Saes H 102

Diunggah oleh

Kaleelur RahmanDeskripsi Asli:

Judul Asli

Hak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

Saes H 102

Diunggah oleh

Kaleelur RahmanHak Cipta:

Format Tersedia

Engineering Standard

SAES-H-102 Safety Requirements for Coating Applications Paints and Coatings Standards Committee Members

Barouky, F.F., Chairman Hammad, B.S., Vice Chairman Al-Homayed, M.A. Al-Khashram, M.S. Al-Nujaim, S.A. Al-Seba, Z.A. Suller, A.A.

31 July 2004

Saudi Aramco DeskTop Standards

Table of Contents

1 2 3 4

Scope........................................................... Conflicts and Deviations............................... References................................................... Safety Requirements....................................

2 2 2 3

Previous Issue: 31 December 2000 Next Planned Update: 1 August 2007 Revised paragraphs are indicated in the right margin Primary contact: Fikry F. Barouky on 872-5116

Page 1 of 10

Document Responsibility: Paints and Coatings Issue Date: 31 July 2004 Next Planned Update: 1 August 2007

SAES-H-102 Safety Requirements for Coating Applications

Scope This Standard prescribes the minimum mandatory safety requirements applicable during shop or field coating applications for construction, maintenance, and/or coating maintenance programs of Saudi Aramco industrial facilities and equipment.

Conflicts and Deviations 2.1 Any conflicts between this standard and other applicable Saudi Aramco Engineering Standards (SAESs), Materials System Specifications (SAMSSs), Standard Drawings (SASDs), or industry standards, codes, and forms shall be resolved in writing by the Company or Buyer Representative through the Manager, Consulting Services Department of Saudi Aramco, Dhahran. Direct all requests to deviate from this standard in writing to the Company or Buyer Representative, who shall follow internal company procedure SAEP-302 and forward such requests to the Manager, Consulting Services Department of Saudi Aramco, Dhahran.

2.2

References The selection of material and equipment, and the design, construction, maintenance, and repair of equipment and facilities covered by this standard shall comply with the latest edition of the references listed below, unless otherwise noted. 3.1 Saudi Aramco References Saudi Aramco Engineering Procedure SAEP-302 Instructions for Obtaining a Waiver of a Mandatory Saudi Aramco Engineering Requirement

Saudi Aramco General Instruction GI-0002.100 GI-0006.021 3.2 Industry Codes and Standards American Society of Mechanical Engineers ASME SEC VIII D1 NEC Article 500 Unfired Pressure Vessels Hazardous (Classified) Locations Work Permit System Safety requirements for abrasive blasting

Page 2 of 10

Document Responsibility: Paints and Coatings Issue Date: 31 July 2004 Next Planned Update: 1 August 2007

SAES-H-102 Safety Requirements for Coating Applications

Occupational Safety & Health Administration (OSHA) - Construction Industry Safety & Health Standards 29 CFR 1926 U. S. Department of Labor, Chapter XVII, Section 1926.105

Safety Requirements 4.1 Fire and Explosion Prevention 4.1.1 Smoking and/or the use of open flames, shall be permitted only in designated safe areas and never inside vessels. Welding and the use of heating coils are prohibited in areas where coating is in progress. All electrical lighting, equipment, and connections shall conform to National Electric Code, Class I, Division 1, Group D explosion proof requirements (NEC Article 500). Solvents and paints shall not be applied to surfaces warmer than 80C if practical alternatives exist. Work Permits for hot work, cold work, and confined space entry shall be obtained in accordance with GI-0002.100.

4.1.2

4.1.3 4.1.4 4.2

Ventilation 4.2.1 Forced ventilation shall be used in confined spaces whenever abrasive blasting, solvent cleaning, and/or painting are in progress. 4.2.1.1 4.2.1.2 4.2.2 Forced ventilation shall continue until the coating is fully cured and ready for service. Natural ventilation (through opened manholes, etc.) shall not be substituted for forced ventilation in confined spaces.

