Cement Base Course

Diunggah oleh

Raizen Roldan Babanto SomobayDeskripsi Asli:

Judul Asli

Hak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

Cement Base Course

Diunggah oleh

Raizen Roldan Babanto SomobayHak Cipta:

Format Tersedia

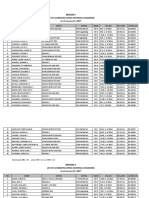

ITEM 206 PORTLAND CEMENT TREATED PLANT MIX BASE COURSE 206.

.1 Description: This Item shall consist of a foundation for surface course composed of aggregate, Portland Cement and water in proper proportions, mixed by a travel plant or in a central plant and spread and compacted on a prepared subgrade/subbase in one or more layers, in accordance with this Specification and the lines, grades, thickness and typical cross-sections shown on the Plans or as established by the Engineer. 206.2 Material Requirements 1. Soil Aggregate: It shall conform to the grading and quality requirements of Subsection 203.2.1. 2. Portland Cement: It shall conform to the requirements of Item 700, Hydraulic Cement. 3. Water: It shall conform to the requirements of Item 714, Water. 4. Proportioning of Mixture: The amount of cement to be added to the soil-aggregate shall be from 6 to 10 mass percent of the dry soil. The exact percentage to be added shall be fixed by the Engineer on the basis of preliminary laboratory tests and trial mixes of the materials furnished by the Contractor. 5. Strength Requirements: Strength requirements shall conform in all respects to those specified in Subsection 203.2.5 206.3 Construction Requirements 1. Weather Limitations Portland cement shall not be applied during windy, rainy or impending bad weather. In the event rain occurs, work shall be promptly stopped and the entire section shall be reconstructed in accordance with this Specification. 2. Travel Plant Method The salvaged or new soil-aggregate shall be pulverized until at least 80 mass percent of all material other than stone or gravel will pass a 4.75 mm (No. 4) sieve. Any material retained on a 50 mm (2 inches) sieve and other unsuitable material shall be removed. If additional material is specified, it shall be blended with the existing material. All butt joints at existing pavements or other structures shall be cleaned prior to mixing. The subgrade/subbase shall support all equipment required in the construction of the base course. Soft or yielding areas shall be corrected prior to mixing. The soilaggregate to be treated shall be placed in a uniform windrow and spread to a uniform thickness to the required width. The specified quantity of Portland Cement shall be applied uniformly in a trench on top of the windrows or spread uniformly over the soil-aggregate. Spread cement that has been lost shall be replaced, without additional compensation, before mixing is started. Mixing shall be accomplished by means of a mixer that will thoroughly blend the cement with the soil-aggregate. The mixer shall be equipped with a water metering device that will introduce the required quantity of water during the mixing cycle. The cement soil-aggregate mixture shall be sufficiently blended to prevent the formation of cement balls when water is applied.A maximum time of 2 hours shall be permitted for wet mixing, laydown, and finishing when this method is used. 3. Central Plant Method The soil-aggregate shall be proportioned and mixed with cement and water in a central mixing plant. The plant shall be equipped with feeding and metering devices which will introduce the cement, soil-aggregate, and water into the

