Viscosity Changes in Black Liquor When Bleach Plant Filtrates Are Added

Diunggah oleh

Arjunan Parappurath NarayananDeskripsi Asli:

Judul Asli

Hak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

Viscosity Changes in Black Liquor When Bleach Plant Filtrates Are Added

Diunggah oleh

Arjunan Parappurath NarayananHak Cipta:

Format Tersedia

VISCOSITY CHANGES IN BLACK LIQUOR WHEN BLEACH PLANT FILTRATES ARE ADDED Lars Ledung, Per Ulmgren Swedish

Pulp and Paper Research Institute (STFI) Box 5604 S- 114 86 Stockholm Sweden

The viscosity of black liquor affects evaporation, pumping and droplet formation, that are important for the firing in the recovery furnace. In this paper, we present results from viscosity measurements on two different softwood black liquors, and black liquors mixed with: D- (chlorine dioxide), P- (peroxide) and Q-stage (chelating) bleach plant filtrates. The viscosity was measured at three temperatures, l00C, 115C and 130C. The dry solids content was varied in the range of 50 to 75% by weight. The viscosity of the black liquor was not significantly affected at a given dry solids content by the addition of P-stage filtrate but increased 2-3 times when Q-stage filtrate was added. The addition of D-filtrate also resulted in an increase in viscosity, but not to the same extent as the Q-filtrate. The filtrates were added to the black liquor either by a quick mixing by pouring the components together or by a dropwise and controlled mixing. The difference in viscosity following these two techniques was negligible. From chemical analysis and a multivariate data evaluation, it was concluded that the increase in viscosity when bleach plant filtrates were added was not a result of one single variable but rather a series of compositional changes, such as a higher concentration of inorganic ions, such as calcium and magnesium ions, which cause flocculation of the lignin in black liquors, a lower residual alkali content and a lower COD-value (Chemical Oxygen Demand).

INTRODUCTION Today, two major changes are being introduced into the chemical recovery area of a kraft pulp mill: recycling of bleach plant filtrates and firing of black liquor at a high dry solids content in the recovery boiler. Bleach plant filtrate recycling is one way to reduce the amount of pollutants going to the receiving waters from the bleach plant. However, this may lead to changes in some black liquor properties, such as the viscosity and the combustion properties. The effects on the combustion properties have been reported elsewhere [ 1]. Changes in black liquor viscosity affect both the heat transfer during evaporation and the capacity of pumps. An increase in viscosity increases the pump work and decreases the heat transfer coefficient; a tenfold increase in viscosity can, for example, reduce the evaporator capacity by a factor of 1.5 to 2 [2]. The viscosity also affects the droplet formation in the recovery boiler. Empie et al. [3] have reported that an increase in viscosity by a factor of 3 results in an increase of 17% in the median droplet diameter which corresponds to a droplet volume increase of 60%. Results of viscosity measurements on black liquors have been reported by Sderhjelm et al. [4, 5]. The effects of pulping conditions on viscosity have also been investigated by Zaman and Fricke [6]. However, to our knowledge, the effects of adding bleach plant filtrates on the black liquor viscosity have not previously been reported. In this paper, we report changes in the viscosity of a black liquor due to the addition of D- (chlorine dioxide), P- (peroxide) or Q-stage (chelating) bleach plant filtrates. The effects of metal ions on the viscosity were also studied by adding 2+ 2+ compounds of Ca2+ , Mg and Mn to the black liquor. Theoretical Background Most polymer solutions are non-Newtonian, i.e. the shear stress is not a linear function of the shear rate. However, most softwood black liquors are Newtonian or almost Newtonian, whereas hardwood liquors usually are nonNewtonian [5]. The non-Newtonian black liquors are pseudoplastic, i.e. the viscosity decreases with higher shear

1998 International Chemical Recovery Conference / 157

Anda mungkin juga menyukai

- Tappi 3-1 Black Liquor Properties PDFDokumen6 halamanTappi 3-1 Black Liquor Properties PDFserseh100% (1)