Ventilation shall ensure good air circulation with no dead air pockets in the confined space. 4.2.2.1 4.2.2.2 4.2.2.3 The fresh air inlet shall be located near the top of the confined space whenever practical. The discharge opening shall be located near the bottom of the confined space. Supplementary fans shall be used if necessary to ensure adequate air circulation in low spots or dead spaces.

Page 3 of 10

Document Responsibility: Paints and Coatings Issue Date: 31 July 2004 Next Planned Update: 1 August 2007

SAES-H-102 Safety Requirements for Coating Applications

4.2.3 4.2.4

Ventilation requirements for various sizes of confined spaces are given in Table 4-1. Respirable air-fed hoods shall be worn by all personnel inside confined spaces whenever: 4.2.4.1 4.2.4.2 Blasting or spray painting is in progress. Solvent cleaning or brush painting is in progress in a confined space having a volume of less than 16 m.

4.3

Health Hazards 4.3.1 If alkaline catalysts (such as used in many epoxy paints) come in contact with the skin, they shall be immediately washed off with water to avoid chemical burns.

4.3.2 The appropriate personnel protection equipment listed in Table 4-2 shall be worn. In addition, safety belts and lines shall always be used by personnel working from unguarded platforms or in confined spaces where a manhole accessed by a ladder is the only exit. 4.3.3 Adequate washing facilities shall be readily available so that paints and solvents splashed on the body or in the eyes can be immediately removed. Safety shoes and coveralls shall always be worn and safety hats shall be worn as required by proponent organizations. Air hoses shall not be used by personnel for cleaning or cooling themselves. Solvents shall not be used by personnel for washing up. Materials Safety Data Sheets for all coatings, solvents, and cleaners in use shall be readily available on-site.

4.3.4 4.3.5 4.3.6 4.3.7 4.4

Equipment Hazards 4.4.1 Power tools 4.4.1.1 4.4.1.2 Electrically driven power tools shall be properly grounded to prevent shock. Power equipment shall be operated at the speeds recommended by the manufacturer and shall have proper safety guards.

Page 4 of 10

Document Responsibility: Paints and Coatings Issue Date: 31 July 2004 Next Planned Update: 1 August 2007

SAES-H-102 Safety Requirements for Coating Applications

4.4.1.3 4.4.1.4

Hearing protection shall always be worn whenever chipping guns or pneumatic hammers are in use. Vessels such as air receivers that are used as a surge tank between the compressor and the blasting pot shall be manufactured and stamped in accordance with ASME SEC VIII D1, Unfired Pressure Vessels. They shall be hydrotested at a pressure of at least 1.73 Mpa (250 psig) at ambient temperature using clean water. These vessels shall be revalidated by hydrotesting at least annually and the test certificates shall be submitted to the Saudi Aramco Inspector for verification. All pressure relief valves, gauges, and devices shall be tested annually and tagged with the expiration date. The test certificates shall be submitted to the Saudi Aramco Inspector for verification. All blasting and coating equipment and associated attachments shall be adequately earthed to avoid electrostatic discharges.

4.4.1.5

4.4.1.6 4.4.2

Abrasive Blasting 4.4.2.1 4.4.2.2 Blasting shall be equipped with a remote control shut-off "deadman". The blast nozzle shall be electrically connected to an external ground in order to prevent static electrical discharges or shocks to operating personnel. Grounding wire shall be AWG-4 or larger. The blasting hose shall be the static dissipating type with external couplings. Respirable air-fed abrasive blasting hoods and OSHAapproved in-line respirable air filters shall be utilized at all times by abrasive blasting personnel. Compressor hoses, air lines, and blast hoses shall be safety wired at each coupling using proper safety pins. Hearing protection shall be worn in confined spaces where abrasive blasting is in progress.

