IndustriesDari EverandThermal Insulation Handbook for the Oil, Gas, and Petrochemical IndustriesPenilaian: 3.5 dari 5 bintang3.5/5 (3)

- Machines, Tools and Methods of Automobile ManufactureDari EverandMachines, Tools and Methods of Automobile ManufacturePenilaian: 4 dari 5 bintang4/5 (1)

- The FMCG Packaging Moving The Market Towards Sustainable Packaging MaterialsDokumen6 halamanThe FMCG Packaging Moving The Market Towards Sustainable Packaging MaterialsRajib ChatterjeeBelum ada peringkat

- Basic Needs of Rural India: Where Our Roots Are Falling WeakDokumen20 halamanBasic Needs of Rural India: Where Our Roots Are Falling WeakRajib ChatterjeeBelum ada peringkat

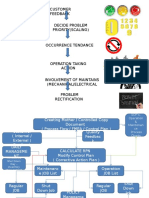

- Problem Solving With QC Tools: AspireDokumen54 halamanProblem Solving With QC Tools: AspireRajib ChatterjeeBelum ada peringkat

- TeslaDokumen5 halamanTeslaRajib ChatterjeeBelum ada peringkat

- Middle East Steel Supplement 2012Dokumen24 halamanMiddle East Steel Supplement 2012Rajib ChatterjeeBelum ada peringkat

- An Analysis of The Mission Statements of Selected Bangladeshi CompaniesDokumen13 halamanAn Analysis of The Mission Statements of Selected Bangladeshi CompaniesRajib ChatterjeeBelum ada peringkat

- Iso Documents PreparationDokumen2 halamanIso Documents PreparationRajib ChatterjeeBelum ada peringkat

- Your Habits & YouDokumen21 halamanYour Habits & YouRajib ChatterjeeBelum ada peringkat

- Visitor Instruction PDFDokumen1 halamanVisitor Instruction PDFRajib ChatterjeeBelum ada peringkat

- Types of Fuguai: Presented byDokumen32 halamanTypes of Fuguai: Presented byRajib ChatterjeeBelum ada peringkat

- X 9005 14430 Total Gross CV: 22460 : Iso-Butene: 0.157% N Butene: 0.099%. .....Dokumen2 halamanX 9005 14430 Total Gross CV: 22460 : Iso-Butene: 0.157% N Butene: 0.099%. .....Rajib ChatterjeeBelum ada peringkat

- Fuels and CombustionDokumen14 halamanFuels and CombustionRajib ChatterjeeBelum ada peringkat

- Multipliers Used To Convert To Standard Measurement Units: Draft For Public CommentDokumen7 halamanMultipliers Used To Convert To Standard Measurement Units: Draft For Public CommentRajib ChatterjeeBelum ada peringkat

- Industrial FurnacesDokumen20 halamanIndustrial FurnacesRajib ChatterjeeBelum ada peringkat

- Multipliers Used To Convert To Standard Measurement Units: Draft For Public CommentDokumen7 halamanMultipliers Used To Convert To Standard Measurement Units: Draft For Public CommentRajib ChatterjeeBelum ada peringkat

- Basics of ThermodynamicsDokumen51 halamanBasics of ThermodynamicsRajib ChatterjeeBelum ada peringkat

- Fuels and CombustionDokumen14 halamanFuels and CombustionRajib ChatterjeeBelum ada peringkat

- Engineer WebDokumen35 halamanEngineer Webpedrocaels989Belum ada peringkat

- Visual Basic 6 BlackbookDokumen1.182 halamanVisual Basic 6 Blackbookapi-19711924Belum ada peringkat

- PRINT MEDIA - Yesterday, Today and TomorrowDokumen21 halamanPRINT MEDIA - Yesterday, Today and Tomorrowmonirba48Belum ada peringkat

- MODULE - Maintaining Plumbing Tool and EquipmentDokumen14 halamanMODULE - Maintaining Plumbing Tool and EquipmentJanine ReyesBelum ada peringkat

- Euromold Elastimold PITO E Plug in Termination Up To 24kV 250ADokumen2 halamanEuromold Elastimold PITO E Plug in Termination Up To 24kV 250AMosa Elnaid ElnaidBelum ada peringkat

- Bahan Air Mancur MenariDokumen1 halamanBahan Air Mancur Menariarlan alexandriaBelum ada peringkat