- Advanced Pharmaceutical analysisDari EverandAdvanced Pharmaceutical analysisPenilaian: 4.5 dari 5 bintang4.5/5 (2)

- Dyes and Pigments 21 (1993) 45-66 PDFDokumen22 halamanDyes and Pigments 21 (1993) 45-66 PDFAmitBelum ada peringkat

- A Further Investigation of the Symmetrical Chloride of Paranitroorthosulphobenzoic AcidDari EverandA Further Investigation of the Symmetrical Chloride of Paranitroorthosulphobenzoic AcidBelum ada peringkat

- 11 3 Umit+Sezgi MANUSCRIPTDokumen13 halaman11 3 Umit+Sezgi MANUSCRIPTRockhy SyahrialBelum ada peringkat

- BioRes 10-1-1696 Zhu T Precipitation Lignin Softwood Black Liquor 6518Dokumen19 halamanBioRes 10-1-1696 Zhu T Precipitation Lignin Softwood Black Liquor 6518strangeraccBelum ada peringkat

- Effects of Solvent Polarity On The Hydrogenation of Xylose: Jyri-Pekka Mikkola, Tapio Salmi and Rainer Sjo HolmDokumen11 halamanEffects of Solvent Polarity On The Hydrogenation of Xylose: Jyri-Pekka Mikkola, Tapio Salmi and Rainer Sjo HolmEdgar Fernando Jerez GarciaBelum ada peringkat

- Black Liquor Recovery - How Does It WorkDokumen7 halamanBlack Liquor Recovery - How Does It Workmancini10Belum ada peringkat

- EPA Alternative Disinfectants GuidanceDokumen1 halamanEPA Alternative Disinfectants GuidanceRavindra WadelBelum ada peringkat

- Potentiometric Titration of A Mixture of CL in BeerDokumen11 halamanPotentiometric Titration of A Mixture of CL in BeerMinichBelum ada peringkat

- Pulp and Paper IndustryDokumen4 halamanPulp and Paper IndustryAditya BannuBelum ada peringkat

- Study of Acids Used For The Acidified Cobalt Thiocyanate Test For Cocaine BaseDokumen5 halamanStudy of Acids Used For The Acidified Cobalt Thiocyanate Test For Cocaine BaseGabriela Virginia Faría VirlaBelum ada peringkat

- Removal of Colour in Sugar Cane Juice ClarificatioDokumen9 halamanRemoval of Colour in Sugar Cane Juice Clarificationitha telkar nitaBelum ada peringkat

- JPPS 0209 Zhen GalleyDokumen8 halamanJPPS 0209 Zhen GalleyGregorio ValeroBelum ada peringkat

- Water Determination by Karl FischerTitrationDokumen81 halamanWater Determination by Karl FischerTitrationtraffik100% (1)

- Kinetics of Wood Saccharification Hydrolysis of Cellulose and Decomposition of Sugars in Dilute Acid at High Temperature.Dokumen10 halamanKinetics of Wood Saccharification Hydrolysis of Cellulose and Decomposition of Sugars in Dilute Acid at High Temperature.René MartínezBelum ada peringkat

- Vol 43 - 3 0004Dokumen112 halamanVol 43 - 3 0004karamniaBelum ada peringkat

- Biochemical Test For CarbohydrateDokumen24 halamanBiochemical Test For Carbohydrateanandbggu88% (8)

- Quantitative Determination of WaterDokumen23 halamanQuantitative Determination of WaterApurba Sarker Apu100% (1)

- The Effect of Liming Conditions in Juice ClarificationDokumen12 halamanThe Effect of Liming Conditions in Juice Clarificationmohammed amerBelum ada peringkat

- Toward Zero Waste Production in The Paint IndustryDokumen5 halamanToward Zero Waste Production in The Paint IndustryAkhi LaBelum ada peringkat

- Chem 415 Experiment 1Dokumen6 halamanChem 415 Experiment 1ttussenoBelum ada peringkat