mixer in the quantities specified. Mixing shall continue until a uniform mixture has been obtained. 4. Spreading, Compacting and Finishing The mixture shall be spread on a prepared and moistened subgrade/subbase in a uniform layer by an approved equipment. Not more than 60 minutes shall elapse between the start of mixing and the time of starting compaction of the spread mixture. After spreading, the mixture shall be compacted and finished conforming to the procedures/requirements specified under Subsection 203.3.6, Spreading, Compacting and Finishing. The compaction and finishing shall be completed within 2 hours of the time water is added to the mixture. 5. Protection, Curing and Maintenance The completed cement treated base shall be cured with a bituminous curing seal applied as soon as possible after the completion of final rolling. The surface shall be kept moist until the seal is applied. The rate of application shall be between 0.5 L/m2 to 1.00 L/m2 of surface. The exact rate will be determined by the Engineer. Curing seal will be applied insufficient quantity to provide a continuous film over the base. The film shall be maintained at least 5 days unless the treated base is protected by a subsequent course. The Contractor shall be responsible for adequate maintenance of the base at all times as specified under Subsection 203.3.7, Protection, Curing and Maintenance. 6. Trial Sections Trial sections of the stabilized base shall be constructed at least 2 weeks before actual base construction. These shall conform to the applicable requirements of Subsections 200.3.4, Trial Sections. 7. Tolerances The stabilized base course shall be laid to the designed level and transverse slopes shown on the Plans. The allowable tolerances shall be in accordance with Subsection 201.3.5, Tolerance 8. Traffic The Contractor will not be permitted to drive heavy equipment over completed portions prior to the end of five (5) days curing period except pneumatic-tired equipment required for constructing adjoining sections. Turning areas on completed portions of the base shall be protected by a layer of stable granular materials of not less than 50 mm of compacted depth. 206.4 Method of Measurement Portland Cement Treated Plant Mix Base Course will be measured by the cubic meter (m3). The quantity to be paid for shall be the design volume compacted in-place as shown on the Plans, accepted in the completed course. No allowance shall be given for materials placed outside the design limits shown 57 on the cross-sections. Trial sections shall not be measured separately but shall be included in the quantity of Portland Cement Treated Plant Mix Base Course. 206.5 Basis of Payment The accepted quantities, measured as prescribed in Section 206.4, shall be paid for at the contract unit price for Portland Cement Treated Plant Mix Base Course which price and payment shall be full compensation for furnishing and placing all materials, including all labor, equipment, tools and incidentals necessary to complete the work prescribed in this item.

Anda mungkin juga menyukai

- Item 307Dokumen50 halamanItem 307xyxyquaz100% (2)

- DESCRIPTION: ITEM 405-Structural ConcreteDokumen11 halamanDESCRIPTION: ITEM 405-Structural ConcreteKioBelum ada peringkat

- Statement of Single Largest Completed Contract (SLCC) Similar To The ProjectDokumen1 halamanStatement of Single Largest Completed Contract (SLCC) Similar To The ProjectJonhell Dela Cruz Soriano100% (1)

- Metal Roofing Prices Philippines - PHILCON PRICESDokumen1 halamanMetal Roofing Prices Philippines - PHILCON PRICESjohn reyesBelum ada peringkat

- (STE) Philippine Contractors Accreditation Board (PCAB)Dokumen3 halaman(STE) Philippine Contractors Accreditation Board (PCAB)Charlon GrospeBelum ada peringkat

- Item 204Dokumen2 halamanItem 204Jeffrey BolimaBelum ada peringkat

- Construction MethodsDokumen2 halamanConstruction Methodsanamarie baloBelum ada peringkat

- Disbursement Voucher: DPWH-Sorsogon 1st DEODokumen60 halamanDisbursement Voucher: DPWH-Sorsogon 1st DEOTIMMY BOYBelum ada peringkat

- DO 001 s2023-CMPDDokumen1 halamanDO 001 s2023-CMPDEric IbarraBelum ada peringkat

- 13 - List of Roads Pursuant To EO 113 PDFDokumen24 halaman13 - List of Roads Pursuant To EO 113 PDFDexter Domingo Vengua100% (2)

- Sample Letter of Extension of Time For Construction (EOT Letter)Dokumen2 halamanSample Letter of Extension of Time For Construction (EOT Letter)claims ksa100% (1)

- AGGREGATE SURFACE COURSE SPECIFICATIONSDokumen75 halamanAGGREGATE SURFACE COURSE SPECIFICATIONSShammir Tabayag MangidaBelum ada peringkat

- Annex A.1 - Water Source Validation Form For Potable Water Supply Projects (Water)Dokumen2 halamanAnnex A.1 - Water Source Validation Form For Potable Water Supply Projects (Water)Menro San ClementeBelum ada peringkat