4.4.2.3 4.4.2.4

4.4.2.5 4.4.2.6 4.4.3

Solvent Cleaning

Page 5 of 10

Document Responsibility: Paints and Coatings Issue Date: 31 July 2004 Next Planned Update: 1 August 2007

SAES-H-102 Safety Requirements for Coating Applications

Benzene, gasoline, carbon tetrachloride, and chlorinated hydrocarbons with low threshold limit values (less than 20) shall not be used. 4.4.4 Paint Preparation and Equipment Cleaning 4.4.4.1 4.4.4.2 4.4.4.3 4.4.5 Coatings shall be mixed outside or in an adequately ventilated area. Use eye protection (goggles) and protective gloves. Electrically driven power mixers shall be grounded. Avoid splash or spillage during mixing. Clean spilled paints immediately using proper cleaning solvent.

Airless Spray Paint Application 4.4.5.1 4.4.5.2 4.4.5.3 4.4.5.4 4.4.5.5 Airless spray guns shall never be pointed at anyone or at any part of the body. The tip guard shall always be in place on the airless gun while spraying. Leather gloves shall be worn by the operator whenever the airless spray gun is in use. The trigger safety catch shall be engaged whenever the airless gun is left unattended. Hoses, pumps, and accessories shall never be operated at pressures exceeding their rated pressure. In no case shall the working pressure in the paint line exceed 34.5 MPa (5000 psi). Safety pressure relief valves shall be used on outbound side of the pressure pump(s). The pump shall be shut down and the fluid pressure in the system relieved before servicing or cleaning any components, including clogged spray tips. Hoses shall be grounded, anti-static type. Airless spray equipment shall not be operated unless all grounds (earths) are in place, connected, and in good condition. Grounding wire shall be AWG-4 or larger. Airless spray equipment shall not be operated if any of the pressure system components is not in good condition.

4.4.5.6

4.4.5.7 4.4.5.8

4.4.5.9

Page 6 of 10

Document Responsibility: Paints and Coatings Issue Date: 31 July 2004 Next Planned Update: 1 August 2007

SAES-H-102 Safety Requirements for Coating Applications

4.4.5.10 Solvents shall not be flushed into containers that are hotter than 50C. 4.4.5.11 Emergency medical care shall be obtained immediately if any high pressure fluid from the airless equipment penetrates the skin. (High pressure fluid injection injuries can be extremely serious, including the need for amputation).

Revision Summary Revised the "Next Planned Update". Reaffirmed the contents of the document, and reissued with editorial changes.

31 July, 2004

Page 7 of 10

Document Responsibility: Paints and Coatings Issue Date: 31 July 2004 Next Planned Update: 1 August 2007

SAES-H-102 Safety Requirements for Coating Applications

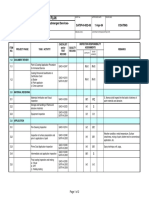

Table 4-1 - Ventilation Requirements for Confined Spaces

Volume of Confined Area m 16 80 160 800 1600 4000 BBL 100 500 1000 5000 10000 25000 Required Air Mover Capacity L/s 472 1180 2360 4720 7080 9440 cfm 1000 2500 5000 10000 15000 20000

Page 8 of 10

Document Responsibility: Paints and Coatings Issue Date: 31 July 2004 Next Planned Update: 1 August 2007

SAES-H-102 Safety Requirements for Coating Applications

Table 4-2 - Personal Protective Equipment to be Worn or Used During Surface Preparation & Paint Application

Key: O C = = Outdoors Confined Spaces

OSHA-Approved Respirable Airfed Hood and Filter 21-444-934 21-443-500 O Surface Preparation Wire Brushing, Chipping, Scrapping & Grinding Sandblasting - operator - other workmen Paint Removing X X X X X X X X C Respirator; Chemical Cartridge 21-370-800 21-370-810 21-370-820 O C Face Shield

(1)

Type of Work to be Performed

Dust Respirator 21-370-500

21-426-121 21-426-125 21-426-142 O C

X X X

Solvent Cleaning X X X -----------------------------------------------------------------------------------------------------------------------------------------------------Brush Spray Brush Spray Brush Spray Brush Spray Paint Application O C O C O C O C O C O C O C O C -----------------------------------------------------------------------------------------------------------------------------------------------------Epoxy and Coal\ Tar Epoxy Alkyd Inorganic Zinc Chlorinated Rubber X X X X X X X X X X X

Bituminous X X ----------------------------------------------------------------------------------------------------------------------------------------------------Note:

(1)

Face shields shall always be used when working overhead.