- H2O2 DecompositionDokumen14 halamanH2O2 Decompositionpulcherimus1Belum ada peringkat

- A Tentative Explanation For The SubstantialDokumen9 halamanA Tentative Explanation For The SubstantialluisbrumovskyBelum ada peringkat

- Jar TestingDokumen4 halamanJar TestingVel MuruganBelum ada peringkat

- Chem 31.1 Experiment 9 Synthesis of Organic CompoundsDokumen68 halamanChem 31.1 Experiment 9 Synthesis of Organic Compoundshello87623100% (1)

- Chapt - 4 CHLORINE DIOXIDE PDFDokumen41 halamanChapt - 4 CHLORINE DIOXIDE PDFRaul Tixe100% (4)

- An Analysis of Black Liquor Falling Film Evaporation: Fang C. Chen, Zhiming GaoDokumen15 halamanAn Analysis of Black Liquor Falling Film Evaporation: Fang C. Chen, Zhiming GaoTamil SelvanBelum ada peringkat

- 1955 - Boyes - Methods For The AnalysisDokumen8 halaman1955 - Boyes - Methods For The Analysisjlcheefei9258Belum ada peringkat

- AquametryDokumen36 halamanAquametryFoyz Ahmed Shohel80% (5)

- The Kraft Chemcial Recovery Process: Honghi TranDokumen8 halamanThe Kraft Chemcial Recovery Process: Honghi TranYudhi Dwi KurniawanBelum ada peringkat

- Informe para Trabajo 1Dokumen9 halamanInforme para Trabajo 1alexander Gomez OsorioBelum ada peringkat

- Freezing Point DepressionDokumen4 halamanFreezing Point DepressionJuan Agustin Garcia TancoBelum ada peringkat

- An Improved Procedure For Synthesis of Dl-4-Hydroxy-3-Methoxymandelic Acid (DL - Ilvanillylll-Mandelic Acid, Vma)Dokumen2 halamanAn Improved Procedure For Synthesis of Dl-4-Hydroxy-3-Methoxymandelic Acid (DL - Ilvanillylll-Mandelic Acid, Vma)Brandon TimmBelum ada peringkat

- Factors Influenc, Ing The Reduction of Alkaline Copper Reagents by GlucoseDokumen18 halamanFactors Influenc, Ing The Reduction of Alkaline Copper Reagents by GlucoseNurul Aulia HusainBelum ada peringkat

- ECF Bleaching of Softwood and Eucalyptus Pulps - A Comparative StudyDokumen14 halamanECF Bleaching of Softwood and Eucalyptus Pulps - A Comparative StudySamuel Irwan JayaBelum ada peringkat

- Quantitative Determination of Total Hardness of WaterDokumen11 halamanQuantitative Determination of Total Hardness of WaterJoshua Oliveros50% (2)

- Kraft Pulping With Sulfide Pretreatment - Part2Dokumen10 halamanKraft Pulping With Sulfide Pretreatment - Part2cgiovanioliveiraBelum ada peringkat

- N6lab 1Dokumen9 halamanN6lab 1sachinkurhekarBelum ada peringkat

- Jeet (5) - Merged (1) DDokumen12 halamanJeet (5) - Merged (1) DRahul JadhavBelum ada peringkat

- Decomposition of Hydrogen Peroxide by Various CatalystsDokumen3 halamanDecomposition of Hydrogen Peroxide by Various CatalystsKRAMER88Belum ada peringkat

- Laboratory Activity #2 Chemical Oxygen Demand (COD) DeterminationDokumen7 halamanLaboratory Activity #2 Chemical Oxygen Demand (COD) DeterminationJohnBelum ada peringkat

- Hydrogenolysis of Glycerol To Propylene GlycolDokumen7 halamanHydrogenolysis of Glycerol To Propylene GlycolLelecosBelum ada peringkat

- Classification Test For Carbonyl and Hydroxyl Containing Compound ReferenceDokumen6 halamanClassification Test For Carbonyl and Hydroxyl Containing Compound ReferenceErica OcheaBelum ada peringkat