- Guidelines Regular MemberDokumen1 halamanGuidelines Regular MemberHarvey Ian Pagatpatan AquinoBelum ada peringkat

- Discharge Through an Orifice ExperimentDokumen5 halamanDischarge Through an Orifice ExperimentMichaeldon MarquezBelum ada peringkat

- Construction methodology for road replacementDokumen1 halamanConstruction methodology for road replacementnicole pampangaBelum ada peringkat

- Equipment Utilization Schedule TemplateDokumen1 halamanEquipment Utilization Schedule TemplateJim Bot33% (3)

- LogbookDokumen48 halamanLogbookLouie MacniBelum ada peringkat

- Office of The Building Official Application For Building PermitDokumen2 halamanOffice of The Building Official Application For Building Permitrmrv valdezBelum ada peringkat

- Manpower Utilization ScheduleDokumen1 halamanManpower Utilization ScheduleKeirl John Asingua0% (2)

- Affidavit of Site InspectionDokumen1 halamanAffidavit of Site Inspectionmgllacuna100% (1)

- Example of Company ProfileDokumen11 halamanExample of Company Profilenoyax xayon0% (1)

- Imall Antipolo Bayan Construction Guidelines 02 06 19Dokumen19 halamanImall Antipolo Bayan Construction Guidelines 02 06 19Jimson Rhey Uy Miranda100% (1)

- Boq Bom Template 1 - General Renovation SummariesDokumen2 halamanBoq Bom Template 1 - General Renovation SummariesVholts Villa VitugBelum ada peringkat

- Civil Engineering Project Research ProposalDokumen8 halamanCivil Engineering Project Research ProposalMl KrishaBelum ada peringkat

- GE Report Lot 5948 Pob 4 IndangDokumen3 halamanGE Report Lot 5948 Pob 4 IndangJan Gatchalian ReolaBelum ada peringkat

- Atlanta HDPE pipe advantagesDokumen14 halamanAtlanta HDPE pipe advantagesMarvin MartinezBelum ada peringkat

- Construction logbook J.P. Rizal St. traffic signal installationDokumen4 halamanConstruction logbook J.P. Rizal St. traffic signal installationRo LandBelum ada peringkat

- Reaction Paper Water Treatment Group 1Dokumen3 halamanReaction Paper Water Treatment Group 1Hrv AquinoBelum ada peringkat

- Rececoat Base Mortar Data SheetDokumen2 halamanRececoat Base Mortar Data SheetAmira Ramlee100% (1)

- PCAB - Application For Registration and Classification of Contractor For Gov't Infra. Proj. (ARC) 2015-2016Dokumen5 halamanPCAB - Application For Registration and Classification of Contractor For Gov't Infra. Proj. (ARC) 2015-2016AngerreyfieCambaMasinas75% (8)

- Civil-Structural Permit (For Building Permit)Dokumen2 halamanCivil-Structural Permit (For Building Permit)Gabriel C. ObiasBelum ada peringkat

- Island Super Kinis Skim Coat (TDS)Dokumen1 halamanIsland Super Kinis Skim Coat (TDS)WILAN ENGINEERING INCBelum ada peringkat

- Do - 066 - s2017 As Built Plan As Variation OrderDokumen2 halamanDo - 066 - s2017 As Built Plan As Variation OrderrubydelacruzBelum ada peringkat

- NSCP 2015 wind load provisions summaryDokumen5 halamanNSCP 2015 wind load provisions summaryJam CawidBelum ada peringkat

- Cash Flow Payment 20KDokumen1 halamanCash Flow Payment 20KrestyBelum ada peringkat

- Form 8Dokumen2 halamanForm 8Ronnie Endaya100% (1)

- Solignum Colourless Wood Preservative TDSDokumen2 halamanSolignum Colourless Wood Preservative TDSudithaireshaBelum ada peringkat