Page 9 of 10

Document Responsibility: Paints and Coatings Issue Date: 31 July 2004 Next Planned Update: 1 August 2007

SAES-H-102 Safety Requirements for Coating Applications

Table 4-2 - Personal Protective Equipment to be Worn or Used During Surface Preparation & Paint Application (Cont'd)

Key: O C = = Outdoors Confined Spaces

Goggles Safety Impact 21-434-249 O C Gloves; Leather 21-432-353 O C Gloves; Rubber 21-432-630 Hearing Protection 21-327-100/105/110/272 O C

Type of Work to be Performed Surface Preparation Wire Brushing, Chipping, Scrapping & Grinding Sandblasting - operator - other workmen - in vicinity Paint Removing

X X

X X X

Solvent Cleaning X --------------------------------------------------------------------------------------------------------------------------------------------------Brush Spray Paint Application O C O C ALL --------------------------------------------------------------------------------------------------------------------------------------------------Epoxy and Coal\ Tar Epoxy Alkyd Inorganic Zinc Chlorinated Rubber

Bituminous X X X

X X X X X X X X X X

Polyurethane

Page 10 of 10

Anda mungkin juga menyukai

- Saes H 102Dokumen10 halamanSaes H 102HaleemUrRashidBangash100% (1)

- SAES-H-102-Safety Requirements For Coating Applications2Dokumen12 halamanSAES-H-102-Safety Requirements For Coating Applications2محمد العيسوىBelum ada peringkat

- SAEP-303: 2 Conflicts and DeviationsDokumen19 halamanSAEP-303: 2 Conflicts and DeviationsnasirBelum ada peringkat

- Saes H 101V PDFDokumen389 halamanSaes H 101V PDFQA QCBelum ada peringkat

- Saes H 201Dokumen9 halamanSaes H 201heartbreakkid132Belum ada peringkat

- Materials System SpecificationDokumen6 halamanMaterials System SpecificationAjeetKumarBelum ada peringkat

- Corrodere Brochure 12ppDokumen12 halamanCorrodere Brochure 12ppJoventino AlvesBelum ada peringkat

- 09 SAMSS 089 (Final Draft - 2018)Dokumen28 halaman09 SAMSS 089 (Final Draft - 2018)lhanx2Belum ada peringkat

- Saes H 004Dokumen8 halamanSaes H 004kaleeswaran s100% (1)

- 01 Samss 012 2014Dokumen10 halaman01 Samss 012 2014lhanx2Belum ada peringkat

- Saes H 200Dokumen9 halamanSaes H 200راجہ شہزاد انورBelum ada peringkat

- 09 Samss 060Dokumen4 halaman09 Samss 060asimazami69Belum ada peringkat

- SATIP H 002 08 Pipe Internal CoatingDokumen3 halamanSATIP H 002 08 Pipe Internal CoatinghossamalsherbinyBelum ada peringkat

- Paint System Recommendations PDFDokumen6 halamanPaint System Recommendations PDFKumarBelum ada peringkat

- Saudi Aramco Typical Inspection PlanDokumen10 halamanSaudi Aramco Typical Inspection PlanMoghal AliBelum ada peringkat

- Saes H 204Dokumen34 halamanSaes H 204heartbreakkid132Belum ada peringkat

- Materials System SpecificationDokumen7 halamanMaterials System SpecificationAjeetKumarBelum ada peringkat

- 09 Samss 021Dokumen8 halaman09 Samss 021Kalanithi KasirajanBelum ada peringkat

- 09 Samss 068Dokumen7 halaman09 Samss 068AjeetKumarBelum ada peringkat

- APCS DeatailsDokumen3 halamanAPCS DeatailsnasirBelum ada peringkat

- SAES-H-201 General Specification For Over-The-Ditch External & Internal ... 2017 VersionDokumen13 halamanSAES-H-201 General Specification For Over-The-Ditch External & Internal ... 2017 VersiondanishBelum ada peringkat