- Sludge ProductionDokumen6 halamanSludge ProductionjnmanivannanmechBelum ada peringkat

- 2008IECREffectofSolubilityonFoamBehaviour PDFDokumen9 halaman2008IECREffectofSolubilityonFoamBehaviour PDFShehzad AhmedBelum ada peringkat

- Environmental LabDokumen13 halamanEnvironmental Lab17GICIV0625.Mudasir Zaman AfridiBelum ada peringkat

- Lab Manuel For Analytical Chemistry and Environmental ScienceDokumen13 halamanLab Manuel For Analytical Chemistry and Environmental Scienceআলশাহরিয়ার খানBelum ada peringkat

- Jar Test-1full ReportDokumen6 halamanJar Test-1full ReportSamuelBelum ada peringkat

- Iahs 250 0491Dokumen6 halamanIahs 250 0491farbod_eBelum ada peringkat

- Chem 28.1 Experiment 8 Formal ReportDokumen6 halamanChem 28.1 Experiment 8 Formal ReportMara Krista CooBelum ada peringkat

- Us 4222819Dokumen10 halamanUs 4222819Omar NinoBelum ada peringkat

- Change Color ReactionsDokumen10 halamanChange Color Reactionsj4yakBelum ada peringkat

- Reaction Testing of Phenol Hydroxylation and Cyclohexane Oxidation by Gas Chromatography: Influence of Residual Hydrogen PeroxideDokumen10 halamanReaction Testing of Phenol Hydroxylation and Cyclohexane Oxidation by Gas Chromatography: Influence of Residual Hydrogen PeroxideAmino BowwowBelum ada peringkat

- Lab Report On Oxidation and ReductionDokumen7 halamanLab Report On Oxidation and ReductionkasuleBelum ada peringkat

- Evan2873 UnvDokumen6 halamanEvan2873 UnvKamil JBelum ada peringkat

- Physicochemical and Functional Properties of Soy Protein Isolate As A Function of Water Activity and StorageDokumen9 halamanPhysicochemical and Functional Properties of Soy Protein Isolate As A Function of Water Activity and StoragePaul Jefferson Flores HurtadoBelum ada peringkat

- Orifice and Chemical Tracer Flow Test Measurements On Production Geothermal WellsDokumen1 halamanOrifice and Chemical Tracer Flow Test Measurements On Production Geothermal WellsindeskeyBelum ada peringkat

- Chapter 4 - Enzymes & MetabolismDokumen4 halamanChapter 4 - Enzymes & MetabolismGrace LeungBelum ada peringkat

- SIPA SFR EVO Rotary-Blowing-SystemsDokumen6 halamanSIPA SFR EVO Rotary-Blowing-SystemsSundar MoorthiBelum ada peringkat

- Sigma Phase in 309 Anchor RefractoryDokumen7 halamanSigma Phase in 309 Anchor RefractoryJustin EvansBelum ada peringkat

- Keeler Cryomatic Brochure PDFDokumen4 halamanKeeler Cryomatic Brochure PDFrossiBelum ada peringkat

- Astm e 1252 PDFDokumen13 halamanAstm e 1252 PDFMonalisa RodriguesBelum ada peringkat

- We Are Intechopen, The World'S Leading Publisher of Open Access Books Built by Scientists, For ScientistsDokumen21 halamanWe Are Intechopen, The World'S Leading Publisher of Open Access Books Built by Scientists, For ScientistsAllan PaoloBelum ada peringkat

- Ap & TS - SR Elite Neet Grand Test - 2 Paper - 14-03-2022Dokumen28 halamanAp & TS - SR Elite Neet Grand Test - 2 Paper - 14-03-2022srsoumyaranjantareiBelum ada peringkat

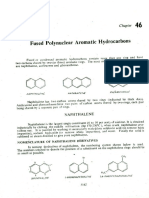

- Chapter 46-51 PDFDokumen179 halamanChapter 46-51 PDFHasan RabyBelum ada peringkat