- Updated List of DPWH Accredited Materials Engineers As of January 31, 2017 - Department of Public Works and HighwaysDokumen37 halamanUpdated List of DPWH Accredited Materials Engineers As of January 31, 2017 - Department of Public Works and Highwaysbravo deltafox0% (5)

- Schedule of Minimum Test Requirements Governing Items of Work of The DPWH Standard Specifications For HighwaysDokumen24 halamanSchedule of Minimum Test Requirements Governing Items of Work of The DPWH Standard Specifications For HighwayseddieBelum ada peringkat

- Quick Panel BrochureDokumen11 halamanQuick Panel BrochuretantanBelum ada peringkat

- Technical Specifications (STRUCTURAL)Dokumen16 halamanTechnical Specifications (STRUCTURAL)Lenielle AmatosaBelum ada peringkat

- Grouted RiprapDokumen3 halamanGrouted RiprapRey BaguioBelum ada peringkat

- Road ClassificationDokumen3 halamanRoad ClassificationalingjomarBelum ada peringkat

- 818 Building Structural Investigation and Design ProposalDokumen2 halaman818 Building Structural Investigation and Design ProposalRóndoBelum ada peringkat

- Construction Method for Drainage System ProjectDokumen2 halamanConstruction Method for Drainage System ProjectNeil Mark Solarte UndagBelum ada peringkat

- Luffa and Water Hyacinth Research PaperDokumen66 halamanLuffa and Water Hyacinth Research PaperHana RasidBelum ada peringkat

- 1) Issuance of Building and Ancillary PermitsDokumen24 halaman1) Issuance of Building and Ancillary PermitsRolly Marc G. Sotelo0% (1)

- Surveyed Construction Materials Prices for 3rd Quarter 2018Dokumen34 halamanSurveyed Construction Materials Prices for 3rd Quarter 2018CDRRMO ValenciaBelum ada peringkat

- Affidavit For DPWHDokumen3 halamanAffidavit For DPWHGenevieve GayosoBelum ada peringkat

- DPWH Issues New Road Construction Cost Estimation ManualDokumen1 halamanDPWH Issues New Road Construction Cost Estimation ManualIan JamesBelum ada peringkat

- PCAB 2015 Categorization Classification TableDokumen2 halamanPCAB 2015 Categorization Classification TableRotsen Kho Yute100% (2)

- QAUDokumen90 halamanQAUakclams77Belum ada peringkat

- Affidavit of Non-Hiring of ContractorDokumen1 halamanAffidavit of Non-Hiring of Contractorraymart100% (1)

- Fencing Permit ChecklistDokumen2 halamanFencing Permit ChecklistThe MatrixBelum ada peringkat

- Delays in Work Completion and Liquidated DamagesDokumen3 halamanDelays in Work Completion and Liquidated DamagesJanice Nay-udBelum ada peringkat

- DO - 011 - s2022 Revised Project BillbaordDokumen2 halamanDO - 011 - s2022 Revised Project BillbaordCris Jonneth LabaguisBelum ada peringkat

- Base Course Aggregates StandardsDokumen5 halamanBase Course Aggregates Standardsprobook450_ehsanBelum ada peringkat

- IS008 Soil Cement BlocksDokumen4 halamanIS008 Soil Cement BlocksCiddarthnBelum ada peringkat

- TxDot Specs CTB s275Dokumen4 halamanTxDot Specs CTB s275layisoBelum ada peringkat

- SXQDokumen5 halamanSXQNassim SabriBelum ada peringkat

- S4HANA IT L1 v8Dokumen23 halamanS4HANA IT L1 v8rajankthomasBelum ada peringkat

- AVC ASF r0113-101 PDFDokumen15 halamanAVC ASF r0113-101 PDFSergey MBelum ada peringkat

- Peikko Katalog 2011Dokumen64 halamanPeikko Katalog 2011Vilandas CeBelum ada peringkat

- Trenching Shoring SafetyDokumen29 halamanTrenching Shoring SafetyMullapudi Satish KumarBelum ada peringkat