- 09-SAMSS-071 - (2016) Qualification Requirements For Inorganic Zinc Primer (APCS-17A) and (APCS-17B)Dokumen9 halaman09-SAMSS-071 - (2016) Qualification Requirements For Inorganic Zinc Primer (APCS-17A) and (APCS-17B)middlepermian100% (1)

- Saes H 204Dokumen33 halamanSaes H 204Rei Lizardo100% (1)

- CBT Questions 26022020Dokumen43 halamanCBT Questions 26022020Shawn LeoBelum ada peringkat

- 01 Samss 031Dokumen3 halaman01 Samss 031Awais CheemaBelum ada peringkat

- Typical Inspection Plan (TIP) Index: Project Inspection Division / IAGDokumen5 halamanTypical Inspection Plan (TIP) Index: Project Inspection Division / IAGvajidqcBelum ada peringkat

- Saudi Aramco Test ReportDokumen2 halamanSaudi Aramco Test ReportMoghal AliBelum ada peringkat

- Materials System SpecificationDokumen8 halamanMaterials System SpecificationAjeetKumarBelum ada peringkat

- Materials System SpecificationDokumen10 halamanMaterials System SpecificationAjeetKumar100% (1)

- SAIC-H-2032 Rev 7Dokumen4 halamanSAIC-H-2032 Rev 7Satheesh Rama SamyBelum ada peringkat

- SATR-H-2006 Rev 8Dokumen3 halamanSATR-H-2006 Rev 8ravi ajith100% (1)

- 09 Samss 101Dokumen9 halaman09 Samss 101GOSP3 QC MechanicalBelum ada peringkat

- Saudi Aramco Typical Inspection PlanDokumen10 halamanSaudi Aramco Typical Inspection PlanMoghal AliBelum ada peringkat

- SATIP-H-002-06 Coating For Submerged Services-APCS 113 ABCDokumen2 halamanSATIP-H-002-06 Coating For Submerged Services-APCS 113 ABChossamalsherbinyBelum ada peringkat

- Saes H 101VDokumen83 halamanSaes H 101Vacolombel100% (2)

- Airless Spray PaintingDokumen22 halamanAirless Spray PaintingRajesh KarriBelum ada peringkat

- Inspection Check List 2Dokumen34 halamanInspection Check List 2r.devendranBelum ada peringkat

- Saudi Aramco Test Report: In-Process Inspection of Field Coating SATR-H-2006 27-Jan-19 CoatDokumen3 halamanSaudi Aramco Test Report: In-Process Inspection of Field Coating SATR-H-2006 27-Jan-19 CoatMoghal AliBelum ada peringkat

- Saep 1200Dokumen9 halamanSaep 1200Anonymous 4IpmN7On100% (1)

- Saes N 100Dokumen16 halamanSaes N 100aamirapiBelum ada peringkat

- Ipcoat Exam Test Paper 123Dokumen1 halamanIpcoat Exam Test Paper 123Senthil Kumar100% (1)

- SCM 400 Salt Contamination MeterDokumen2 halamanSCM 400 Salt Contamination MeterJohn WatsonBelum ada peringkat

- Saes H 200 PDFDokumen9 halamanSaes H 200 PDFSohail Aziz Ahmad Malik100% (1)

- Schedule Q - Attachment VIDokumen8 halamanSchedule Q - Attachment VISIVABelum ada peringkat

- Sigmacover 410Dokumen4 halamanSigmacover 410gstketutBelum ada peringkat

- Removing Coatings and Cleaning Masonry Substrates: Kenneth A. Trimber KTA-Tator, IncDokumen46 halamanRemoving Coatings and Cleaning Masonry Substrates: Kenneth A. Trimber KTA-Tator, IncMilagros MorantesBelum ada peringkat

- 175 091300Dokumen2 halaman175 091300Abu Anas M.SalaheldinBelum ada peringkat

- SATIP H 002 08 Rev 4.unlockedDokumen2 halamanSATIP H 002 08 Rev 4.unlockedMohamed Farhan B PositiveBelum ada peringkat