- 2 Structure and Deformation in Material Lecture 1Dokumen79 halaman2 Structure and Deformation in Material Lecture 1Hung HimmyBelum ada peringkat

- 244 Experiment 1 (1) - 1Dokumen7 halaman244 Experiment 1 (1) - 1Bophepa MaseletsaneBelum ada peringkat

- CNT Composite FibersDokumen23 halamanCNT Composite FibersShashwat YadavBelum ada peringkat

- PID Response Factors UK V1.10 1Dokumen18 halamanPID Response Factors UK V1.10 1MeesanBelum ada peringkat

- 5 CrystallographyDokumen32 halaman5 CrystallographyPrabhav DeujaBelum ada peringkat

- STP Random PatentDokumen18 halamanSTP Random PatentPranshu JainBelum ada peringkat

- Chem Q2 WRITTEN WORK 1Dokumen6 halamanChem Q2 WRITTEN WORK 1leyt kanaBelum ada peringkat

- PT Samudera Inti PasifikDokumen8 halamanPT Samudera Inti PasifikGlobal MapindoBelum ada peringkat

- Physiology Linda Costanzo 6thDokumen50 halamanPhysiology Linda Costanzo 6thMoonnime BlueBelum ada peringkat

- IRC-114-2013 Use of Silica Fume in Rigid PavementDokumen14 halamanIRC-114-2013 Use of Silica Fume in Rigid PavementZakee MohamedBelum ada peringkat

- HW 5 Pro 4Dokumen9 halamanHW 5 Pro 4ybobbyxBelum ada peringkat

- Acs Energyfuels 7b03733Dokumen12 halamanAcs Energyfuels 7b03733Dinesh JoshiBelum ada peringkat

- CP Calculation 11-1-2020Dokumen2 halamanCP Calculation 11-1-2020Mohammed HijaziBelum ada peringkat

- Deposit Formation in The Holes of Diesel Injector Nozzles: A Critical ReviewDokumen12 halamanDeposit Formation in The Holes of Diesel Injector Nozzles: A Critical ReviewShova MuhammadBelum ada peringkat

- Starch Hydrolysis by AmylaseDokumen9 halamanStarch Hydrolysis by Amylasegaurav saxenaBelum ada peringkat

- Peek Vs AcetalDokumen3 halamanPeek Vs AcetalMahmoud Gamal El FeelBelum ada peringkat

- Viscosity of Gases: Marcia L. Huber and Allan H. HarveyDokumen2 halamanViscosity of Gases: Marcia L. Huber and Allan H. HarveyUmarBelum ada peringkat

- FAURE Gunter MENSING Teresa - Isotopes Principles and ApplicationsDokumen515 halamanFAURE Gunter MENSING Teresa - Isotopes Principles and ApplicationsCristiano Padalino Galeazzi100% (4)

- Primus 1000 Cessna Ultra SDOMDokumen828 halamanPrimus 1000 Cessna Ultra SDOMcetadmin100% (7)

- CHem Class 10 Icse BondingDokumen36 halamanCHem Class 10 Icse BondingSANDEEP SINGHBelum ada peringkat

- Process Plant Equipment: Operation, Control, and ReliabilityDari EverandProcess Plant Equipment: Operation, Control, and ReliabilityPenilaian: 5 dari 5 bintang5/5 (1)

- Pulp and Paper Industry: Emerging Waste Water Treatment TechnologiesDari EverandPulp and Paper Industry: Emerging Waste Water Treatment TechnologiesPenilaian: 5 dari 5 bintang5/5 (1)

- Sodium Bicarbonate: Nature's Unique First Aid RemedyDari EverandSodium Bicarbonate: Nature's Unique First Aid RemedyPenilaian: 5 dari 5 bintang5/5 (21)

- Guidelines for Chemical Process Quantitative Risk AnalysisDari EverandGuidelines for Chemical Process Quantitative Risk AnalysisPenilaian: 5 dari 5 bintang5/5 (1)