- Basic Knowledge Minihydro Power PlantDokumen26 halamanBasic Knowledge Minihydro Power PlantIfnu SetyadiBelum ada peringkat

- Recloser Chardon R200iDokumen112 halamanRecloser Chardon R200iGustavo Alberto Jaramillo RuedaBelum ada peringkat

- OFITE MODEL 230: Single Cell Cement Analyzer ManualDokumen7 halamanOFITE MODEL 230: Single Cell Cement Analyzer ManualJadeja GirirajsinhBelum ada peringkat

- Ds ChecklistDokumen2 halamanDs ChecklistG-SamBelum ada peringkat

- STP - RSTP - MSTP Comparison LabDokumen28 halamanSTP - RSTP - MSTP Comparison Labbruce floresBelum ada peringkat

- Integral Bridge Design To EN 1992-2Dokumen58 halamanIntegral Bridge Design To EN 1992-2Dem HasiBelum ada peringkat

- FSM 5000 OPC Operation Manual enUS 9007208643043467Dokumen24 halamanFSM 5000 OPC Operation Manual enUS 9007208643043467Misael RodriguezBelum ada peringkat

- ASTM 1784 Rigid CPVC PDFDokumen4 halamanASTM 1784 Rigid CPVC PDFarifin rizal100% (2)

- The Super FMT JigDokumen2 halamanThe Super FMT JigflerziBelum ada peringkat

- Essam Amr - Civil Engineer CV4 PDFDokumen2 halamanEssam Amr - Civil Engineer CV4 PDFAnonymous MYWXjWVp9uBelum ada peringkat

- A Witch Guide To Faery Folk PDFDokumen2 halamanA Witch Guide To Faery Folk PDFEsther JoyBelum ada peringkat

- Desain Pondasi PileDokumen9 halamanDesain Pondasi PilegembulflowBelum ada peringkat

- Icon Library: Current As of June 8, 2011Dokumen36 halamanIcon Library: Current As of June 8, 2011putakoBelum ada peringkat

- Trans-Architecture, de Tim GoughDokumen16 halamanTrans-Architecture, de Tim GoughClevio RabeloBelum ada peringkat

- Flexural DesignDokumen38 halamanFlexural DesignJesús Rodríguez RodríguezBelum ada peringkat

- ASME B31 1 ASME B31 3 Hugo JulienDokumen3 halamanASME B31 1 ASME B31 3 Hugo JulienRami Elloumi0% (1)

- STN 0, Ipinterface Int - S1 Primaryip - Address 10.246.43.37 !siu - Ip Default Gateway - S1 X2!Dokumen16 halamanSTN 0, Ipinterface Int - S1 Primaryip - Address 10.246.43.37 !siu - Ip Default Gateway - S1 X2!fernando_souza385Belum ada peringkat

- WSM West Salem MachineryDokumen7 halamanWSM West Salem Machinerymostafa sherifBelum ada peringkat

- One KL: Close Competitor Service ApartmentsDokumen17 halamanOne KL: Close Competitor Service ApartmentsAshman DanielBelum ada peringkat

- Press Release - The House BeautifulDokumen3 halamanPress Release - The House BeautifulditiBelum ada peringkat

- Doosan DBC130II Installation ManualDokumen122 halamanDoosan DBC130II Installation ManualDarryl Hardt100% (1)

- FlexHammer24&16i UserDokumen63 halamanFlexHammer24&16i Userapi-3831066Belum ada peringkat

- Sharing Tower Vincente Guallart by Ulrich J. BeckerDokumen22 halamanSharing Tower Vincente Guallart by Ulrich J. BeckerMigue GutierrezBelum ada peringkat

- 12 Maya LinDokumen6 halaman12 Maya LinVidishaBelum ada peringkat

- Telit WE866C3 Datasheet-1Dokumen2 halamanTelit WE866C3 Datasheet-1SailajaUngatiBelum ada peringkat