- Engineering Encyclopedia: Protective Coating ApplicationDokumen24 halamanEngineering Encyclopedia: Protective Coating ApplicationAnonymous S9qBDVkyBelum ada peringkat

- Process Industry Practices Insulation: PIP INTG1000 Insulation Inspection ChecklistDokumen7 halamanProcess Industry Practices Insulation: PIP INTG1000 Insulation Inspection ChecklistCristian Jhair PerezBelum ada peringkat

- Saep 119Dokumen11 halamanSaep 119Demac SaudBelum ada peringkat

- Dfy - Coating Quality Key PointsDokumen1 halamanDfy - Coating Quality Key PointsMohammed SadiqBelum ada peringkat

- 18B. Protegol UR 32.55R Data SheetDokumen3 halaman18B. Protegol UR 32.55R Data SheetClarkFedele27Belum ada peringkat

- Materials System SpecificationDokumen10 halamanMaterials System SpecificationAjeetKumar100% (1)

- Paint Types - Important NotesDokumen3 halamanPaint Types - Important Notesmushroom0320Belum ada peringkat

- Saes B 061Dokumen4 halamanSaes B 061SIVABelum ada peringkat

- Operating Instructions FZA Pump PDFDokumen14 halamanOperating Instructions FZA Pump PDFPipe RoblesBelum ada peringkat

- Air Blowing Procedure 2Dokumen4 halamanAir Blowing Procedure 2mostafaBelum ada peringkat

- Method Statement Format (CDRIHBIBSG and Silo DC Pipe Line Cleaning by Hydrojetting MOSDokumen11 halamanMethod Statement Format (CDRIHBIBSG and Silo DC Pipe Line Cleaning by Hydrojetting MOSPrem Preetham Dsouza100% (1)

- Air Blowing Procedure Rev.0Dokumen5 halamanAir Blowing Procedure Rev.0mostafaBelum ada peringkat

- Key Contract ProvisionDokumen1 halamanKey Contract ProvisionKaleelur RahmanBelum ada peringkat

- Contract ContentDokumen1 halamanContract ContentKaleelur RahmanBelum ada peringkat

- Interpretation of Contract DocumentsDokumen1 halamanInterpretation of Contract DocumentsKaleelur RahmanBelum ada peringkat

- 4 Steps Tobetter NegotiationDokumen1 halaman4 Steps Tobetter NegotiationKaleelur RahmanBelum ada peringkat

- CE2402-Estimation and Quantity Surveying PDFDokumen11 halamanCE2402-Estimation and Quantity Surveying PDFKarthik Palaniswamy100% (2)

- Project Delivery MethodDokumen1 halamanProject Delivery MethodKaleelur RahmanBelum ada peringkat

- BQ and Preparation of BQDokumen32 halamanBQ and Preparation of BQArchangelmc86% (43)

- Construction Contract AdministrationDokumen10 halamanConstruction Contract AdministrationKaleelur RahmanBelum ada peringkat

- Installing Oracle Primavera P6 Professional StandaloneDokumen10 halamanInstalling Oracle Primavera P6 Professional Standaloneandresboy123Belum ada peringkat

- 6th Central Pay Commission Salary CalculatorDokumen15 halaman6th Central Pay Commission Salary Calculatorrakhonde100% (436)

- Constructionclaims2012 120202041504 Phpapp01Dokumen4 halamanConstructionclaims2012 120202041504 Phpapp01Kaleelur RahmanBelum ada peringkat

- RICS - Principles of Measurement International Works Construction 1979 (POMI)Dokumen26 halamanRICS - Principles of Measurement International Works Construction 1979 (POMI)Nguyen Hoang TuanBelum ada peringkat

- Preparation of DocumentsDokumen3 halamanPreparation of DocumentsKaleelur RahmanBelum ada peringkat

- Chemical Admixtures For Concrete AciDokumen12 halamanChemical Admixtures For Concrete AciM HAFEEZ RAJA100% (1)

- Chemical Admixtures For Concrete AciDokumen12 halamanChemical Admixtures For Concrete AciM HAFEEZ RAJA100% (1)