- An Applied Guide to Water and Effluent Treatment Plant DesignDari EverandAn Applied Guide to Water and Effluent Treatment Plant DesignPenilaian: 5 dari 5 bintang5/5 (4)

- Functional Safety from Scratch: A Practical Guide to Process Industry ApplicationsDari EverandFunctional Safety from Scratch: A Practical Guide to Process Industry ApplicationsBelum ada peringkat

- Phase Equilibria in Chemical EngineeringDari EverandPhase Equilibria in Chemical EngineeringPenilaian: 4 dari 5 bintang4/5 (11)

- Well Control for Completions and InterventionsDari EverandWell Control for Completions and InterventionsPenilaian: 4 dari 5 bintang4/5 (10)

- Lees' Process Safety Essentials: Hazard Identification, Assessment and ControlDari EverandLees' Process Safety Essentials: Hazard Identification, Assessment and ControlPenilaian: 4 dari 5 bintang4/5 (4)

- Nuclear Energy in the 21st Century: World Nuclear University PressDari EverandNuclear Energy in the 21st Century: World Nuclear University PressPenilaian: 4.5 dari 5 bintang4.5/5 (3)

- Coupled CFD-DEM Modeling: Formulation, Implementation and Application to Multiphase FlowsDari EverandCoupled CFD-DEM Modeling: Formulation, Implementation and Application to Multiphase FlowsBelum ada peringkat

- The Perfumed Pages of History: A Textbook on Fragrance CreationDari EverandThe Perfumed Pages of History: A Textbook on Fragrance CreationPenilaian: 4 dari 5 bintang4/5 (1)

- Water-Based Paint Formulations, Vol. 3Dari EverandWater-Based Paint Formulations, Vol. 3Penilaian: 4.5 dari 5 bintang4.5/5 (6)

- A New Approach to HAZOP of Complex Chemical ProcessesDari EverandA New Approach to HAZOP of Complex Chemical ProcessesBelum ada peringkat

- High Pressure Phase Behaviour of Multicomponent Fluid MixturesDari EverandHigh Pressure Phase Behaviour of Multicomponent Fluid MixturesBelum ada peringkat

- Fundamentals of Risk Management for Process Industry EngineersDari EverandFundamentals of Risk Management for Process Industry EngineersBelum ada peringkat

- Fun Facts about Hydrogen : Chemistry for Kids The Element Series | Children's Chemistry BooksDari EverandFun Facts about Hydrogen : Chemistry for Kids The Element Series | Children's Chemistry BooksBelum ada peringkat

- Distillation Design and Control Using Aspen SimulationDari EverandDistillation Design and Control Using Aspen SimulationPenilaian: 5 dari 5 bintang5/5 (2)

- First U.K. National Conference on Heat Transfer: The Institution of Chemical Engineers Symposium Series, Volume 2.86Dari EverandFirst U.K. National Conference on Heat Transfer: The Institution of Chemical Engineers Symposium Series, Volume 2.86Belum ada peringkat

- The Periodic Table of Elements - Halogens, Noble Gases and Lanthanides and Actinides | Children's Chemistry BookDari EverandThe Periodic Table of Elements - Halogens, Noble Gases and Lanthanides and Actinides | Children's Chemistry BookBelum ada peringkat

- Coulson and Richardson’s Chemical Engineering: Volume 2A: Particulate Systems and Particle TechnologyDari EverandCoulson and Richardson’s Chemical Engineering: Volume 2A: Particulate Systems and Particle TechnologyBelum ada peringkat

- Guidelines for Determining the Probability of Ignition of a Released Flammable MassDari EverandGuidelines for Determining the Probability of Ignition of a Released Flammable MassBelum ada peringkat

- Physical and Chemical Equilibrium for Chemical EngineersDari EverandPhysical and Chemical Equilibrium for Chemical EngineersPenilaian: 5 dari 5 bintang5/5 (1)