- HP Alphaserver Es45Dokumen38 halamanHP Alphaserver Es45Tsure11Belum ada peringkat

- Project: Tasiast Debottlenecking Project - Tailings THICKENER/4699-THK-201Dokumen2 halamanProject: Tasiast Debottlenecking Project - Tailings THICKENER/4699-THK-201Rekhis OussamaBelum ada peringkat

- Akb ResumeDokumen4 halamanAkb ResumeAkshayBelum ada peringkat

- Compression Member Section Constant,: Table 6.3.3 (3) Values of Member Slenderness Reduction Factor (A)Dokumen5 halamanCompression Member Section Constant,: Table 6.3.3 (3) Values of Member Slenderness Reduction Factor (A)kenho2Belum ada peringkat

- Guitar Pickups Magnetic Fields 2 Malcolm MooreDokumen9 halamanGuitar Pickups Magnetic Fields 2 Malcolm Mooremarkrichardmurad100% (1)

- 1sites 1Dokumen6 halaman1sites 1Swagg-Master NigelBelum ada peringkat

- EPA Guidance On Moisture Control (Dragged)Dokumen1 halamanEPA Guidance On Moisture Control (Dragged)Mitesh KumarBelum ada peringkat

- Release NotesDokumen17 halamanRelease NotesDiego AriasBelum ada peringkat

- MATLAB Simulation Comparison For Different Adaptive Noise Cancelation AlgorithmsDokumen6 halamanMATLAB Simulation Comparison For Different Adaptive Noise Cancelation Algorithmsadd313199Belum ada peringkat

- Concise Project Management - Mwayi - Kanyinji - 2020Dokumen19 halamanConcise Project Management - Mwayi - Kanyinji - 2020MWAYIBelum ada peringkat

- 6head Syrup Filling Line Automatic PDFDokumen18 halaman6head Syrup Filling Line Automatic PDFSrinivas0% (1)

- SKGY ProfileDokumen37 halamanSKGY ProfileYogendra SharmaBelum ada peringkat

- Wave Loading On Offshore StructuresDokumen309 halamanWave Loading On Offshore StructuresJorge Cipriano100% (1)

- Barry Honig SEC Settlement 6.17.19Dokumen16 halamanBarry Honig SEC Settlement 6.17.19Teri BuhlBelum ada peringkat

- Flow Diagram Biogas PlantDokumen4 halamanFlow Diagram Biogas PlantDwi SinggihBelum ada peringkat

- Ten Steps For Conducting A Communications Audit by Kaitlin SmithDokumen2 halamanTen Steps For Conducting A Communications Audit by Kaitlin SmithKatrina Escalona De GuzmanBelum ada peringkat

- ABS Fault Codes PDFDokumen11 halamanABS Fault Codes PDFMshiboniumBelum ada peringkat

- Shimano SC6500 ManualDokumen26 halamanShimano SC6500 ManualFletcher FletcherBelum ada peringkat

- Precision Air ConditioningDokumen9 halamanPrecision Air ConditioningF. A AhmedBelum ada peringkat

- Advantage Federal Credit Union - Case Study HDMDokumen2 halamanAdvantage Federal Credit Union - Case Study HDMspaceskipperBelum ada peringkat

- EMIESD Protection Solutions For The CAN BusDokumen9 halamanEMIESD Protection Solutions For The CAN BusascensorimBelum ada peringkat

- Excerpt From: Bible and Is An Exercise On Dynamic Blocks. in The Book, TheDokumen6 halamanExcerpt From: Bible and Is An Exercise On Dynamic Blocks. in The Book, Thebsathish83Belum ada peringkat

- Multiwii - 32U4 - SE Manual: 1. IntroductionDokumen7 halamanMultiwii - 32U4 - SE Manual: 1. IntroductionHugo AlmeidaBelum ada peringkat

- VHDL Project: Composite Color Generation Using RGB LedDokumen15 halamanVHDL Project: Composite Color Generation Using RGB LedArun GoelBelum ada peringkat

- General Spec For Water Main Construction (JKR Sarawak 2011) PDFDokumen64 halamanGeneral Spec For Water Main Construction (JKR Sarawak 2011) PDFmakhsmyBelum ada peringkat

- Carmix 25 FX EngDokumen2 halamanCarmix 25 FX Engjoyli22Belum ada peringkat