- Chapter 3 8th EditionDokumen59 halamanChapter 3 8th EditionNayeemuddin Md100% (1)

- Types of PPEDokumen14 halamanTypes of PPEgshdavidBelum ada peringkat

- CPFAir FiltersDokumen2 halamanCPFAir FilterschuminhBelum ada peringkat

- RD 105 219msdsDokumen2 halamanRD 105 219msdsPita PuentesBelum ada peringkat

- Fleming Gulf Middle East Fire and Safety PPT Firoze Zia HussainDokumen18 halamanFleming Gulf Middle East Fire and Safety PPT Firoze Zia HussainFiroze Zia HussainBelum ada peringkat

- Shipping Container PreservationDokumen16 halamanShipping Container PreservationMohamed Sahnoun100% (1)

- Ker 828 SDSDokumen8 halamanKer 828 SDSLiju DanielBelum ada peringkat

- Msds Gentien VioletDokumen6 halamanMsds Gentien Violetanggita windaBelum ada peringkat

- Material Safety Data Sheet: 1. IdentificationDokumen10 halamanMaterial Safety Data Sheet: 1. IdentificationMai PhuongBelum ada peringkat

- PPE Hazard Assessment Certification FormDokumen4 halamanPPE Hazard Assessment Certification FormHaleem Ur Rashid BangashBelum ada peringkat

- Msds Potassium Chloride: M S D SDokumen1 halamanMsds Potassium Chloride: M S D SQuality AssuranceBelum ada peringkat

- 011 AbrDokumen7 halaman011 AbrMindbookBelum ada peringkat

- Safetydatasheet (SDS) CG Icp en 04232021Dokumen15 halamanSafetydatasheet (SDS) CG Icp en 04232021Ivanie SilviaBelum ada peringkat

- Eastman Effusion-MSDSDokumen11 halamanEastman Effusion-MSDSMohammed Tanjil Morshed remonBelum ada peringkat

- MSDS - Propane (C3H8) Bal AIRDokumen6 halamanMSDS - Propane (C3H8) Bal AIRsathish sivasamyBelum ada peringkat

- Ppe ProcedureDokumen32 halamanPpe ProcedureIbrahim Umer100% (2)

- Tools Catalog enDokumen204 halamanTools Catalog enbarnaBelum ada peringkat

- Spray Painting, WHSPRO-018 CMDokumen6 halamanSpray Painting, WHSPRO-018 CMsanthoshBelum ada peringkat

- Msds GasolinaDokumen11 halamanMsds GasolinaHoracio Chavez R.Belum ada peringkat

- CHAPTER-1 Typical Paint and Shop OperationsDokumen8 halamanCHAPTER-1 Typical Paint and Shop OperationsAmanuelBelum ada peringkat

- SelectionGuide UKDokumen32 halamanSelectionGuide UKMichael TadrosBelum ada peringkat

- Chemset Reo 502EF MSDSDokumen13 halamanChemset Reo 502EF MSDShariBelum ada peringkat

- Master Glossary of Refinery TermsDokumen252 halamanMaster Glossary of Refinery TermsJames Rodriguez100% (1)

- Polymer MSDSDokumen6 halamanPolymer MSDSZhen SinBelum ada peringkat

- Technical Data BookletDokumen53 halamanTechnical Data Booklettracy8763Belum ada peringkat

- Sop 004 PpeDokumen5 halamanSop 004 PpeShahul ValeedBelum ada peringkat

- MRAP-TM 9-2355-106-23-1 MaxxPro Base PDFDokumen1.452 halamanMRAP-TM 9-2355-106-23-1 MaxxPro Base PDFabduallah muhammad50% (2)

- Onboard Maintenance Painting GuideDokumen12 halamanOnboard Maintenance Painting Guideislima100% (1)

- Polygel CADokumen6 halamanPolygel CABIONATURBelum ada peringkat

- Is.9623.2008 Selection of RespiratorsDokumen35 halamanIs.9623.2008 Selection of Respiratorssujith koshyBelum ada peringkat